A self-stressing concrete mixer and a visual detection method

A technology for concrete mixers and detection methods, applied in chemical instruments and methods, cement mixing devices, measuring devices, etc., can solve the problems of insufficient mixing of self-stressed concrete mixtures, too fast setting time and failure to take them out in time, and achieve The effect of stirring quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention is described in detail below in conjunction with accompanying drawing:

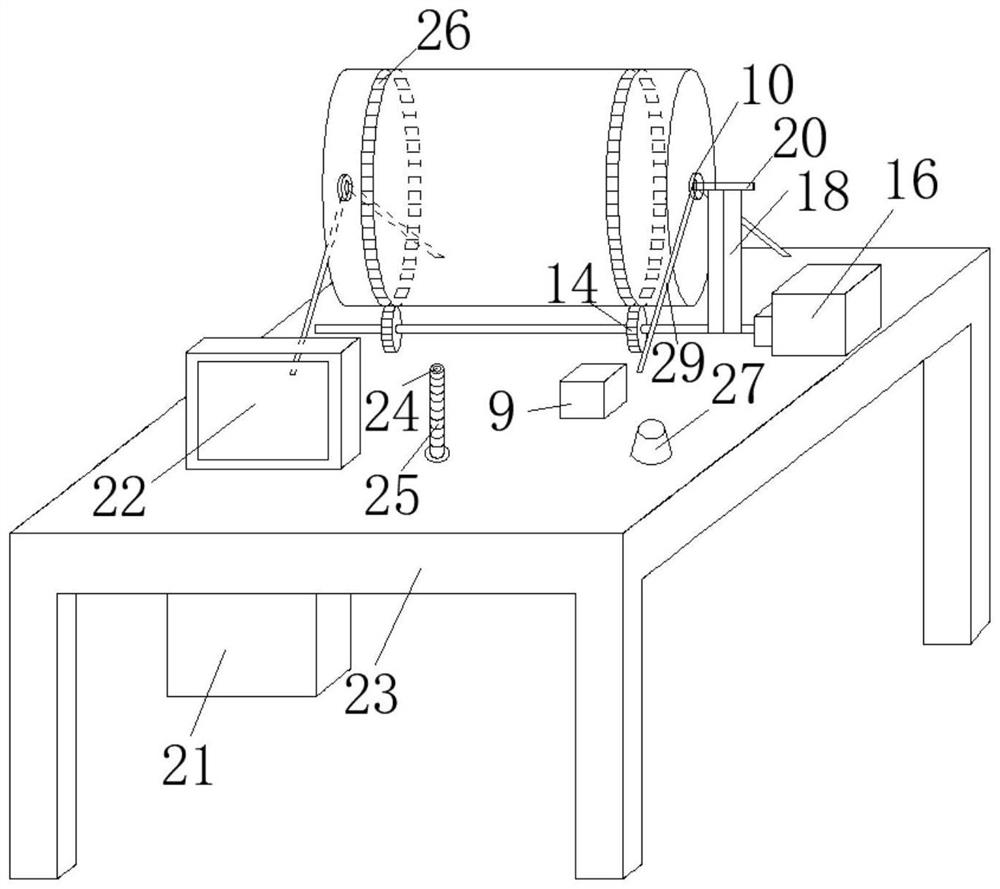

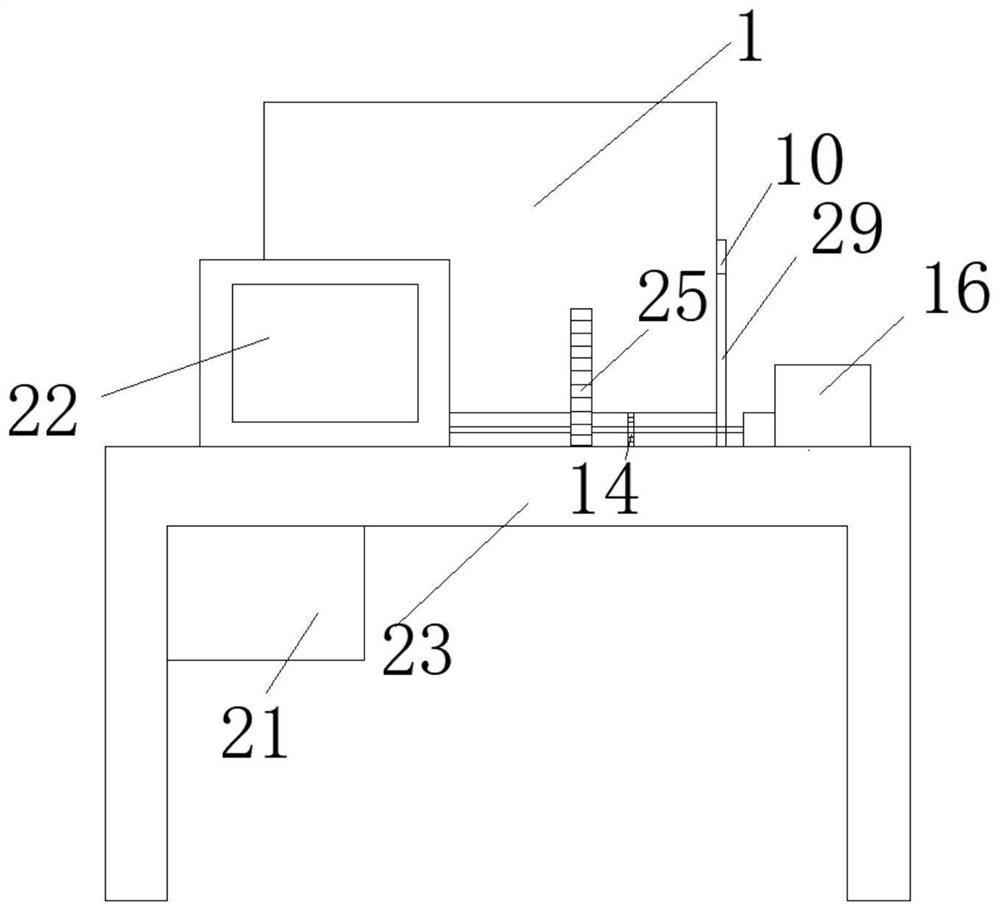

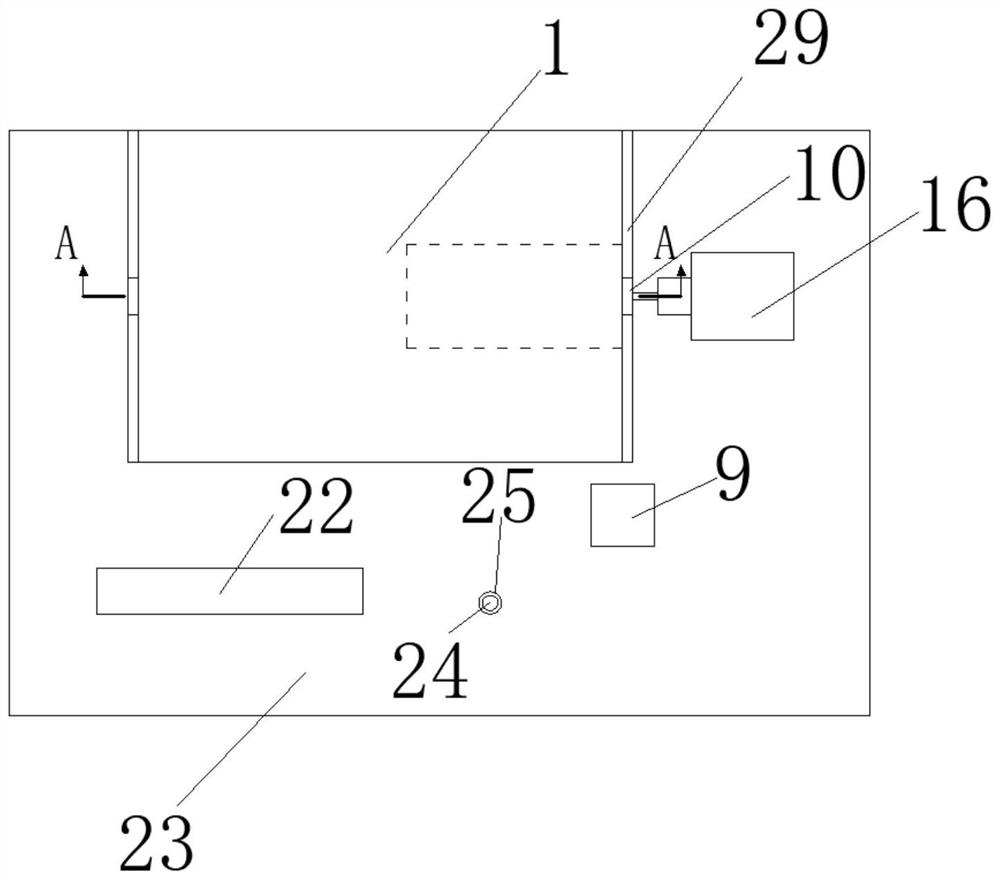

[0054] refer to Figure 1 to Figure 4 , the self-stressing concrete mixer includes a shell component, a stirring component, a power component, an image acquisition component and an image analysis component.

[0055] The shell components include a mixing drum 1 , a lifting nose 2 and a support frame 23 .

[0056] The mixing drum 1 is a cylindrical steel hollow tube, the thickness of the tube wall is 3mm-5mm, the diameter of the left and right tube walls is 1m-1.2m, and the tube length is 2m; Shaped through-holes are used to extend the rotating base 8 and the stirring shaft 20 into the inside of the mixing drum 1; the symmetrical top and bottom walls of the mixing drum 1 are provided with three rectangular arc surface openings, which are the feeding port 3 and the cleaning port in turn. 4. Outlet 13, specifically:

[0057] The feed port 3 is used for the entry of the self-str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com