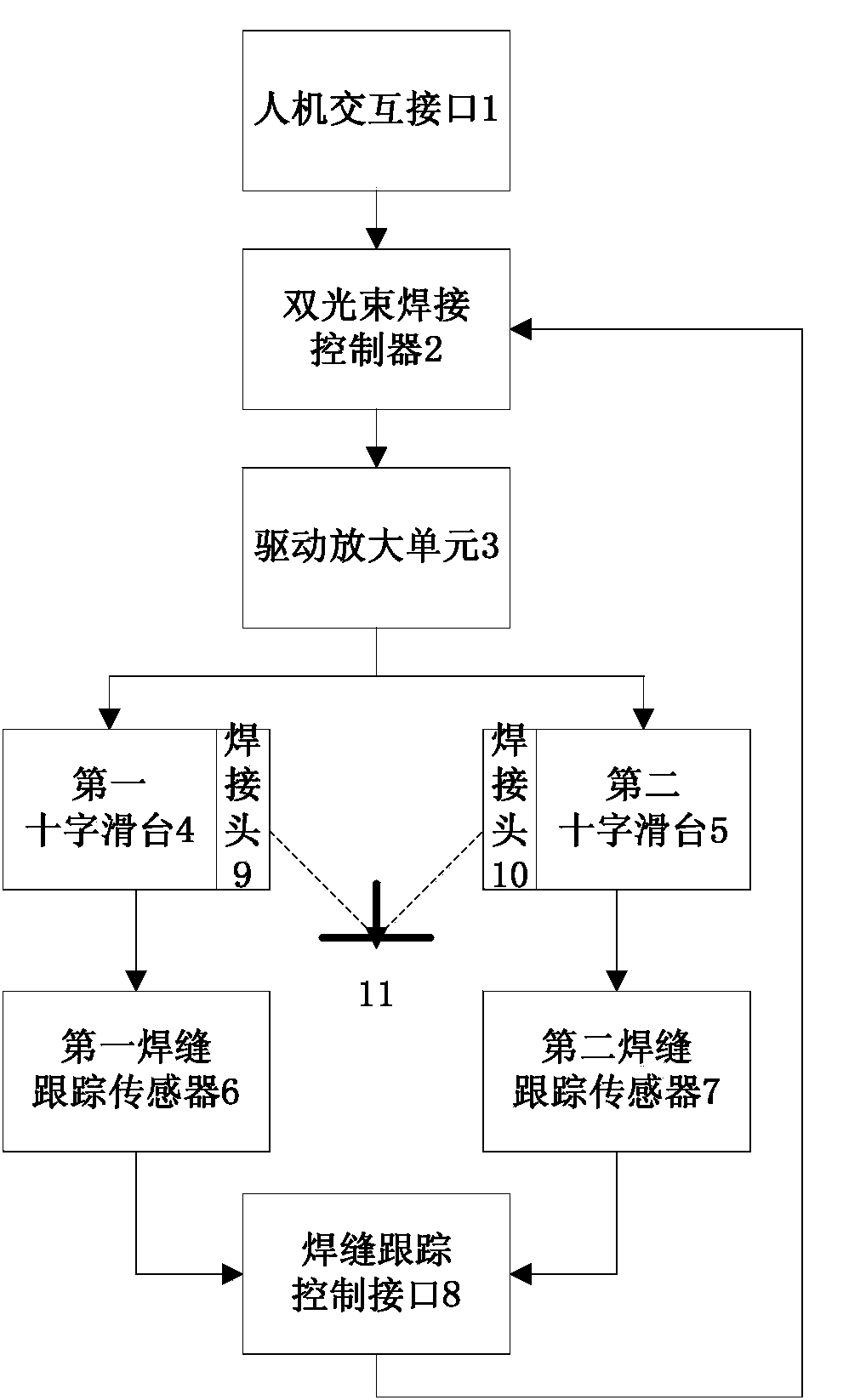

Double-beam welding seam tracking control system

A tracking control and dual-beam technology, which is applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of welding precision influence, welding precision reduction, processing difficulties, etc., to improve welding precision, reduce welding deformation, avoid The effect of repeated positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

