Patents

Literature

57results about How to "Avoid Duplicate Positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

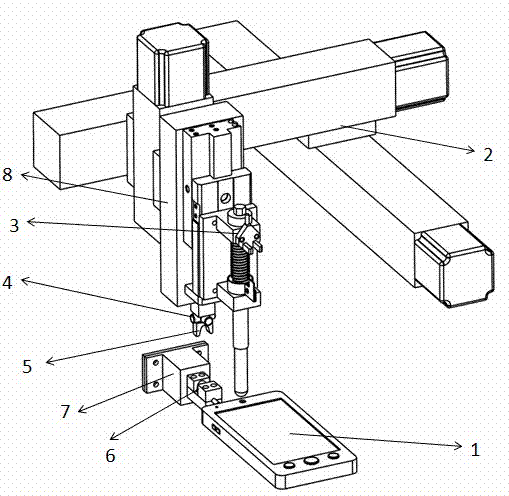

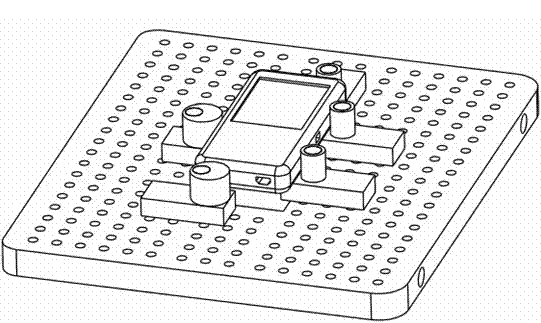

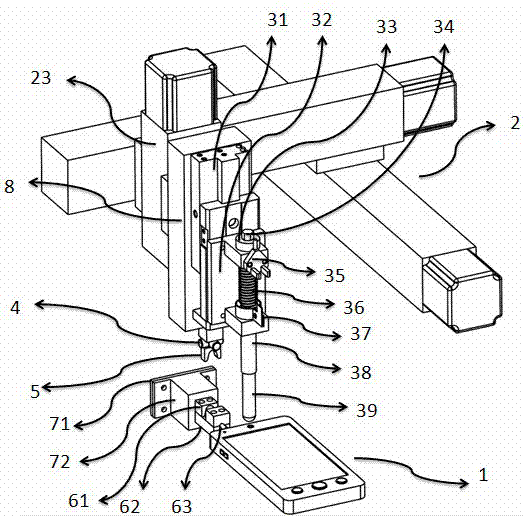

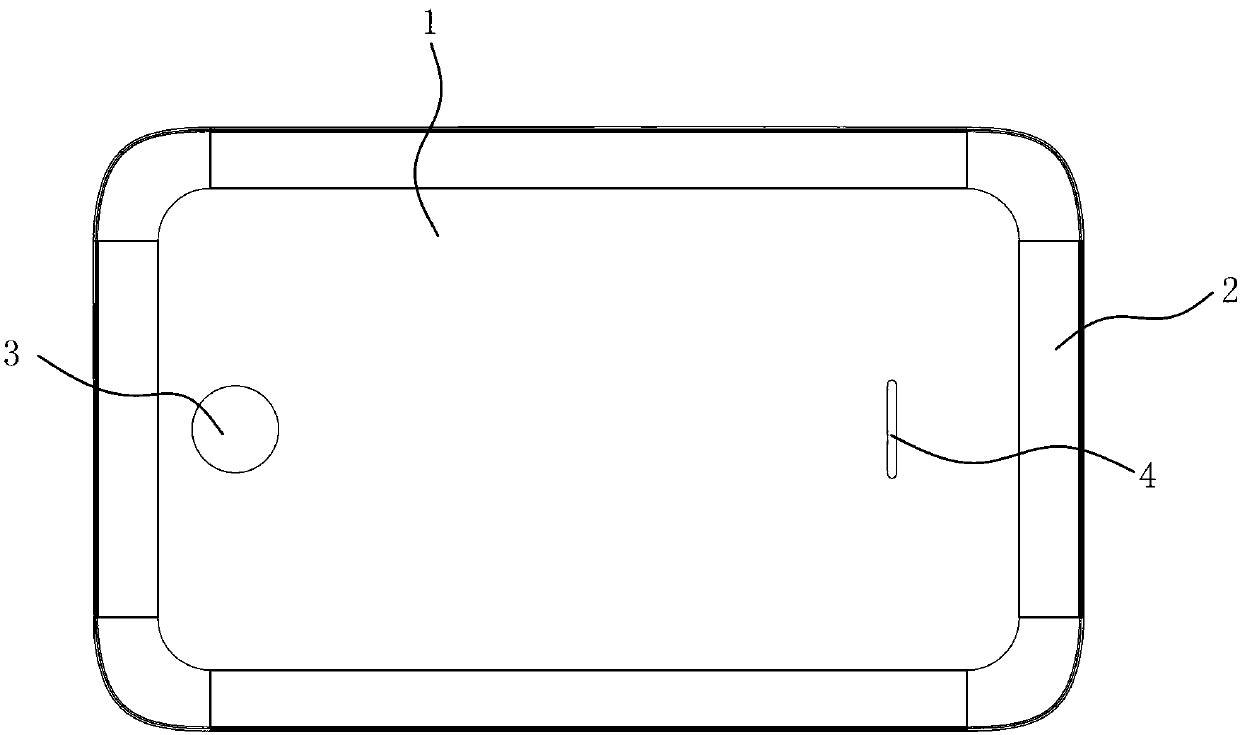

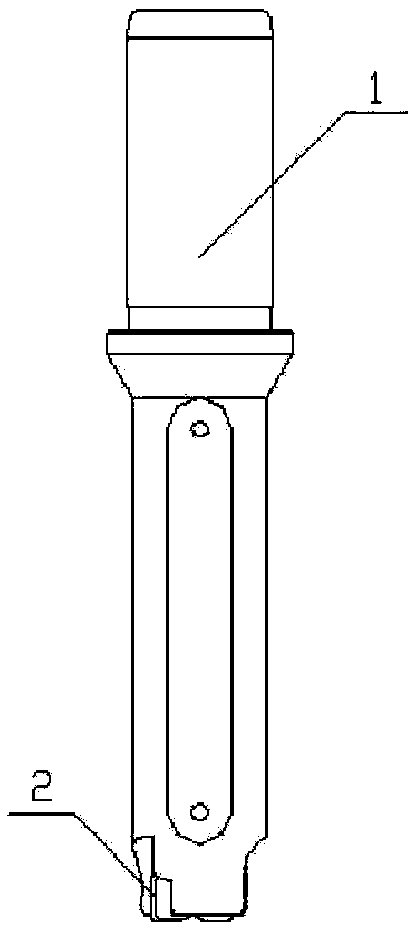

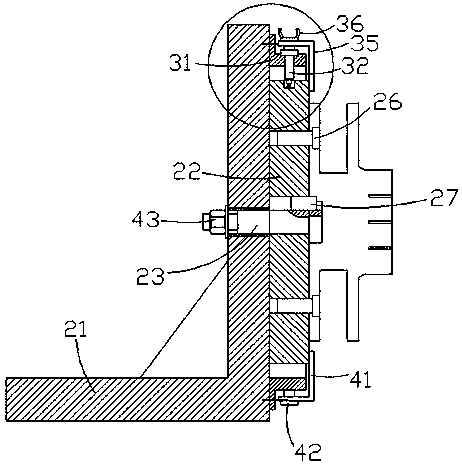

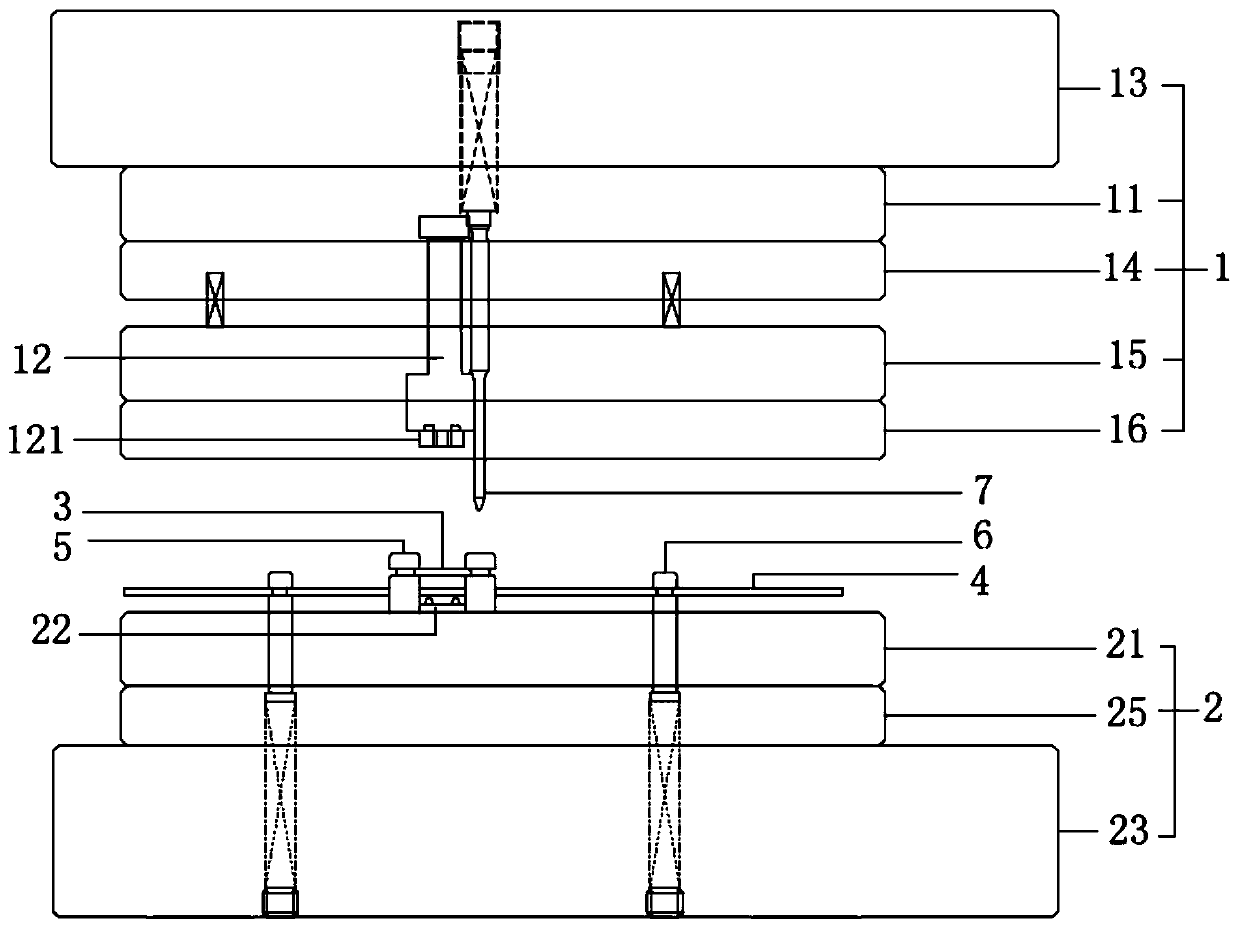

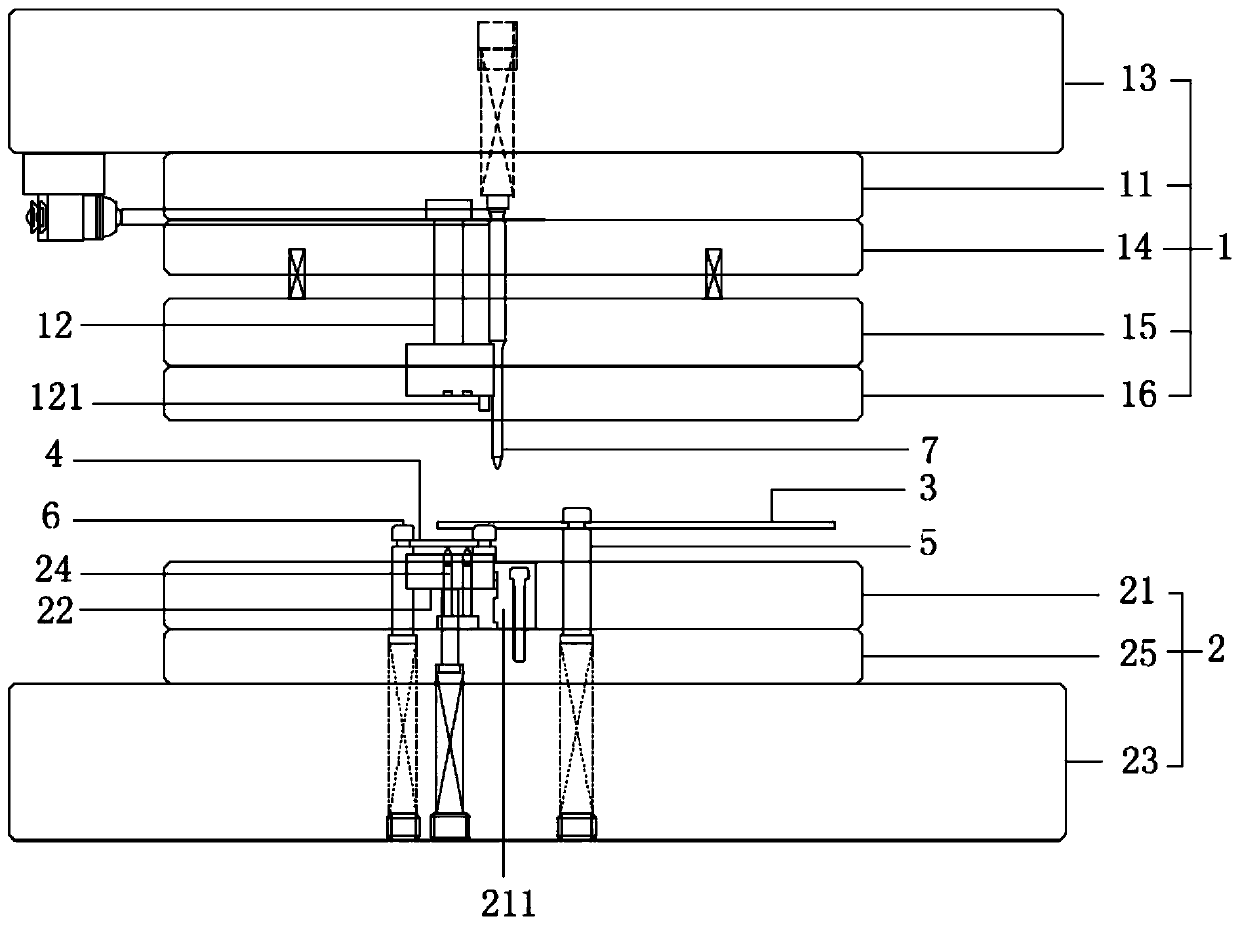

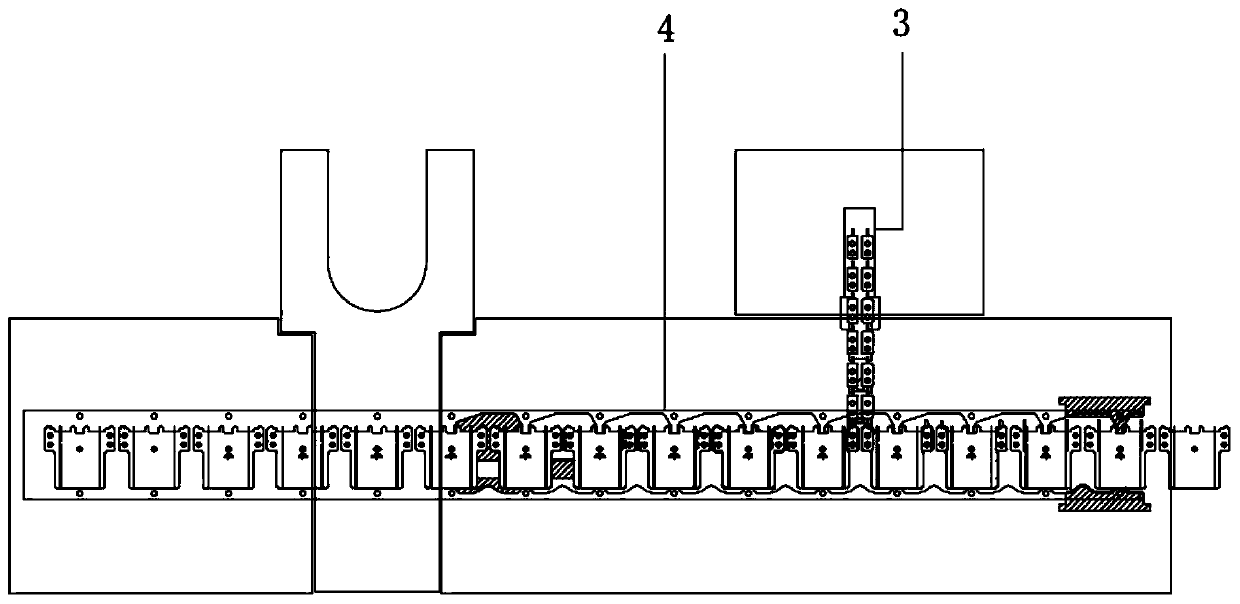

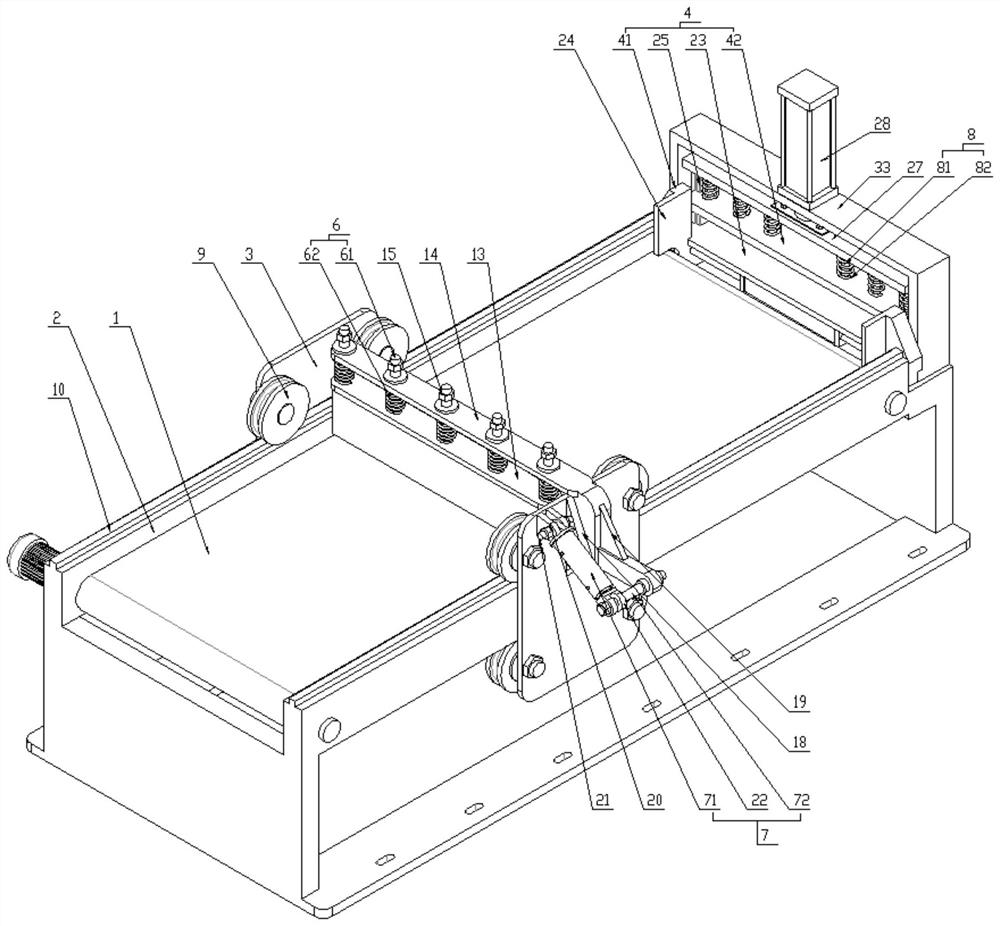

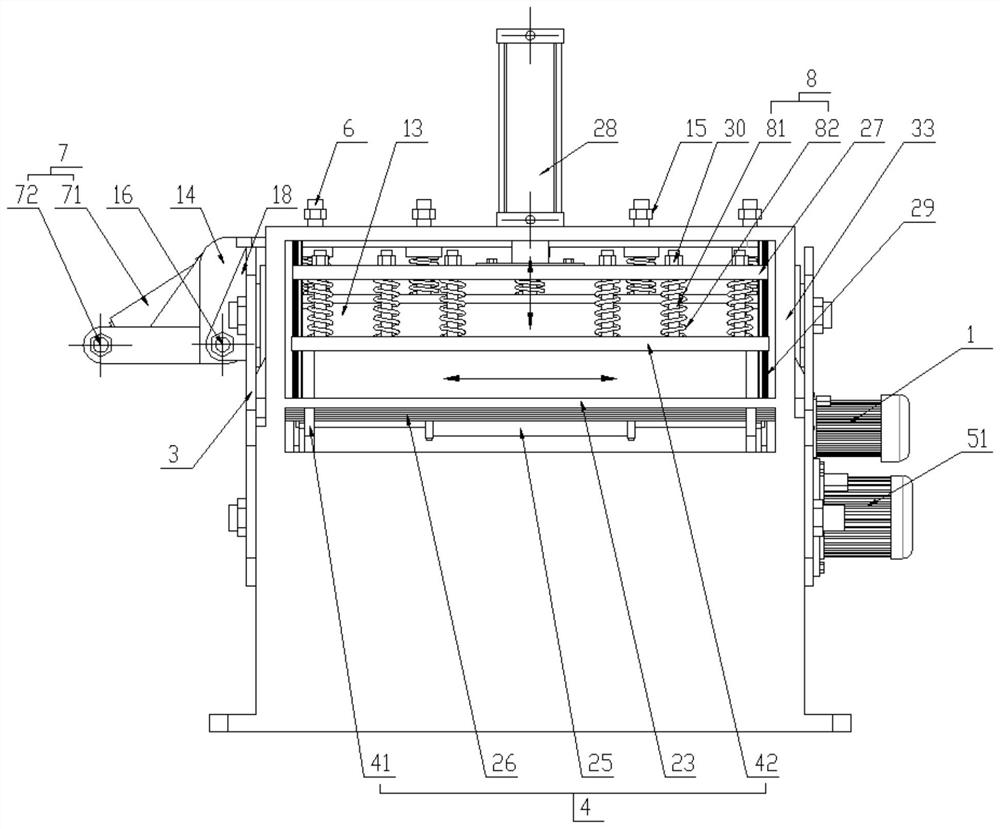

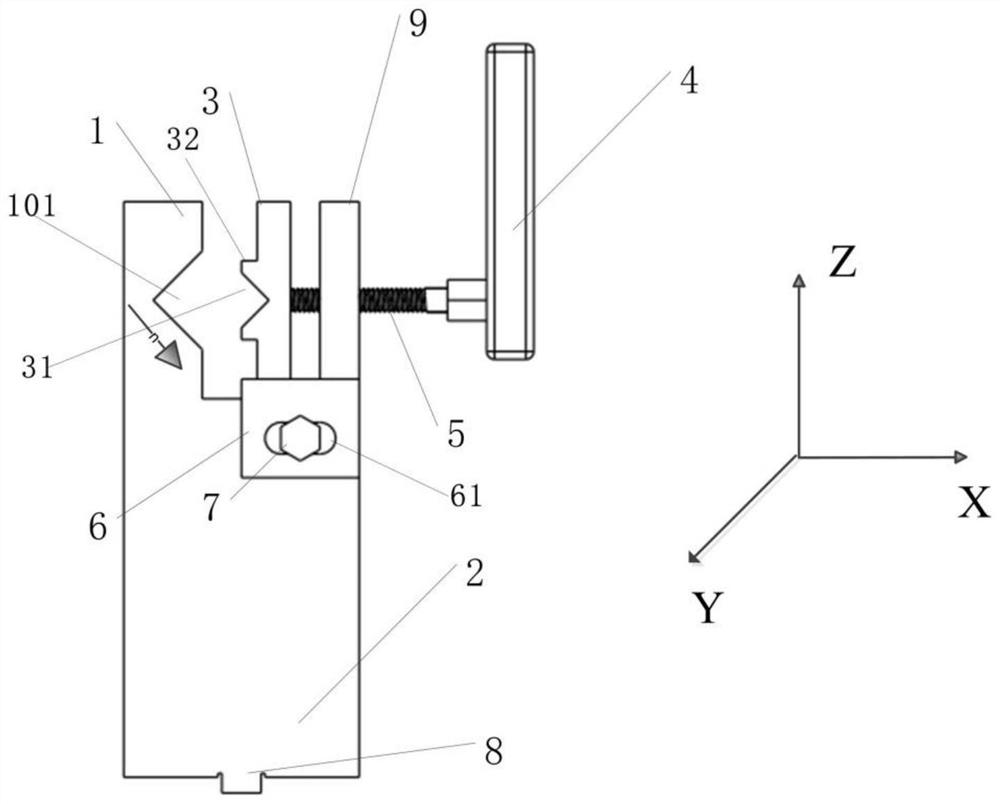

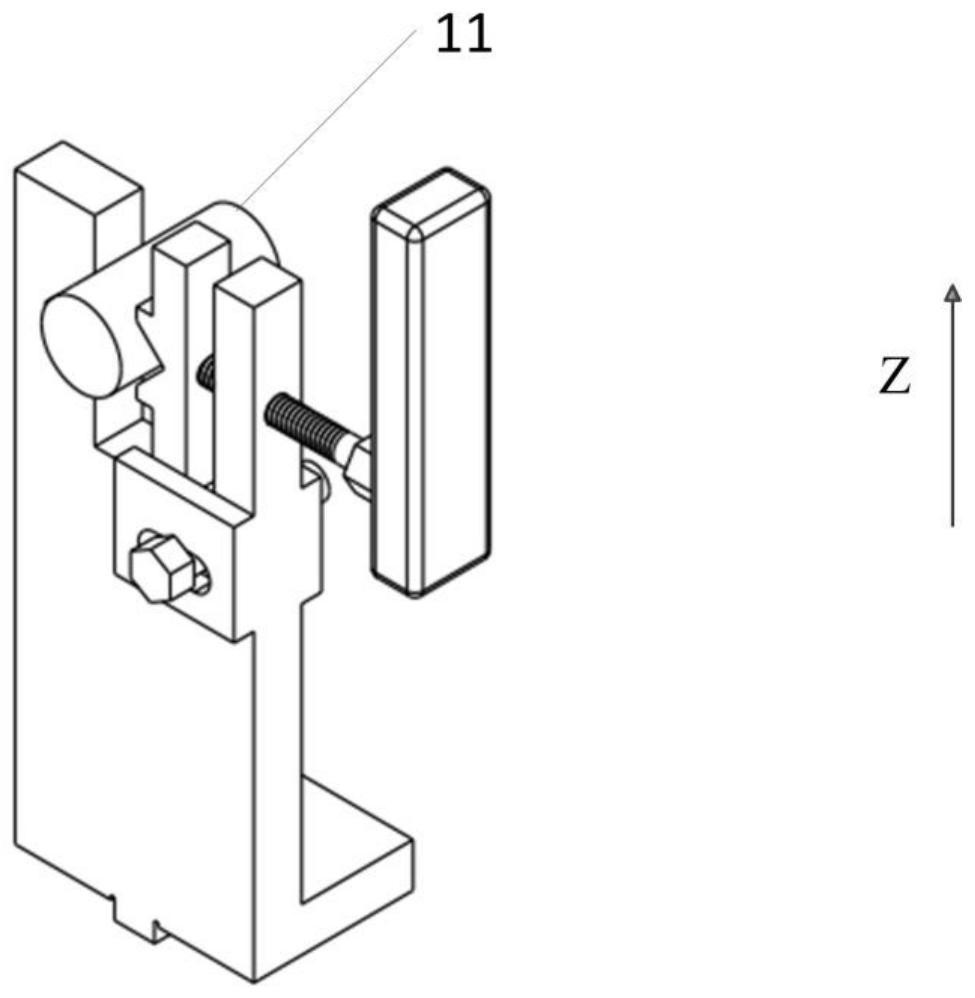

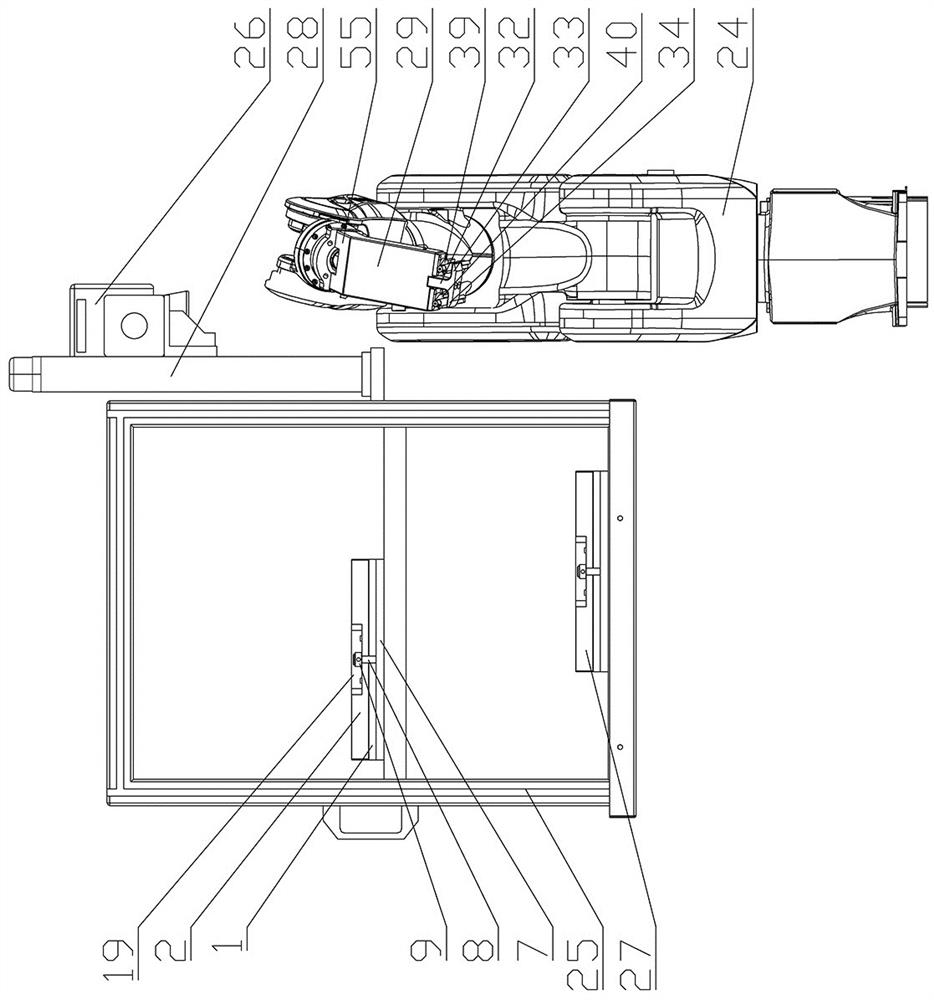

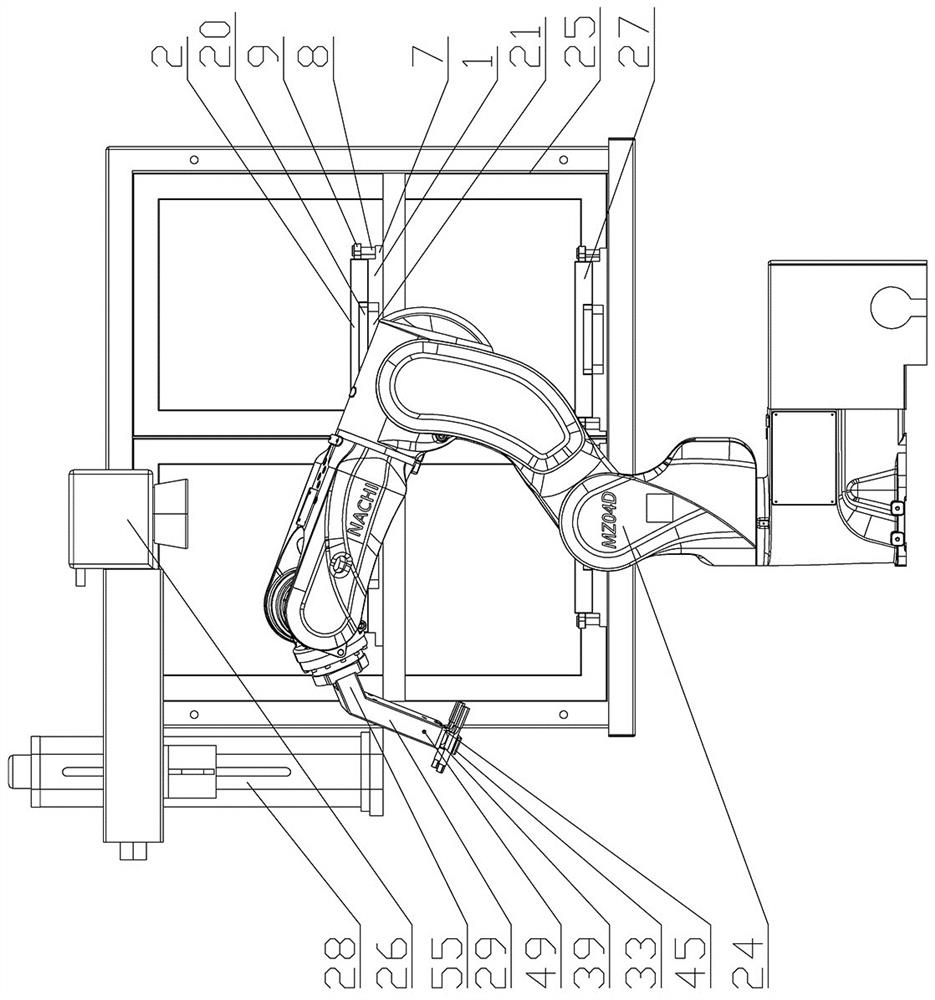

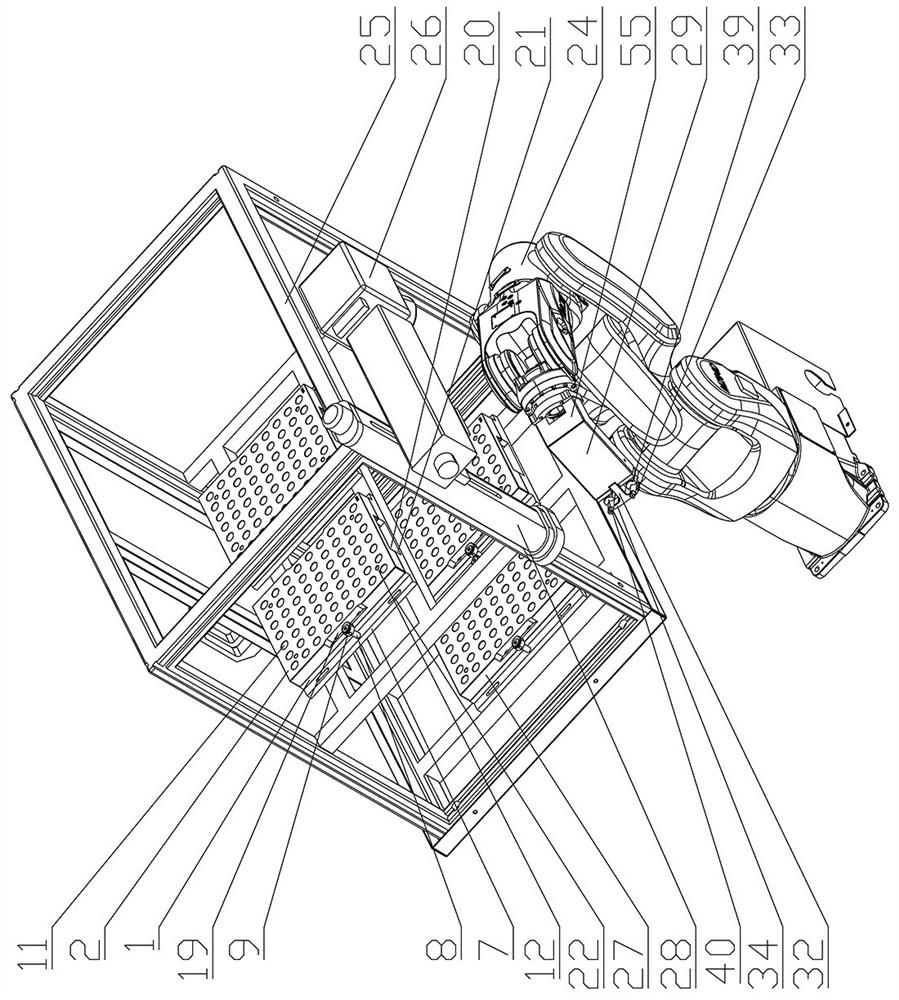

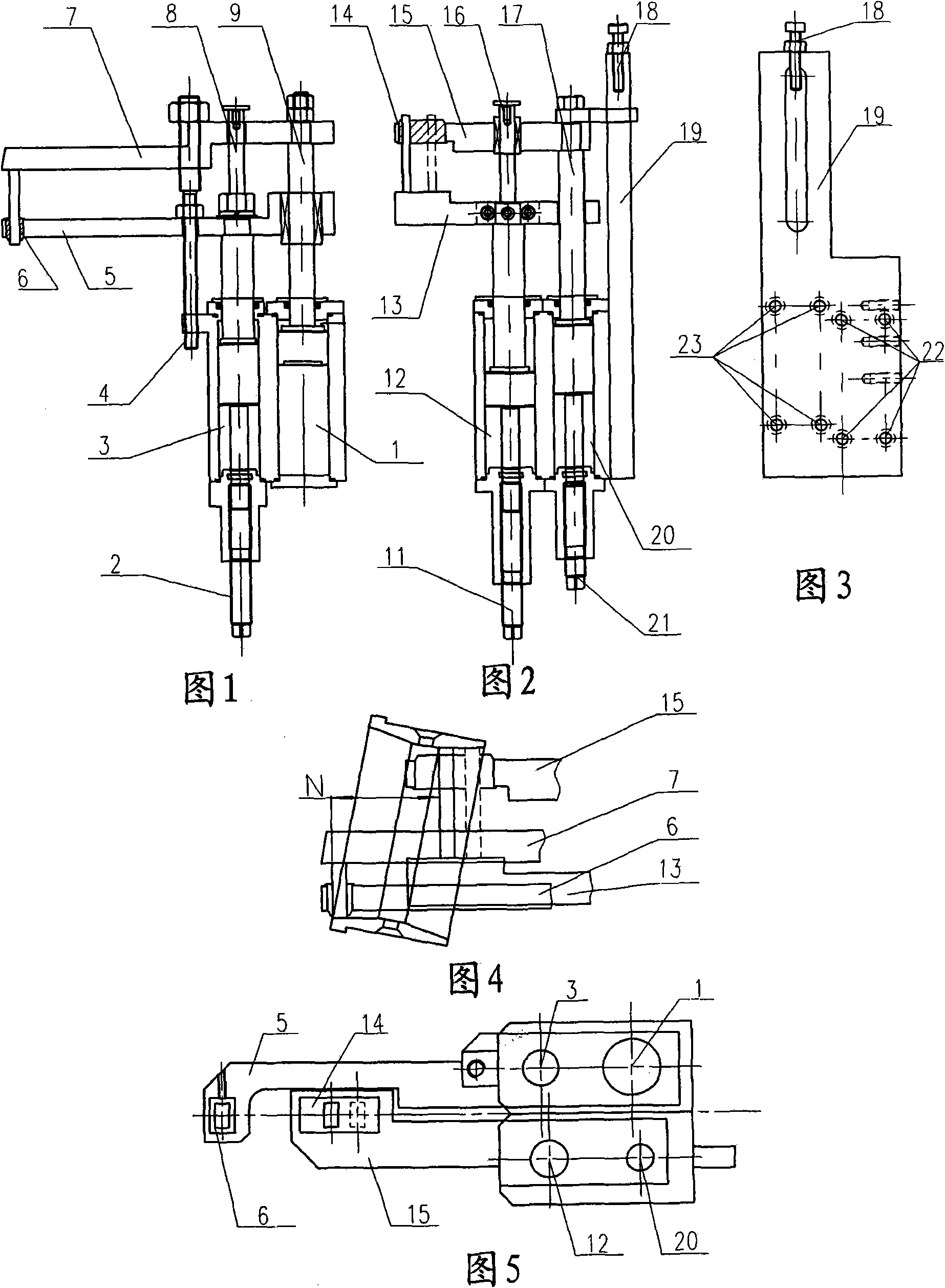

Mechanical arm operation executing device of electronic products

InactiveCN102513989ALow costAvoid Duplicate PositioningProgramme-controlled manipulatorCircuit interrupters testingKey pressingEngineering

The invention provides a mechanical arm operation executing device of electronic products, the operation targets of the executing device are cellphones or other electronic products, and the main part thereof is driven by a three-axis mechanical arm; the executing device comprises a facade key operating device, a multi-end contact terminal, an inserting and pulling member, one or multiple extrapolated equipment adapters, and one or multiple limiting mechanisms; the executing device further comprises a body block used for lapping and mounting the facade key operating device, the multi-end contact terminal and the inserting and pulling member. The device is combined with a common three-axis mechanical arm to finish the automatic function operations of electronic products difficult to be realized by a mechanical arm with six degrees of freedom, and the device is compatible to the operations of touch screens and key cellphones. The executing device of the invention has the advantages of low cost, convenience for manufacture and installation, and capability of accurately and effectively finishing the cellphone function operation and saving the cost.

Owner:湖北众友科技实业股份有限公司

OLED (Organic Light Emitting Diode) panel display defect restoration method

InactiveCN104978916AAvoid Duplicate PositioningImprove accuracyStatic indicating devicesMicroscopeEngineering

Owner:SICHUAN CCO DISPLAY TECH

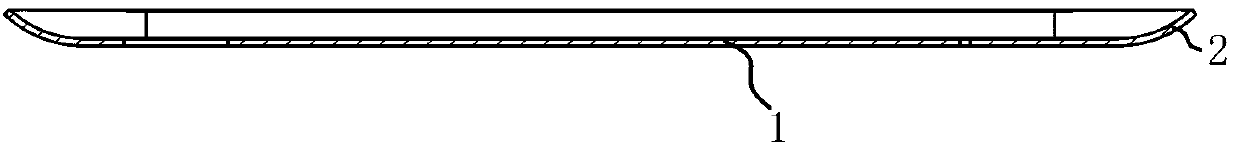

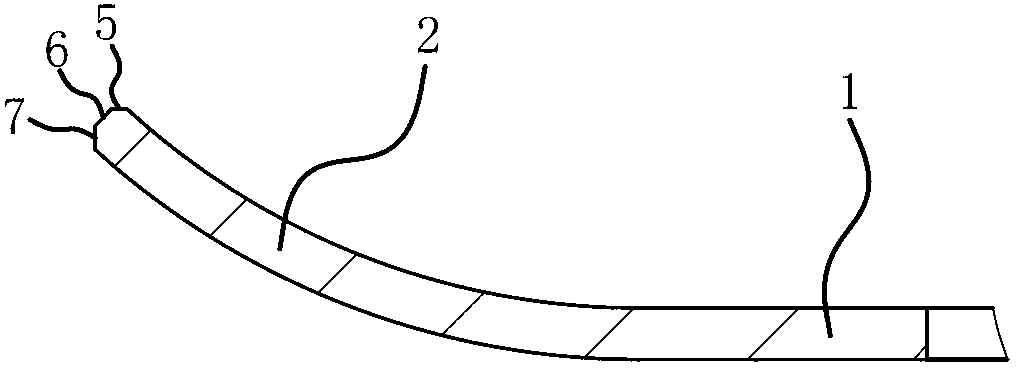

Three-dimensional (3D) glass machining method and cutting tool of numerical control machine

ActiveCN103342460AImprove yieldIncrease productivityGlass severing apparatusPlane surface grinding machinesNumerical controlEngineering

The invention provides a three-dimensional (3D) glass machining method and a cutting tool of a numerical control machine, and belongs to the technical field of machinery. According to the method and the tool, the problems of frangibility and low yield of glass in an existing 3D glass machining method are solved. The 3D glass machining method comprises the following steps of: pretreatment: knowing a margin between a 3D glass blank 8 and a 3D glass finished product; cutting: if the margin is greater than a set margin, performing rough cutting until the margin is smaller than the set margin, and performing fine cutting until the 3D glass finished product meets a product design requirement; if the margin is smaller than the set margin, directly performing fine cutting until the 3D glass finished product meets the product design requirement. The cutting tool of the numerical control machine comprises a cylindrical body, wherein an annular concave shoulder is arranged at one end of the body; the surface of the annular concave shoulder is a tool machining surface; a part matched with the target shape of a product is arranged on the surface of the annular concave shoulder; carborundum is coated on the surface of one end of the body. 3D glass processed by using the 3D glass machining method has the advantages of high yield and high production efficiency.

