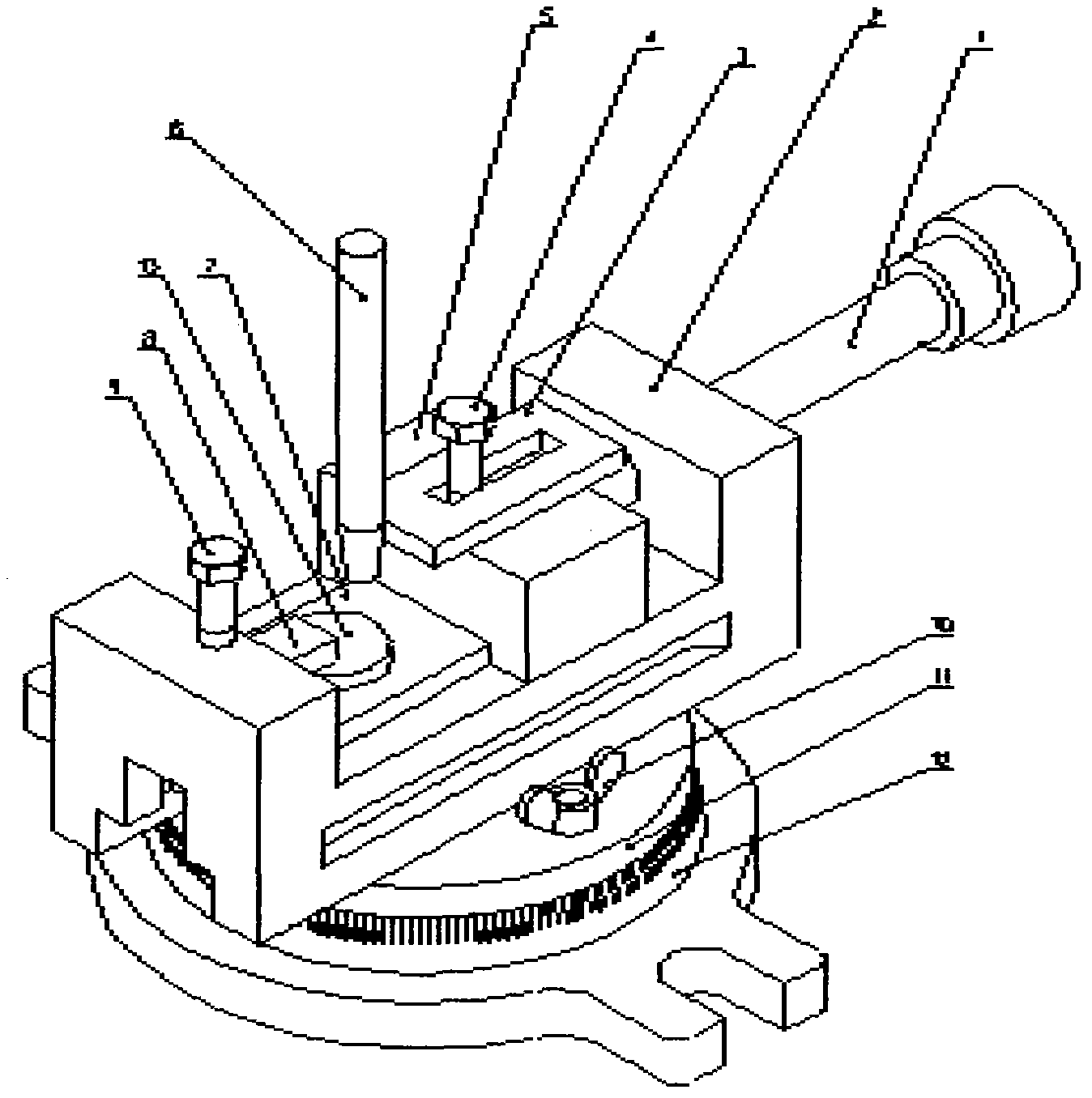

Compressible precision machine vise

A precision machine and platen technology, applied in vices, grinding workpiece supports, manufacturing tools, etc., can solve problems such as reducing accuracy and accumulating errors, and achieve the effects of improving accuracy, avoiding repeated positioning, and reducing labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] It is mainly divided into three parts. First: fix the clamp body. Cut out a T-shaped groove with wire cutting on it, and then make a T-shaped pressure plate to match the T-shaped groove. , and finally use the principle of the nut pair on the fixed clamp body to rotate the screw to adjust the height of the T-shaped pressure plate. When in use, if you do not need to use the T-type pressure plate to press, just screw the T-type pressure plate to the bottom, lower than the base surface of the vise, so that the clamping force will not be affected.

[0008] Second: the production of the movable clamp body, add a pressure plate on the movable clamp body, and open a slot in the middle, and the left and right can be adjusted according to the parts.

[0009] Third: The flat-nose pliers and the base adopt trapezoidal grooves, and there are 2 locking nuts on both sides. The flat-nose pliers and the base can be removed, and they can be used as flat-nose pliers after removal. Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com