Once-forming valve grinding machine

A valve and grinding machine technology, which is applied in the direction of grinding machines, grinding bed, grinding machine parts, etc., can solve the problems of valve bending deformation, loss of positioning accuracy, displacement of positioning rod, etc., to achieve reliable positioning and ensure machining accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

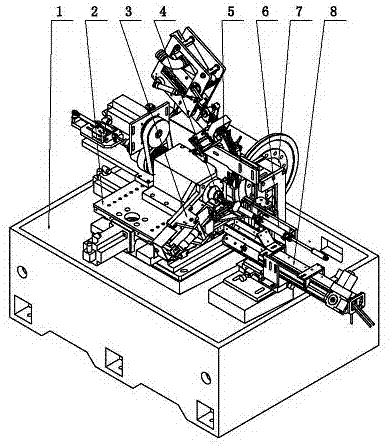

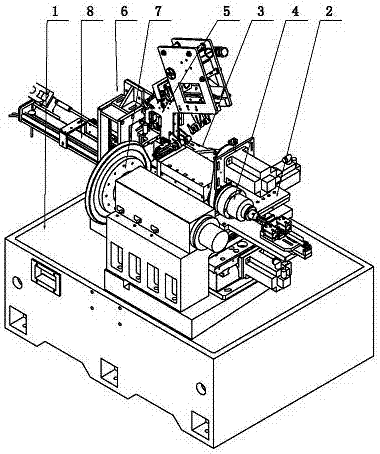

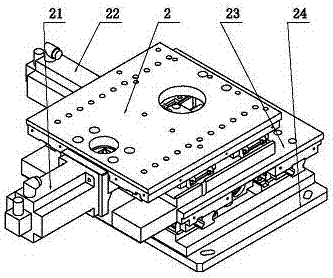

[0036] exist figure 1 and figure 2 In the one-time forming valve grinding machine shown, the bed 1 is the basic supporting member of the entire grinding machine, the grinding wheel spindle 7 is rotatably supported on the grinding wheel spindle support, and the grinding wheel spindle support is fixedly connected to the bed 1, and on the bed 1 is also A workpiece spindle 4 is rotatably supported, and the workpiece spindle 4 is arranged parallel to the grinding wheel spindle 7. A valve centering support mechanism 3 is arranged on the workbench 2. The valve centering support mechanism 3 and the grinding wheel spindle 7 are opposite to each other on both sides of the workpiece spindle 4. Setting, the centering block 37 on the valve centering support mechanism 3 during the grinding process (see Figure 6 ) is in contact with the outer diameter of the cone disc of the valve to be ground to provide support for the valve to be ground, so that the grinding wheel on the grinding wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com