Clamping clamp for circumferential uniform machining of grooves in cam surface of swing sliding base

A technology with uniform circumferential distribution and cam surface, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of affecting processing accuracy, low processing efficiency, error accumulation, etc., to avoid repeated positioning and improve processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

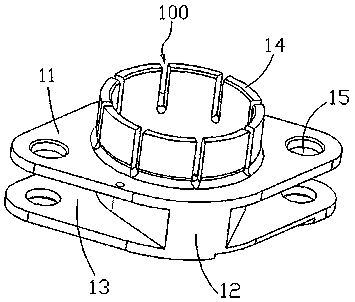

[0023] Such as Figure 2 to Figure 7 , the present invention is a clamping fixture with evenly distributed grooves on the cam surface of the oscillating slide. The oscillating slide includes two connecting pieces 11 arranged in parallel on the upper and lower sides. A slot 13 is formed between the two connecting pieces 11. A connecting block 12 is arranged in the card slot 13 , and the connecting block 12 is integrally formed with the two connecting pieces 11 . A cam surface 14 is provided on the upper end surface of the upper connection piece 11 , and a connection hole 15 is provided at both ends of each connection piece 11 .

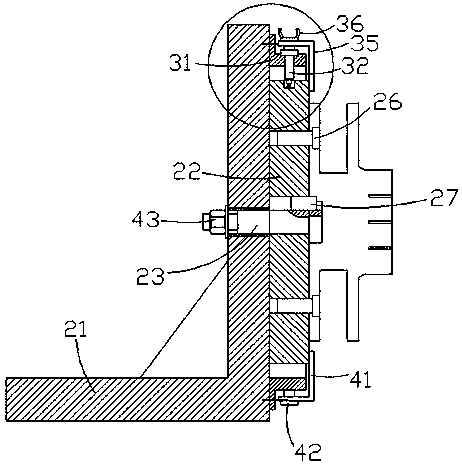

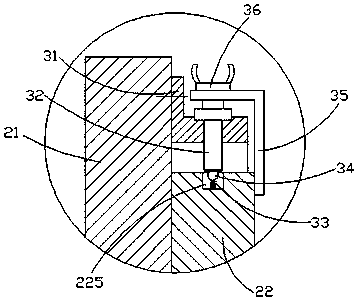

[0024] The fixture of the present invention for clamping the swing slide includes a seat body 21, a turntable 22, a rotating shaft 23, a positioning nail 26, a key 27, a fastening screw 28, a pressure plate 29, a reference seat 31, a reference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com