Drilling and chamfering composite quick forming tool

A technology for forming cutting tools and cutting tools, which is applied in the directions of drilling tool accessories, drilling and manufacturing tools, etc., which can solve the problems of waste of resources, affecting the accuracy of processing, and increasing cycle time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

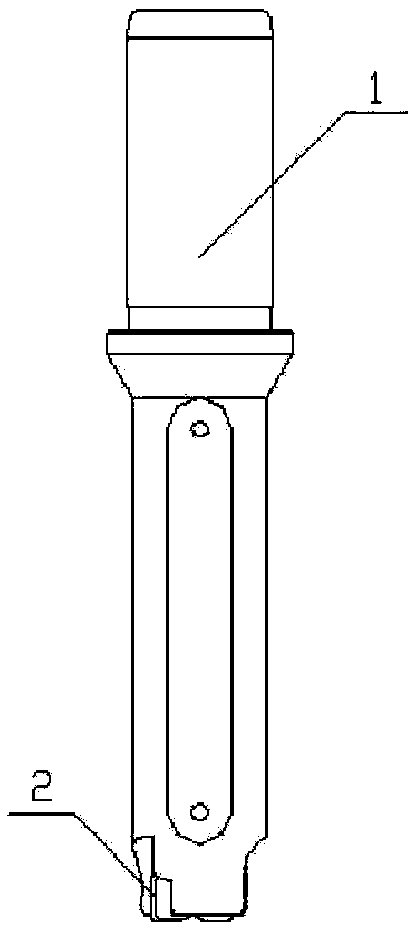

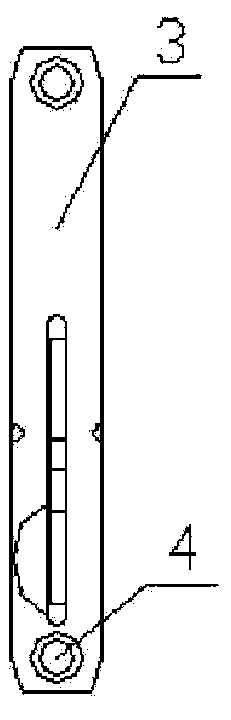

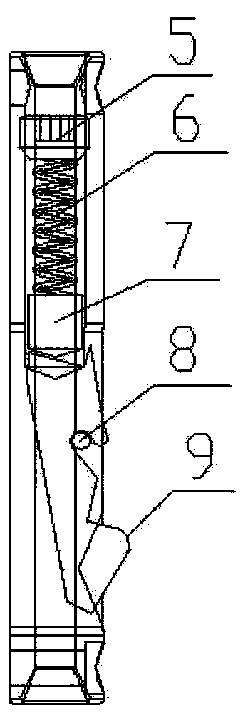

[0012] The drill inverted composite rapid prototyping tool of the present invention is made up of tool handle, knife core, spring, tightening bolt head, pin, ejector rod, M3 bolt, drilling blade and inner hole chamfering blade; At one end, the drilling blade is located on the end surface of the other end of the tool to drill the workpiece; the tightening bolt head, the spring and the ejector rod are located In the axial direction between them, the cutter core is provided with a hole, and the inner hole chamfering blade is installed in the hole, and the inner hole chamfering blade is fixed by the pin at the engaging position, so One end of the inner hole chamfering blade is supported by the lower end of the push rod, and the other end is used to remove burrs; the upper end of the spring is against one end of the tightening bolt head, and the lower end of the spring is against the The upper end of the push rod; the tightening bolt head is used to adjust the length of the spring,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com