Automatic weighting and distributing device and application thereof in aspect of processing raw materials of brake pads and medicine

A material distribution device and automatic weighing technology, which is applied in the directions of loading/unloading, transportation and packaging, conveyors, etc., can solve the problem of high efficiency, large batches, automatic production line production of traditional Chinese medicine pellets, and the inability to realize multiple cups at the same time Accurate material distribution operation, complex and cumbersome equipment debugging, etc., to achieve the effect of simple structure, convenient use and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

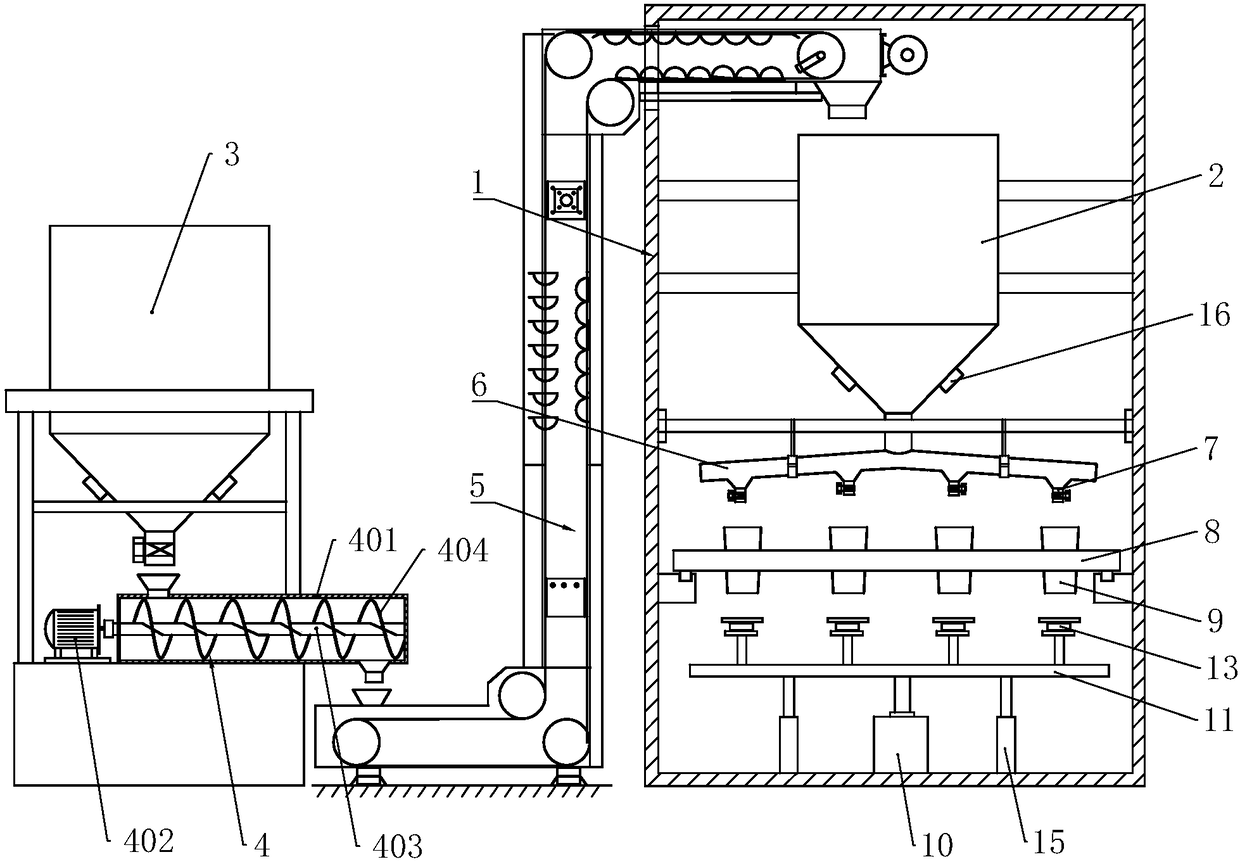

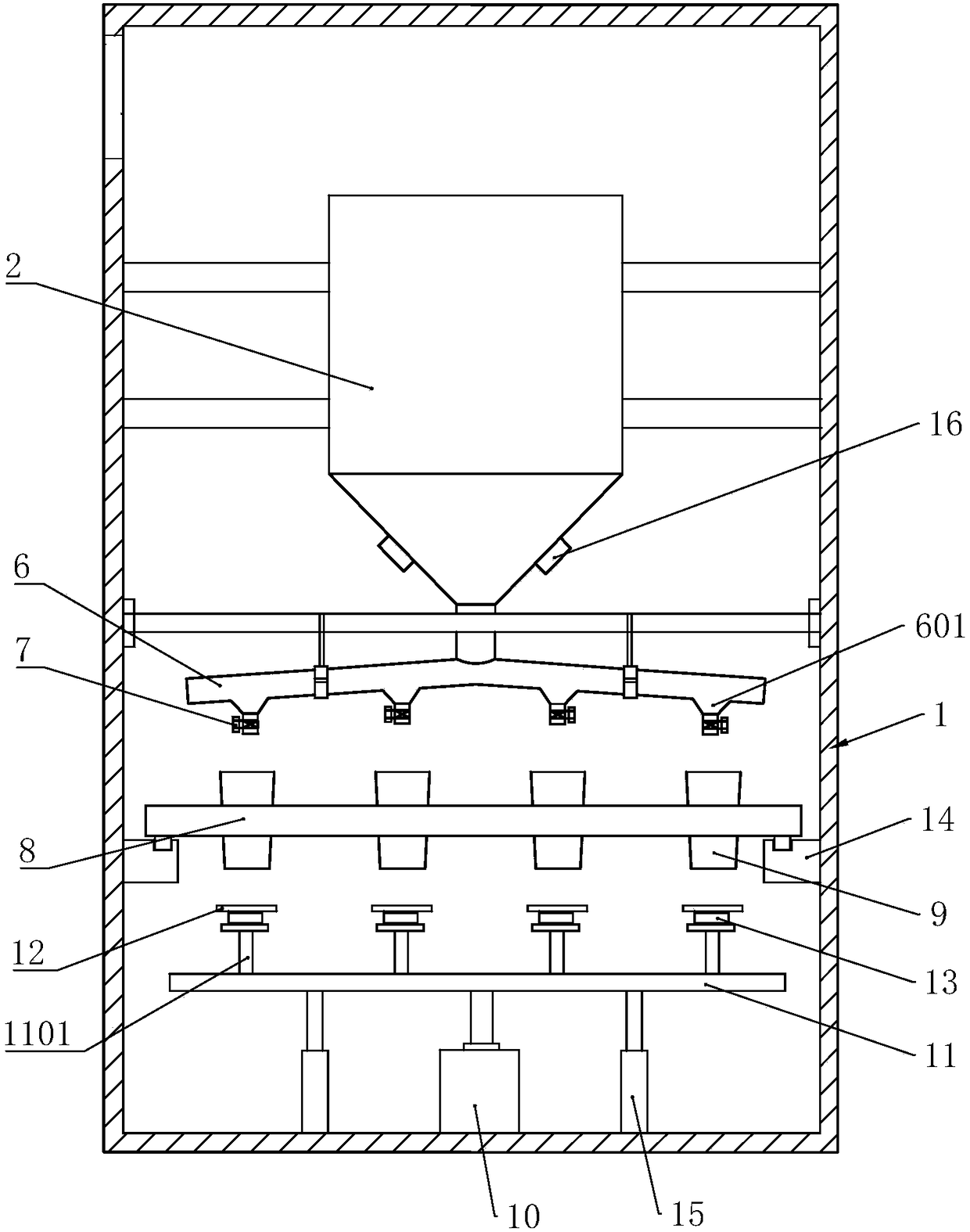

[0054] Such as Figure 1 to Figure 3 As shown, an automatic weighing and distributing device includes a distributing box 1, a storage hopper 2 is fixedly installed in the distributing box 1, and the storage hopper 2 is arranged near the top of the distributing box 1, and also includes a feeding mechanism , Distributing mechanism, receiving mechanism and weighing mechanism.

[0055] The feeding mechanism includes a batching hopper 3, a mixing conveyor 4 and a bucket elevator 5. The batching hopper 3 is connected to the storage hopper 2 through the mixing conveyor 4 and the bucket elevator 5 in order to realize the loading of the storage hopper 2. .

[0056] In this embodiment, the bottom of the batching hopper 3 is provided with a discharge port, the mixing conveyor 4 includes a housing 401, and the two ends of the housing 401 are respectively provided with the discharge port of the batching hopper 3 and the bucket elevator 5. The feeding port and the discharging port, the ro...