Owner:ZHEJIANG XINGXING TECH CO LTD

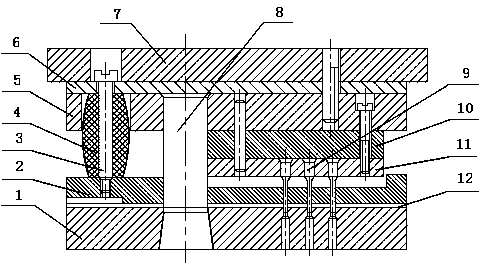

Sectional trimming mould

InactiveCN103567275AGuaranteed positioning accuracyImprove processing efficiencyEngineeringMechanical engineering

The invention discloses a sectional trimming mould and relates to a stamping mould. The sectional trimming mould comprises an upper mould base, a lower mould base and a mould handle, wherein a trimming concave mould is arranged on an upper surface of the lower mould base; trimming convex moulds are respectively arranged on the two sides of the trimming concave mould; the cutting edges of the two trimming convex moulds are different in height; the trimming convex moulds are in sliding connection with the upper surface of the lower mould base through slide blocks; a sloped plane is arranged at one end of each slide block away from the trimming concave mould; tapered wedges matched with the sloped planes of the slide blocks are respectively arranged on the lower surfaces on the two sides of the upper mould base; guiding blocks are respectively arranged in the positions on the two sides of the upper surface of the lower mould base corresponding to the tapered wedges; one end of each slide block away from the trimming concave mould is moveably connected with the corresponding guiding block through a reset bolt; reset rubber pads are sleeved on the reset bolts. The sectional trimming mould can be used for finishing the different-height trimming for the two sides of a box-shaped part at one step, the working efficiency is high, the repeated positioning is avoided and the precision of the products is increased.

Owner:CHENGDU KEXING SEALING TECH

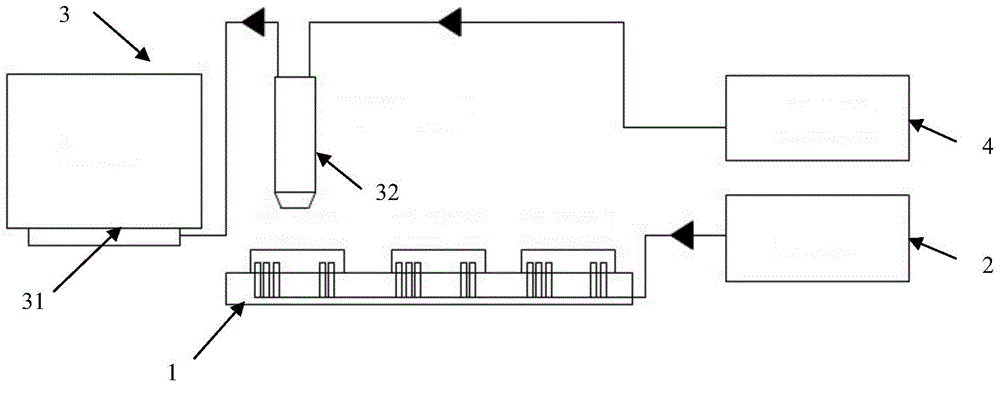

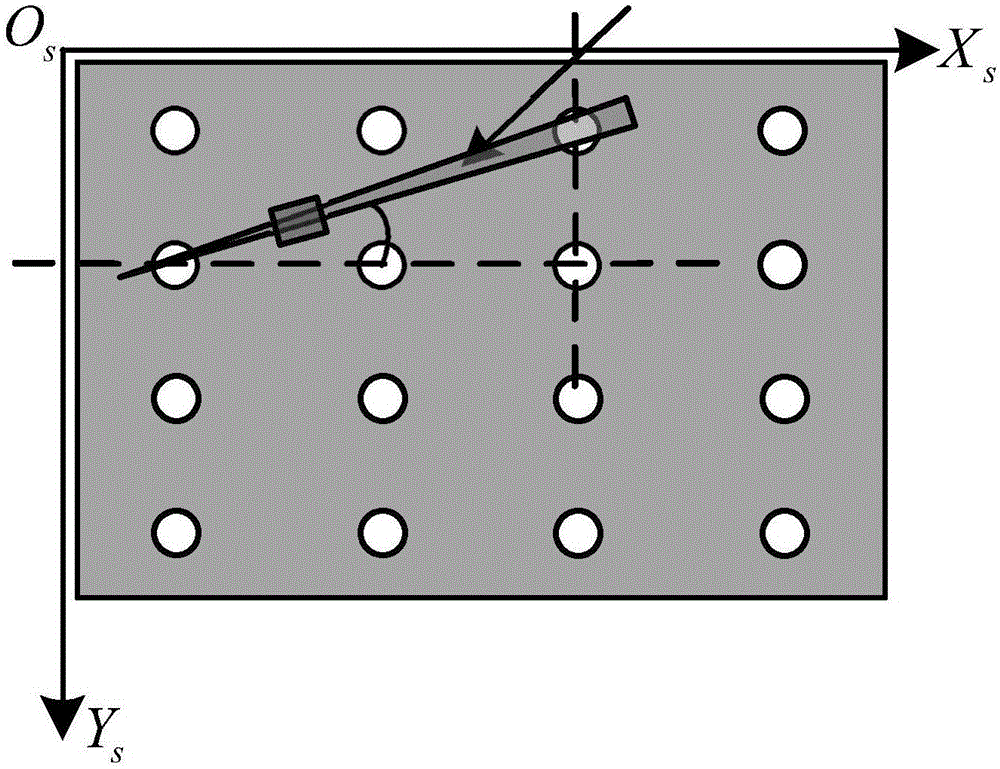

Coordinate calibration method for micro-injection system on basis of robot assistance

ActiveCN106730106APrecise positioningAvoid Duplicate PositioningIntravenous devicesDot matrixRobot assistance

The invention relates to a coordinate calibration method for a micro-injection system on the basis of robot assistance and belongs to the field of the coordinate calibration method for the micro-injection system. A present micro-injection system has a problem of low efficiency of needle moving and positioning. The coordinate calibration method for the micro-injection system on the basis of robot assistance comprises the following steps: selecting M points from a dot matrix in a present view area as calibration points; operating a mechanical arm according to the preset time and the optimal route; causing a needle point pass by the calibration points and acquiring a clear image; moving an objective table to a next view area; repeating the above steps, completing N view areas and recording a mechanical arm coordinate corresponding to a midpoint in a No.j view area; calculating a coordinate transformation matrix; adopting an expected needle point coordinate and the coordinate transformation matrix for calculating the corresponding mechanical arm coordinate; and then moving the mechanical arm and moving the needle point of a micropipette to an expected position. The coordinate calibration method provided by the invention has the advantages of capability of avoiding the problem of repeated positioning, accurate positioning and high working efficiency.

