Stamping die capable of achieving blanking and riveting one-time forming

A stamping die and riveting technology, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of cumbersome process and poor processing accuracy, and achieve the effect of improving processing accuracy, avoiding repeated positioning, and avoiding repeated positioning of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

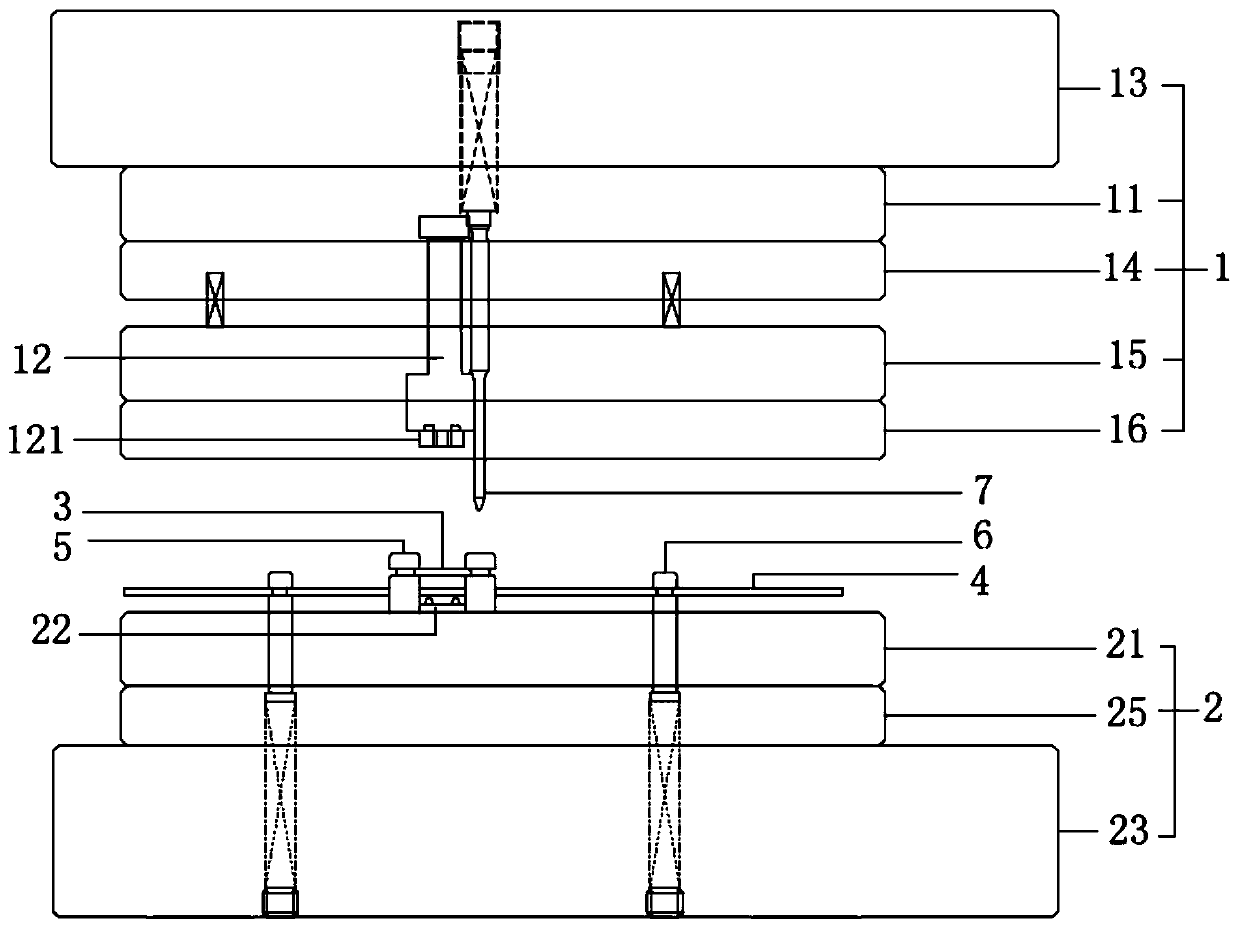

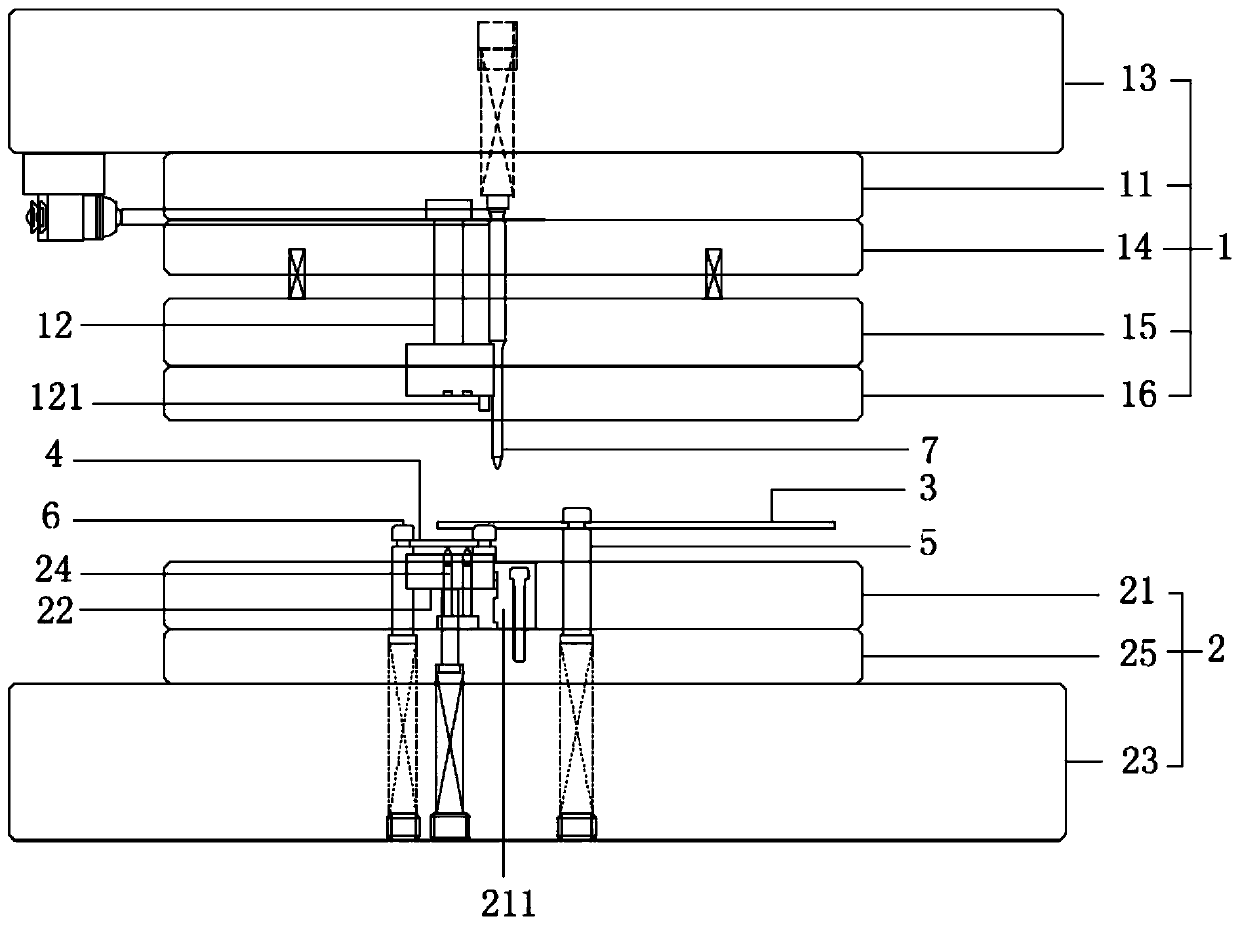

[0025] see Figure 1 to Figure 5 , the figure shows a stamping die for punching and riveting one-time forming provided by Embodiment 1 of the present invention, including:

