Circular-reciprocating-type transporting and carrying device

A technology of reciprocating and handling devices, which is applied in the direction of conveyors, transportation and packaging, etc., can solve the problems of inability to reciprocate conveying movement, complex structure of conveyors, poor wear resistance and corrosion resistance, etc. Promotion value and use value, wear resistance and corrosion resistance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

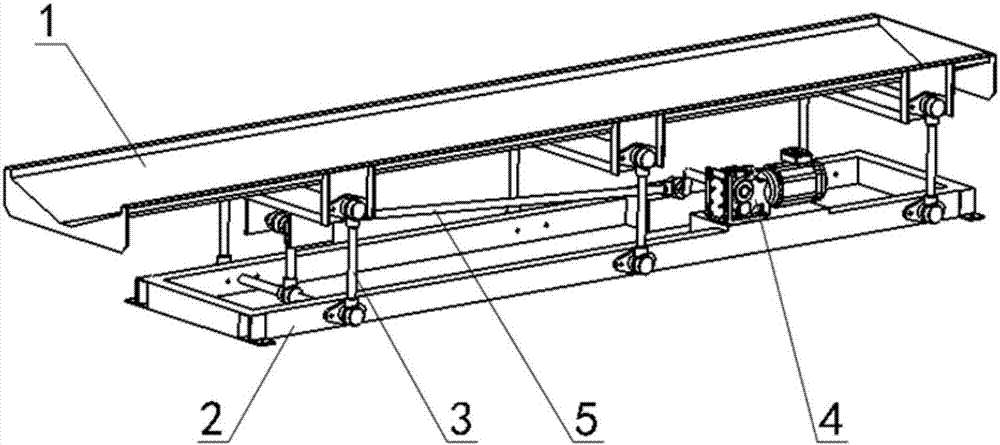

[0027] Example 1, such as Figure 1-2 Shown:

[0028] A reciprocating conveying and handling device, comprising a tray 1, a base 2, a connecting shaft 3, a reduction motor 4 and a linkage mechanism 5; the tray 1 is connected to the base 2 through the connecting shaft 3, and the reduction motor 4 is installed Right part; the upper end of the connecting shaft 3 is a rotatable movable connection with the tray 1, and the lower end of the connecting shaft 3 and the base 2 is also a rotatable movable connection; the connecting shaft 3 is a telescopic rod structure that can be telescopically adjusted; The tray 1 forms a movable connection with the geared motor 4 through the link mechanism 5, and the rotational driving force of the geared motor 4 is transmitted to the tray 1 through the link mechanism 5 to realize the circular reciprocating motion of the driven tray 1; the tray 1 is made of Stainless steel material, the outer surface of the tray 1 is covered with wear-resistant steel...

Embodiment 2

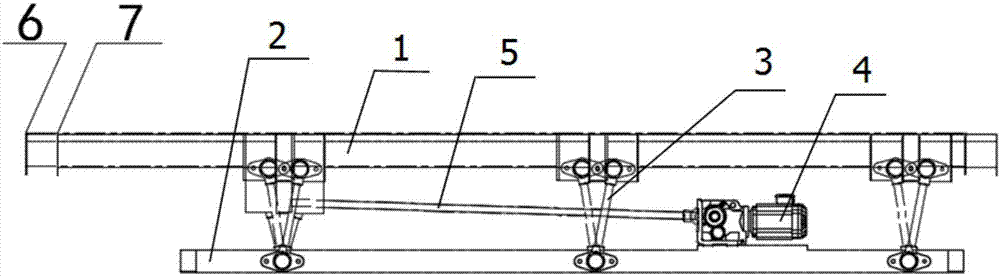

[0036] Example 2, such as Figure 1-2 Shown:

[0037] The tray 1 is connected to the base 2 through the connecting shaft 3 , and the reduction motor 4 is installed on the base 2 . The connecting shaft 3 can be rotated at the connecting point between the connecting shaft 3 and the tray 1, the connecting point between the connecting shaft 3 and the base 2, and the connecting shaft 3 can be telescopically adjusted; Passed to the tray 1, the reduction motor 4 drives the tray 1 to make a reciprocating motion. The connecting rod mechanism 5 is a planar four-bar mechanism, and the reciprocating motion of the tray 1 can be achieved by utilizing the snap-back characteristic of the planar four-bar mechanism: slowly moving forward and rapidly retreating. The tray 1 slowly advances to the front pole 6 and quickly retreats to the rear pole 7. This movement is called the snapback feature, and the conveyed object slides on the tray 1 through the snapback feature of the tray 1 . So as to a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com