Irregular part feeding equipment

A technology of parts and equipment, applied in the field of irregular parts feeding equipment, can solve the problems of unfavorable single pick-up, the conveyor belt cannot disperse the feeding, the conveyor belt cannot be transferred, etc., and achieve the effect of facilitating subsequent feeding operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manner of the present invention will be described in further detail below through the description of the best embodiment with reference to the accompanying drawings.

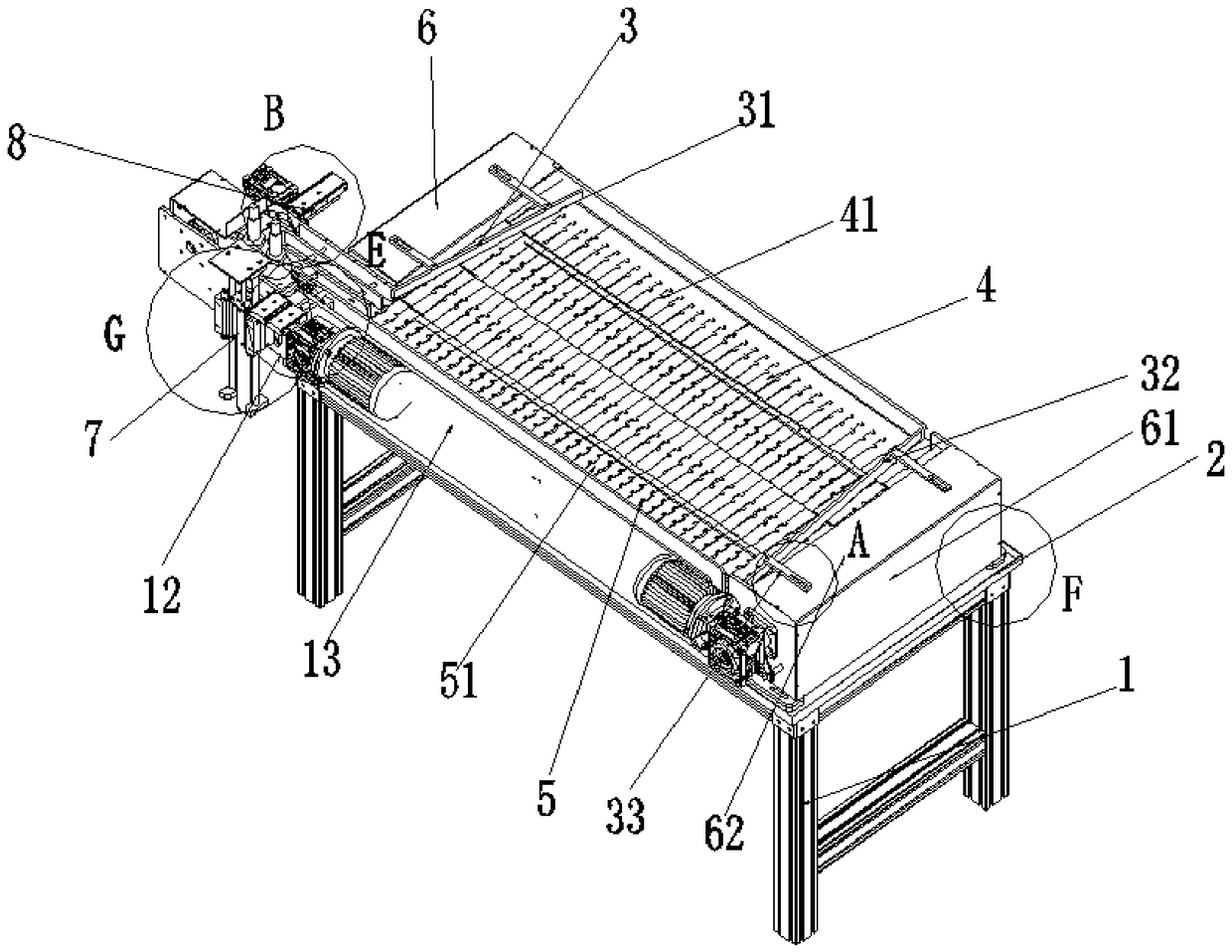

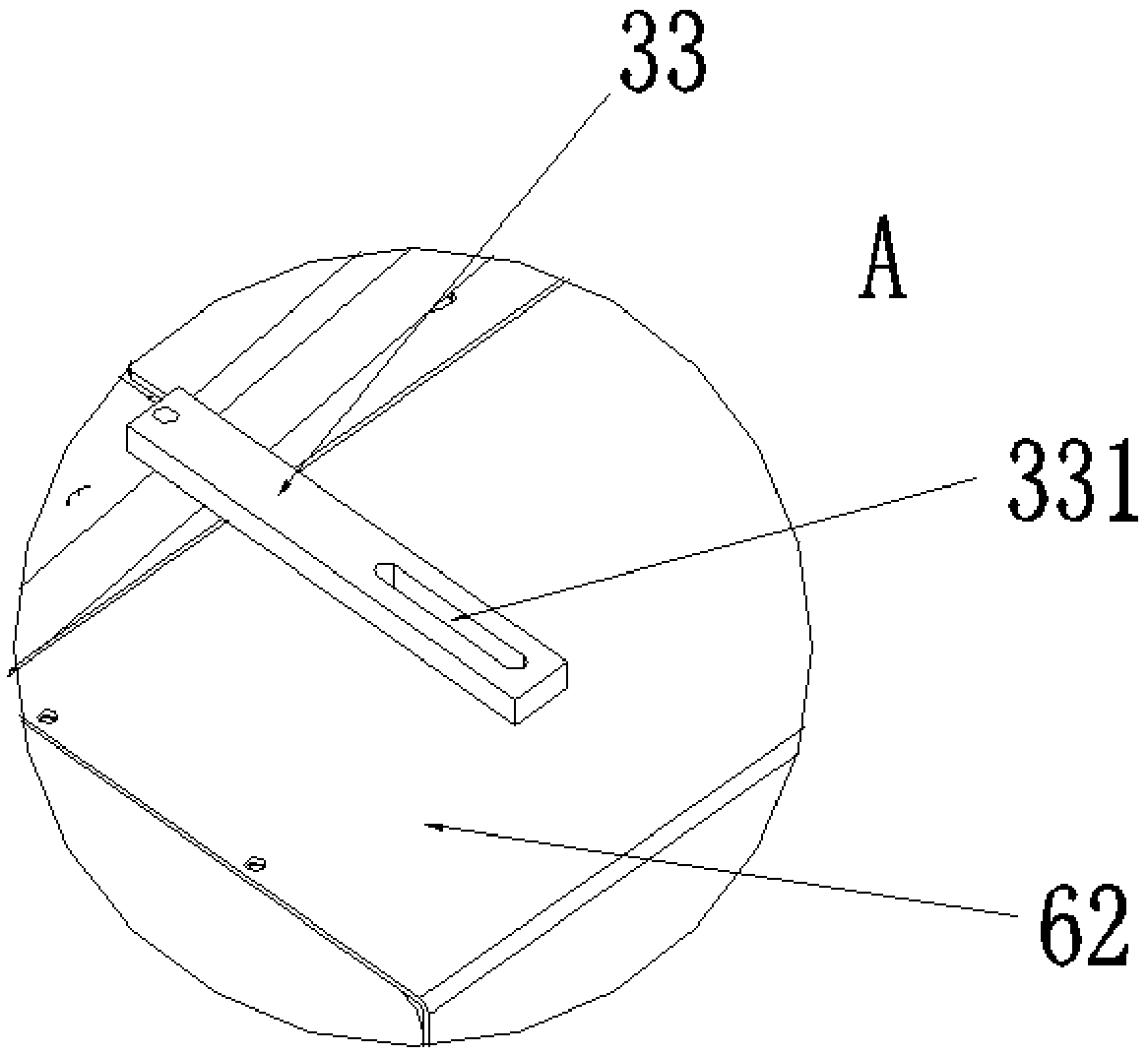

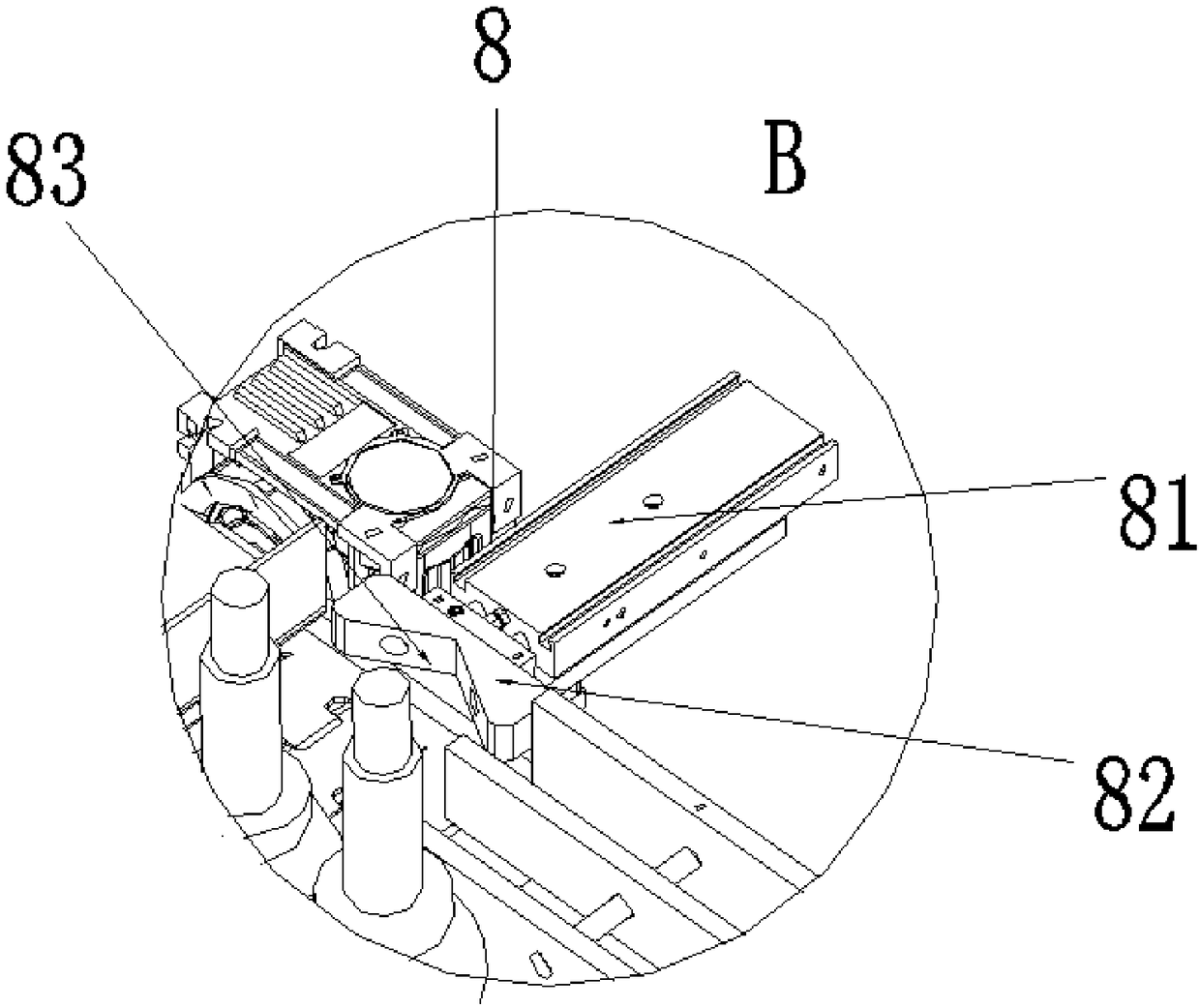

[0039] A feeding device for irregular parts, the feeding device includes a support frame 1, a workbench 2 is arranged on the support frame 1, and at least two transfer parts 4 for driving parts to move are arranged on the workbench 2 , the direction of movement of the adjacent transfer parts 4 is opposite; the feeding device also includes a discharge part 5 for the parts to be transferred out of the feeding device. The invention discloses a device for feeding irregular parts. The setting of the part 4 can realize the movement of the parts on the feeding device and realize the feeding operation of the parts. At the same time, as a greater preference, the feeding device in the present invention also includes a guide part 3 for guiding parts; The guide part 3 includes a first guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com