Automatic book core feeding device for perfect binding book-in-cover mechanism

A technology for wrapping the machine and book block, which is applied in book binding, book case loading, printing, etc. It can solve the problems of complicated loading process and achieve the effect of convenient unloading operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

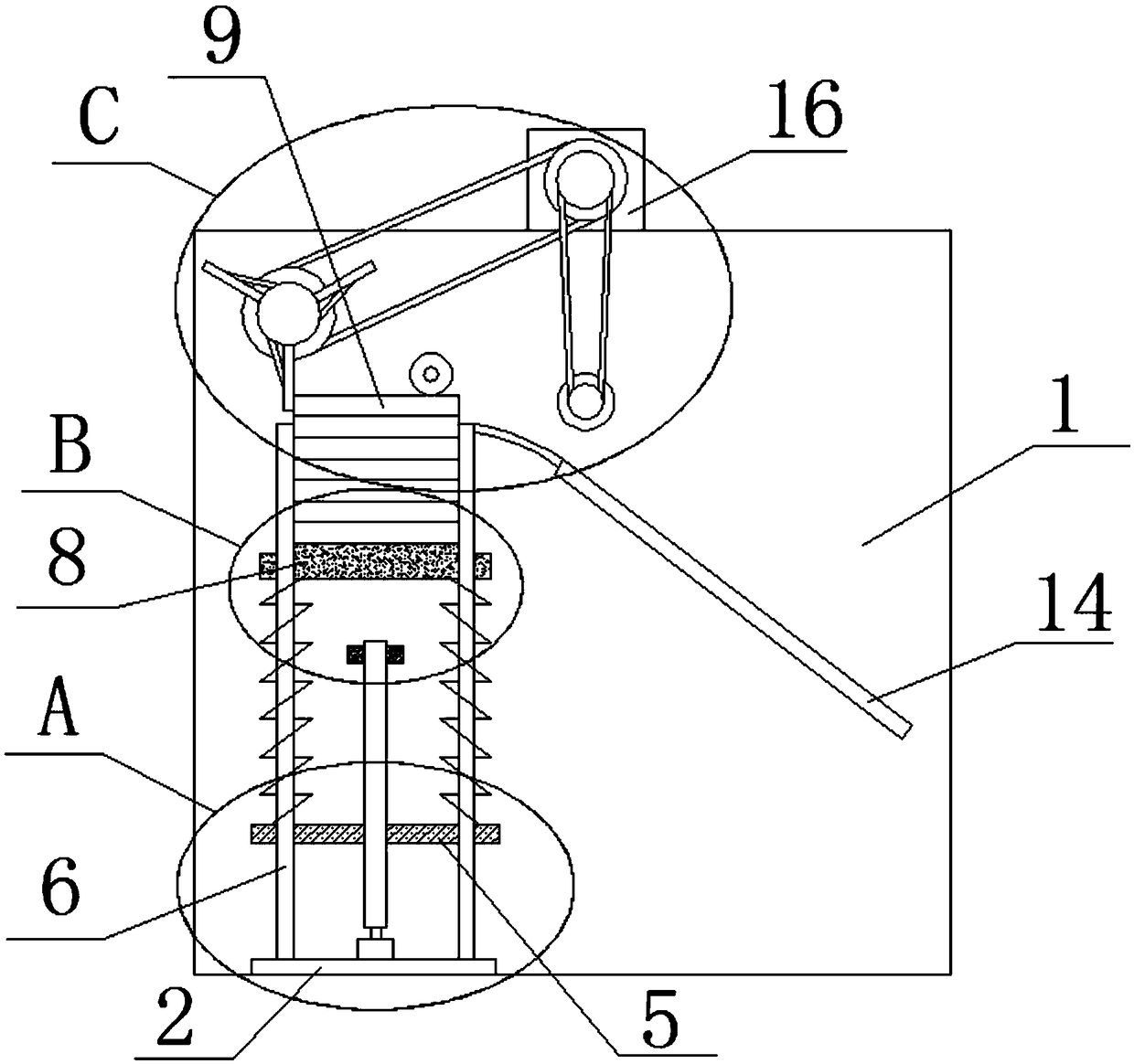

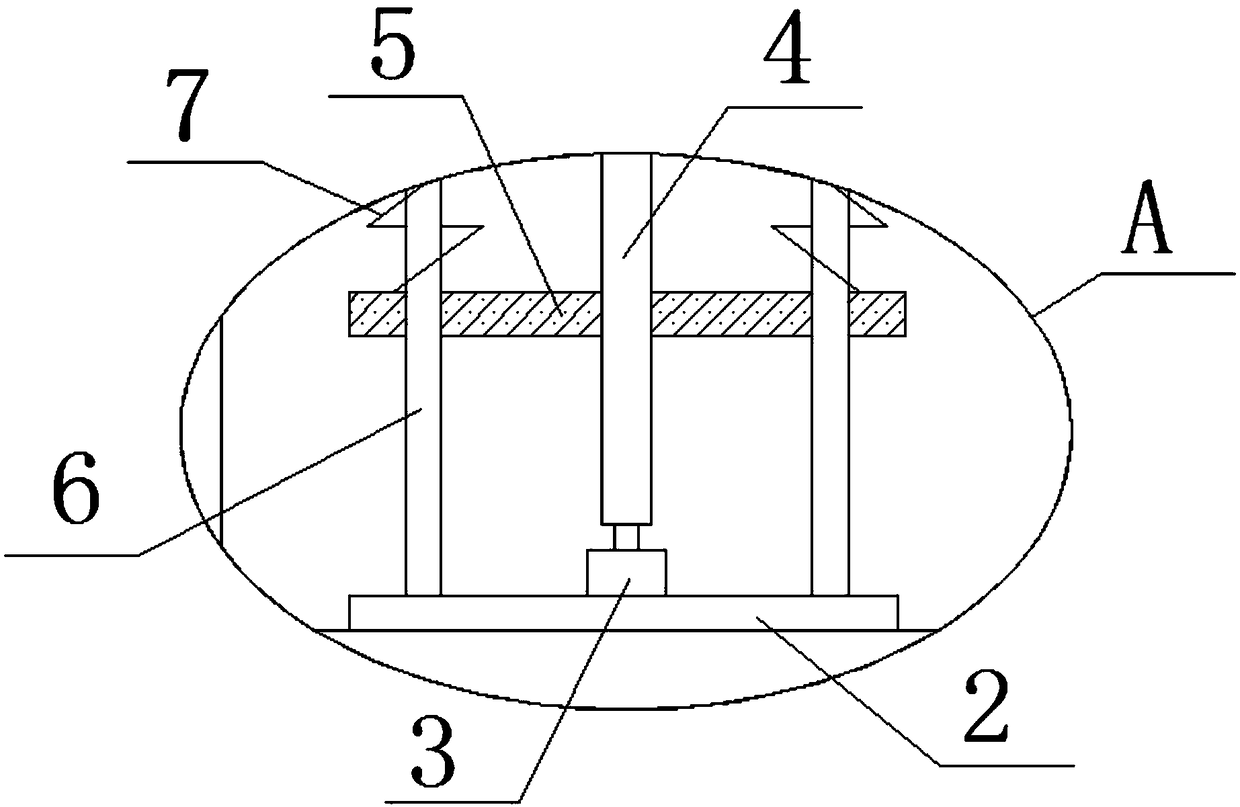

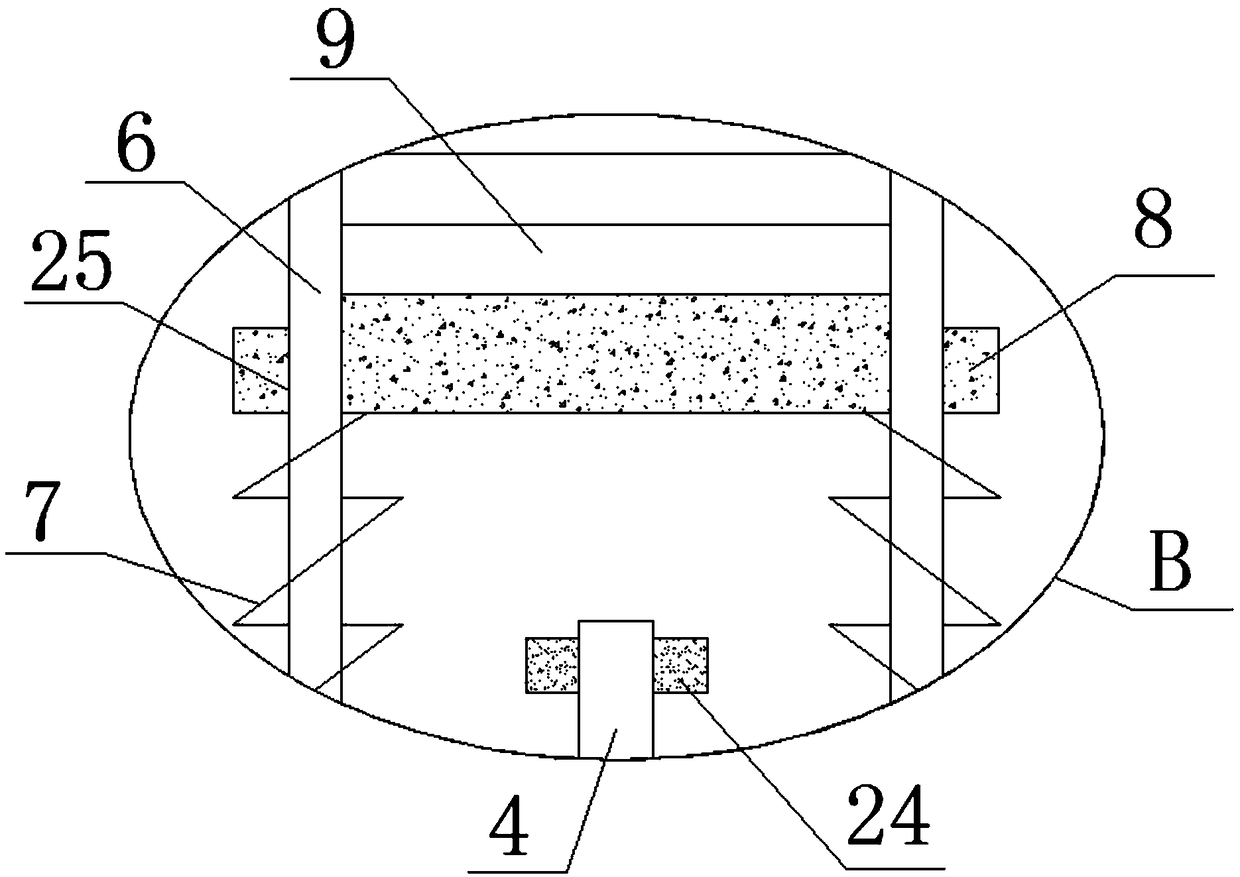

[0028] see Figure 1-5 , the present invention provides a technical solution:

[0029]The binding device is a device for automatically loading book blocks. The book block device includes a frame 1, a support plate 2 is welded on one side of the frame 1, and a first motor 3 is fixedly installed on the top of the support plate 2. The first motor 3 A screw rod 4 is fixedly installed on the output shaft, and the outer thread of the screw rod 4 is fitted with a slide plate 5. The top and both sides of the support plate 2 are welded with guide rods 6. The slide plate 5 is slidably mounted on two guide rods 6. The two guide rods 6 The outer sliding sleeve of the bar 6 has the same stock plate 8, and the bottom of the stock plate 8 is welded with two symmetrically arranged springs 7, and the spring 7 is movably set on the outside of the corresponding guide bar 6, and the bottom end of the spring 7 is in contact with the slide plate. The tops of 5 are welded together, and a plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com