Rapid feeding and grabbing device and feeding method thereof

A material grasping and fast technology, which is applied in the field of fast loading and grabbing devices, can solve the problems of reducing fast loading and production beats, and achieve the effects of avoiding repeated positioning, improving efficiency, and saving positioning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

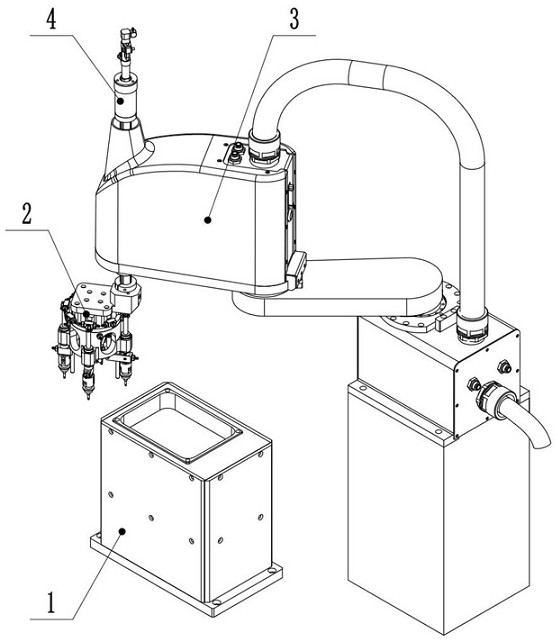

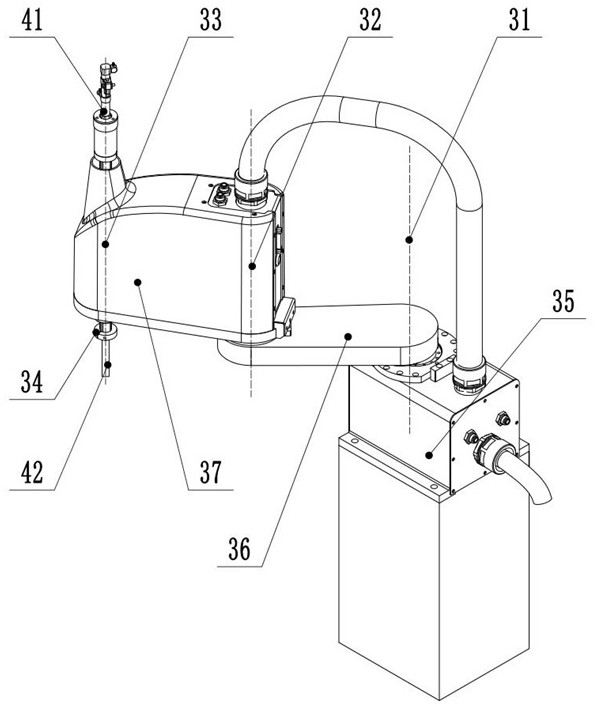

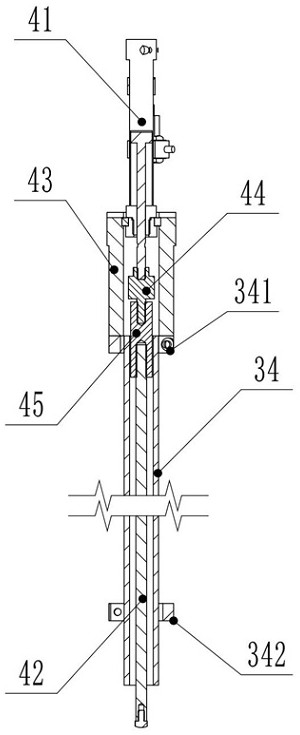

[0032] Such as Figure 1-5 A fast loading and grabbing device is shown, which is used for quickly grabbing regularly stacked materials on the material table, improving the efficiency of equipment grabbing materials, and thus improving production efficiency. The device moves the manipulator 2 directly above the material table 1 through the rotation of the robot arm 3. After obtaining the position information of the material on the material table, the robot arm 3 further aligns the axis of the pressing part 4 with the material to be grasped. The piston rod of the cylinder 41 pushes the pressure rod 42 to press down, and the pressure rod 42 drives the push rod 234 coaxial with it to press down, and the negative pressure at the end of the suction nozzle 231 is used to suck the material. After the material is absorbed, the rebound component 25 dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com