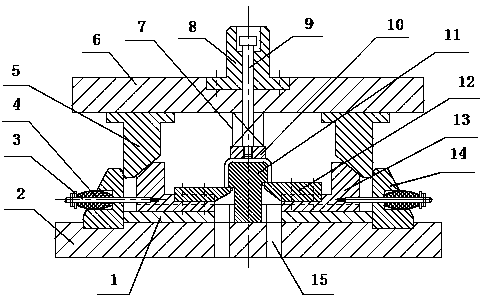

Sectional trimming mould

A trimming die and edge trimming technology, applied in the field of stamping dies, can solve problems affecting product accuracy, low processing efficiency, unevenness, etc., and achieve the effects of improving product accuracy, high processing efficiency, and avoiding repeated positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] As an embodiment of the present invention, such as figure 1 Shown, a kind of segment trimming mold, comprises upper mold base 6, lower mold base 2 and mold handle 8, and lower mold base 2 upper surface is provided with trimming die 11, as preferably, trimming die 11 is upper Large and small ladder shape, convenient for workpiece positioning. Edge trimming die 11 both sides are provided with edge trimming punch 12 respectively, and the edge height of two edge trimming punches 12 is different, as preferably, the edge of edge trimming punch 12 is provided with bevel, facilitates edge trimming Waste leaks. Trimming punch 12 is slidably connected to lower die base 2 upper surface by slide block 13, as preferably, slide block 13 is the L shape that puts horizontally, and slide block 13 is provided with inclined-plane far away from one end of trimming die 11, and upper die base 6. The lower surfaces of both sides are respectively provided with oblique wedges 5 matching with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com