A kind of anodic oxidation production line and production process

An anodizing, production line technology, applied in anodizing, coating, surface reaction electrolytic coating, etc., can solve the problem of reducing the processing efficiency of the workpiece to be anodized, and achieve improved feeding efficiency, simple and stable structure, and improved processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

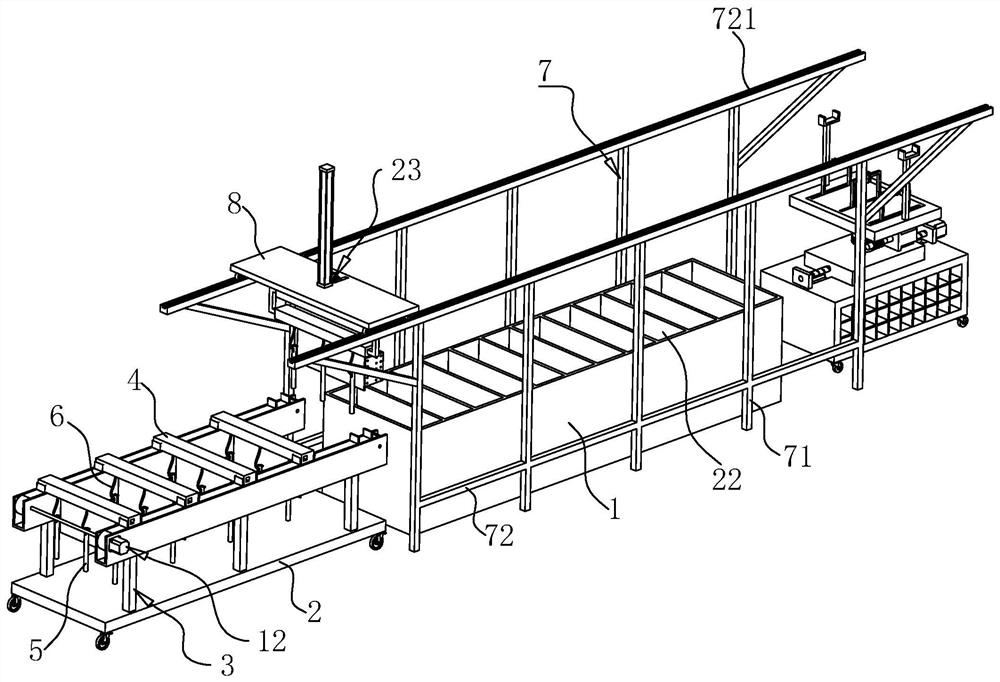

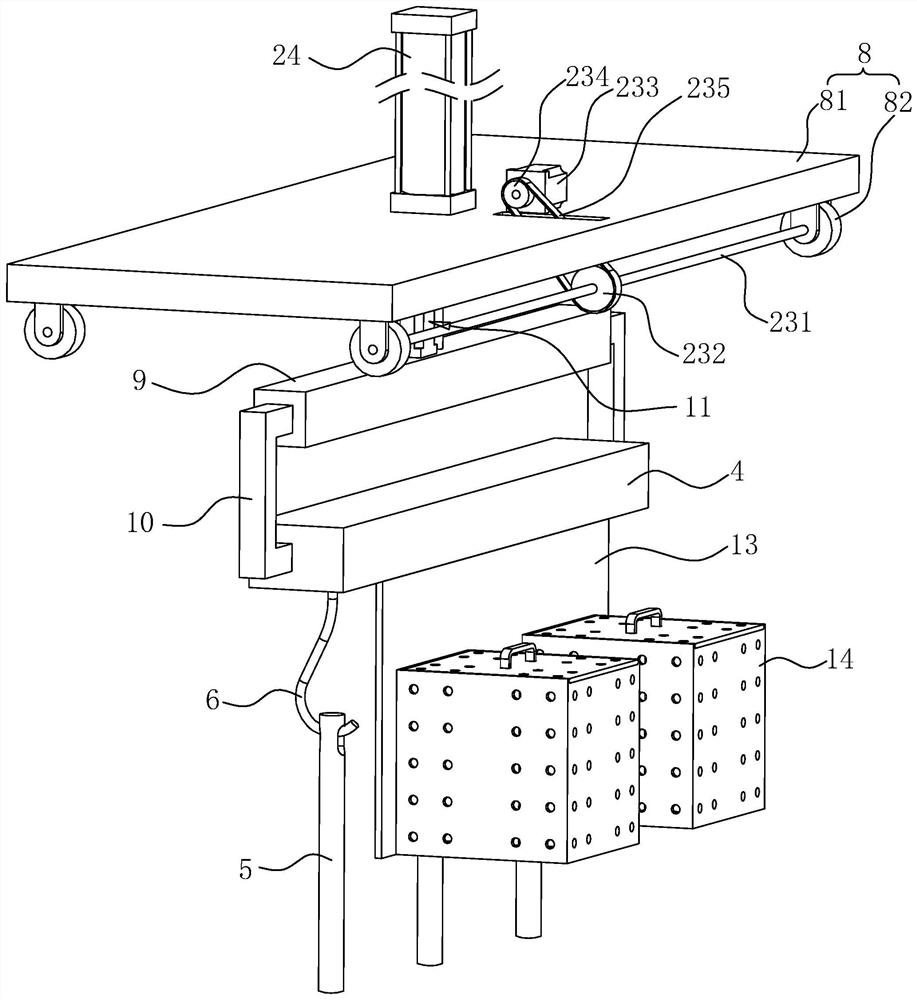

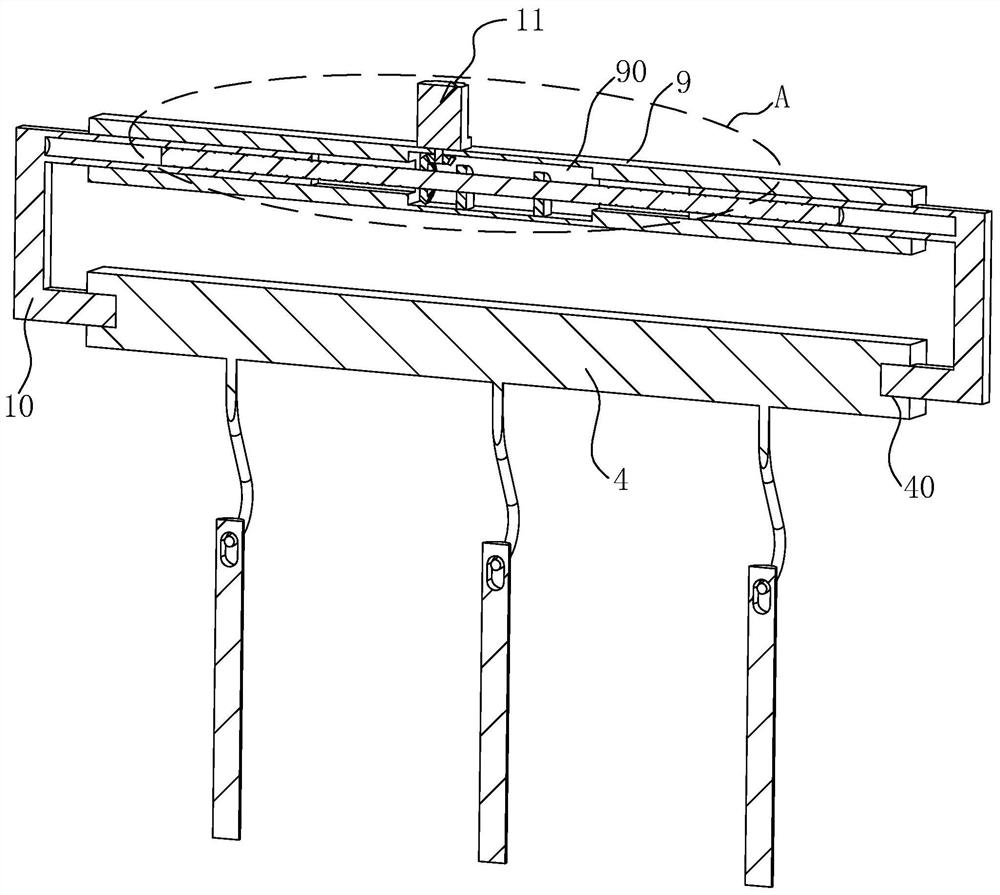

[0047] Attached to the following Figure 1-9 This application will be described in further detail.

[0048] The embodiment of the present application discloses an anodizing production line. refer to figure 1 and figure 2 , an anodizing production line includes a production pool 1, the production pool 1 is provided with a number of treatment pools 22 containing treatment liquid along its length direction, each treatment pool 22 corresponds to a processing step, and the two sides of the production pool 1 are erected with brackets 7. The bracket 7 includes vertical rods 71 arranged opposite each other and a horizontal rod 72 fixedly connected to the top wall of the vertical rod 71. The top wall of the horizontal rod 72 is provided with a guide rail 721, and the guide rail 721 carries a length along the bracket 7. The trolley 8 moves in the direction. The trolley 8 is provided with a power source 23 for driving the trolley 8 to reciprocate by itself. The trolley 8 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com