Owner:HARBIN INST OF TECH

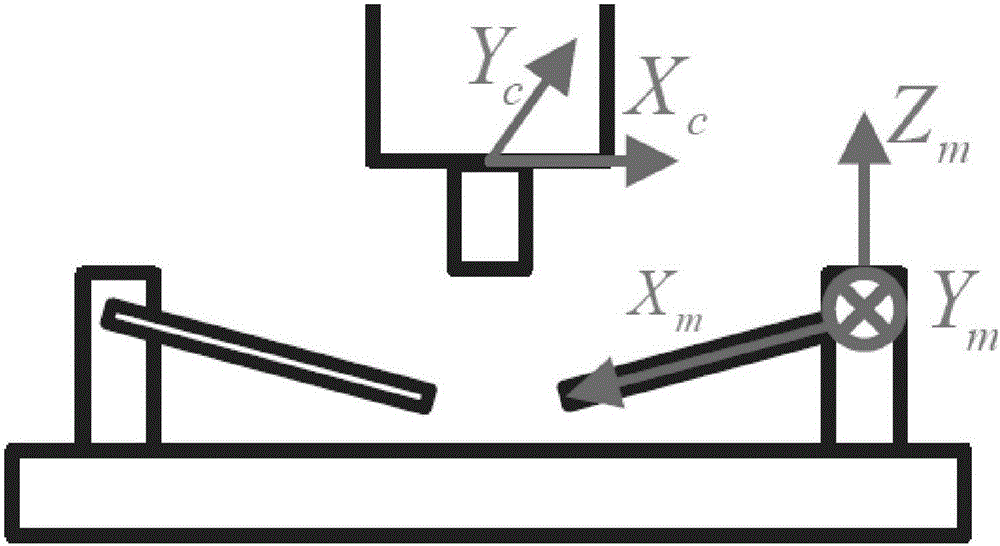

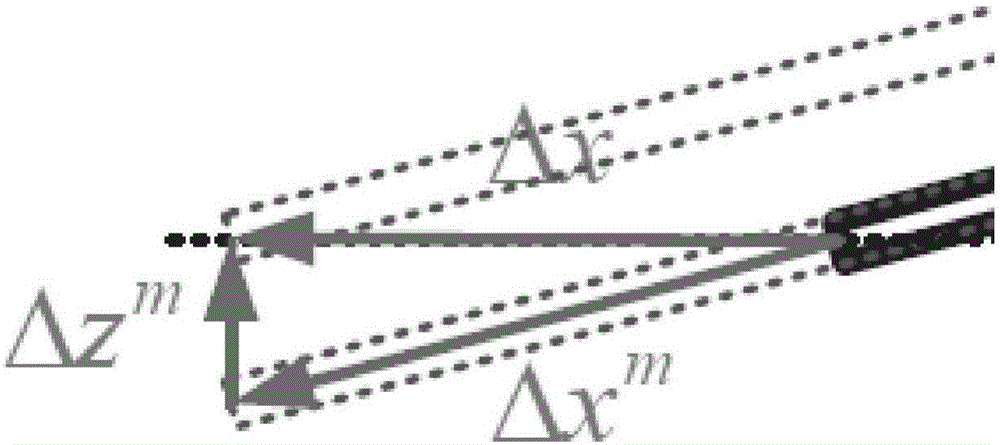

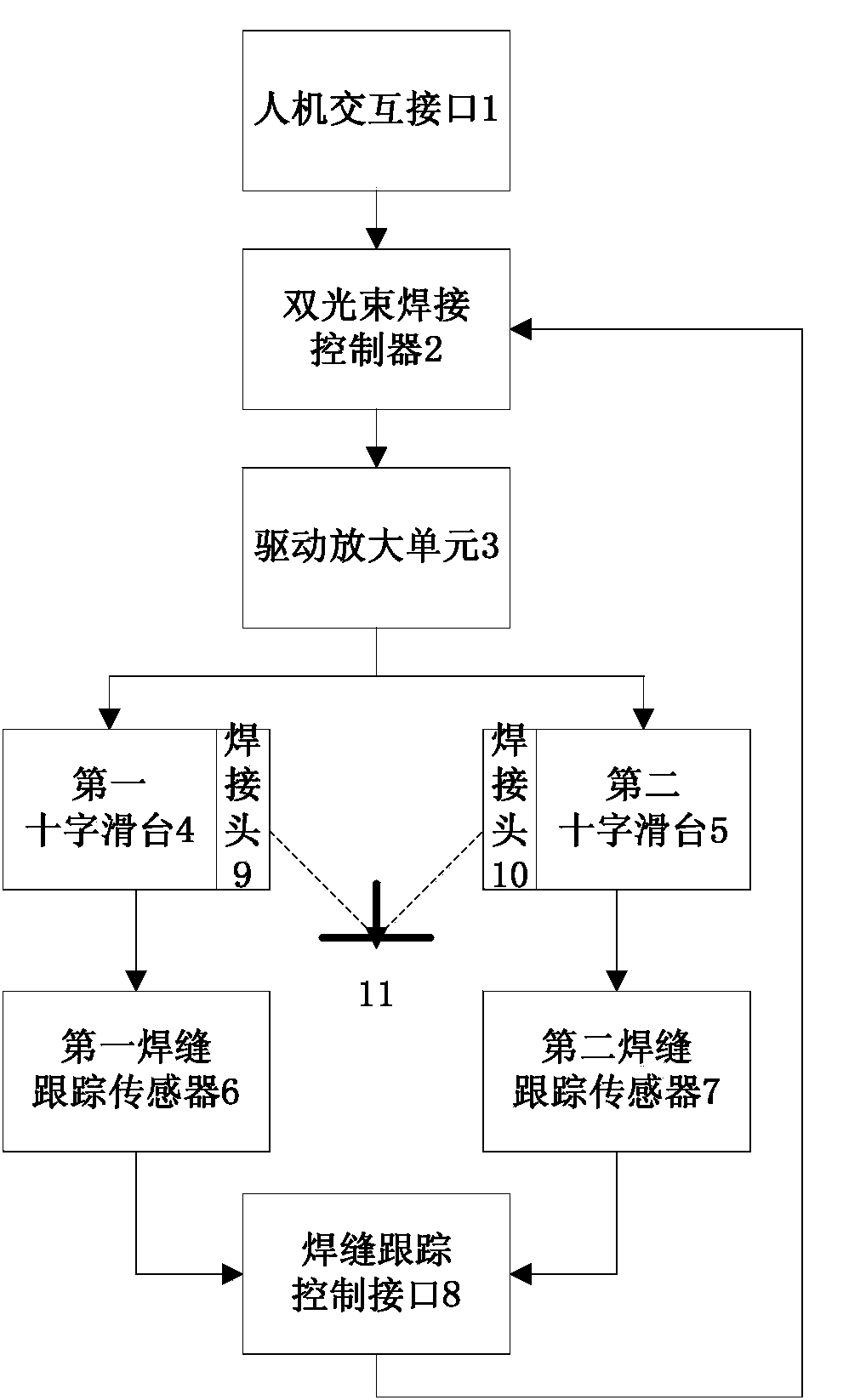

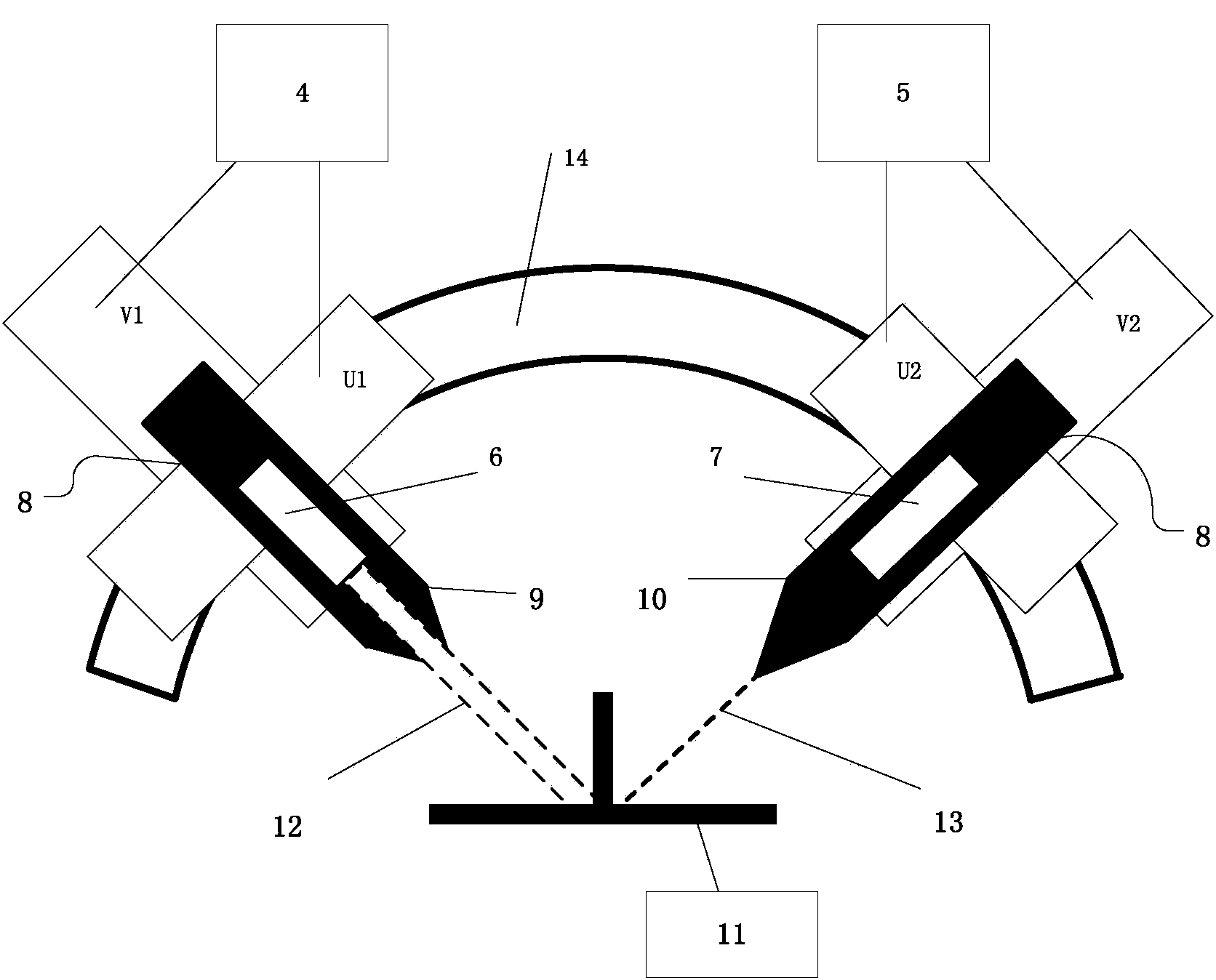

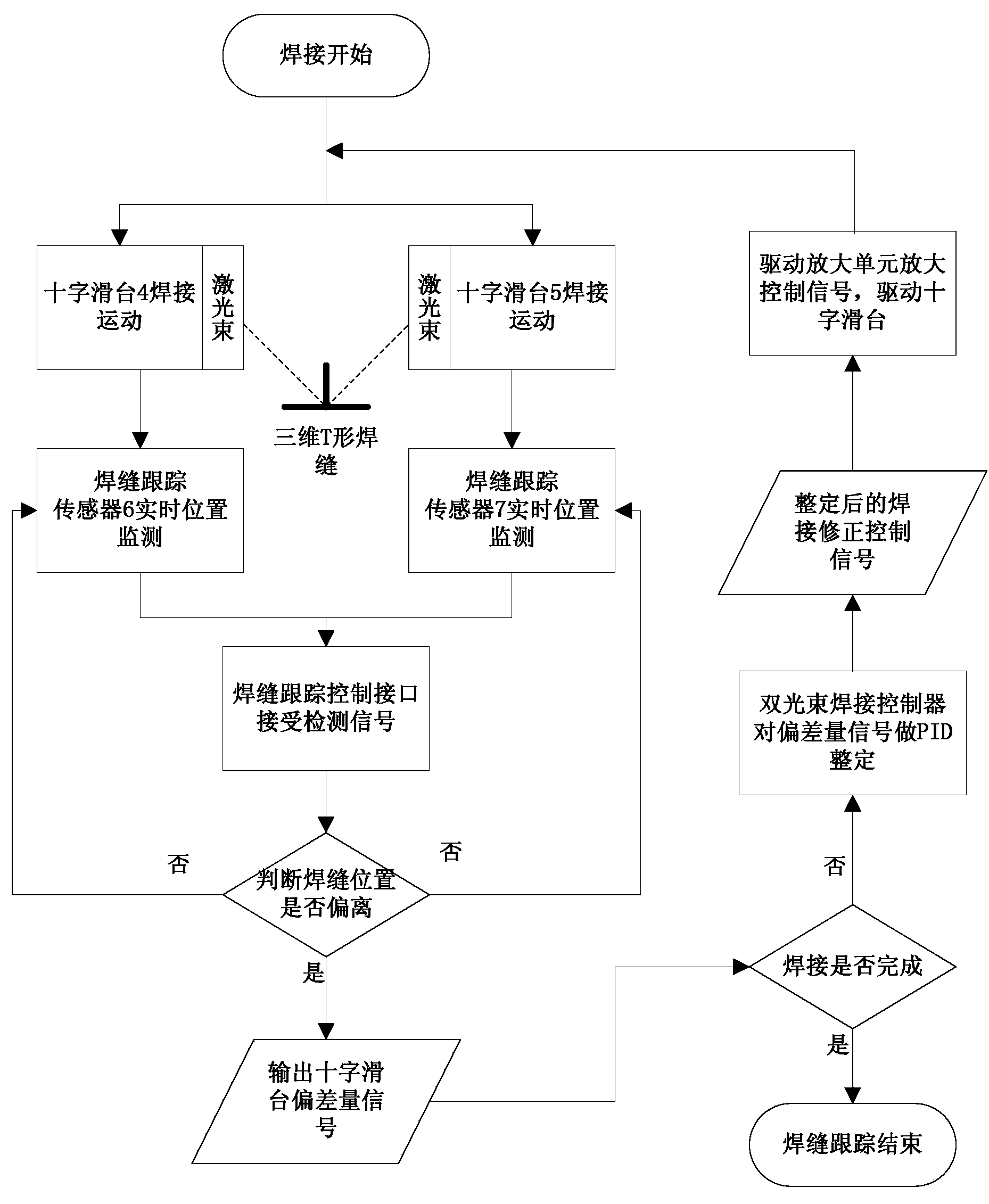

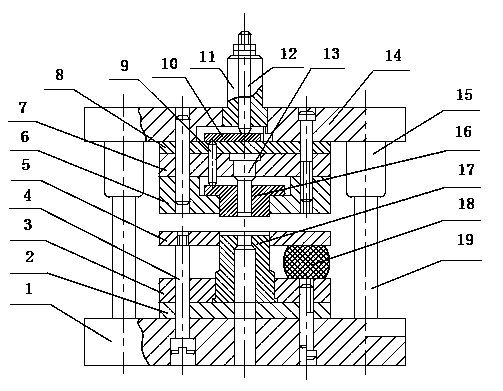

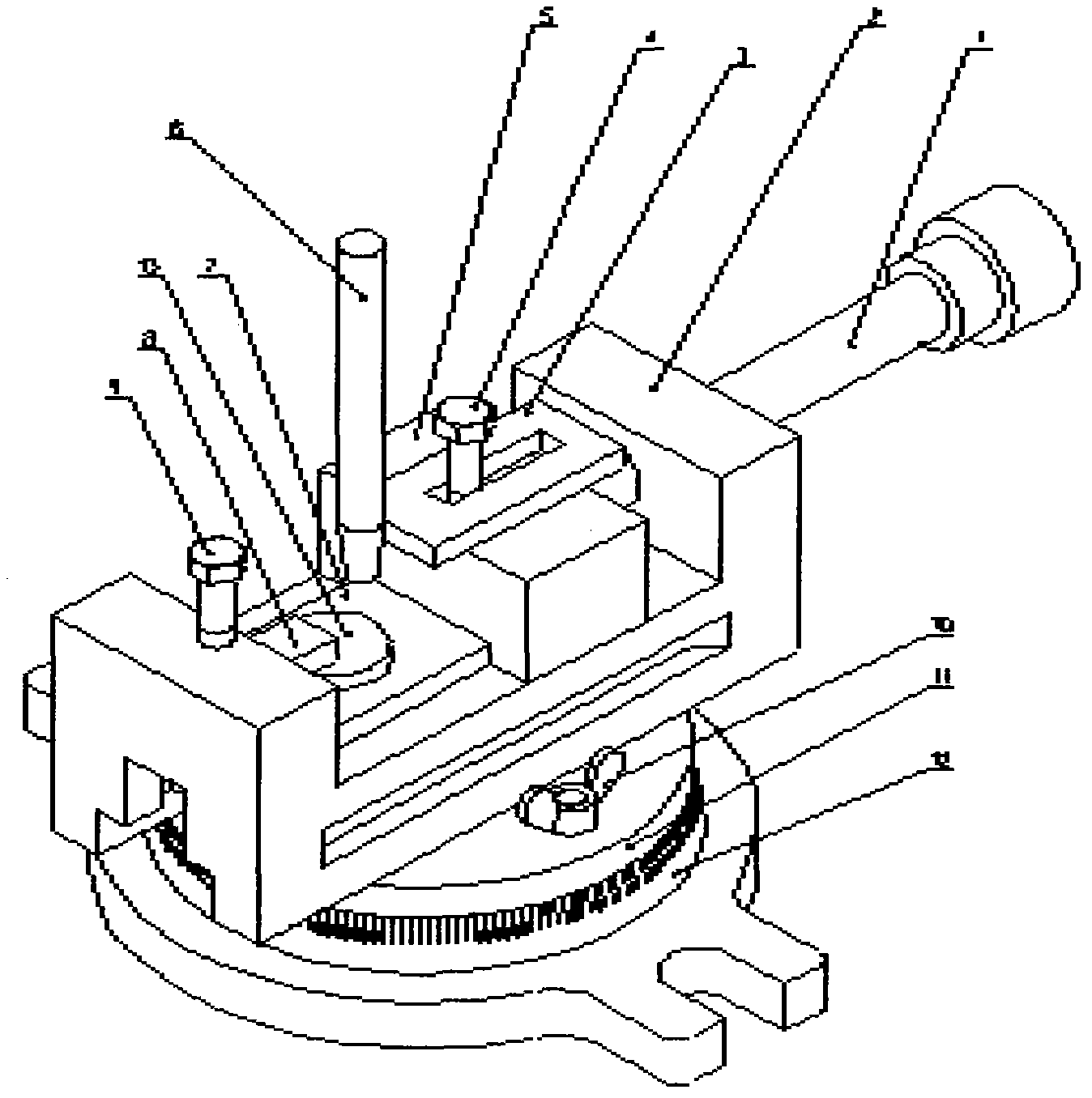

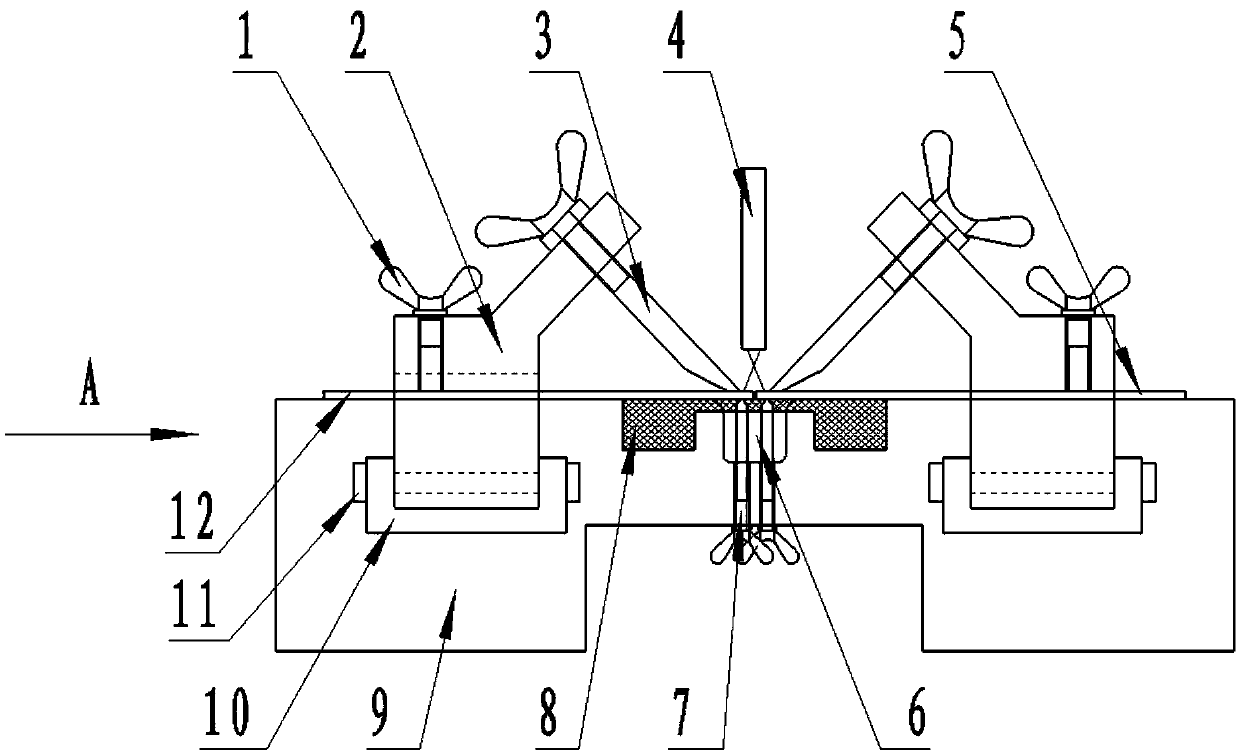

Double-beam welding seam tracking control system

InactiveCN103801825AAvoid Duplicate PositioningReduce welding distortionLaser beam welding apparatusWeld seamLight beam

The invention discloses a double-beam welding seam tracking control system used for tracking control of a three-dimensional T-type welding seam. The system comprises a man-machine interaction port, a double-beam welding controller, a drive amplifying unit, two welding seam tracking sensors and a welding seam tracking control port. A double-beam welding motion controller is used for finishing welding motion control, a welding motion signal transmitted by the double-beam welding motion controller controls an arc plate to move in a correct posture after being amplified by the drive amplifying unit, crossed sliding tables on the left and the right of the arc plate are provided with laser welding heads which enable two beams of laser which is obtained through light splitting and has an identical parameter to be transmitted to the two sides of the three-dimensional T-type welding seam, and accordingly double-beam laser welding control is achieved; the welding seam tracking sensors detect whether the position of the welding seam is deviated from a view area in real time and transmit a detection signal to the welding seam tracking control port while double-beam laser welding is carried out, the detection signal is processed by the welding seam tracking control port and then is fed back to the double-beam welding controller, and accordingly welding deviation correcting is achieved, and welding accuracy is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

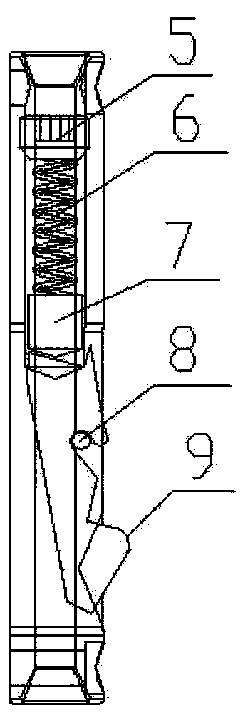

Inverse punching and blanking die

InactiveCN103567293AAvoid Duplicate PositioningHigh precisionShaping toolsEjection devicesPunchingEngineering

The invention relates to an inverse punching and blanking die and relates to a stamping die. The inverse punching and blanking die comprises an upper die base, a lower die base, a die handle, a guide sleeve and a guide post, wherein a male and female die is arranged on the upper surface of the lower die base; a punching profile hole is formed in the male and female die; an unloading plate is sleeved on the male and female die and is moveably connected with the lower die base through an unloading screw; a rubber cushion is arranged between the unloading plate and the lower die base; a blanking female die is arranged on the lower surface of the upper die base; a female die hole is formed in the lower surface of the blanking female die; the position of the female die hole corresponds to the male and female die; a punching male die matched with the punching profile hole is arranged in the female die hole; a workpiece jacking device is arranged on the punching male die. Blanking and punching of a workpiece can be finished in one set of die, so that the production efficiency is improved, the workpiece is prevented from being repeatedly positioned, and the product precision is improved.

