Telescopic G-shaped clamp

A clamp body and movable clamp technology, applied in the direction of clamps, manufacturing tools, etc., can solve the problems of limited adjustable range, non-adjustable size, and inability to use G-shaped clamps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

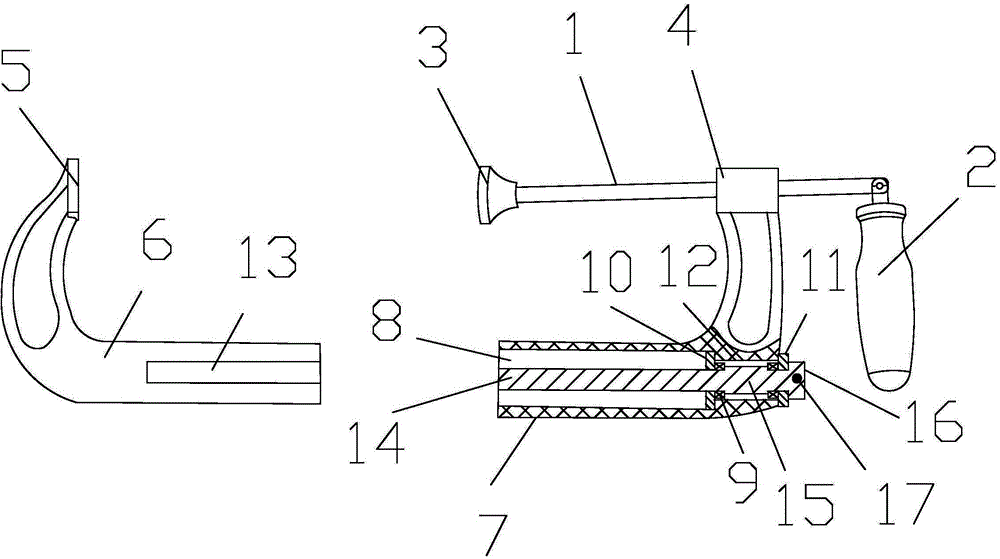

[0016] see figure 1 , a retractable G-shaped clip, including a G-shaped clip body, a screw rod 1, a handle 2, and a joint head 3. The clip body is provided with a clamping end 5 and a mounting end 4, and the mounting end is provided with a threaded hole. The screw rod and the threaded The holes are threaded, the handle and the movable head are respectively arranged at the two ends of the screw rod, the movable head is arranged opposite to the clamping end, the clamp body includes a movable clip and a fixed clip, and the movable clip and the fixed clip both include a horizontal section and a Vertical section, the movable clip vertical section 7 is provided with the slotted hole 8 that can accommodate the fixed clip vertical section 6, and the fixed clip vertical section is movably sleeved in the slotted hole of the movable clip vertical section, and the movable clip is vertically The connection between the segment and the vertical segment of the fixing clip is realized through ...

Embodiment 2

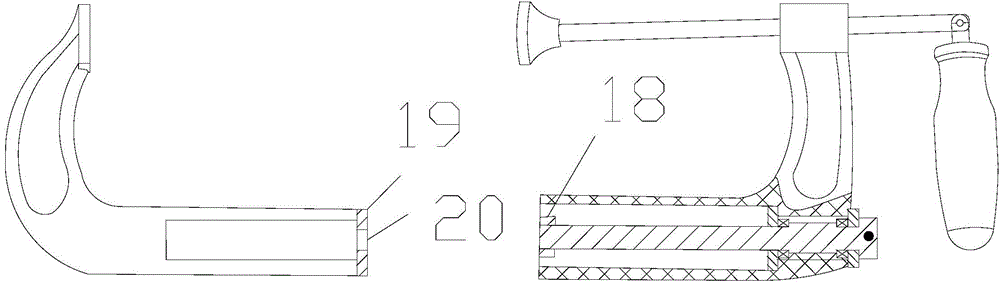

[0022] On the basis of Embodiment 1, the end of the threaded section is provided with a cylindrical block 18 with an external thread and a larger diameter than the threaded section, and the cylindrical block is screwed with the blind hole; the end of the blind hole is provided with End cap B19, the center of the end cap B is provided with a threaded hole 20 equal in diameter to the threaded section, the threaded section is threaded into the threaded hole, and the end cap B is fixedly connected to the end of the vertical section of the fixing frame by bolts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com