Superfine head of double-row tapered roller bearing outer shell

A technology of tapered roller bearings and jackets, applied in the field of grinding tools, can solve problems affecting production efficiency, affecting processing accuracy, step-by-step super-precision, etc., achieve the effects of improving roundness, improving production efficiency, and avoiding repeated positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

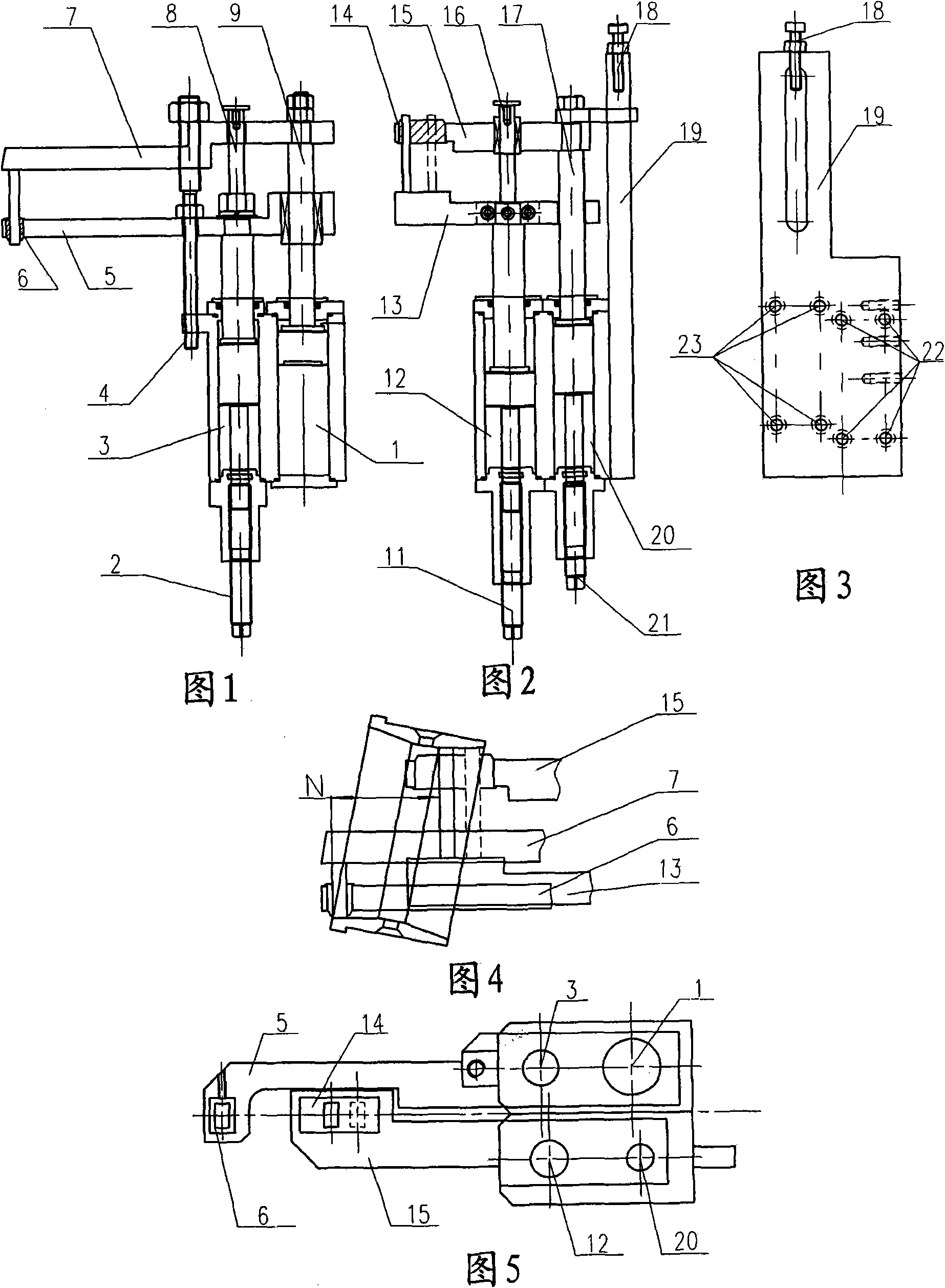

[0012] As shown in the figure: on the connecting plate 19, there are two groups of cylinders. In the first group of cylinders, there are first pressurized cylinders 1 and first jump-in and jump-out cylinders 3 arranged side by side. The first pressing rod 7 is connected on the pressing piston rod 9, and the first knife rest 5 is set on the first jumping piston rod 8 of the first jumping in and out of the cylinder 3, and the first knife rest 5 for fixing the oil stone is set on the first knife rest 5. One oil stone box6.

[0013] In the second group of cylinders, the second jumping in and out cylinder 20 and the second pressurized cylinder 12 arranged side by side are arranged, and the second tool rest 15 is connected on the second pressurized piston rod 17 of the second jumped in and out cylinder 20, A second pressing rod 13 is arranged on the second jumping piston rod 16 of the second pressurizing cylinder 12 , and a second oil stone box 14 for fixing the oil stone is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com