Owner:CHENGDU KEXING SEALING TECH

Compressible precision machine vise

InactiveCN104290049AAvoid Duplicate PositioningHigh precisionVicesGrinding work supportsIndustrial engineeringRepair processes

Provided is a compressible precision machine vise. The compressible precision machine vise is used for clamping and compressing a workpiece, and is a universal precision clamp. A T-type pressing plate and a nut are mainly combined and are arranged on a fixed vise body, and compression height is adjusted by the nut. A movable pressing plate is arranged on a movable vise body, and when the vise is used, the compression height can be adjusted according to the height of a part. According to the machine vise, some locating problems in the repairing process of a mould are solved, the workpiece is clamped on the machine vise, meanwhile, the workpiece is compressed, repeated locating of the workpiece is avoided, and machining precision and efficiency are improved.

Owner:郑童予

Drilling and chamfering composite quick forming tool

InactiveCN103706847ALow costReduce labor costsTransportation and packagingMilling equipment detailsEngineeringMachining

The invention aims to provide a drilling and chamfering composite quick forming tool. The drilling and chamfering composite quick forming tool has the advantages that the drilling and inner hole deburring integrated tool is formed according to merits of a short-hole drill and merits of a spring tool, two traditional machining tools are integrated into the single drilling and chamfering composite quick forming tool, and accordingly the cost of the drilling and chamfering composite quick forming tool can be greatly reduced; drilling and inner hole deburring can be completed on the same equipment and machine, so that the cost of the equipment can be saved; an operation worker can complete machining parts, so that the labor cost can be reduced; the machining period can be greatly shortened, and the drilling and chamfering composite quick forming tool is high in efficiency; each part can be machined after being clamped at one step and can be completely machined at one step, accordingly, repeated positioning can be omitted, and the machining precision can be improved.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Novel progressive die

The invention discloses a novel progressive die, and relates to a stamping die. The novel progressive die comprises an upper die holder, a lower die holder and a die handle. A female die is arranged on the upper surface of the lower die holder, a feed male die is arranged on the lower surface of the upper die holder, a feed female die hole is formed in the position, corresponding to the feed male die, of the female die, a stripper plate is connected to the feed male die in a sleeved mode, the stripper plate is movably connected with the upper die holder through a stripper bolt, a discharge rubber blanket is connected to the stripper bolt in a sleeved mode, a lower base plate is arranged at the position, close to the feed male die, of the lower surface of the upper die holder, a punching male die is arranged on the lower surface of the lower base plate, and a punching female die hole is formed in the position, corresponding to the punching male die, of the female die. Punching and feeding of workpieces can be successively completed in a die, production efficiency is improved, repeated positioning of the workpieces is avoided, and product accuracy is improved. The punching male die can not be easily broken, the service life is long, the die manufacturing process is simple, and die cost is reduced.

Owner:CHENGDU KEXING SEALING TECH

Laser positioning system and method

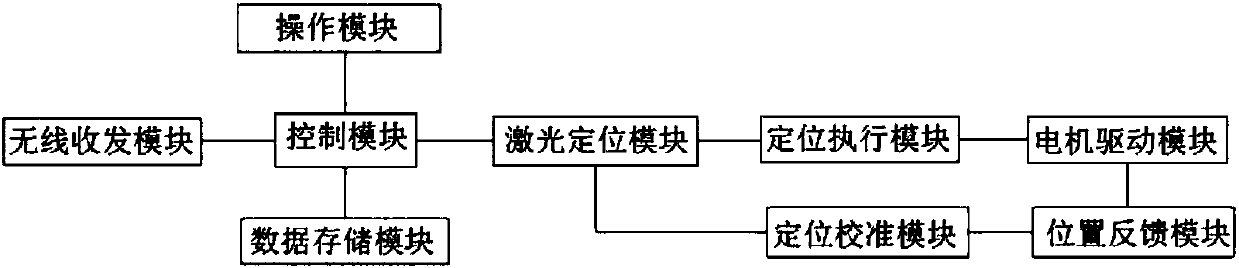

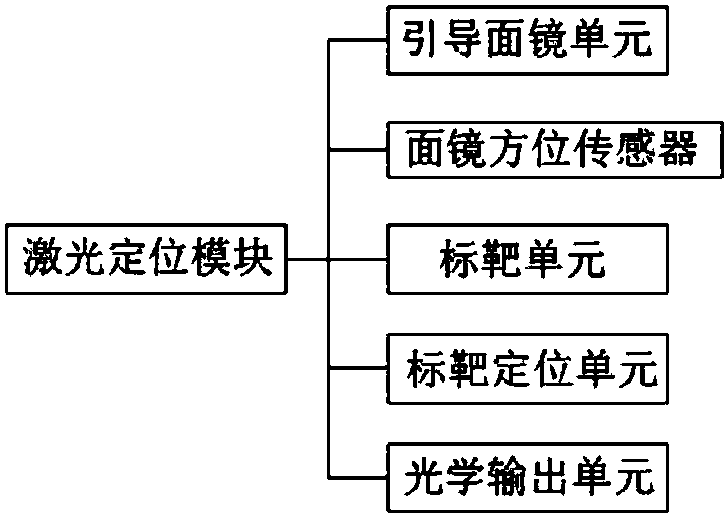

PendingCN107907876AHigh positioning accuracyWith self-calibration functionUsing reradiationWireless transceiverEngineering

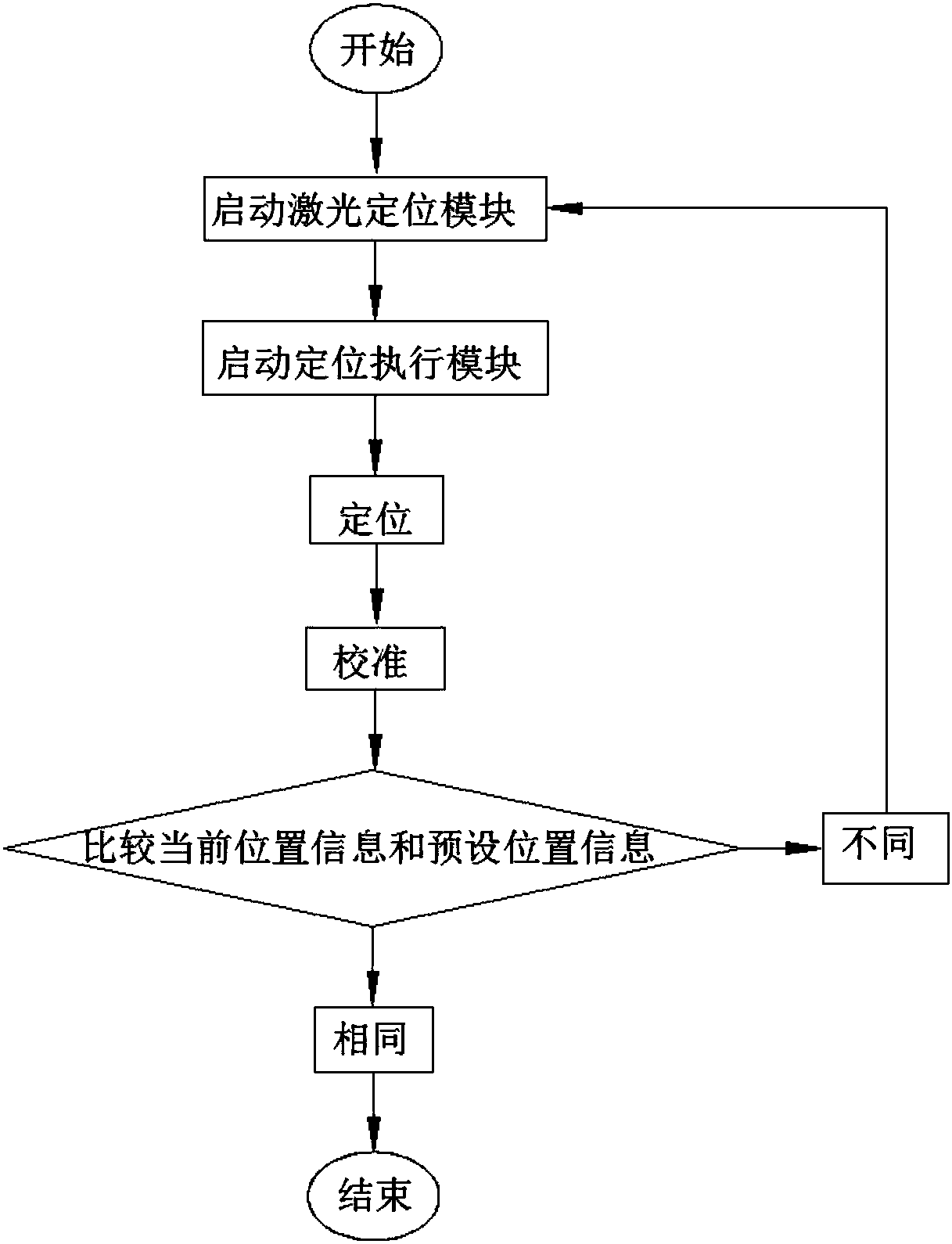

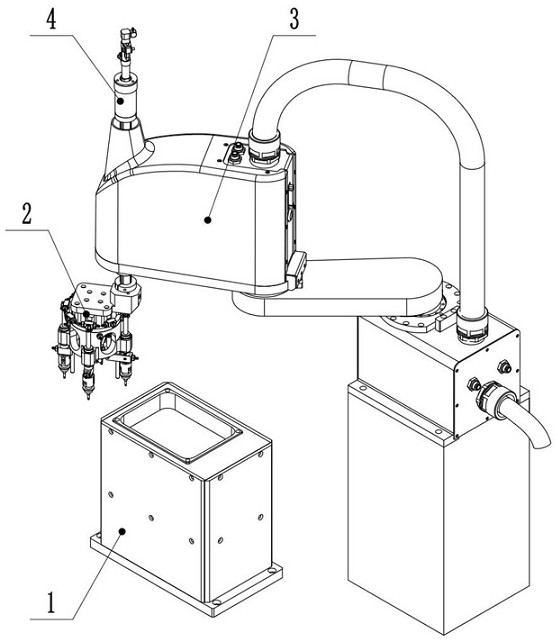

The invention discloses a laser positioning system which includes a control module used for controlling the operation of other modules, a laser positioning module used for positioning a target, an operation module used for data input, a wireless transceiver module used for being connected with other remote terminals, a data storage module used for storing collected and processed data, a positioning execution module used for issuing an executing instruction according to a positioned target, a motor driving module used for receiving the instruction issued by the positioning execution module andconverting the instruction into an actual action, and a position feedback module used for making signal feedback for a changed position. The invention further presents a positioning method of the laser positioning system, which includes the following steps: S1, starting a laser positioning module; S2, starting a positioning execution module; S3, positioning; and S4, calibration. The laser positioning system of the invention has high work efficiency and high positioning accuracy, has a self-calibration function, is quick in laser output, and is suitable for popularization.

Owner:HEFEI TONSAIL AUTOMATION EQUIP

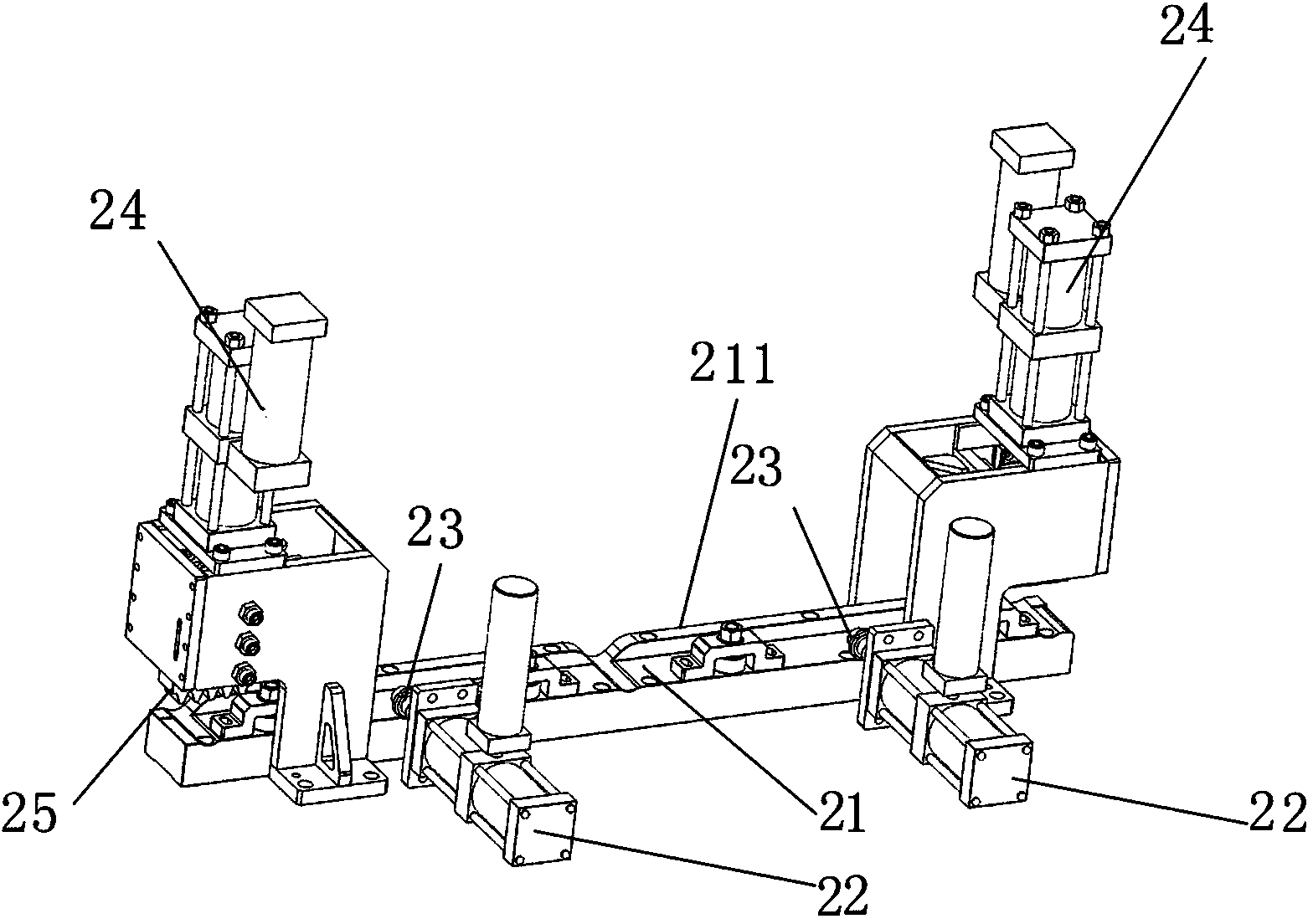

Rapid feeding and grabbing device and feeding method thereof

InactiveCN112278855ASimple actionAvoid multiple repositioningConveyor partsRotational axisRobot hand

The invention relates to automatic mechanical equipment, in particular to a rapid feeding and grabbing device and a feeding method thereof. A mechanical arm of the device is fixedly mounted on one side of a material table of a material taking station through a mounting seat, and a manipulator and a pressing component are fixedly mounted on the mechanical arm. The manipulator comprises a manipulator connecting block used for being connected with the mechanical arm, suction head assemblies, a springback assembly and a rotating motor. A first through hole is formed in the manipulator connecting block and used for allowing the pressing component to press the suction head assemblies. The multiple suction head assemblies are fixedly mounted on suction head fixing blocks with the rotating axis ofthe rotating motor as the axis and the distance between the axis of the pressing component and the rotating axis of the rotating motor as the radius. The pressing component is used for pressing a suction nozzle to the material taking height from the initial height, the springback assembly is used for springback the suction nozzle to the initial height from the material taking height, and the rotating motor is used for switching the suction head assemblies. According to the rapid feeding and grabbing device and the feeding method thereof, the structure of the manipulator is improved, and the equipment with higher material taking efficiency is provided.