[0026] Upper mold mechanism 1, which includes an upper template 11, an upper punch 12 is provided at the bottom of the upper template 11, and a forming bump 121 is provided on the bottom end surface of the upper punch 12;

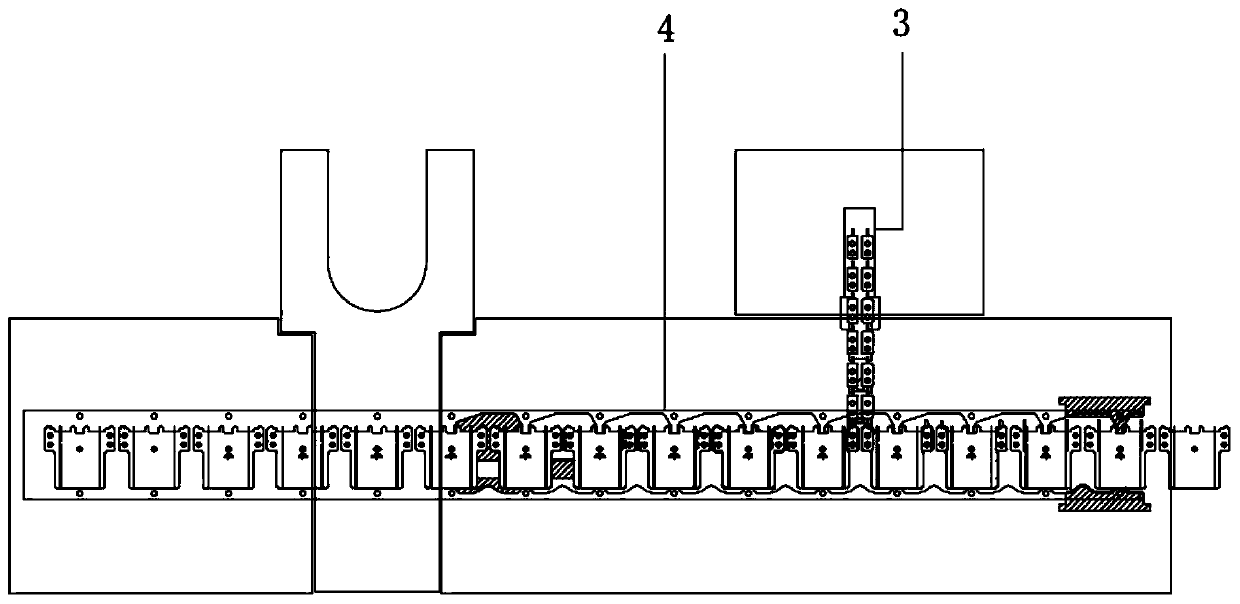

[0027] The lower mold mechanism 2 includes a lower template 21, the first strip 3 and the second strip 4 are fed in a cross mode on the lower template 21, the lower mold 21 is provided with a lower forming male 22, and the lower forming male 22 is elastically connected to the lower mold On the seat 23, the lower forming male 22 is provided with a blanking hole 221 corresponding to the forming bump 121, the lower template 21 is provided with a riveting punch 24, and the riveting punch 24 is arranged on the lower forming male 22, and the bottom of the upper punch 12 A forming groove corr...

Embodiment 2

[0036] see Figure 1 to Figure 5 , the figure shows a punching and riveting stamping die provided by Embodiment 2 of the present invention. On the basis of the above embodiment, this embodiment further makes the following technical solutions as improvements: upper die base 13 is provided with an anti-misfeed detection needle mechanism, and in the anti-misfeed detection needle mechanism, the anti-misfeed detection needle 7 is elastically connected on the upper mold base 13, and the lower forming male 22 is provided with a guide corresponding to the anti-misfeed detection needle 7. Positive groove 222 ; the guiding groove 222 is tangent to the first strip 3 .

[0037] The stamping die detects whether the position of the lower forming male is correct through the cooperation of the anti-misfeed detection needle and the guide groove, and stops stamping if the position deviates, so as to ensure the accuracy of riveting and punching. In addition, since the guide groove is tangent to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com