Hourglass worm turning and grinding complex machine tool based on turning center

A technology of toroidal worms and compound machine tools, which is applied in the direction of worms, mechanical equipment, and components with teeth, etc., can solve the problems of low efficiency, achieve the effects of avoiding repeated positioning, improving processing efficiency, and ensuring processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be described below according to the accompanying drawings.

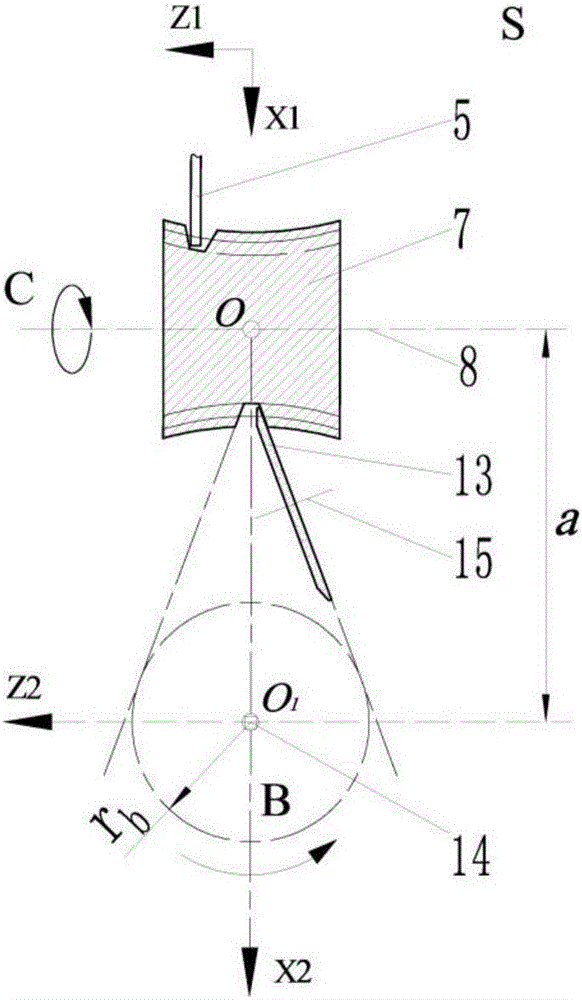

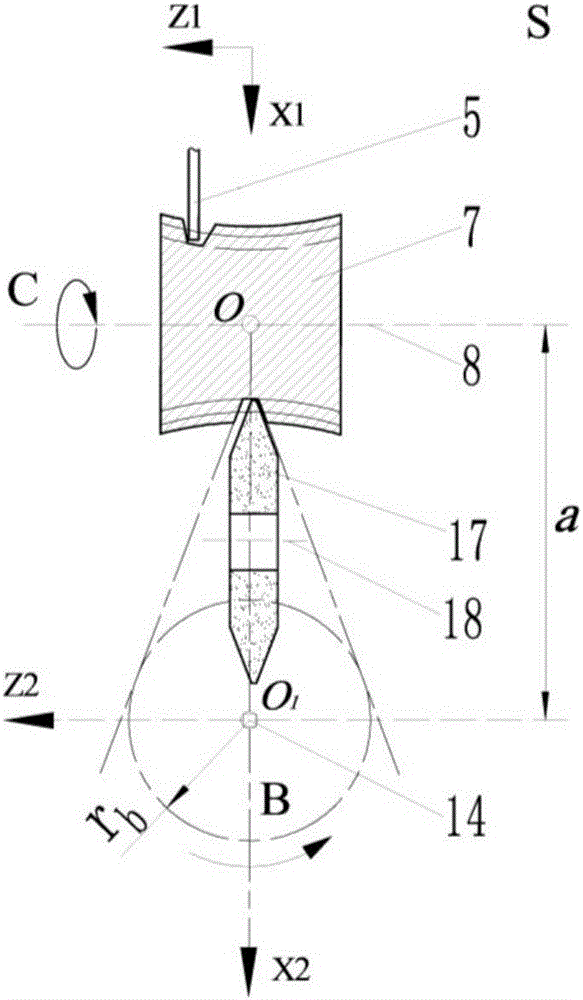

[0019] Taking the modified toroidal worm pair as an example, the relevant parameters are: number of right-handed toroidal worm heads z 1 =1, the number of worm gear teeth z 2 =40, meshing center distance a=250mm, transmission ratio i=40, worm gear end face modulus m t =10.45mm, main base circle diameter d b =158mm, worm working length L w =130mm, turntable angle φ d The value range of 0~0.8rad.

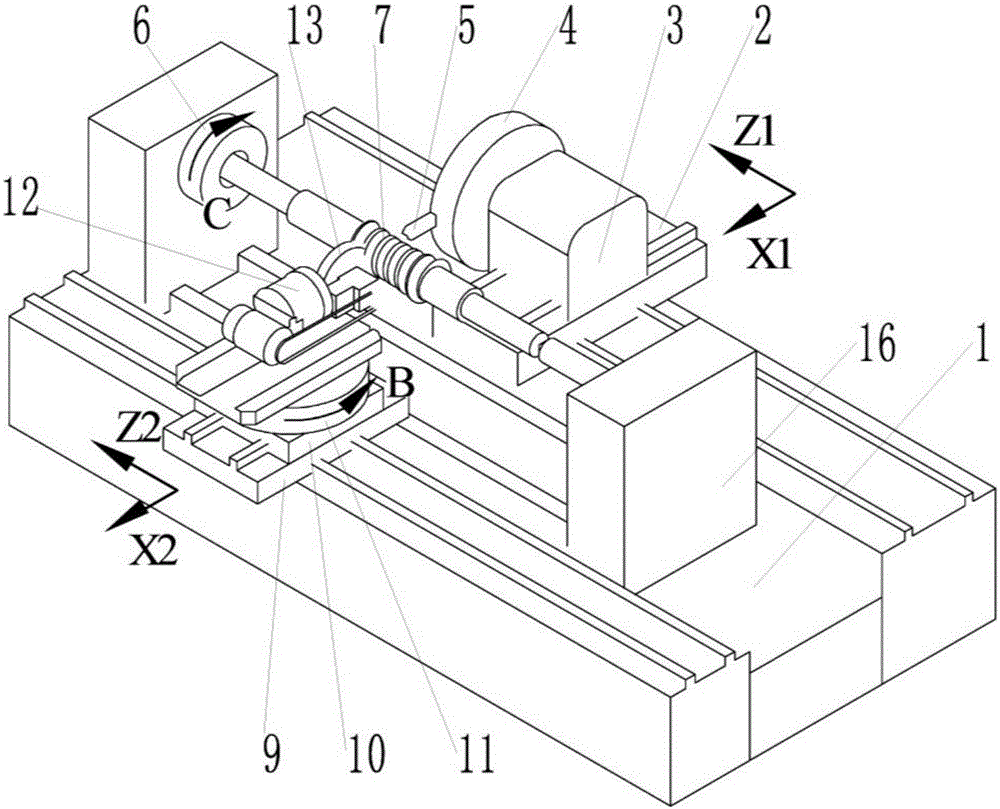

[0020] image 3 It is the structural diagram of the toroidal worm turning and grinding compound machine tool based on the turning center. The toroidal worm turning and grinding compound machine tool based on the turning center includes: the bed (1), the turning longitudinal slide plate (2) and the turning transverse slide of the turning center Plate (3), tool holder (4), turning tool (5), chuck (6), torus worm (7), worm axis (8), grinding longitudinal slide (9) and grind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com