Owner:天堃自动化科技(苏州)有限公司

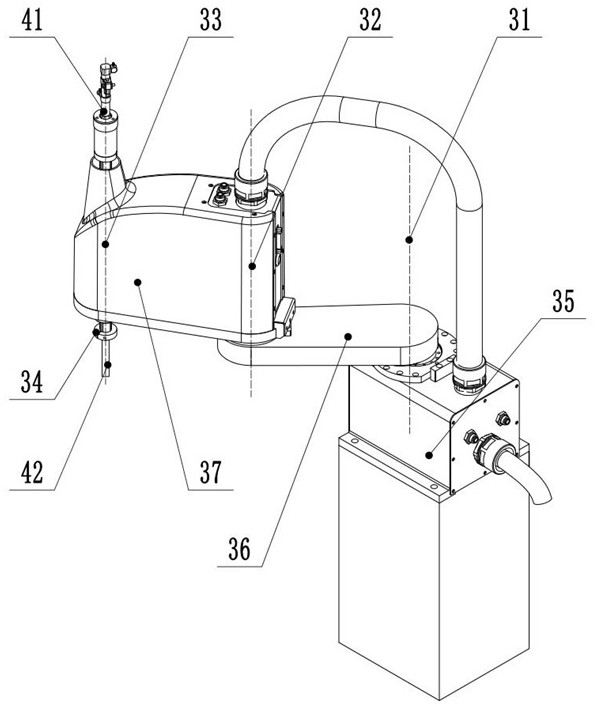

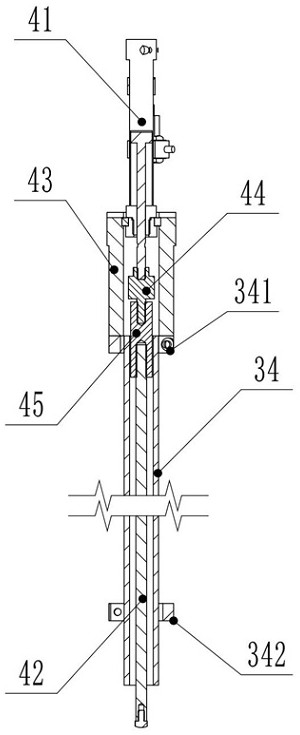

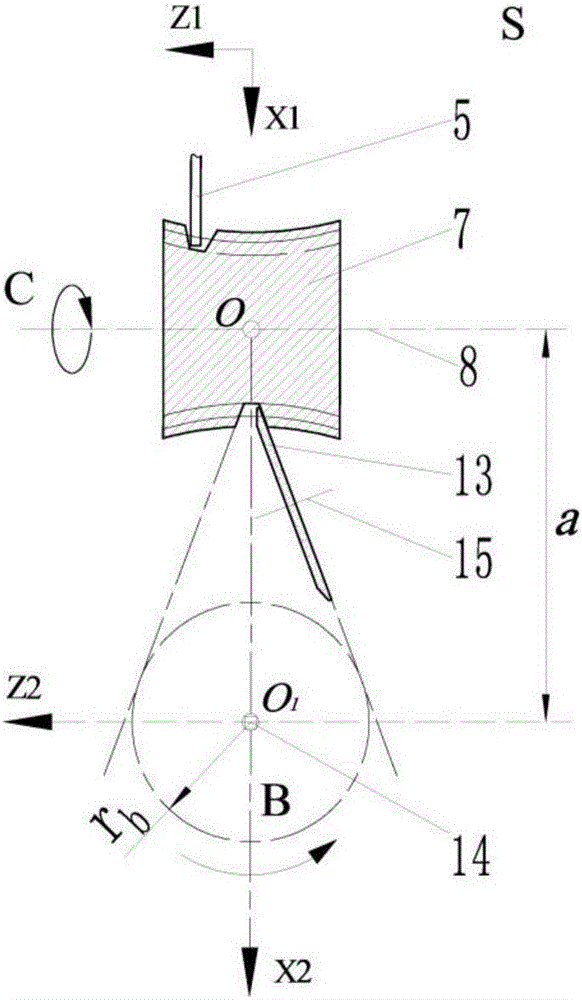

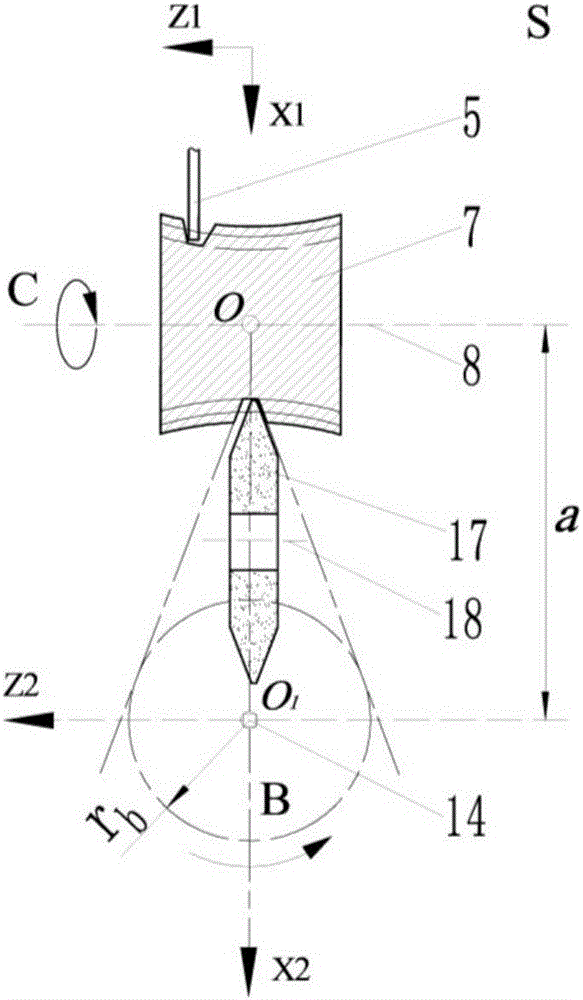

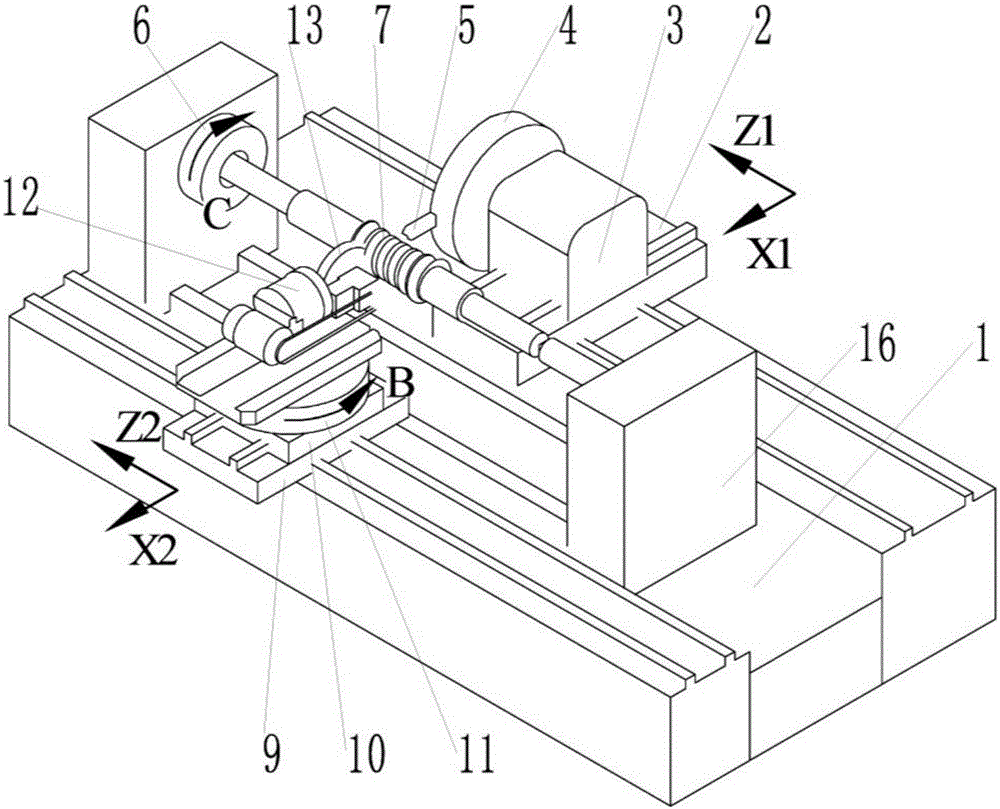

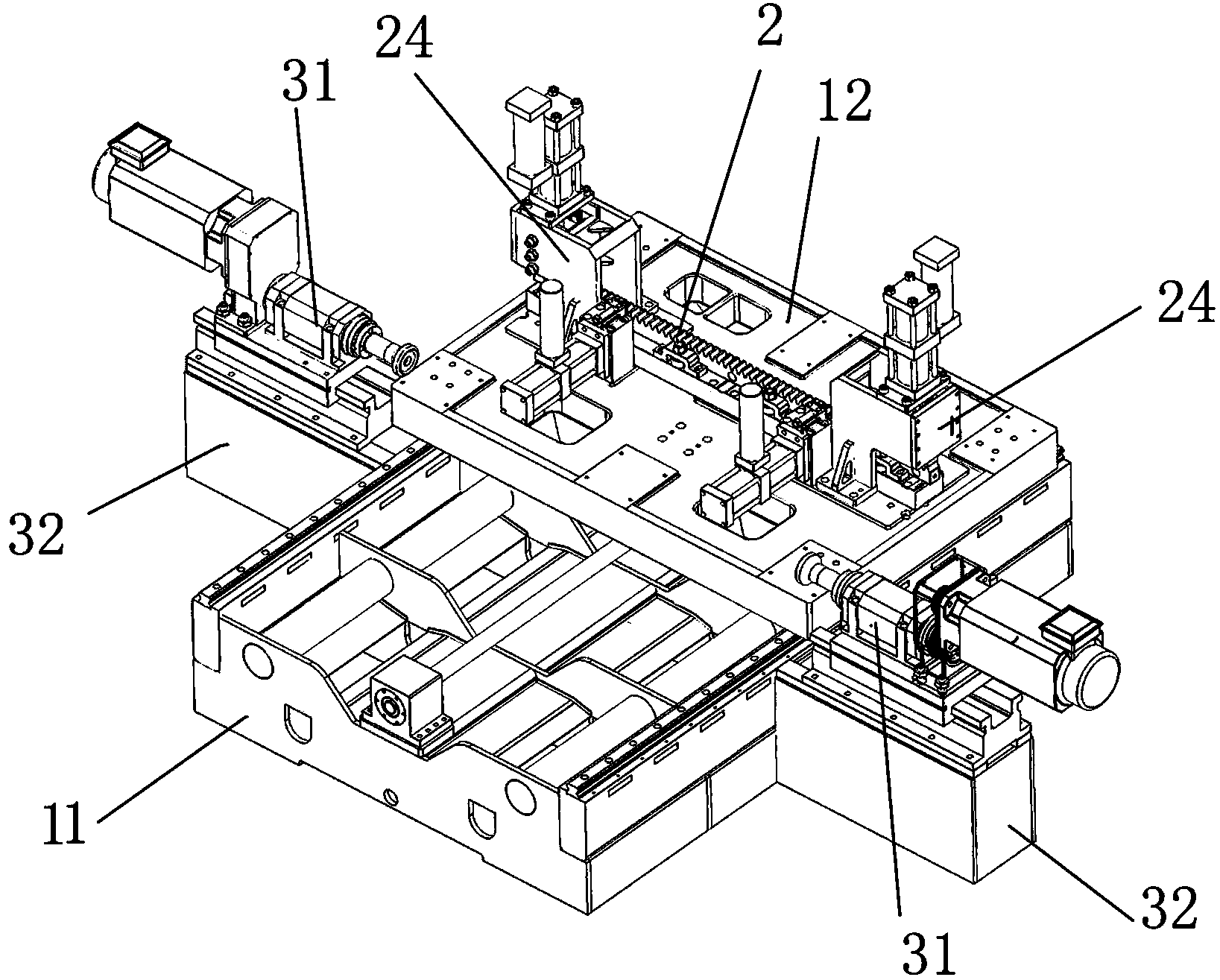

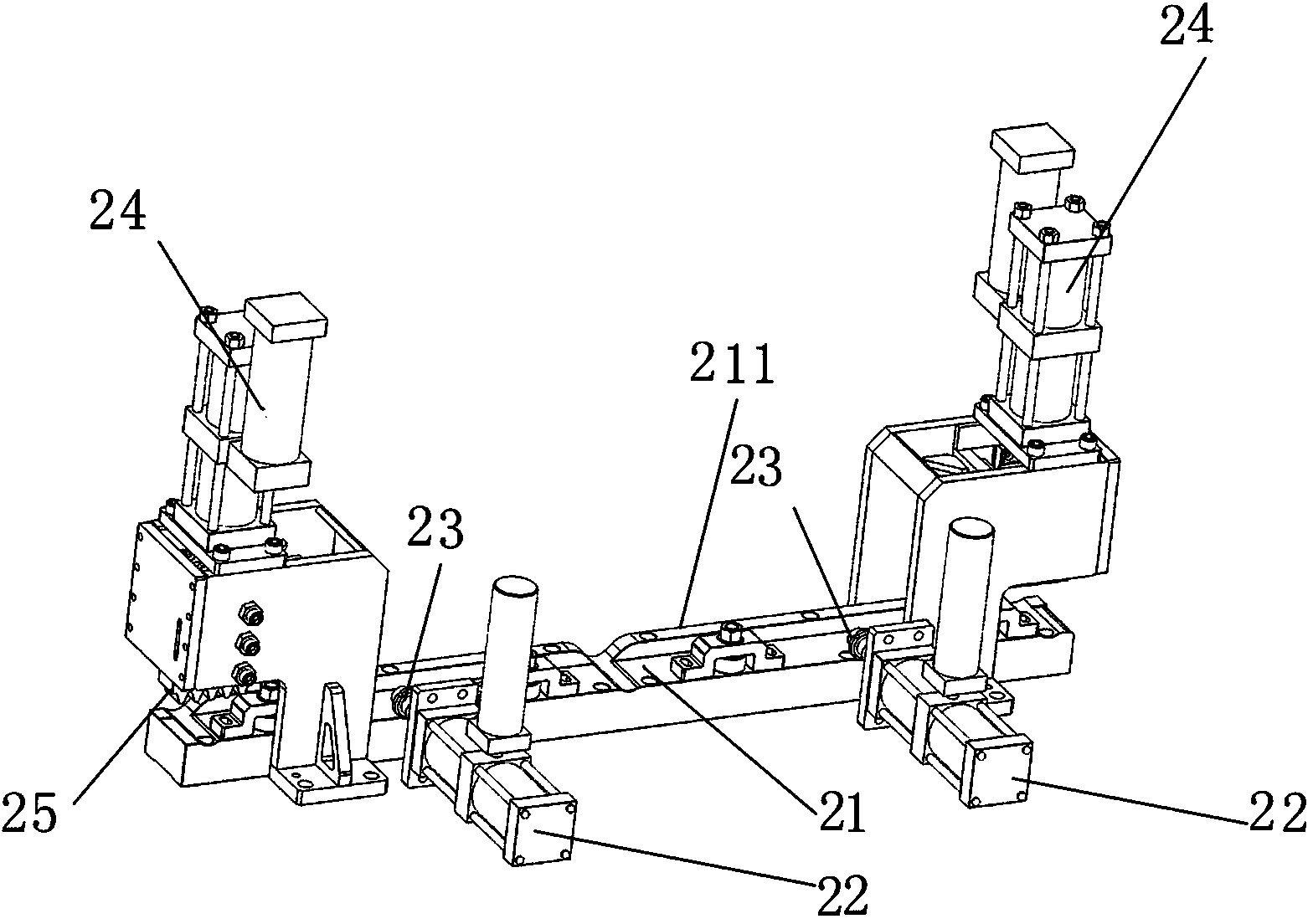

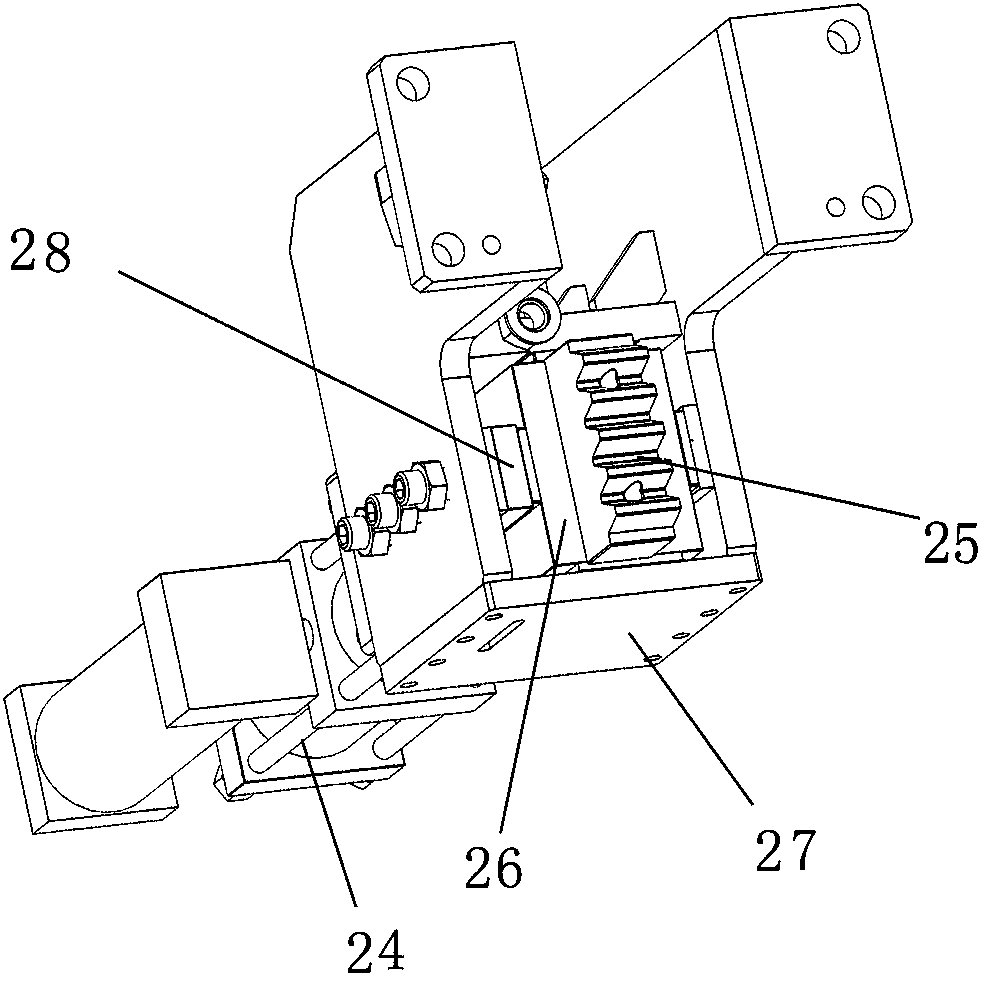

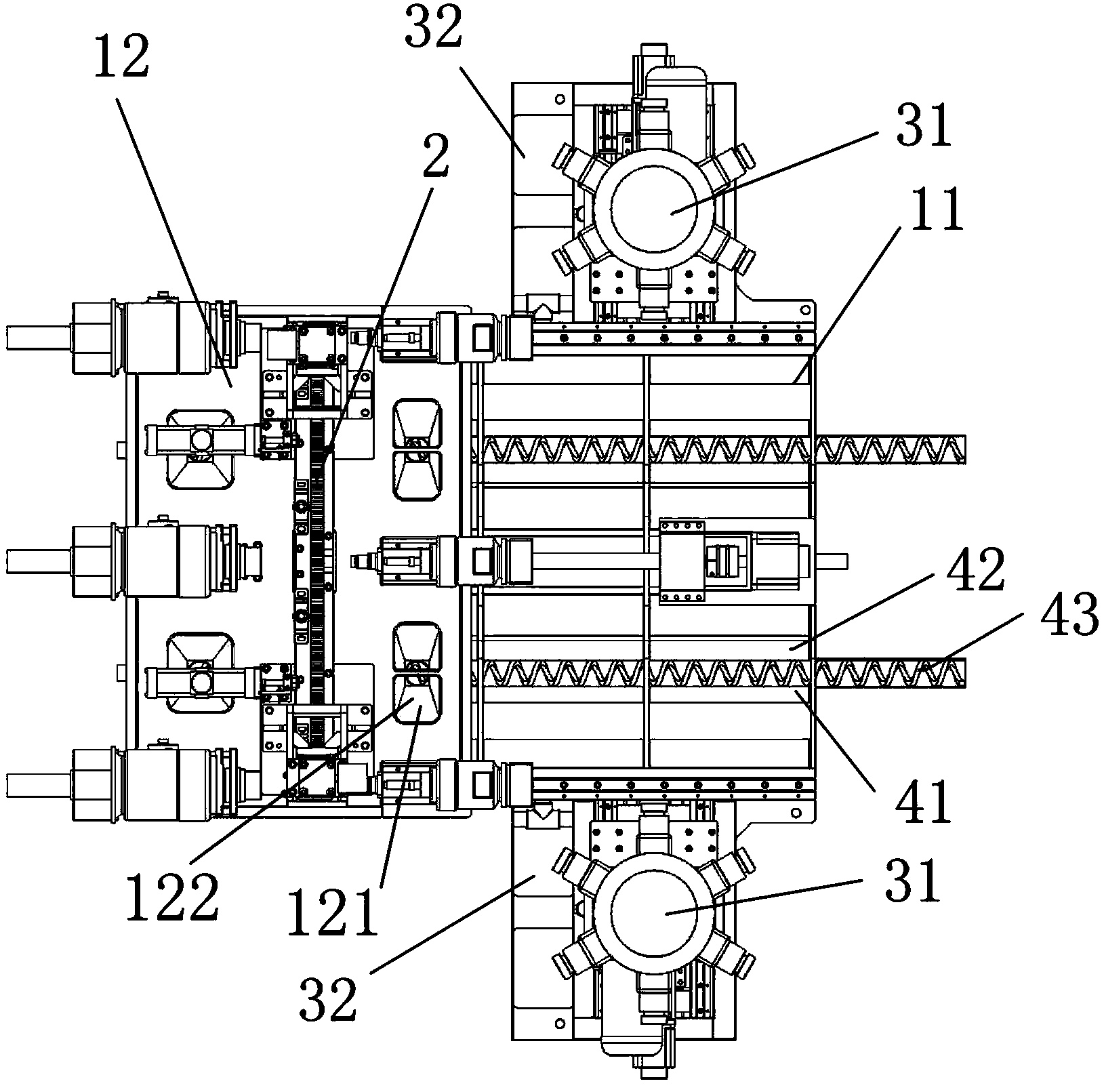

Hourglass worm turning and grinding complex machine tool based on turning center

InactiveCN105921826AAvoid Duplicate PositioningGuaranteed machining accuracyWormsEngineeringMachine tool

The invention relates to the field of hourglass worm machining and discloses a hourglass worm turning and grinding complex machine tool based on a turning center. A C axis is established on the center line of a chuck, an X1 axis is established on a transverse turning slide carriage, a Z1 axis is established on a longitudinal turning slide carriage, the X1 axis, the Z1 axis and the C axis are in linkage, and a spiral groove of a hourglass worm is turned. An X2 axis is established on a transverse grinding slide carriage, a Z2 axis is established on a longitudinal grinding slide carriage, a B axis is established on a rotary table, the B axis and the C axis are in linkage, and a toothed face of the hourglass worm is ground. By the adoption of the hourglass worm turning and grinding complex machine tool, the two processes of turning and grinding of the hourglass worm are finished through one-time clamping, repeated localization is avoided, and the machining accuracy is improved.

Owner:北京奎恩特科技有限公司

Milling equipment for milling two ends of rack

InactiveCN103920917ASimple structureRealize automatic positioning processingMilling equipment detailsPositioning apparatusEngineeringMechanical engineering

The invention discloses milling equipment for milling two ends of a rack. The milling equipment is characterized by comprising a workbench base, a workbench, a rack positioning structure and a first screw rod power head, wherein the rack positioning structure comprises a rack base, a rack fixing pressurizing cylinder, a rack fixing pressurizing block, a rack positioning pressurizing cylinder and a rack positioning pressurizing block; two sides of the workbench base are respectively provided with end face processing power head bases, rack end face processing power heads are fixed onto the end face processing power head bases, and the end face processing power head bases are fixed on the workbench base; the feeding direction of the rack end face processing power heads is parallel to the length direction of the rack base. Compared with the prior art, the milling equipment has a simple and reasonable structure and reaches automatic positioning processing, two end faces simultaneously process, the repeated positioning is avoided, and the processing efficiency is improved.

Owner:徐州彭城塑业有限公司

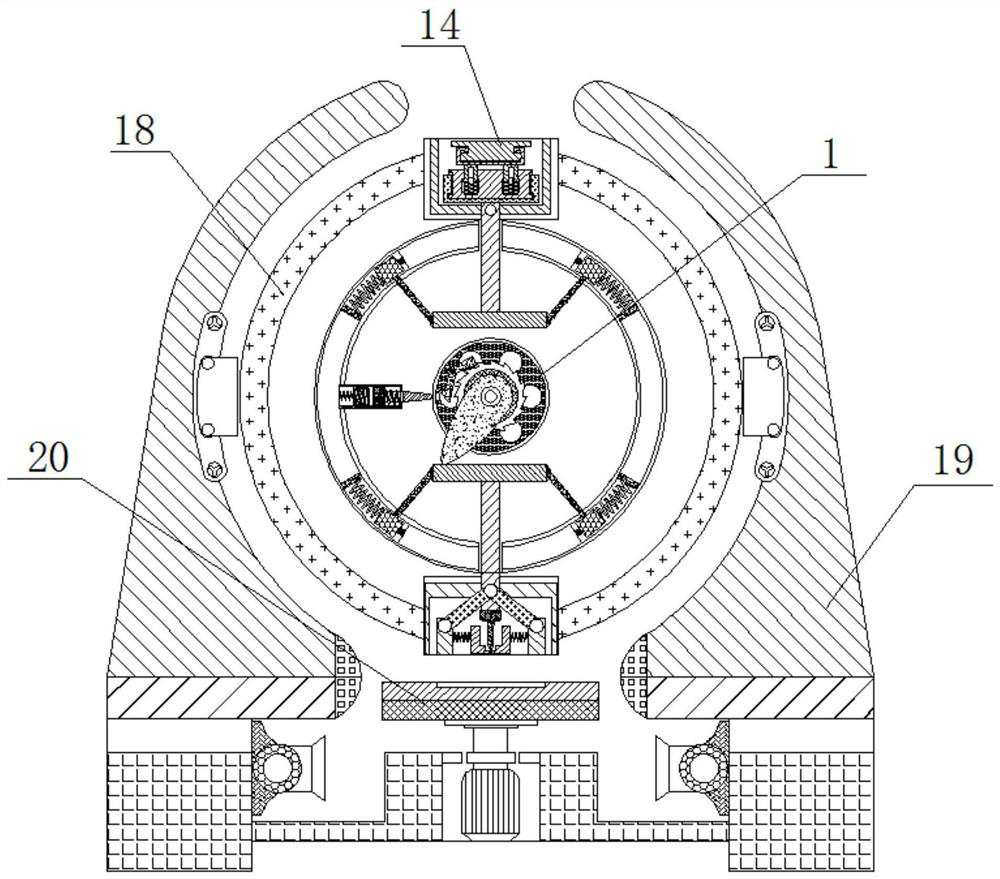

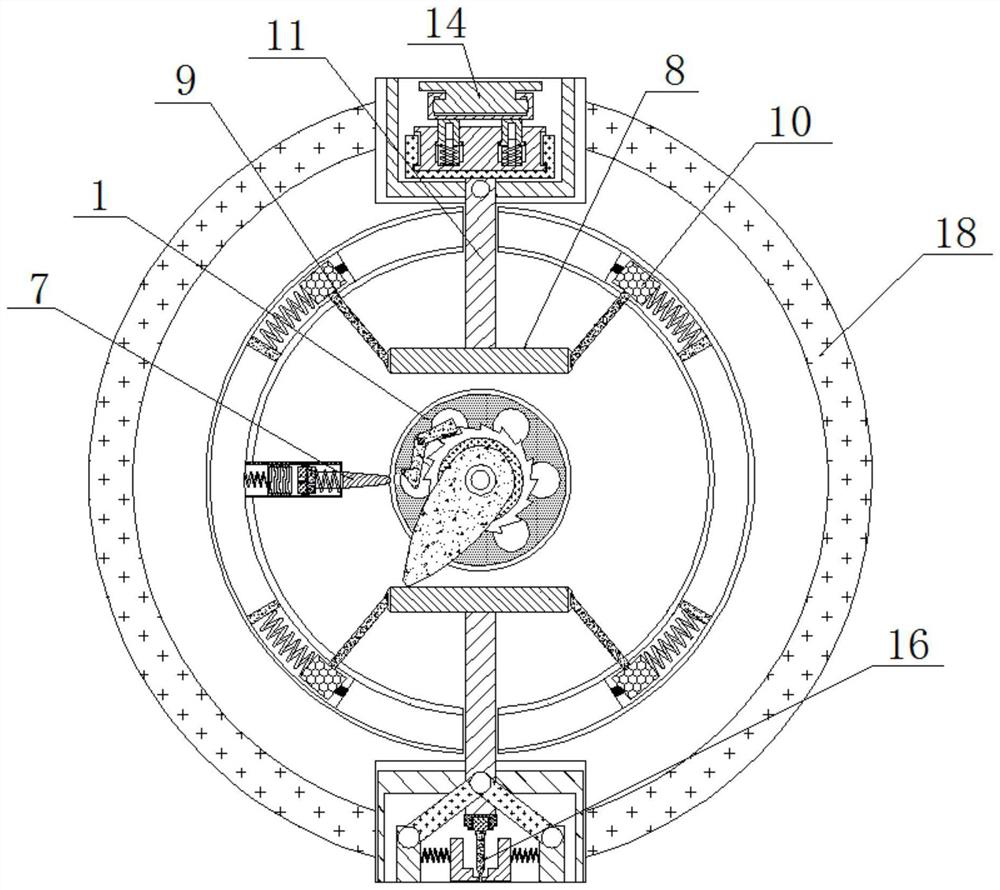

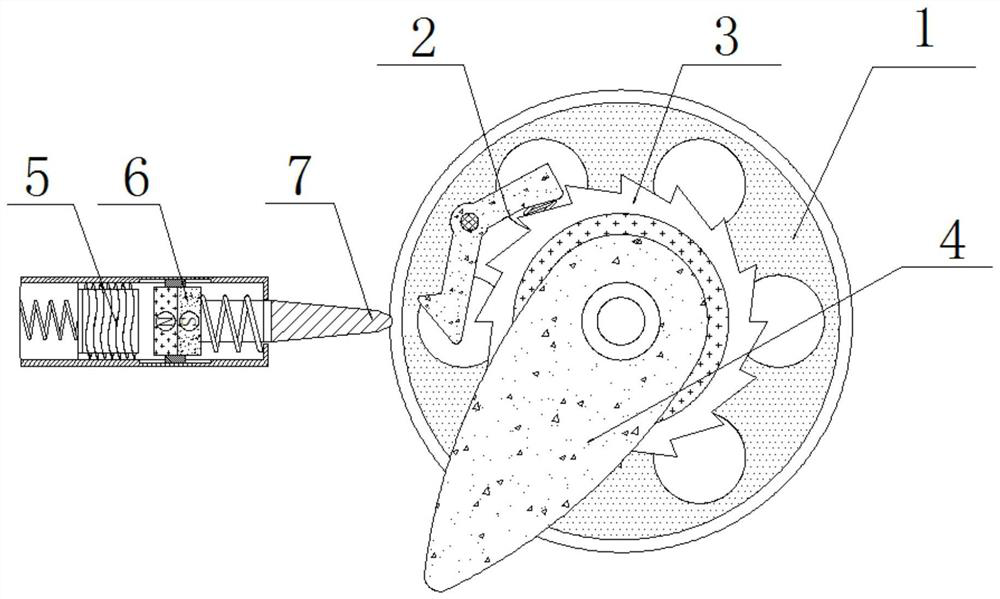

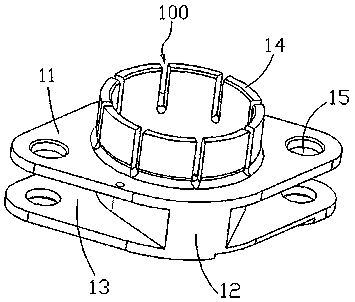

Intelligent manufacturing universal instrument panel PCB board punching and grinding integrated equipment

InactiveCN112356147AAvoid Duplicate PositioningImprove work efficiencyEdge grinding machinesGrinding machine componentsRatchetWorking environment

The invention relates to the technical field of universal equipment manufacturing, and discloses intelligent manufacturing universal instrument panel PCB board punching and grinding integrated equipment. The intelligent manufacturing universal instrument panel PCB board punching and grinding integrated equipment comprises a positioning disc, wherein the front surface of the positioning disc is movably connected with a clamping jaw, and the middle of the positioning disc is movably connected with a ratchet wheel. According to the intelligent manufacturing universal instrument panel PCB board punching and grinding integrated equipment, a cam, a push plate, a push rod, a punching drill bit, a positioning plate, a U-shaped plate and a grinding plate are matched, so that two procedures of punching and grinding are completed; an electromagnetic push block, a magnet, a clamping shaft and the clamping jaw are matched, so that the ratchet wheel can drive the cam or the whole rotating disc to rotate together, punching and grinding work in the device can be completed on the equipment, the working efficiency is improved, and the equipment cost is saved; and the U-shaped plate, a positioning plate blind hole positioning shaft and a buffer spring are matched, so that a relatively stable pressure is kept between the grinding plate and a PCB board, the vibration of the grinding plate is avoided, the grinding effect is improved, a dust collection fan is matched to collect wastes, and a good working environment is kept.