Embodiment 2

[0065] This embodiment provides an application of an automatic weighing and distributing device in the processing of raw materials for brake pads. It is realized by using the automatic weighing and distributing device described in Embodiment 1. The distributing steps are as follows:

[0066] S1. First mix the brake pad raw materials in the batching hopper. After the batching is mixed, control the operation of the mixing conveyor and the bucket elevator to realize the loading operation to the storage hopper;

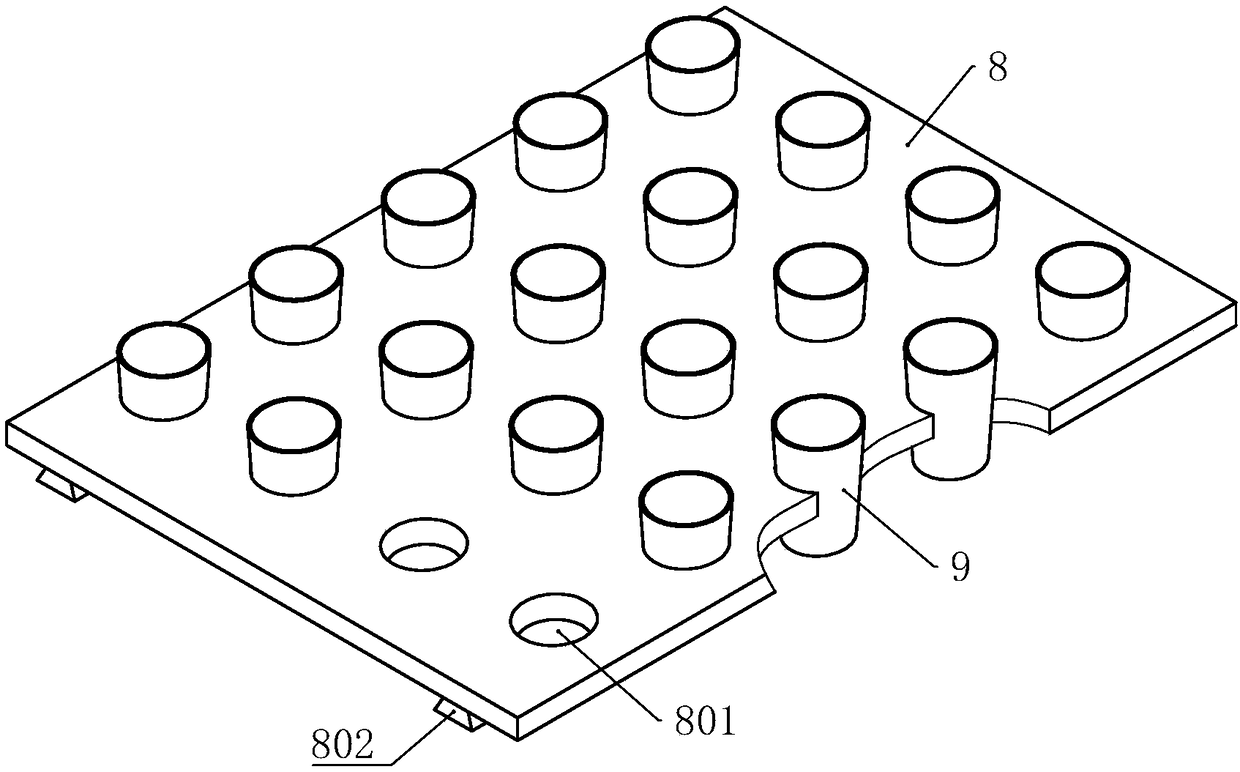

[0067] S2. When weighing and distributing the raw materials of the brake pads, place the material cups in the through holes provided on the slide plate correspondingly, and install the slide plate into the material distributing box;

[0068] S3. The cylinder works, the material cup is lifted up by the ejector rod and the tray, the solenoid valve is opened, and the brake pad raw material in the storage hopper is distributed into the corresponding material cup below through ...

Embodiment 3

[0074] This embodiment provides an application of an automatic weighing and distributing device in the processing of medicinal raw materials, which is realized by using the automatic weighing and distributing device described in Embodiment 1. The distributing steps are as follows:

[0075] S1. First mix the raw materials of medicinal materials in the batching hopper. After the batching and mixing are completed, control the operation of the mixing conveyor and the bucket elevator to realize the loading operation to the storage hopper;

[0076] S2. When weighing and distributing the raw materials of medicinal materials, place the material cups in corresponding through holes provided on the slide plate, and install the slide plate into the material distributing box;

[0077] S3. The cylinder works, the material cup is lifted up by the ejector rod and the tray, the solenoid valve is opened, and the medicinal material in the storage hopper is distributed into the corresponding mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com