Screw tap feeding and discharging device

A technology of taps and trays, applied in the field of loading and unloading, can solve the problems of long tray exchange time, large load of conveying trays, low work efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

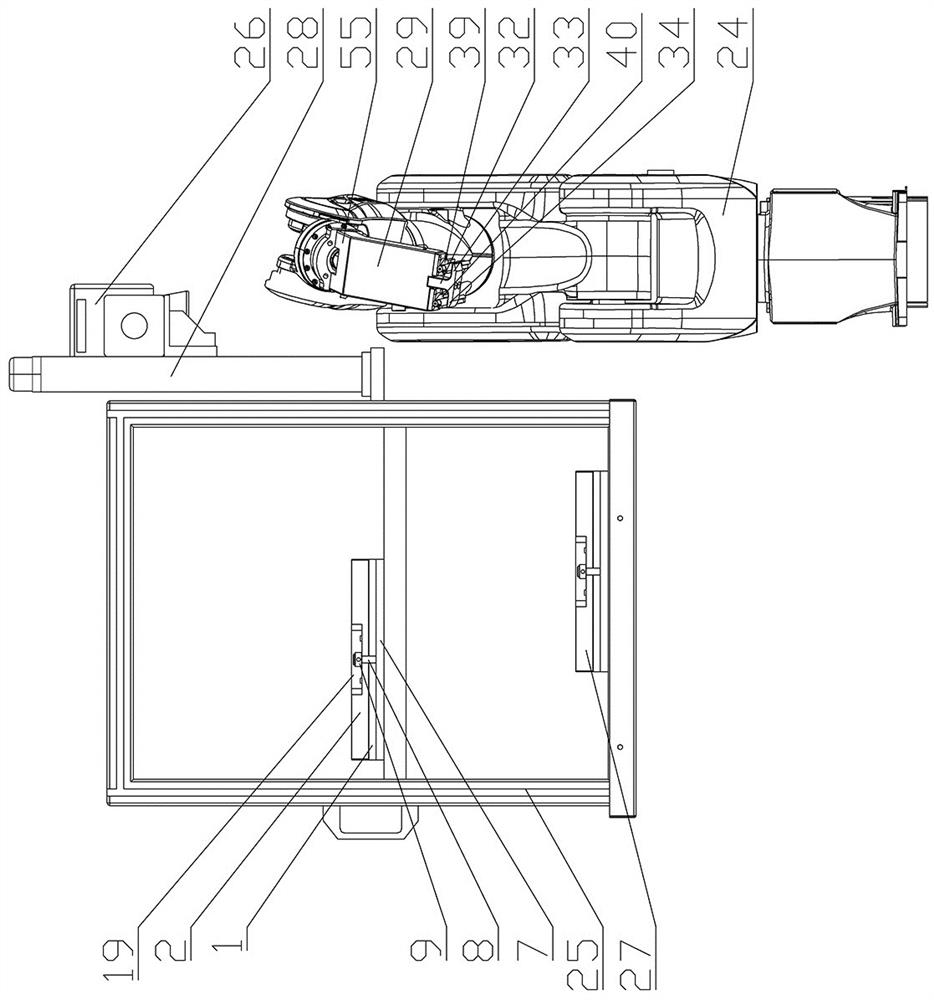

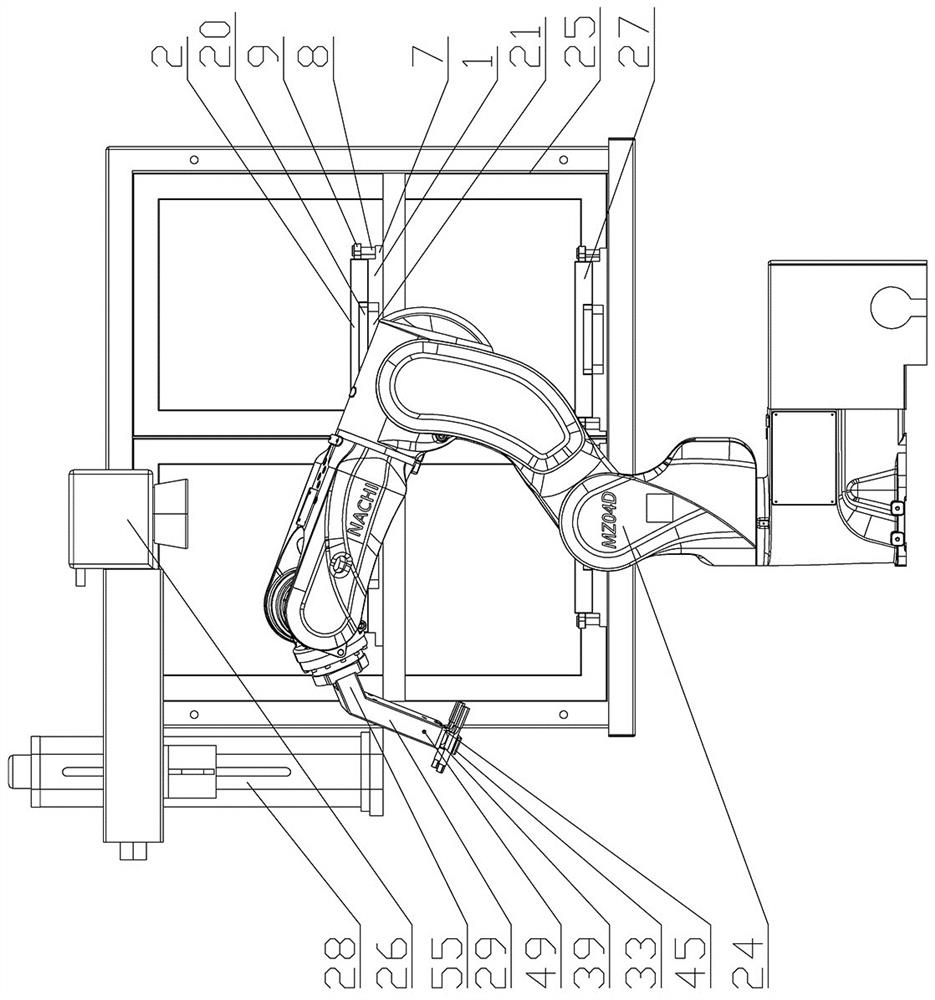

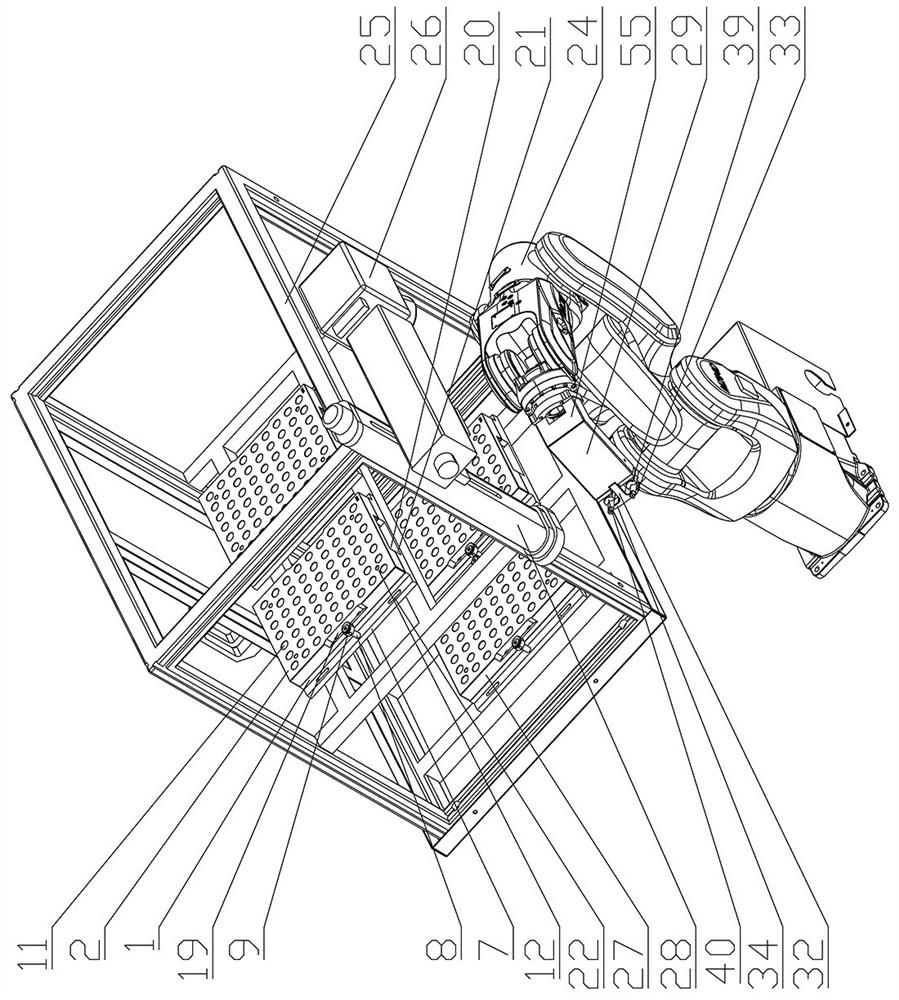

[0048] Embodiment 2, as attached figure 1 , 2 , 3, 8, 9, and 10, the clamping mechanism includes a cylinder body 29, a right piston rod 30, a left piston rod 31 and a gripper 32, and the rear side of the cylinder body 29 is fixedly installed with the end of the mechanical arm 24, and the cylinder body The front side of 29 is provided with a right piston chamber and a left piston chamber at intervals from right to left, and a handle 32 is fixed in the center of the cylinder body 29 corresponding to the position between the right piston chamber and the left piston chamber. A right finger 33 and a left finger 34 are respectively fixed on the sides, the right piston chamber is coaxially provided with a right piston rod 30 whose front end is sealed and passes through the front part of the right piston chamber, and the front end of the right piston rod 30 is provided with a V-shaped first clip with an opening forward. Groove, the first clamping groove is provided with the right cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com