Terminal cutting and press-fitting device with H-shaped stamping head

A technology of press-fitting device and punching head, which is applied in the direction of shearing device, accessory device of shearing machine, manufacturing tools, etc., can solve problems such as process stagnation, terminal and workpiece product scrapping, single function, etc., and achieve improved cutting and press-fitting Efficiency, avoiding stagnation between processes, and improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

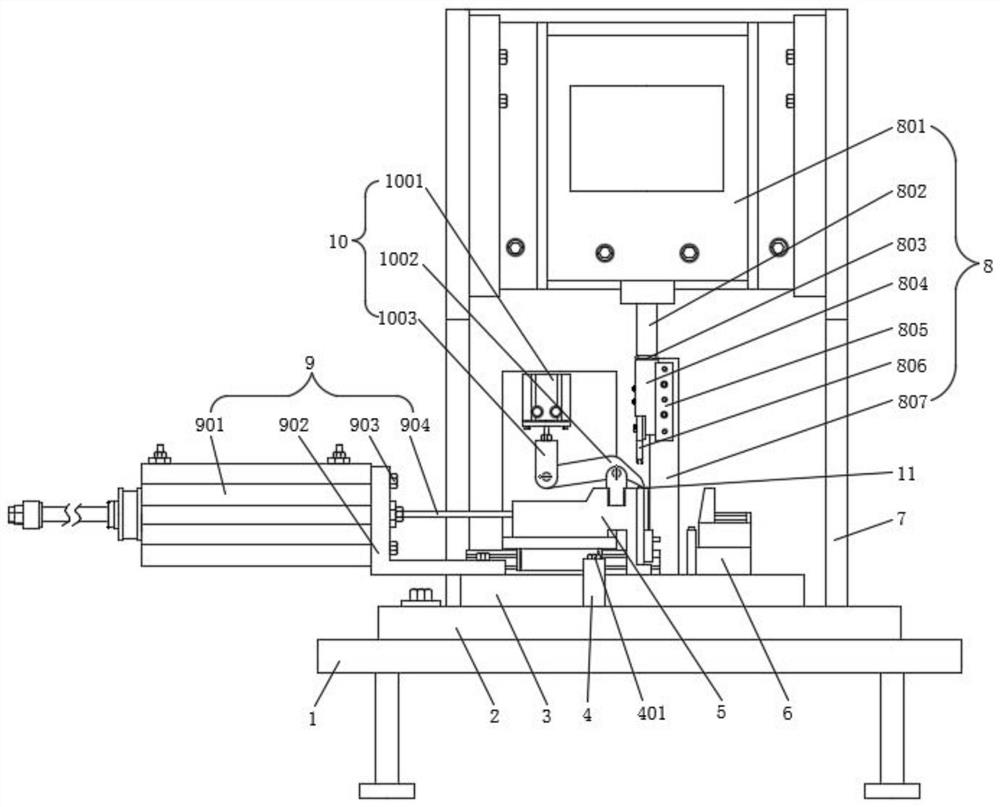

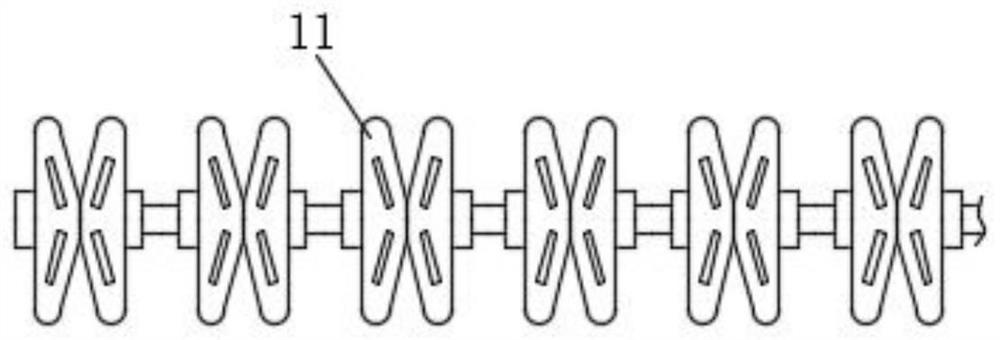

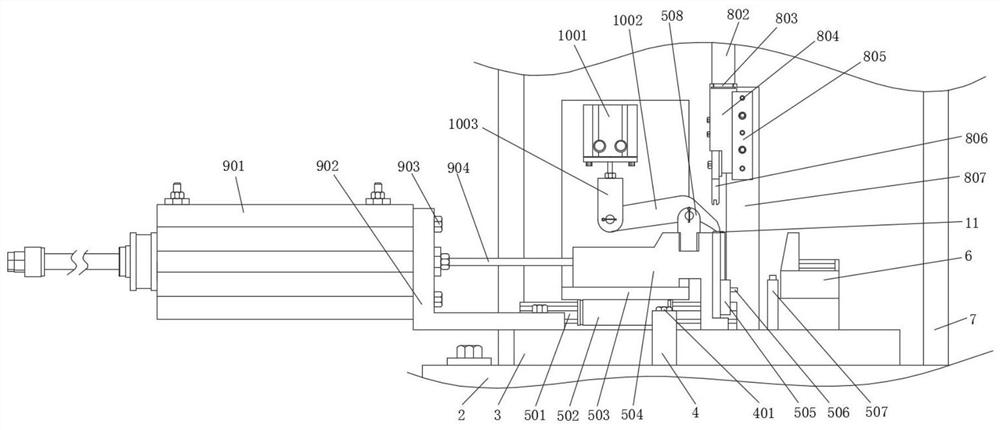

[0026] like Figure 1-Figure 6 As shown, the specific structure of the present invention is: a terminal cutting and pressing device with an H-shaped stamping head, including a workbench 1 and a bottom plate 2, the upper surface of the bottom plate 2 is connected by a clamp block 4 and a clamping bolt 401 to set a lower support plate 3. One side of the lower support plate 3 is provided with a pushing assembly 9 for pushing the sliding block assembly 5, and the side of the sliding block assembly 5 away from the pushing assembly 9 is provided with a workpiece limit seat 6 for placing workpieces. The slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com