Batched bulk parts separating device, loading system and loading method

A technology for separating devices and parts, applied in the field of feeding systems, can solve the problems of limited specifications of bearing products, reduced production capacity, and inability to achieve, and achieves the effect of reducing design and debugging cycles, reducing production costs, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

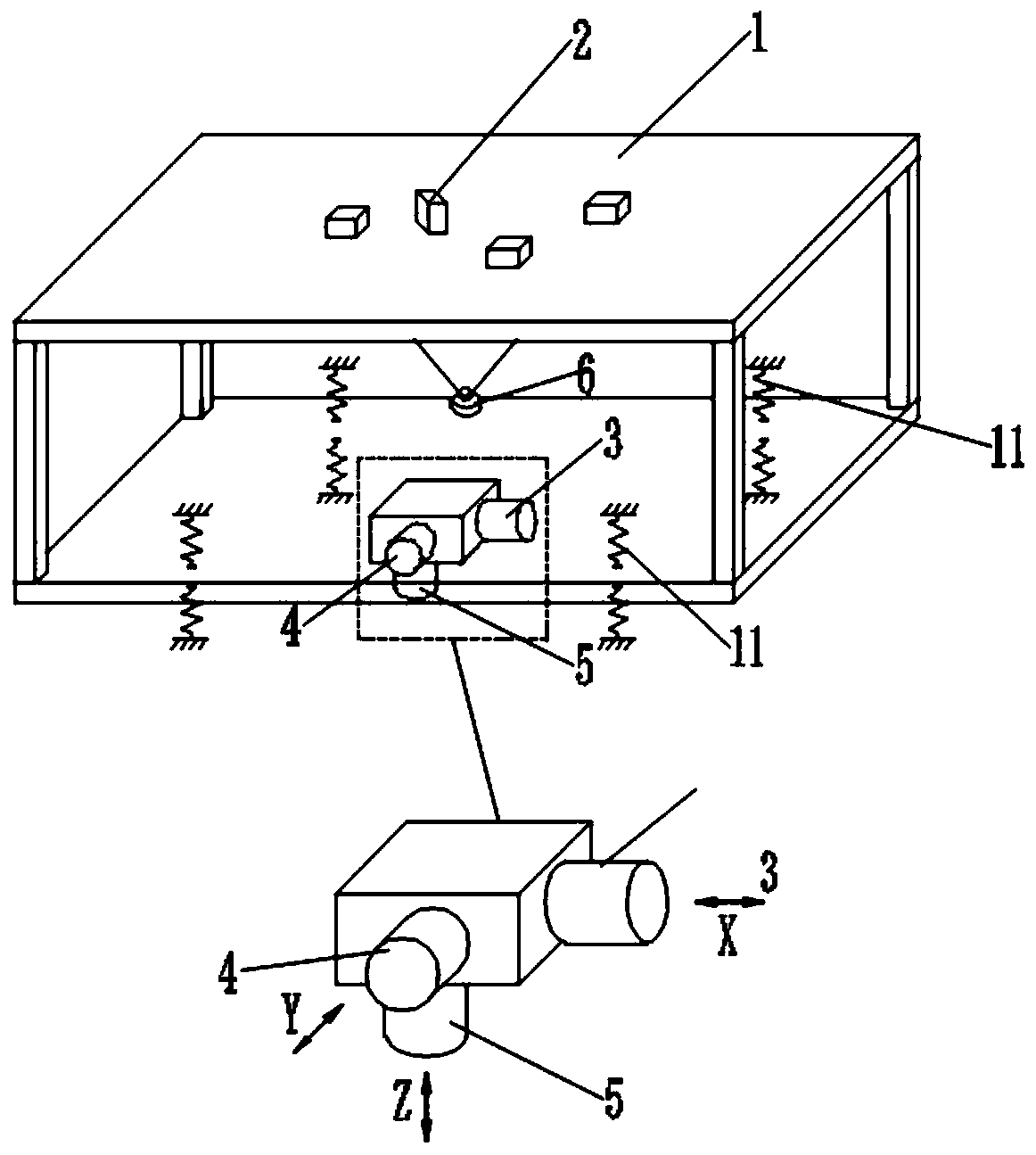

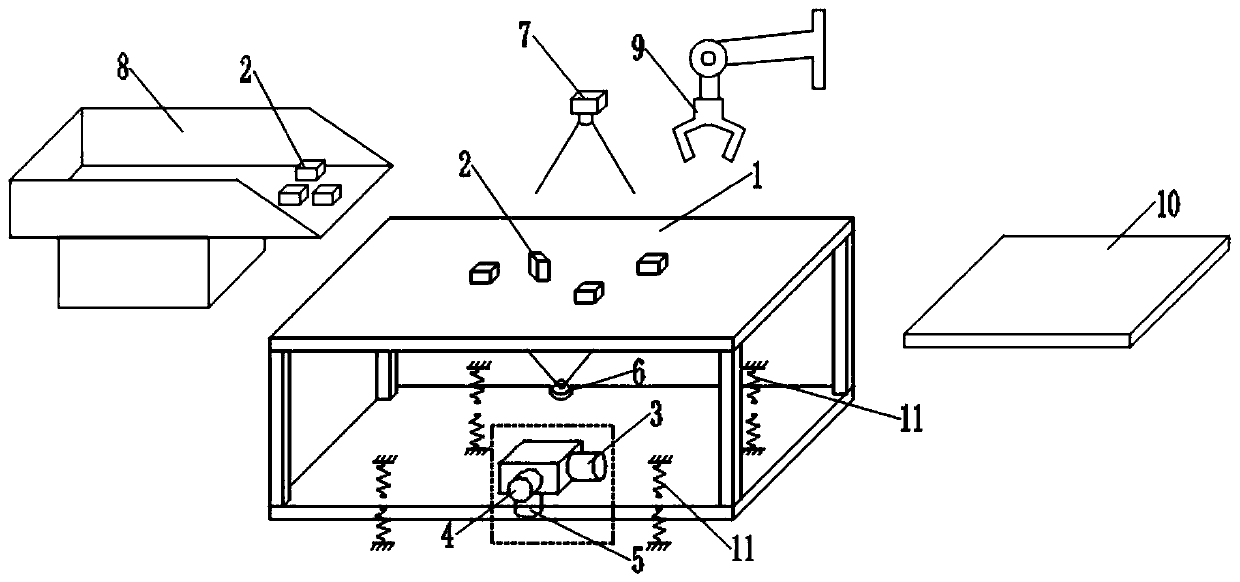

[0049] During specific implementation, the positional relationship between the X-axis force part, the Y-axis force part, the Z-axis force force part and the tray 1 is as follows: figure 1 shown.

[0050] The first electromagnet 3 is set in the X-axis force part, the second electromagnet 4 is set in the Y-axis force force part, the third electromagnet 5 is set in the Z-axis force force part, the first electromagnet 3, the second electromagnet 4, the third electromagnet The electromagnets 5 are all arranged at the bottom of the tray 1, the third electromagnet 5 is arranged at the bottom of the middle of the tray 1, the first electromagnet 3 is arranged beside the third electromagnet 5 and arranged along the X-axis direction, and the second electromagnet 4 is arranged at the bottom