Owner:周怡春

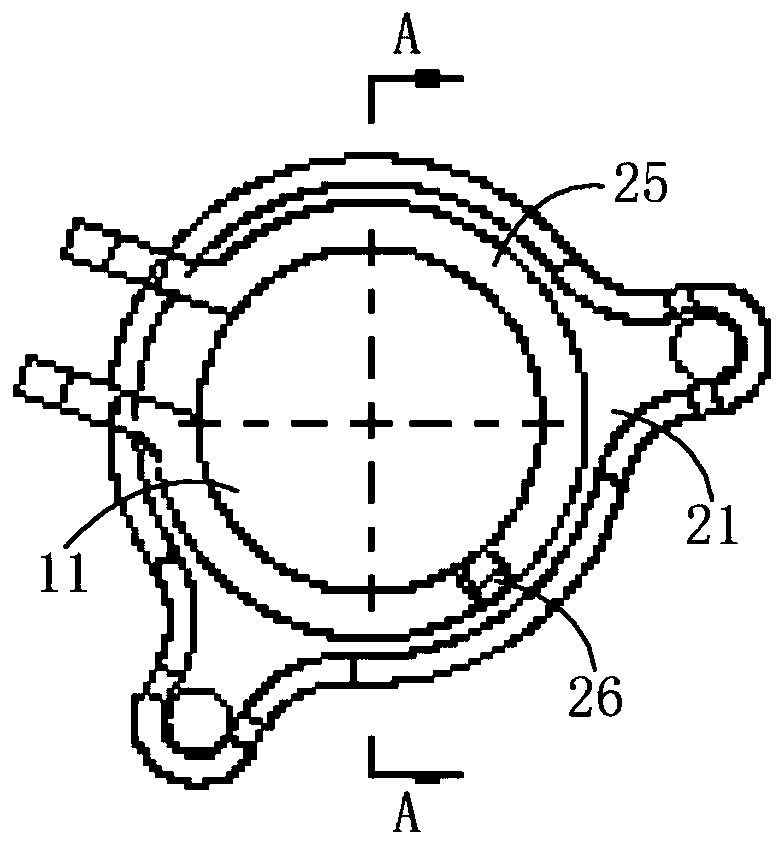

Clamping clamp for circumferential uniform machining of grooves in cam surface of swing sliding base

PendingCN108284336AAvoid Duplicate PositioningThe number of clamps is smallMilling equipment detailsPositioning apparatusSteel ballCam

The invention discloses a clamping clamp for the circumferential uniform machining of grooves in the cam surface of a swing sliding base. A rotating shaft is connected to a seat body in a rotating manner, the rotating shaft is connected with a turn plate through a key, and two locating holes are arranged in the turn plate. Locating nails penetrate through connecting holes in a lower connecting plate and extend into the locating holes. A pressing plate is fixed to the turn plate through a fastening screw, the fastening screw is tightened, and the pressing plate is pressed on the lower connecting plate. A reference base is fixedly connected to the seat body, and the reference base is located at the outer side of the turn plate and coaxially arranged with the turn plate. An even number of reference nails are inserted to the circumferential wall of the reference base, steel balls are connected to the circumferential wall of the turn plate through the elastic support of springs, and the steel balls are pressed against the reference nails. A fixed plate is fixedly connected to the turn plate, butterfly screws are connected to the fixed plate through threads, and the bottom ends of the butterfly screws are pressed against the reference nails against which the steel balls are pressed. The clamping number is low, the repeated locating of the swing sliding base is avoided, and the machining efficiency is greatly increased.

Owner:JIANGSU RUIDE MACHINERY CO LTD

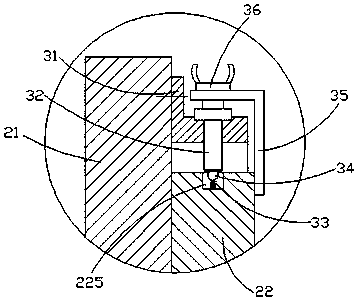

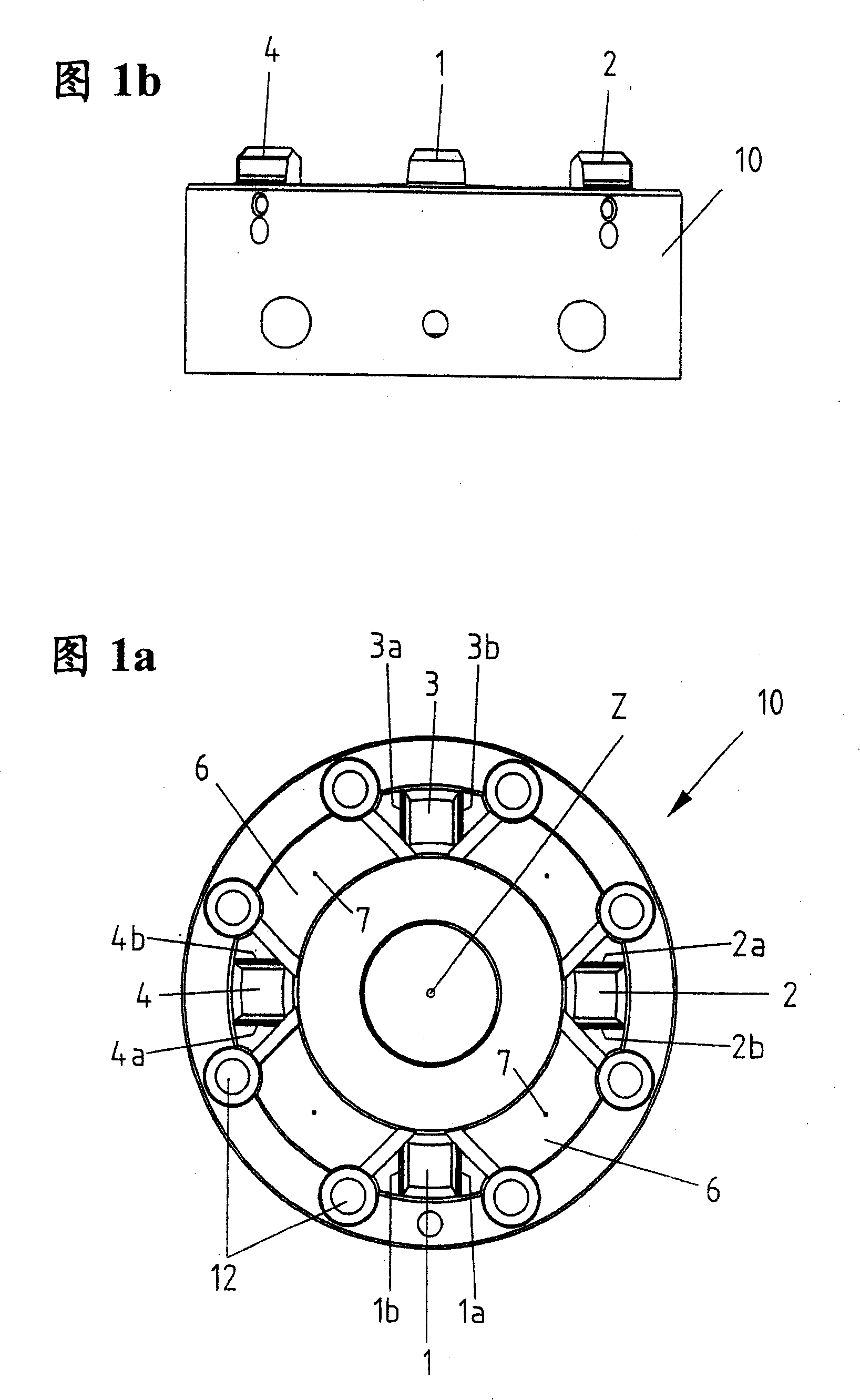

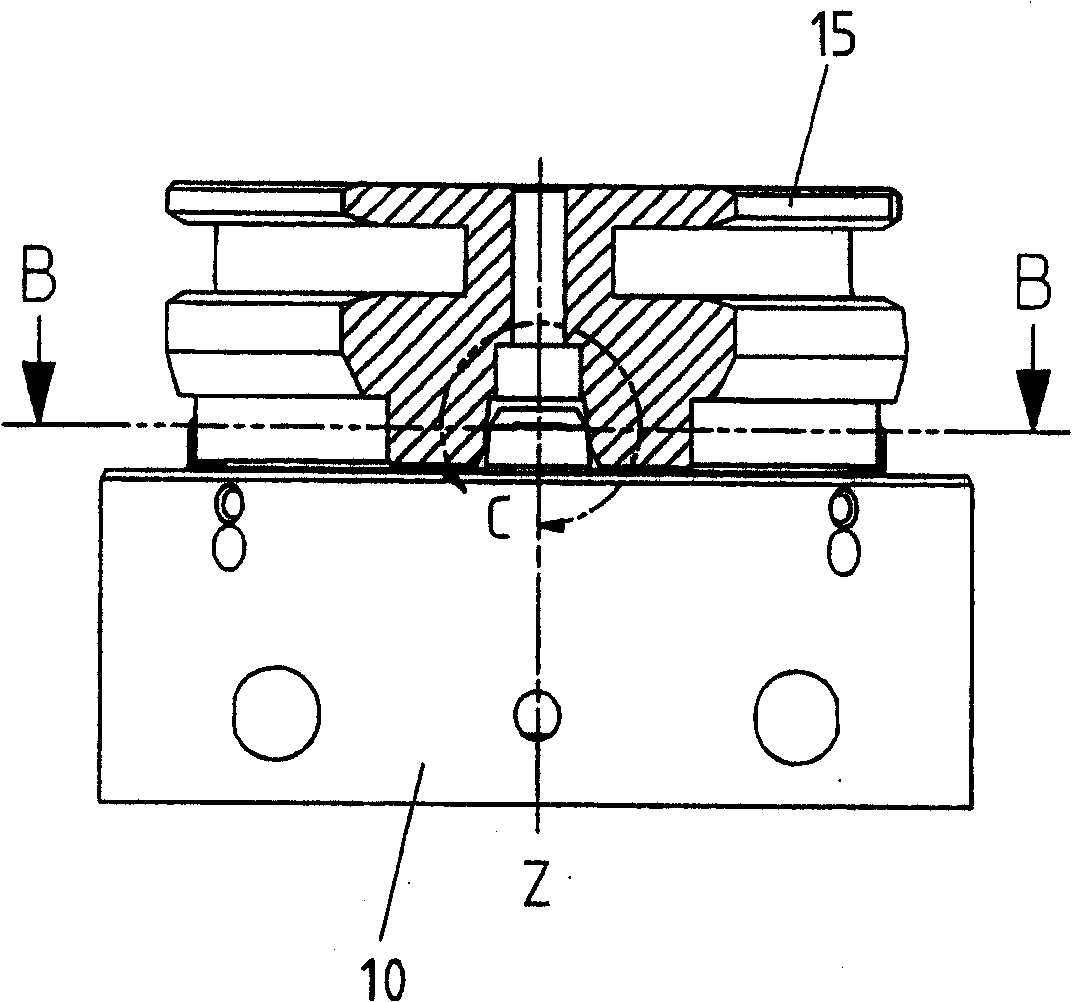

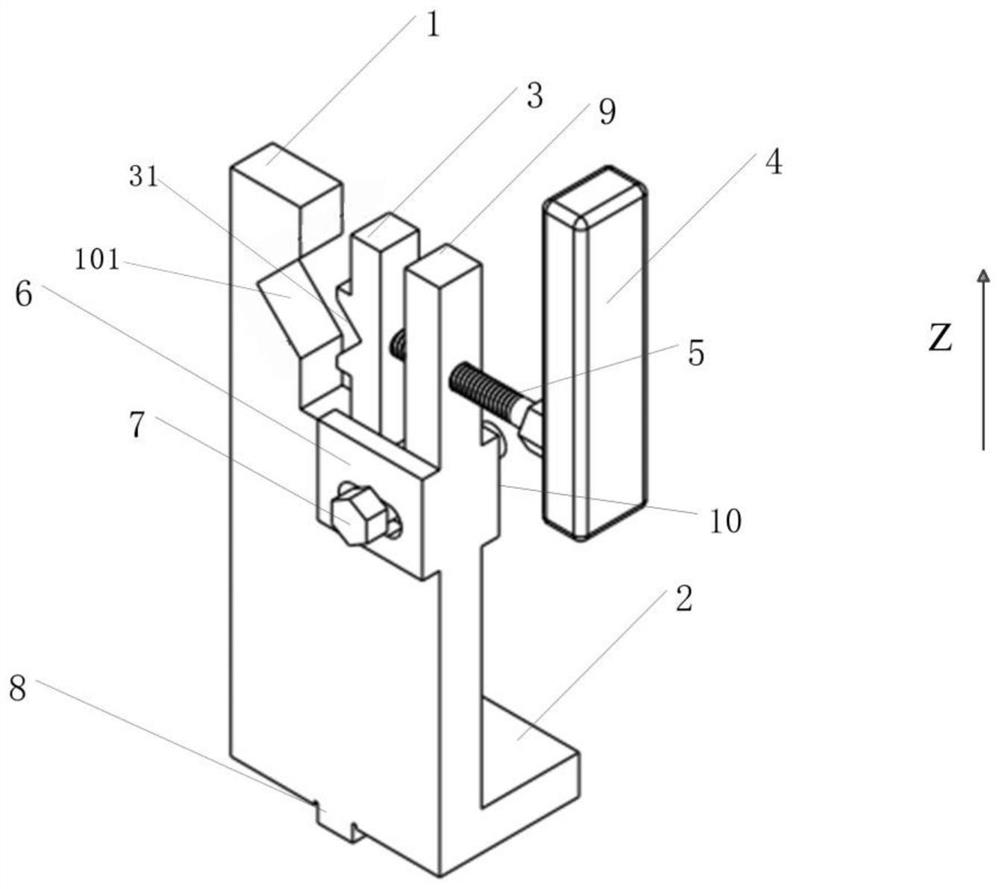

Clamping device

ActiveCN100429038CReduce riskAvoid Duplicate PositioningPrecision positioning equipmentSolid-state devicesMachine toolClutch

The clamping system, to hold one or more workpieces in defined positions at a machine tool, and the like, has one clutch section (10) and a second clutch section (15) which can be fixed and released. The first clutch section has at least three tapering centering lugs (1-4) which engage in matching grooves (21-24) at the other section. The lugs rest against only one flank (21a,22b,23a,24b) of their grooves, leaving a gap (S1-S4) between them and the other groove flanks (21b,22a,23b,24a). The structure ensures that the clutch facing surfaces are clamped together in the X- and Y-directions and are pressed together on the Z-axis.

Owner:EROWA

Stamping die capable of achieving blanking and riveting one-time forming

InactiveCN111545645AAvoid Duplicate PositioningAccurate riveting positionShaping toolsStructural engineeringProcessing accuracy

The invention discloses a stamping die capable of achieving blanking and riveting one-time forming. The stamping die comprises an upper die mechanism and a lower die mechanism, wherein the upper die mechanism comprises an upper die plate, an upper punch is arranged at the bottom of the upper die plate, and a forming protruding block is arranged on the end face of the bottom of the upper punch; thelower die mechanism comprises a lower die plate, a first material belt and a second material belt are fed on the lower die plate in a crossed mode, a lower forming male die is arranged on the lower die plate and elastically connected to a lower die base, a blanking hole corresponding to the forming protruding block is formed in the lower forming male die, a riveting punch is arranged on the lowerdie plate and penetrates through the lower forming male die, and a forming groove corresponding to the riveting punch is formed in the bottom end face of the upper punch. According to the stamping die capable of achieving blanking and riveting one-time forming, the blanking and riveting procedures of a material strip are completed through one-time stamping, repeated workpiece positioning is avoided, and the machining precision of products is improved.

Owner:SHENZHEN EVA PRECISION TECH GRP CO LTD

Limiting and clamping device for machining center

ActiveCN112108897AReduce frictional resistanceMeet processing needsWork clamping meansMetal working apparatusClassical mechanicsControl theory

The invention relates to a limiting and clamping device for a machining center. The device comprises a rack outside a machining center conveyor, the rack is provided with at least one limiting frame and a clamping mechanism, a walking driving mechanism used for driving the limiting frame to reciprocate in the parallel direction of the conveyor is arranged at one side of the limiting frame, a driving plate is arranged at the top of a limiting plate of the limiting frame, a deflection shaft and a deflection mechanism are arranged between the driving plate and the other side of the limiting frame, the deflection mechanism is used for driving the driving plate to deflect around the deflection shaft in a reciprocating manner, and the clamping mechanism comprises two first clamping plates movingoppositely in the vertical conveying direction of the conveyor and a second clamping plate moving relative to a fixing table in a lifting manner. The walking limiting frame drives the driving plate to deflect in a reciprocating manner through the deflection mechanism, side opening and closing of the limiting plate at the top of the conveyor can be achieved, top feeding is facilitated, repeated positioning is avoided, workpiece clamping is achieved through multi-face limiting clamping in the side direction and the vertical direction of the clamping mechanism, the positioning precision, the clamping efficiency and the reliability can be improved, and the compact continuous production requirement of the machining center is met.

Owner:苏州艾米欧精密机械股份有限公司

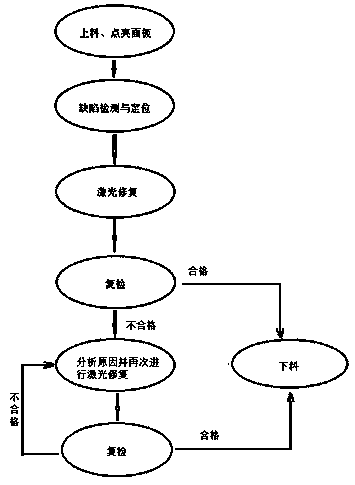

Display screen intelligent detection laser repairing method

PendingCN111203631AAvoid Duplicate PositioningImprove detection and repair efficiencySortingLaser beam welding apparatusLaser processingRapid scan

The invention discloses a display screen intelligent detection laser repairing method. The method comprises the following steps of firstly, carrying out automatic feeding, then controlling a visual identification system to scan a display panel and identify defective pixels in the display panel, and carrying out clearing operation on the defective pixels through a laser machining system; after thelaser machining system finishes machining, controlling the visual identification system to quickly scan the display panel again, and re-checking whether the known defective pixels of the panel are qualified or not; if the machining effect is qualified, controlling automatic discharging; if the machining effect is not qualified, machining the defective pixels after intelligent analysis and processing; and after machining is completed, detecting and confirming the machined defective pixels again through the visual identification system, carrying out blanking after machining is qualified, if machining is not qualified, repeating the re-inspection analysis and the machining process, and repeating the steps till the machining effect is qualified. The display screen intelligent detection laser repairing method effectively improves the detection repairing efficiency, in addition, reduces the labor intensity and the labor cost and improves the product yield, and the practicability is high.

Owner:苏州鑫业诚智能装备有限公司

AR positioning system of radiotherapy

ActiveCN109364387ARadiation Therapy AchievementAvoid Duplicate PositioningX-ray/gamma-ray/particle-irradiation therapyPhysical MarkingEngineering

The invention relates to an AR positioning system of radiotherapy. The system comprises a chassis, a positioning bed, an operating console, a computer, a HoloLens, a Kinect and a lead; the chassis iscomposed of base plate, bottom rollers, a height adjusting pedal, horizontal guide rails, a circular guide rail, a fixed block and an adjusting device; the positioning bed is composed of a bed board,supports, transparent synthetic glass and pushing handles; the chassis is connected to the operating console via the lead; and the computer and HoloLens are placed on the operating console. The systemhas the advantages that radiotherapy can be carried out on a patient without a body surface physical mark; the patient can be avoided form repeated positioning, and the radiation absorbed dose and medical cost of the patient can be reduced; the patient is avoided from decrease of positioning precision caused by unclear physical marks in the body surface, and the accuracy of radiotherapy is improved; a doctor draws positioning lines less frequently, and time is saved; the working efficiency is improved; the whole process is clear in ideal, easy to master and includes a shorter learning curve;and different body parts of the patients can be collected.