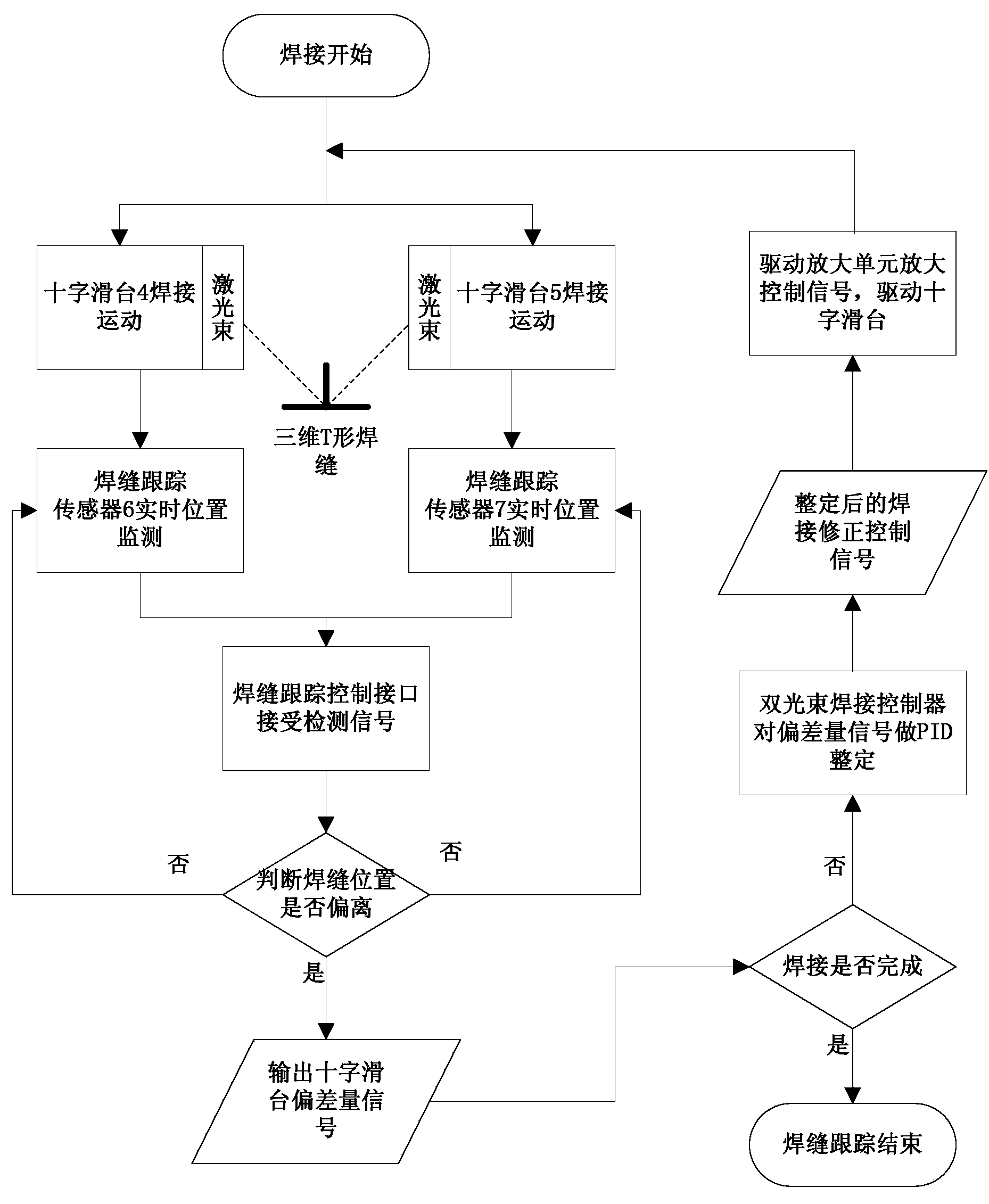

Method used

Image

Examples

Embodiment Construction

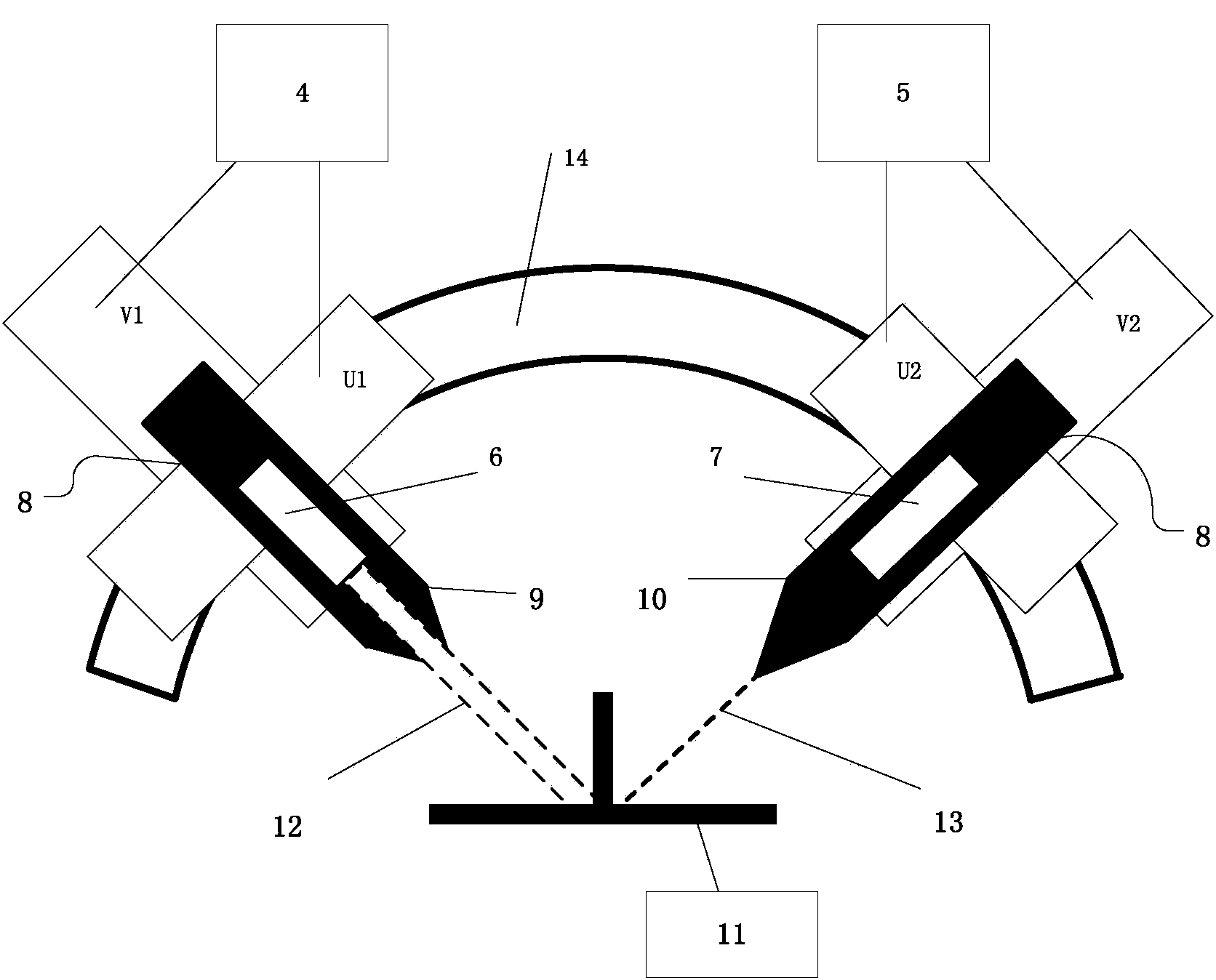

[0014] For three-dimensional T-shaped welds, laser welding is difficult to process and poor in manufacturability. Because laser welding is mostly carried out by robots driving laser welding heads, robots have low processing precision for three-dimensional paths, poor fitting, and difficult processing. This is an inherent defect of the robot system. obvious. In addition, the robot can only fix one side of the T-shaped weld, and two robots are required for welding on both sides. Two different robots cannot control the same processing parameters on both sides of the T-shaped weld, resulting in uncertainty in the welding process. .

[0015] At present, for the processing technology of T-shaped welds, laser beams are generally used to hit one side of the weld first, so that one side is welded first, and then repositioned to process the other side. This processing method has two disadvantages. One is to repeat the processing twice, and the repeatability error is inevitable. The ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com