Fiber Concrete Mixer and Monitoring Method Based on Machine Vision

A fiber-reinforced concrete and machine vision technology, applied in chemical instruments and methods, cement mixing devices, instruments, etc., can solve problems such as easy agglomeration and uneven fiber dispersion, and achieve the effect of mixing quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention is described in detail below in conjunction with accompanying drawing:

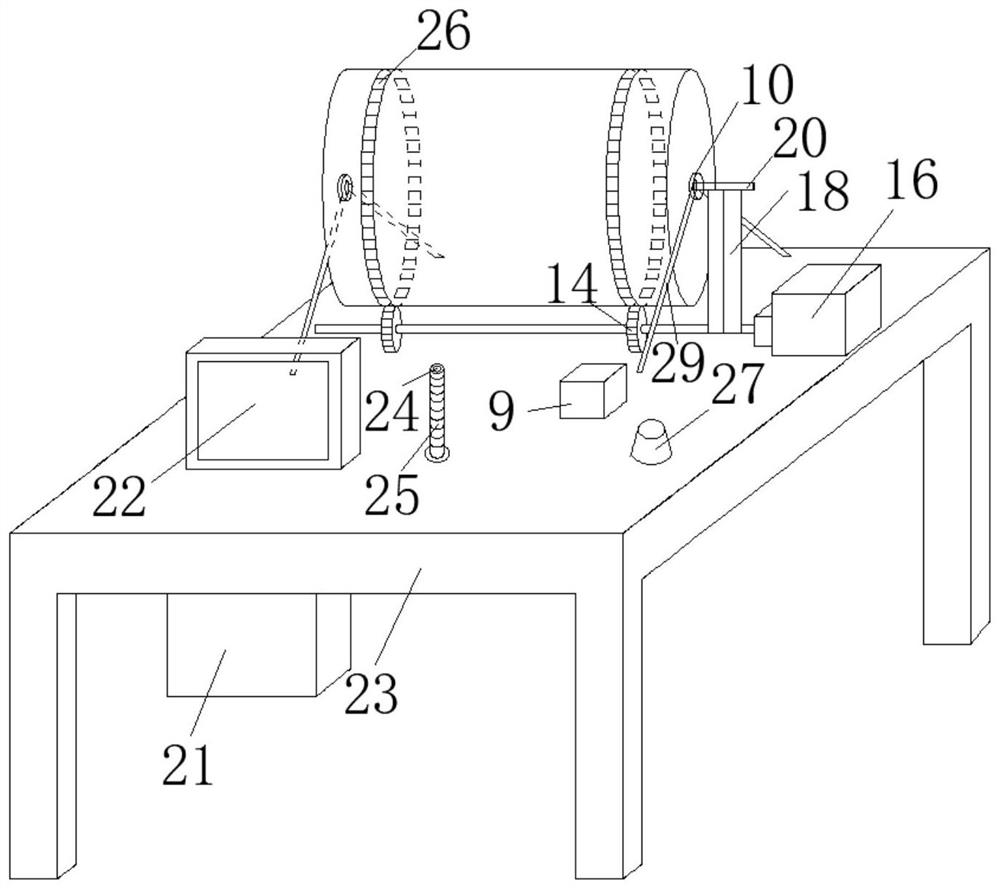

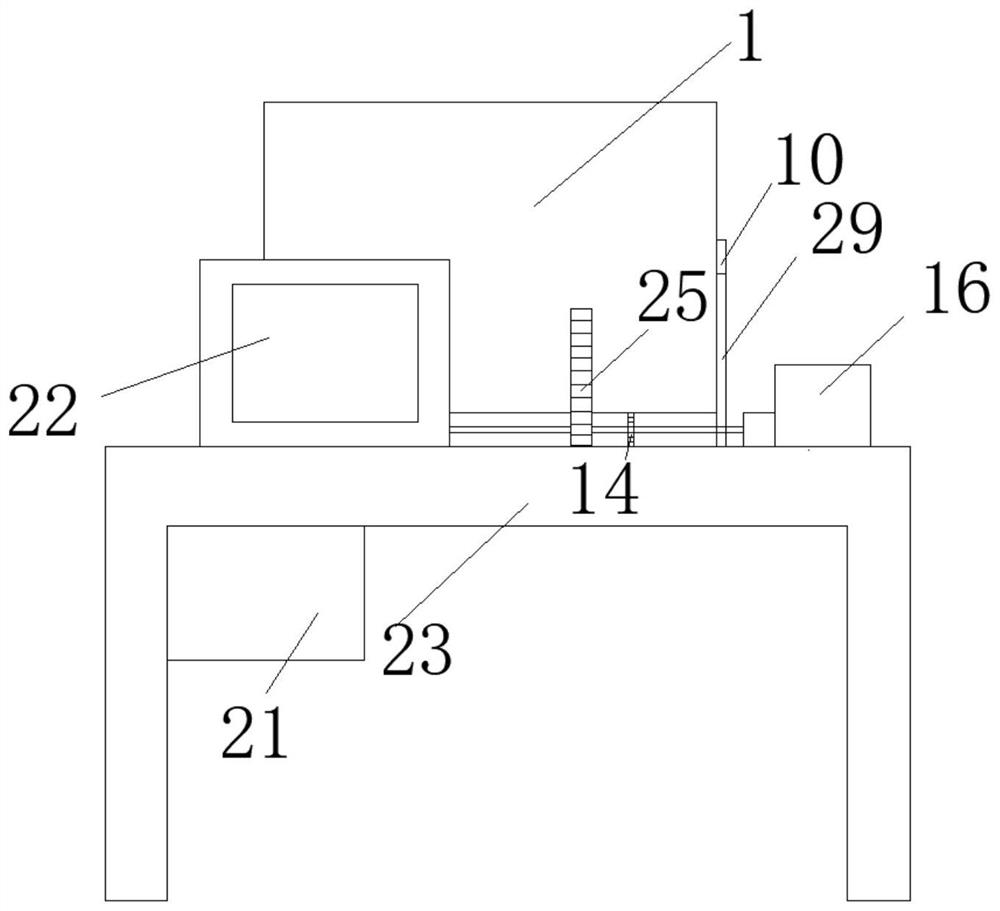

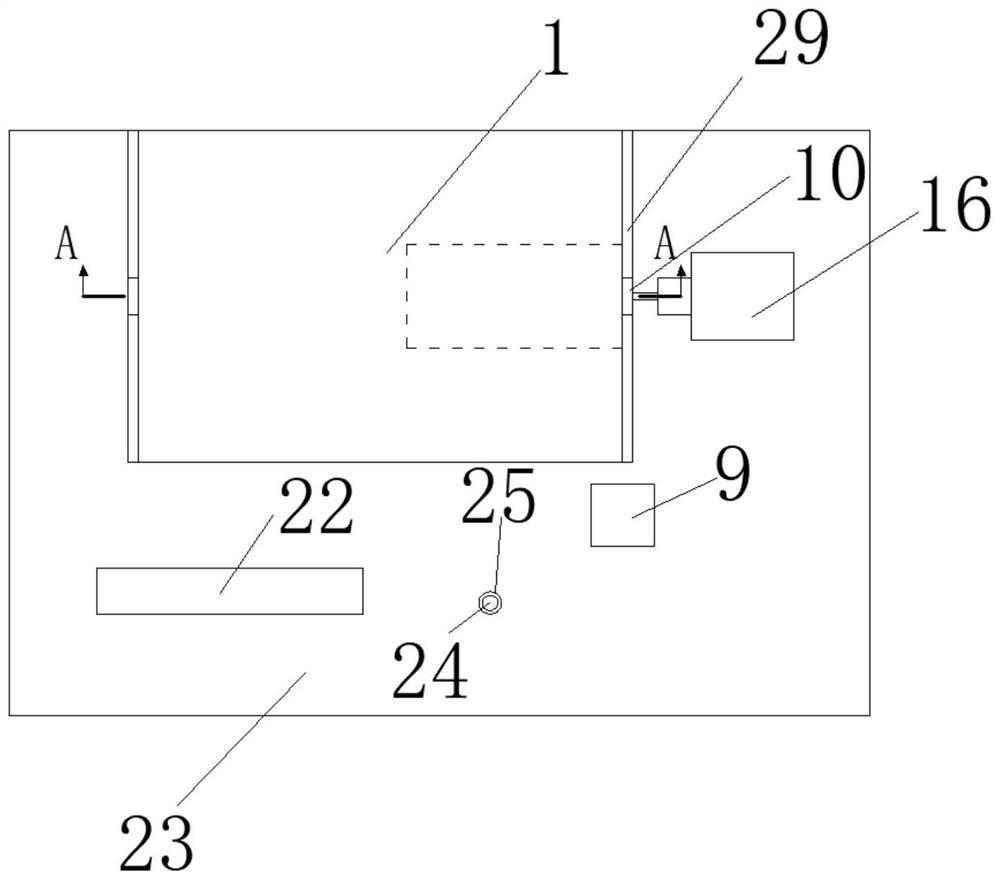

[0055] refer to Figure 1 to Figure 4 , The fiber concrete mixer based on machine vision includes a shell component, a stirring component, a power component, an image acquisition component and an image analysis component.

[0056] The shell components include a mixing drum 1 , a lifting nose 2 and a support frame 23 .

[0057] The mixing drum 1 is a cylindrical steel hollow tube, the thickness of the tube wall is 3mm-5mm, the diameter of the left and right tube walls is 1m-1.2m, and the tube length is 2m; Shaped through-holes are used to extend the rotating base 8 and the stirring shaft 20 into the inside of the mixing drum 1; the symmetrical top and bottom walls of the mixing drum 1 are provided with three rectangular arc surface openings, which are the feeding port 3 and the cleaning port in turn. 4. Outlet 13, specifically:

[0058] The feed port 3 is used for the entry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com