of the tray 1. Next to the third electromagnet 5 and arranged along the Y-axis direction, the first electromagnet 3 , the second electromagnet 4 and the third electromagnet 5 are electrically connected...

Embodiment 2

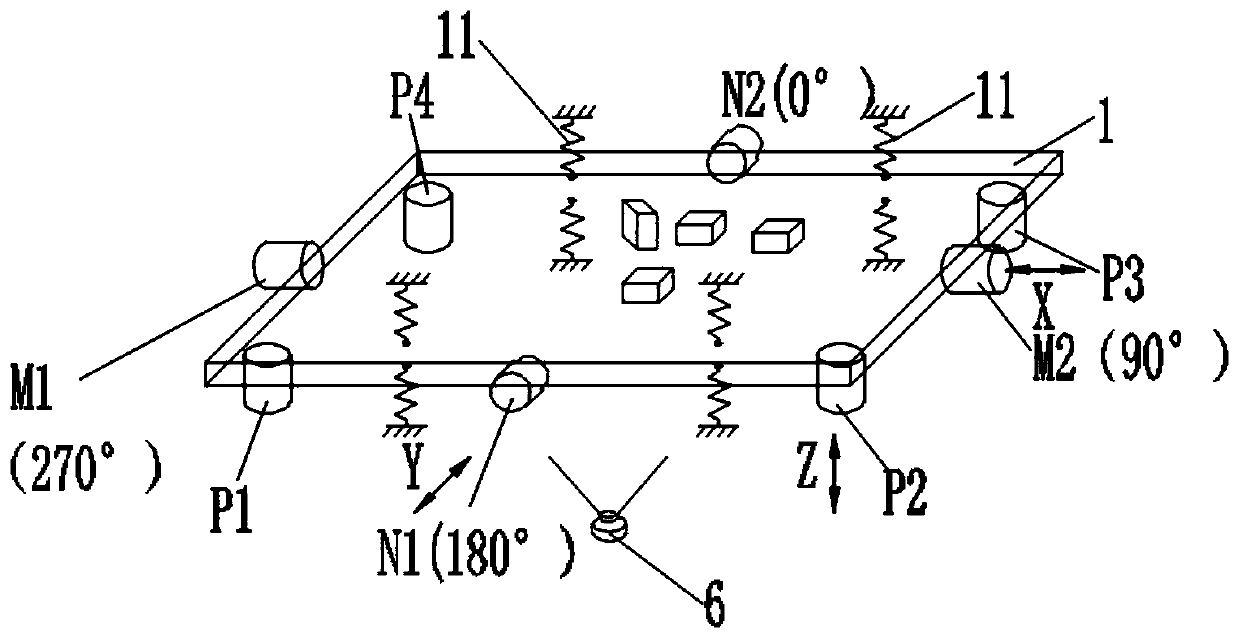

[0052] In this embodiment, the positional relationship between the X-axis force part, the Y-axis force part, the Z-axis force force part and the tray 1 is as follows image 3 shown.

[0053] The X-axis force part is set in the X-axis direction, the Y-axis force force part is set in the Y-axis direction, and the Z-axis force force part is set in the Z-axis direction. The coordinate origin of the X-axis, Y-axis and Z-axis is at the center of gravity of the tray 1 On the vertical axis, the X-axis force part, the Y-axis force force part, and the Z-axis force force part are distributed along the vertical axis of the center of the tray. The X-axis force force part, the Y-axis force force part, and the Z-axis force force part The direction of action of the action points to the tray 1, and the X-axis force part, the Y-axis force force part and the Z-axis force force part are electrically connected with the control part.

[0054] In order to realize the force on the tray 1, the X-axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com