Owner:SHANGHAI PULMONARY HOSPITAL

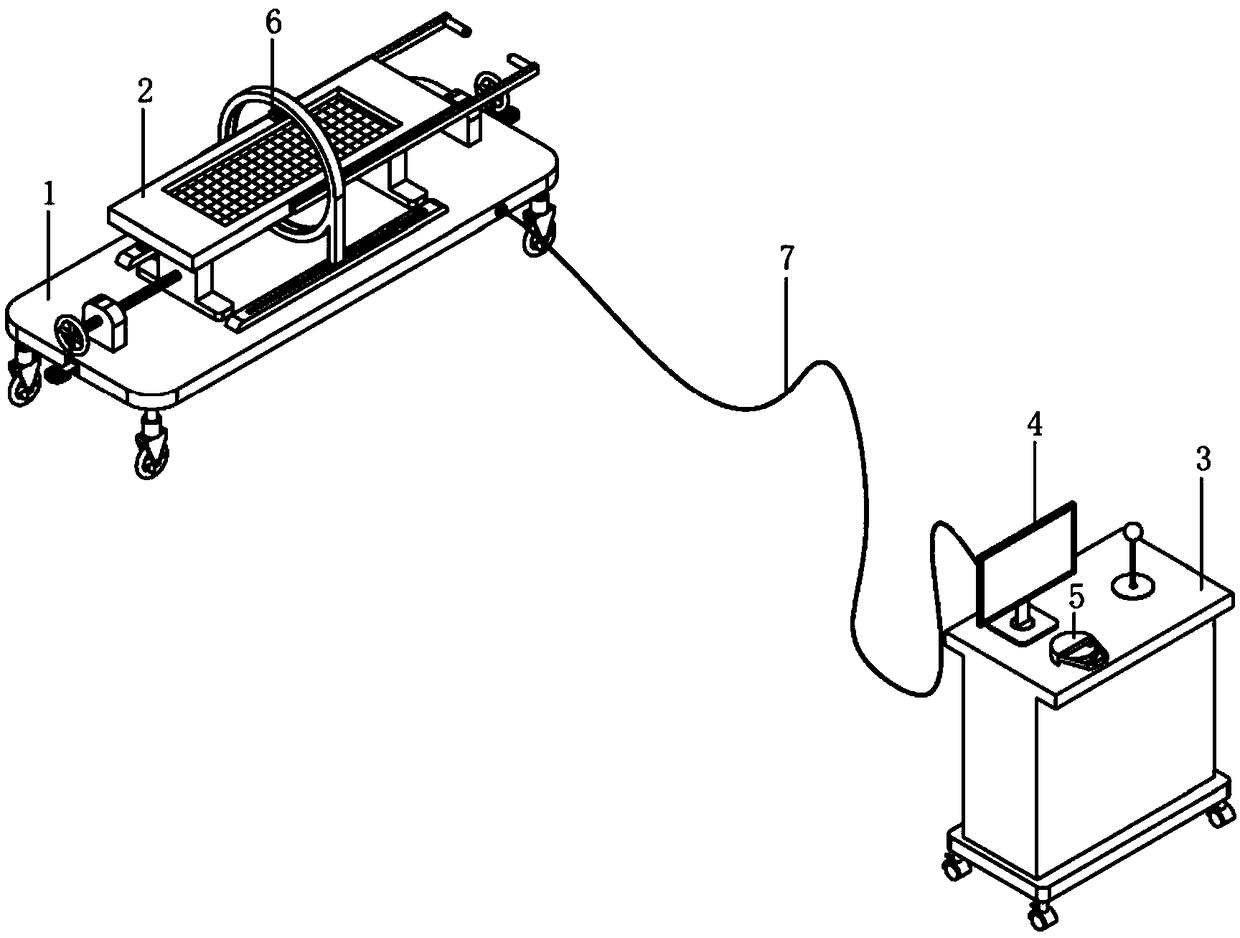

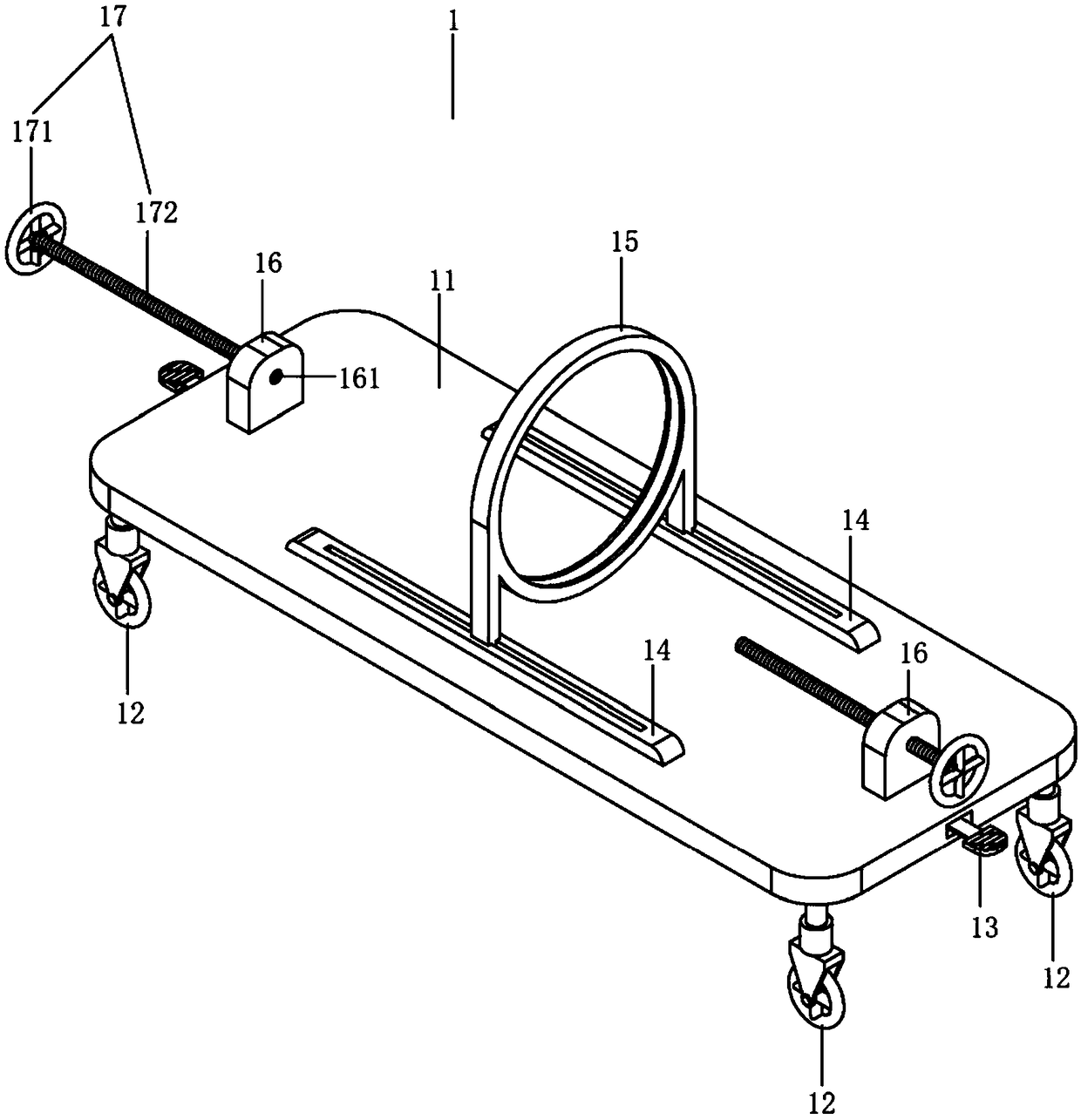

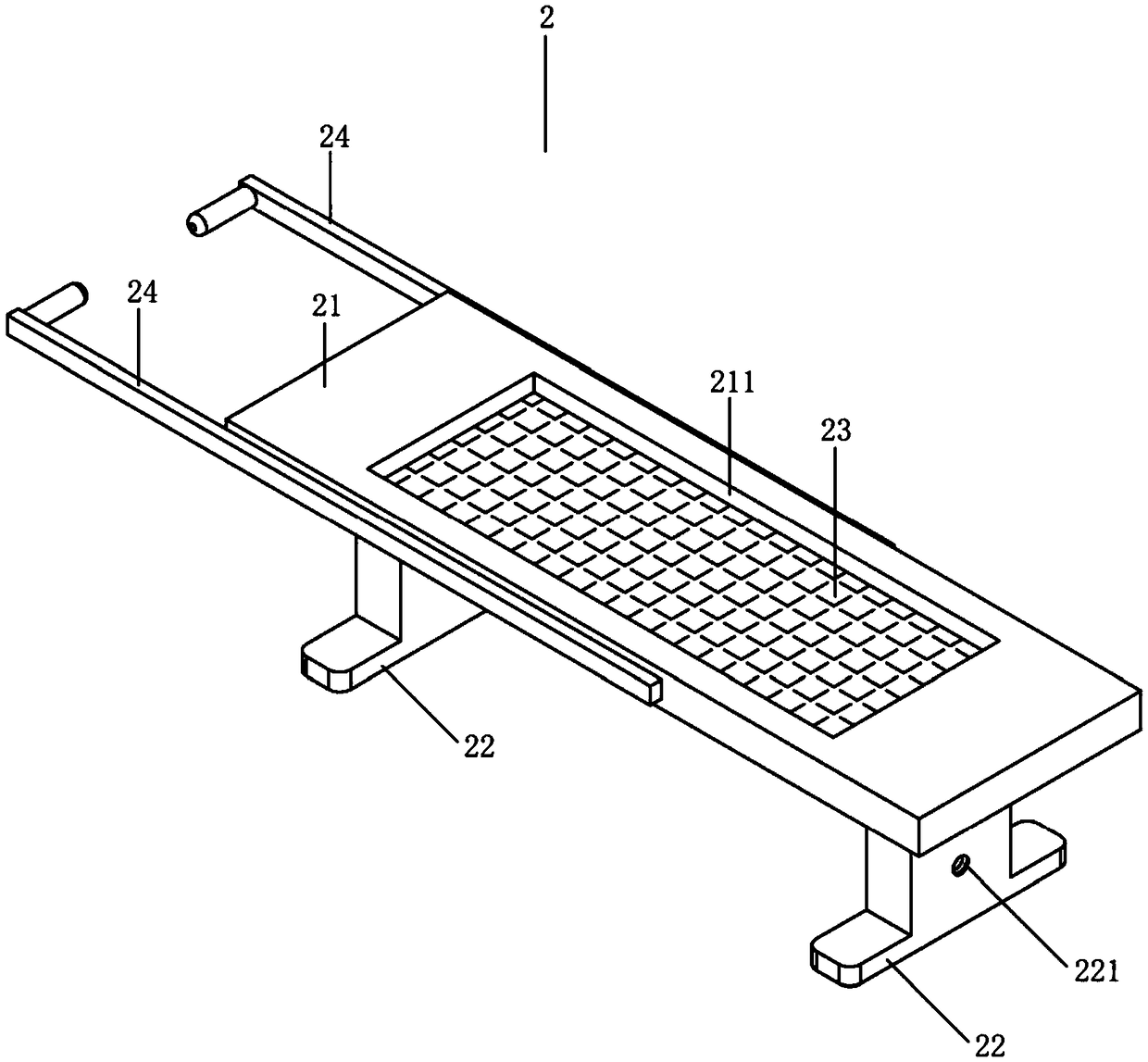

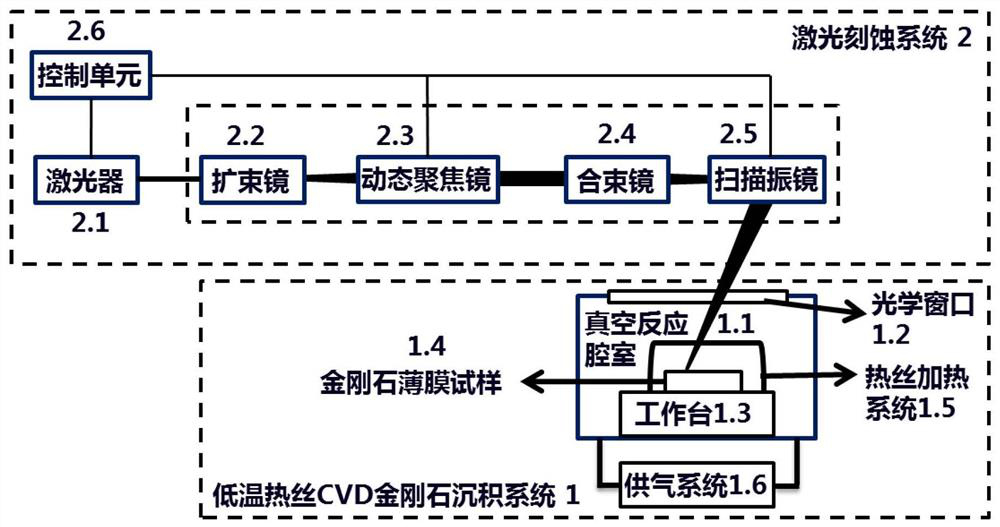

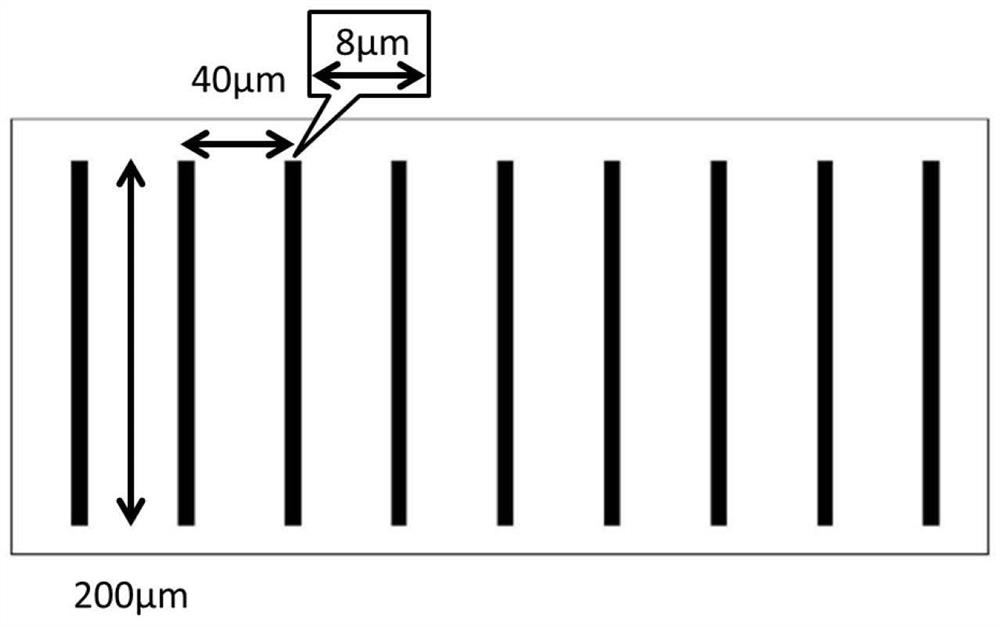

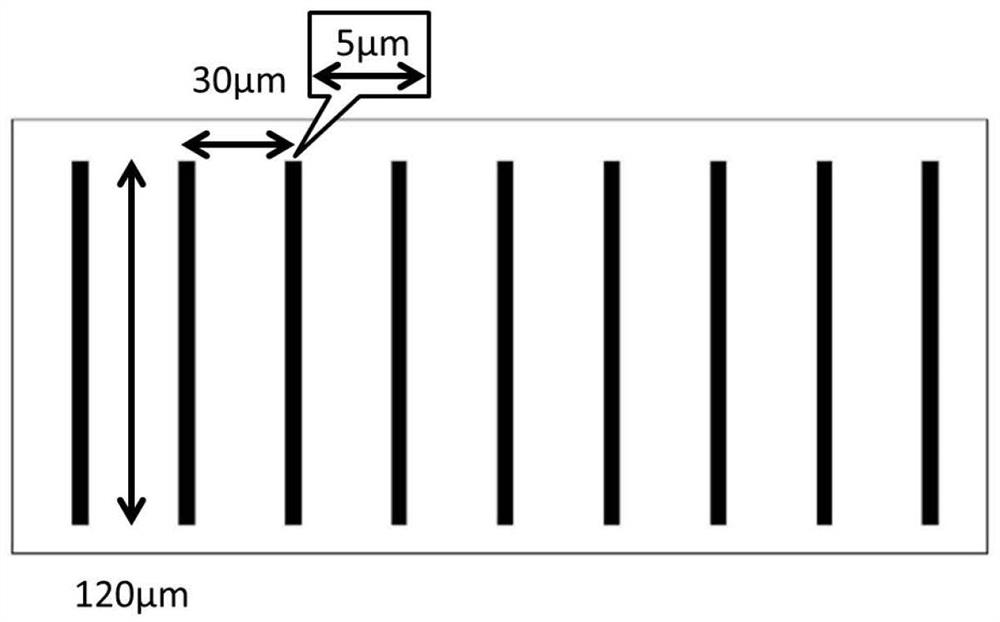

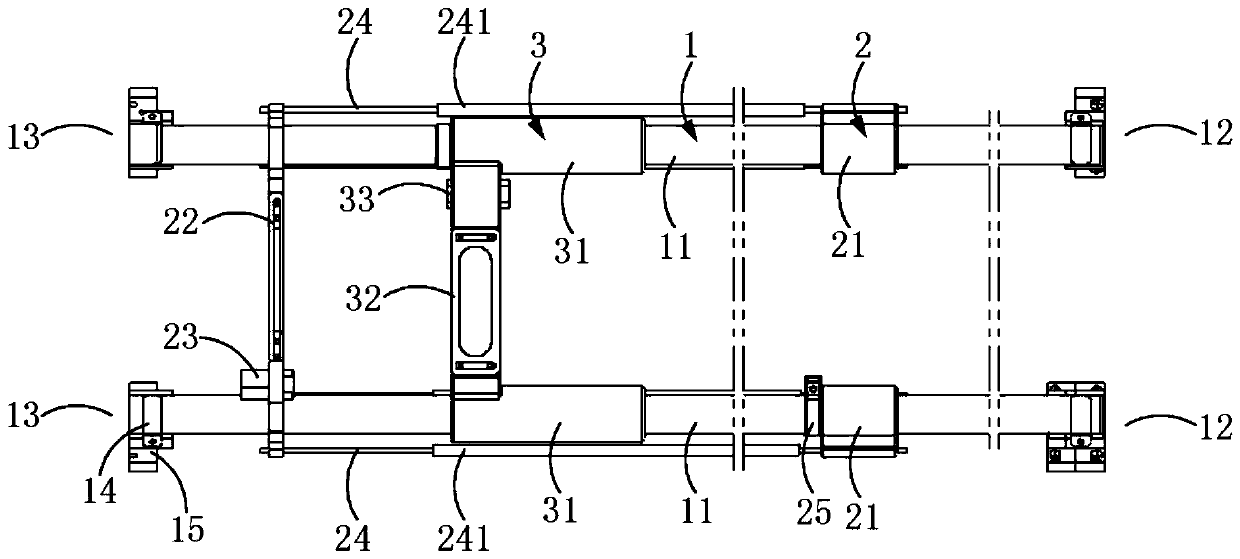

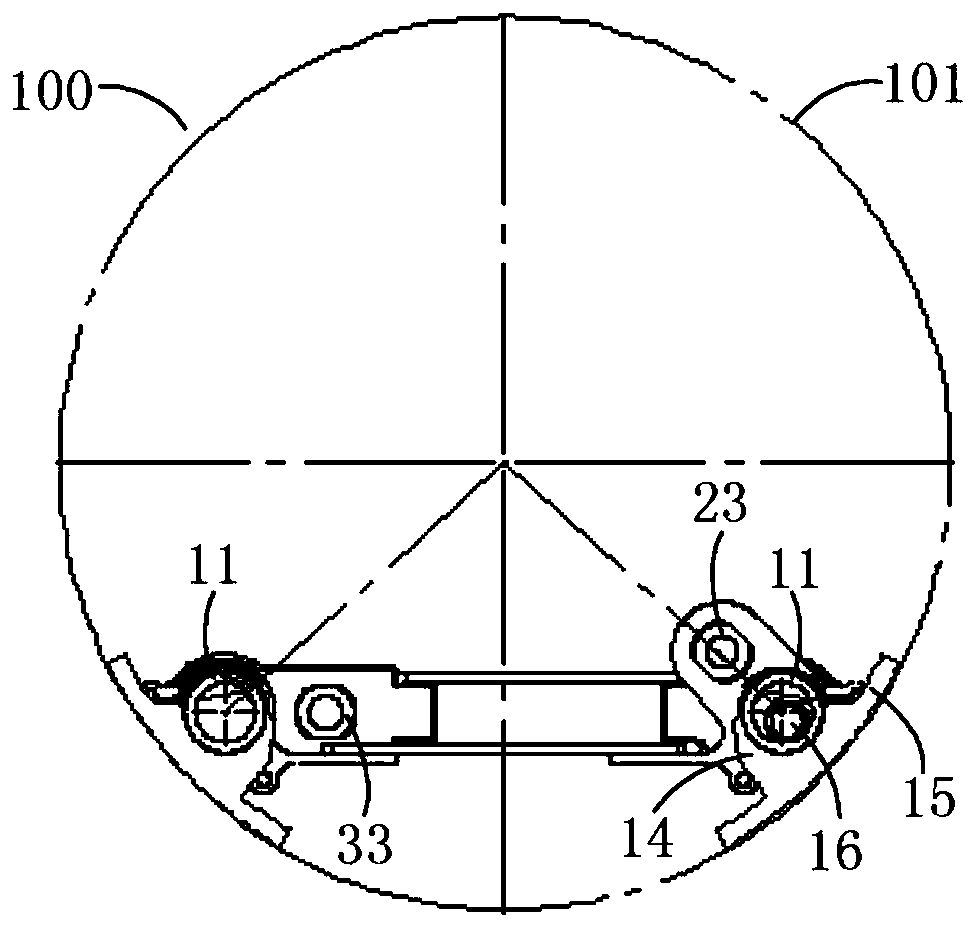

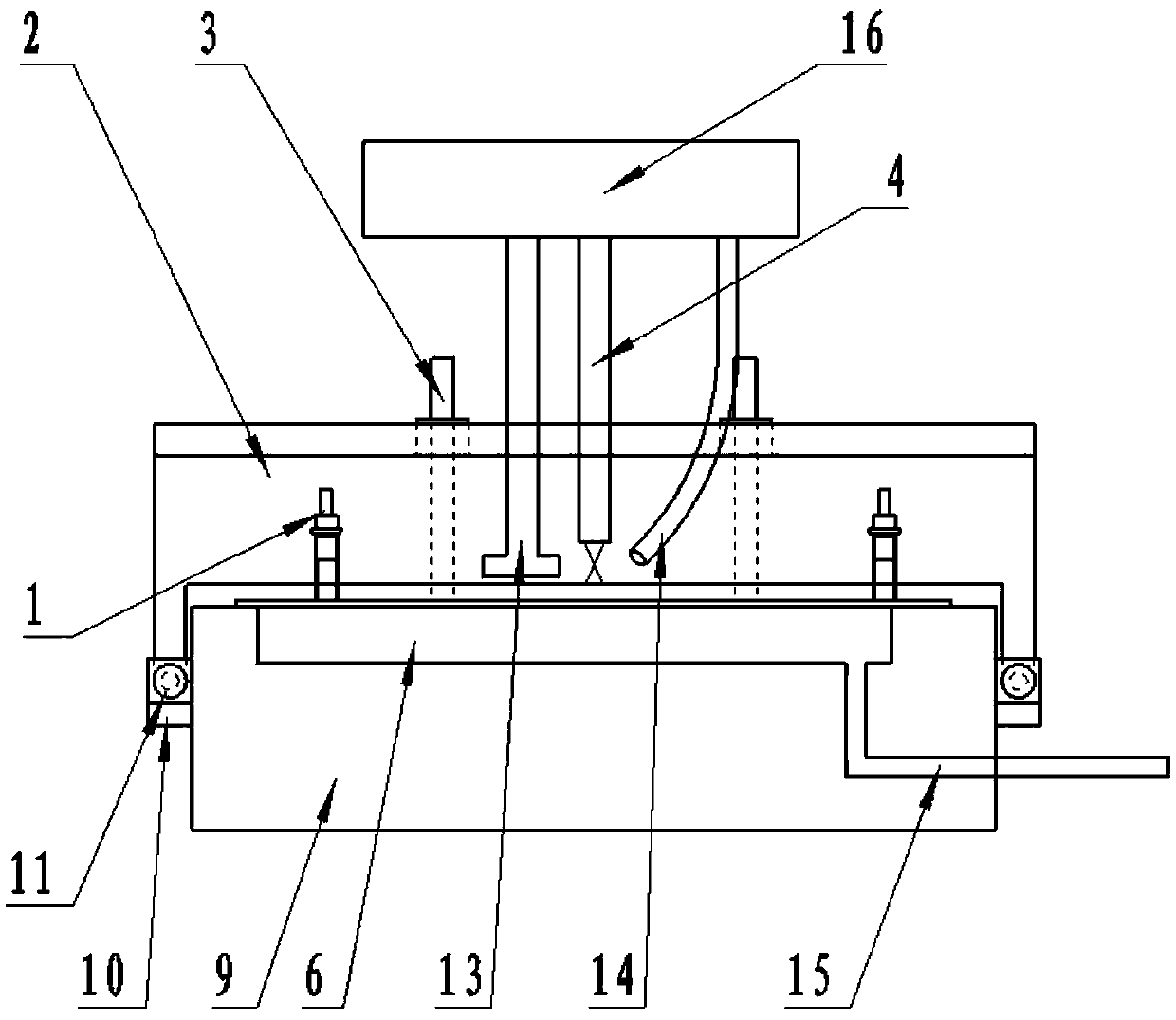

Method and device for synchronously compounding and manufacturing diamond micro-grating based on micro-additive and micro-subtractive

ActiveCN111850507AAvoid Duplicate PositioningGraphical micromachining is fast and efficientChemical vapor deposition coatingLaser beam welding apparatusLaser etchingGrating

The invention discloses a method and device for synchronously compounding and manufacturing a diamond micro-grating based on micro-additive and micro-subtractive. The method comprises the steps of pretreating the surface of a diamond film sample to remove surface impurities, performing low-temperature hot wire CVD diamond deposition on the surface of the diamond film sample, and performing graphicmicro-machining on the surface of a CVD diamond film to obtain the diamond micro-grating. The device is provided with a low-temperature hot wire CVD diamond deposition system for performing low-temperature hot wire CVD diamond deposition and a laser etching system for performing graphic micro-machining, wherein the low-temperature hot wire CVD diamond deposition system is provided with a vacuum reaction chamber with an optical window formed in the upper end; a workbench is arranged in the vacuum reaction chamber; a gas supply system is arranged outside the vacuum reaction chamber; and a heating wire adding system for exciting reaction gas and heating the diamond film sample is arranged on the workbench. According to the method and device for synchronously compounding and manufacturing thediamond micro-grating based on the micro-additive and the micro-subtractive, spatio-temporal synchronous compounding of micro-additive machining and micro-subtractive machining is achieved, and continuous in-situ growth of a diamond in a non-etching area is achieved.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

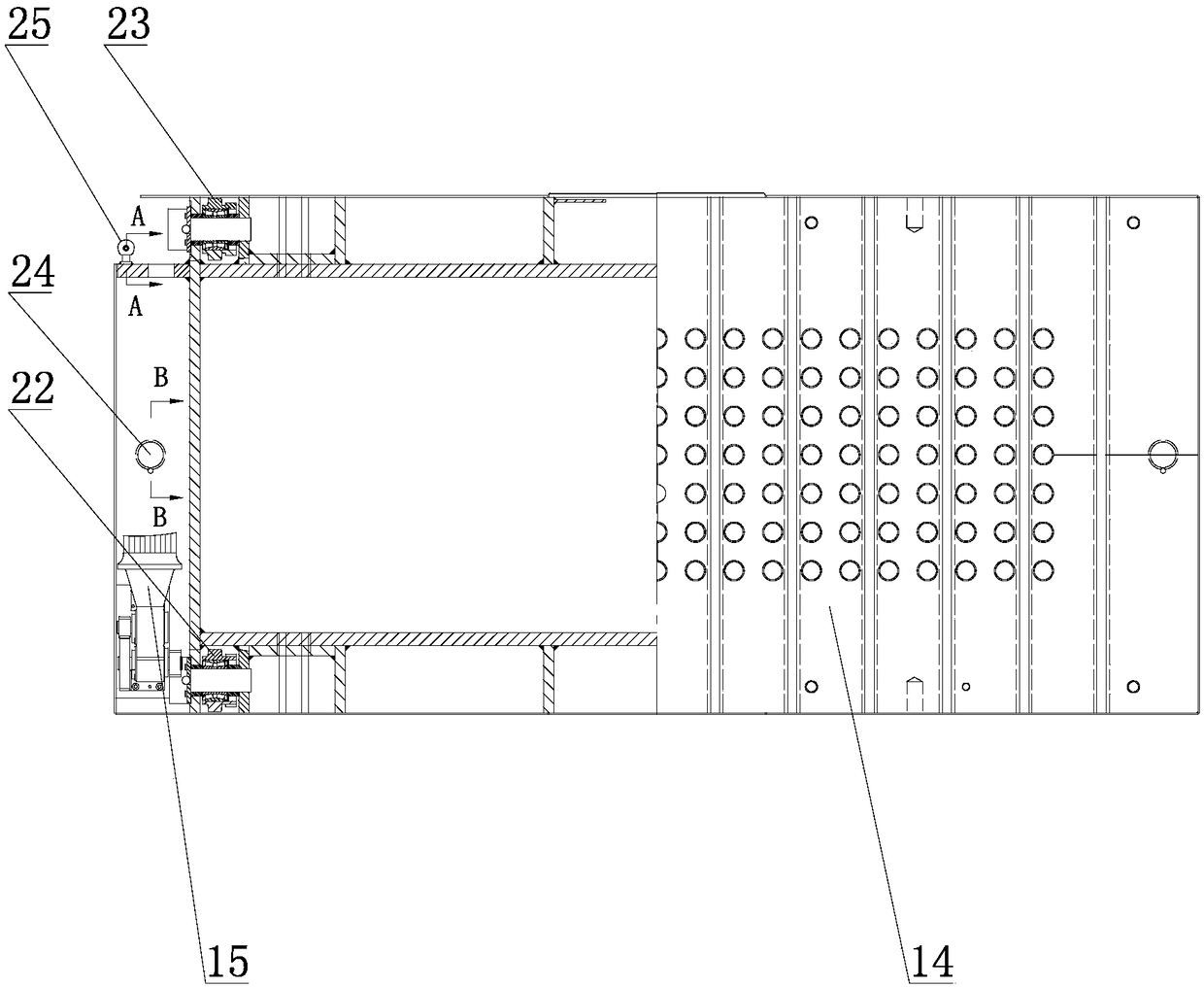

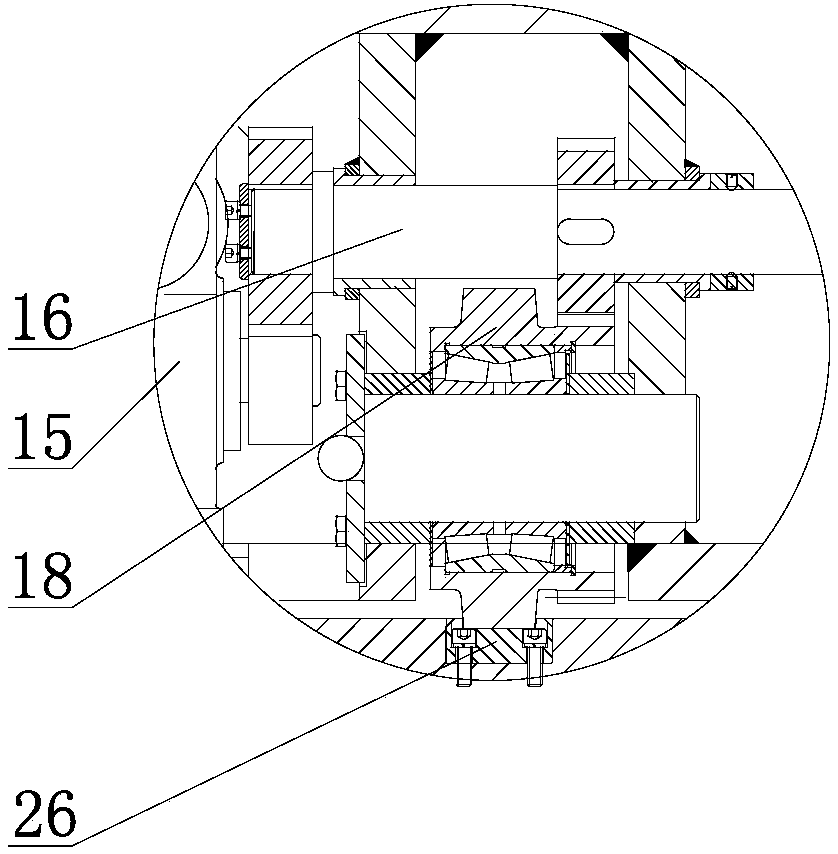

Radio frequency introduction device and semiconductor processing device

InactiveCN111139460AImprove uniformityImprove passivation effectFinal product manufactureChemical vapor deposition coatingElectrical connectionRadio frequency

The embodiment of the invention provide a radio frequency introduction device and a semiconductor processing device. The radio frequency introduction device is used for introducing radio frequency toa cassette located inside a semiconductor process furnace, and comprises a supporting mechanism, a front radio frequency mechanism and a rear radio frequency mechanism. The supporting mechanism comprises a supporting rod, the first end of the supporting rod is connected with a furnace opening of the semiconductor process furnace, and the second end of the supporting rod is connected with the furnace tail of the semiconductor process furnace; the front radio frequency mechanism and the rear radio frequency mechanism are arranged on the supporting rod in parallel and used for bearing the cassette; the front radio frequency mechanism is arranged close to the first end of the supporting rod, and the rear radio frequency mechanism is arranged close to the second end of the supporting rod; and the front radio frequency mechanism is electrically connected with one end of the cassette, and the rear radio frequency mechanism is electrically connected with the other end of the cassette. According to the device, the radio frequency of the cassette is introduced in two directions, so that the current direction between positive and negative electrodes of the cassette in the semiconductor process furnace is changed, and then the uniformity and passivation effect of the process are improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

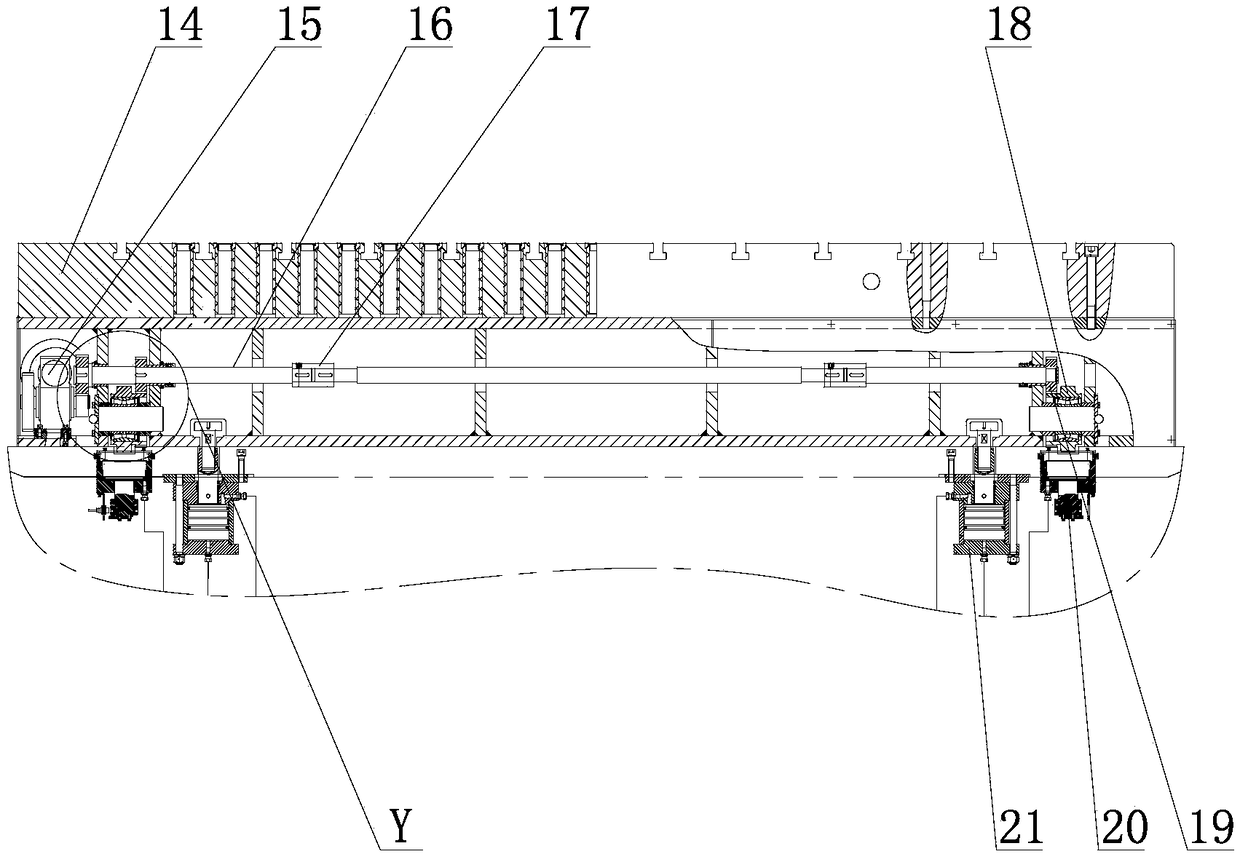

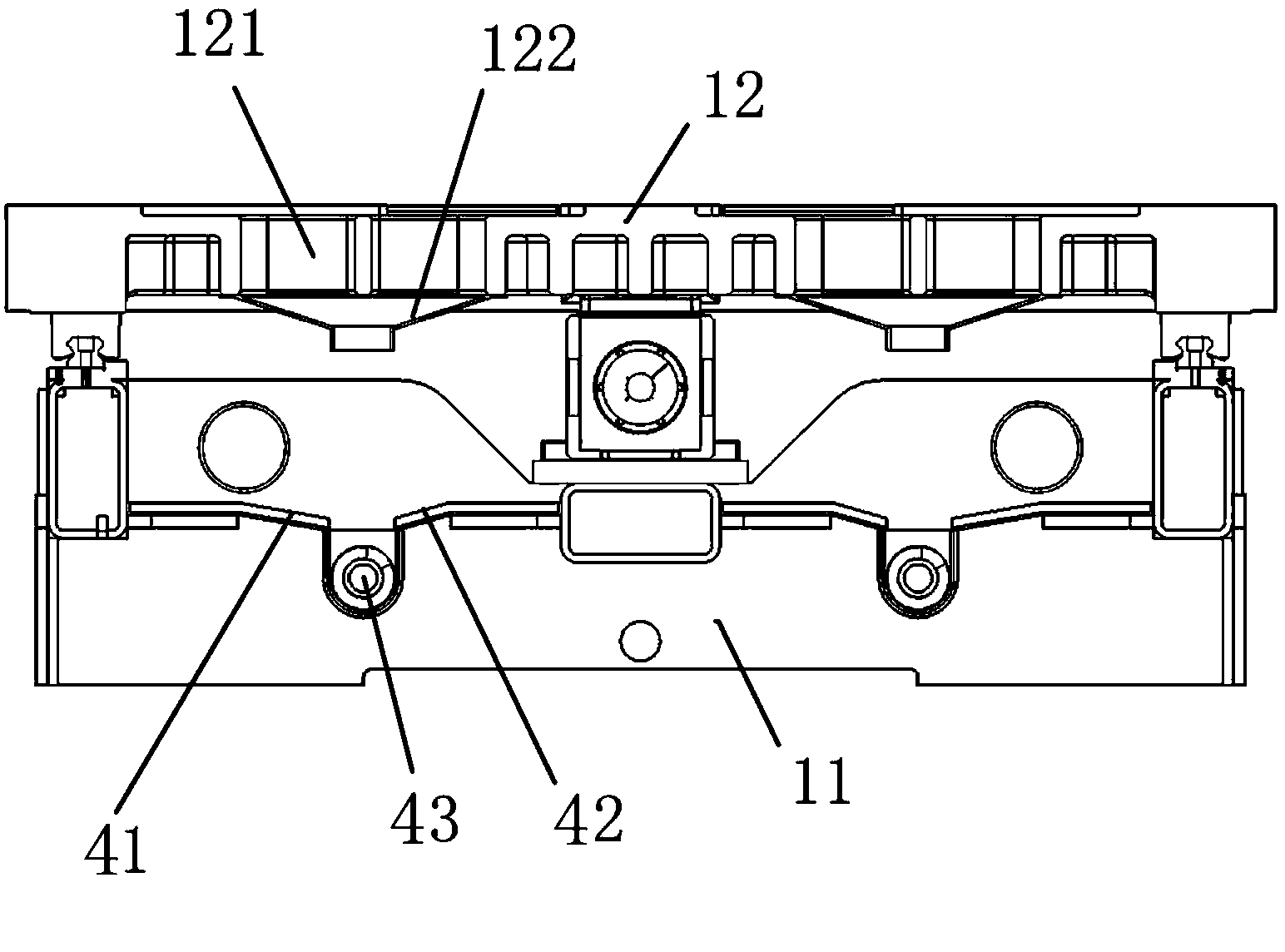

Hydraulic driving automatic exchange workbench of closed mechanical press

ActiveCN108202124APrecise positioningExtended service lifeForging/hammering/pressing machinesForging press detailsHydraulic pumpEngineering

The invention provides a hydraulic driving automatic exchange workbench of a closed mechanical press. The hydraulic driving automatic exchange workbench comprises a base, wherein a steel rail is arranged on the base, and one or two exchange workbench bodies are arranged on the steel rail. Roller jacking devices are arranged at four corners of the exchange workbench bodies, a set of multi-stage hydraulic oil cylinder driving device is arranged between each exchange workbench body and the base, guide devices are arranged between the two sides of the exchange workbench bodies and the base, conical positioning devices are arranged between the middles of the two sides of the exchange workbench bodies and the base, clamping devices are arranged between the exchange workbench bodies and the base,position detection devices are arranged at the front and back of the exchange workbench bodies, steel rail cleaning devices are arranged on the front outer walls and the rear outer walls of the exchange workbench bodies, four sets of collision block automatic lifting devices are arranged in the middle of the base at intervals, the four corners of the base are provided with edge collision block devices, and a hydraulic pump station device is arranged in the base. The hydraulic driving automatic exchange workbench has the advantages of being accurate in guiding, precise in positioning, accuratein moving distance and the like.

Owner:RONGCHENG HUADONG METAL FORMING MACHINERY +1

Drilling equipment used for drilling holes in two ends of rack

InactiveCN103920906ARestricted movementRealize automatic positioningOther manufacturing equipments/toolsPositioning apparatusEngineeringMachining

The invention discloses drilling equipment used for drilling holes in the two ends of a rack. The drilling equipment comprises a work table base, a work table, a rack locating structure and a first screw rod power head. The rack locating structure is arranged on the work table and comprises a rack base, a rack fixing pressurization cylinder, a rack fixing pressurization block, a rack locating pressurization cylinder and a rack locating pressurization block. The two ends of the rack base are respectively provided with one rack end face drilling power head. A multi-shaft power head is adopted in each rack end face drilling power head. The multi-shaft power heads are provided with end face drilling cutters and end face reaming cutters. The two sides of the work table base are respectively provided with one end face drilling power head base. The rack end face drilling power heads are fixed to the end face drilling power head bases. The end face drilling power head bases are fixed to the work table base. Compared with the prior art, the drilling equipment is simple and reasonable in structure, automatic locating and machining are achieved, drilling or reaming is carried out on the two end faces at the same time, repeated location is avoided, and the machining efficiency is improved.

Owner:康美美

Form and position measurement flexible clamp and form and position measurement method for columnar part

PendingCN114734392AAvoid Duplicate PositioningImprove flexibilityMeasurement devicesWork holdersStructural engineeringMechanical engineering

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Automatic laser welding device and method

InactiveCN110877152AAvoid Duplicate PositioningMeet mass production needsWelding/cutting auxillary devicesAuxillary welding devicesPhysicsLaser soldering

The invention discloses an automatic laser welding device. The device comprises a butterfly-shaped process screw rod I, a clamping mechanism, a butterfly-shaped process screw rod II, a laser welding head, a back gas protection cavity, a butterfly-shaped process screw rod III, a compressible sealing gasket, a welding table, clamping grooves, process pins, a delay protection gas spray head, a side blowing protection gas spray head, a gas inlet pipe and a laser welding machine head, the clamping grooves are located in the two sides of the welding table and fixed to the welding table to form a whole, the clamping mechanism and the clamping grooves are provided with holes for assembly and positioning of the process pins, and the clamping mechanism and the clamping grooves can be connected to the side surface of the welding table surface through the process pins, and the butterfly-shaped process screw I and the butterfly-shaped process screw II are mounted on the clamping mechanism and are screwed with threaded holes in the clamping mechanism to fasten a part I to be welded and a part II to be welded. The automatic laser welding device can effectively avoid the problem of repeated positioning of parts in the batch production process, and can avoid the problems that the positioning precision is not high and the gas protection effect of the weld joint position is poor during welding.

Owner:AVIC GUIZHOU AIRPLANE

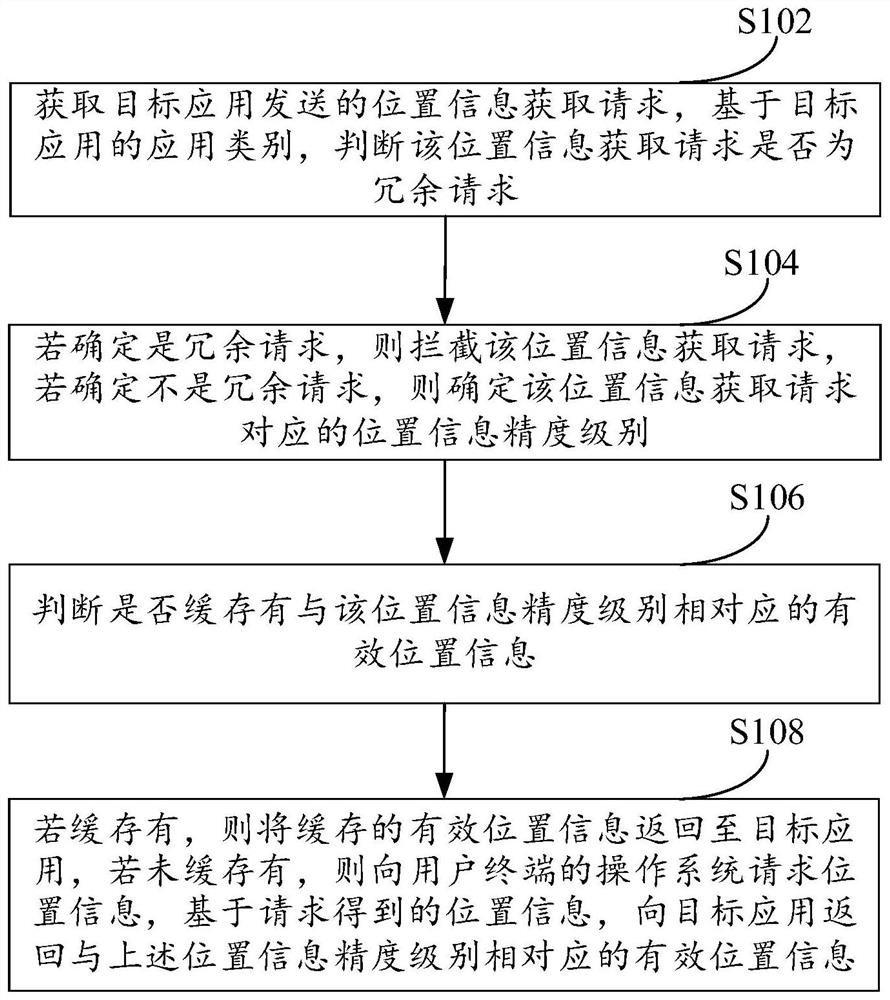

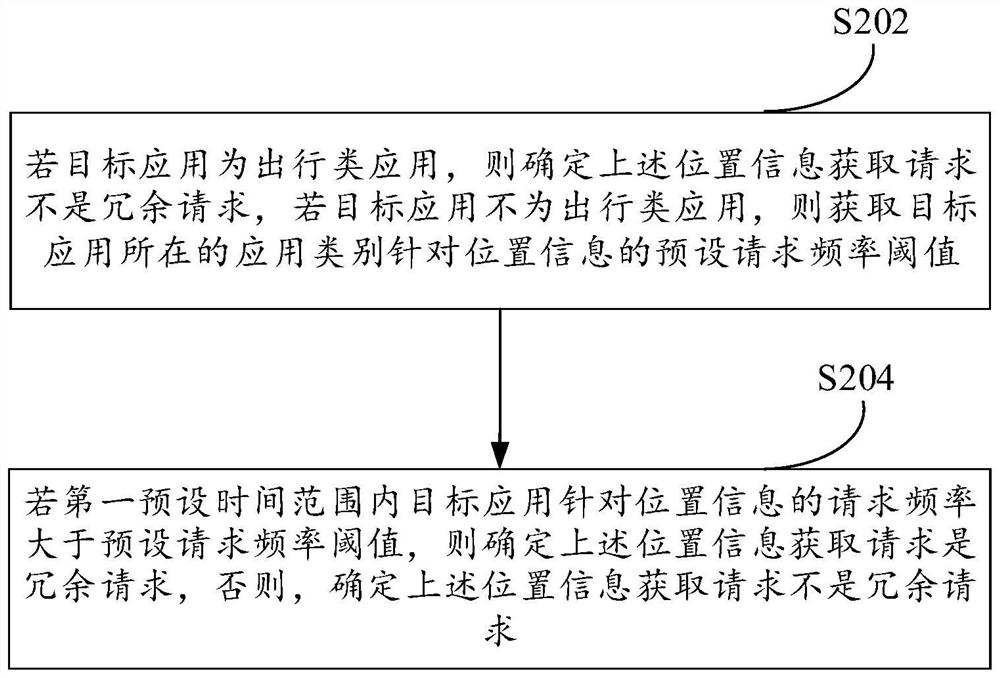

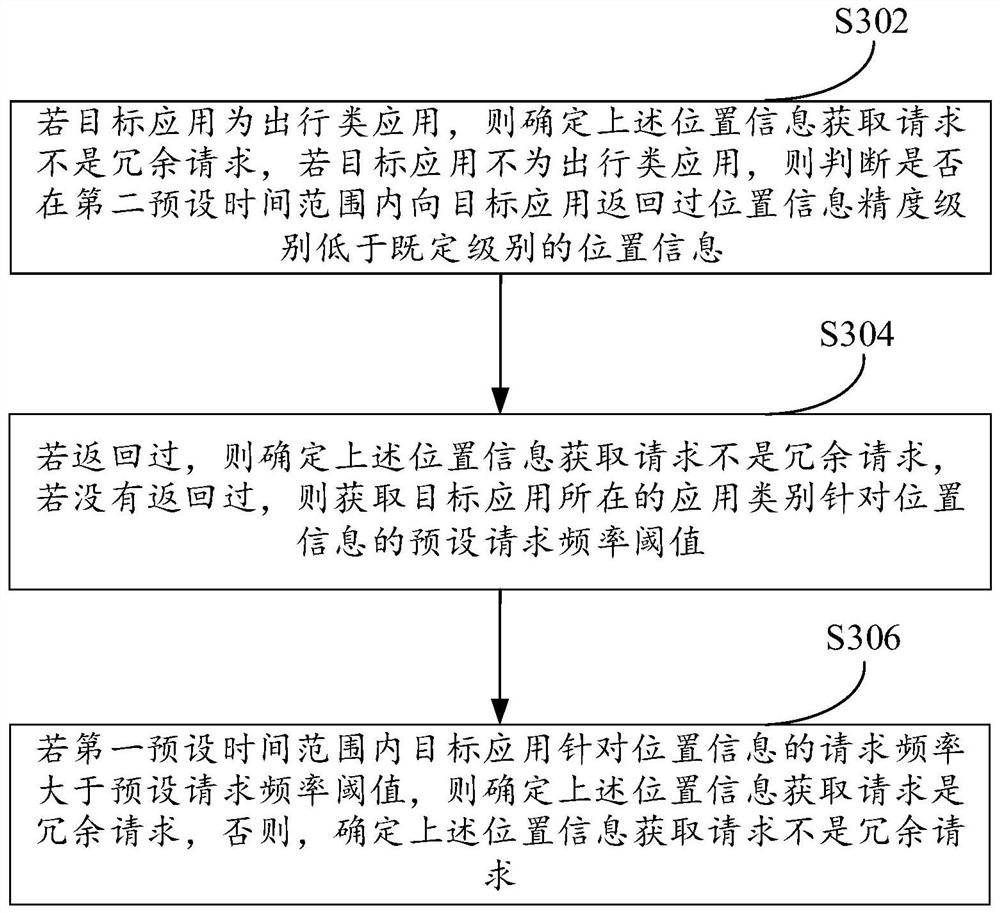

Application positioning processing method and device, equipment and storage medium

ActiveCN114205455AReduce power consumptionAvoid Duplicate PositioningSubstation equipmentHigh level techniquesComputer hardwareOperational system

The embodiment of the invention provides an application positioning processing method and device, equipment and a storage medium, and the method comprises the steps: obtaining a position information obtaining request sent by a target application, and judging whether the position information obtaining request is a redundant request or not based on the application type of the target application; if it is determined that the request is the redundant request, intercepting the position information acquisition request, and if it is determined that the request is not the redundant request, determining a position information precision level corresponding to the position information acquisition request; judging whether effective position information corresponding to the position information precision level is cached or not; if yes, the cached effective position information is returned to the target application, and if not, the position information is requested from an operation system of the user terminal, and the effective position information corresponding to the position information precision level is returned to the target application. According to the embodiment of the invention, the problems that excessive positioning operations consume the electric quantity of the mobile phone, and repeated positioning is caused by the fact that multiple positioning results are possibly the same can be solved.

Owner:ZHENGZHOU APUS DIGITAL CLOUD INFORMATION TECH CO LTD

Screw tap feeding and discharging device

ActiveCN113894698ALarge capacityReduce the difficulty of positioningGripping headsGrinding feedersRobot handEngineering

The invention relates to the technical field of feeding and discharging, in particular to a screw tap feeding and discharging device which comprises a mechanical arm, a clamping mechanism, a material frame, material disc mechanisms and a laser marking device, wherein at least one turnover mechanism is arranged on the lower portion of the material frame in a front-back spaced mode, and at least one material disc mechanism is arranged on the upper portion of the material frame in a front-back spaced mode. The screw tap feeding device has a reasonable and compact structure; through the arrangement of the weight reducing grooves, the weight of a material disc can be reduced, the load of the material disc containing screw tap raw materials or finished products in the transferring process is reduced, the labor intensity or the driving capacity is reduced, and the production cost is reduced; Through the arrangement of the mechanical arm, mechanical part raw materials can be flexibly controlled to be sequentially taken out and placed into processing stations; meanwhile, the machined finished products are taken down and placed on the other material disc; through the arrangement of the turnover mechanism, the material disc filled with the finished products can be buffered, the waiting time during feeding is reduced; and through the arrangement of the mechanical arm and the laser marking device, the machined finished products can be marked, and the machine has the beneficial effects of high reliability, simplicity, convenience and high efficiency.

Owner:ZHEJIANG WEIKE MACHINERY TECH

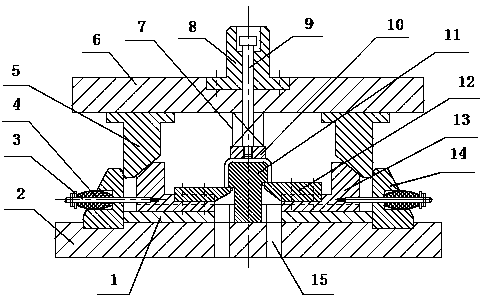

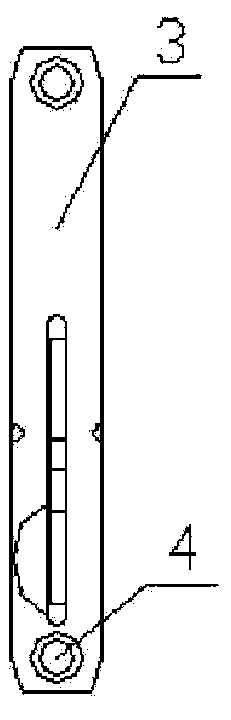

Superfine head of double-row tapered roller bearing outer shell

InactiveCN101633139AAvoid Duplicate PositioningImprove roundnessGrinding machinesCircular coneMachine tool

The invention relates to a grinding tool for a grinding machine tool, in particular to a superfine head of a double-row tapered roller bearing outer shell. According to the technical scheme of the invention, the superfine head of the double-row tapered roller bearing outer shell comprises a connecting plate and two groups of cylinders installed on the connecting plate, and the superfine head is characteristic in that each group of the cylinders is provided with a pressurizing cylinder and a jump-into and jump-out cylinder both of which are parallel arranged, a pressurizing piston rod of the pressurizing cylinder is connected with a compressive rod, and a tool carrier is arranged on a jumping piston rod of the jump-into and jump-out cylinder. A mechanism provided by the technical scheme can simultaneously process two roller paths, thus the positioning error of secondary positioning can be avoided and the production efficiency can be improved.

Owner:WUXI HAIBO PRECISION MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com