Limiting and clamping device for machining center

A technology of machining center and clamping device, which is applied in the direction of clamping device, positioning device, metal processing, etc., can solve the problem of difficulty in meeting the continuous production requirements of machining centers, poor clamping efficiency and positioning accuracy, affecting feeding efficiency and positioning accuracy, etc. problems, to meet the needs of compact continuous production, improve positioning accuracy, and reduce life loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

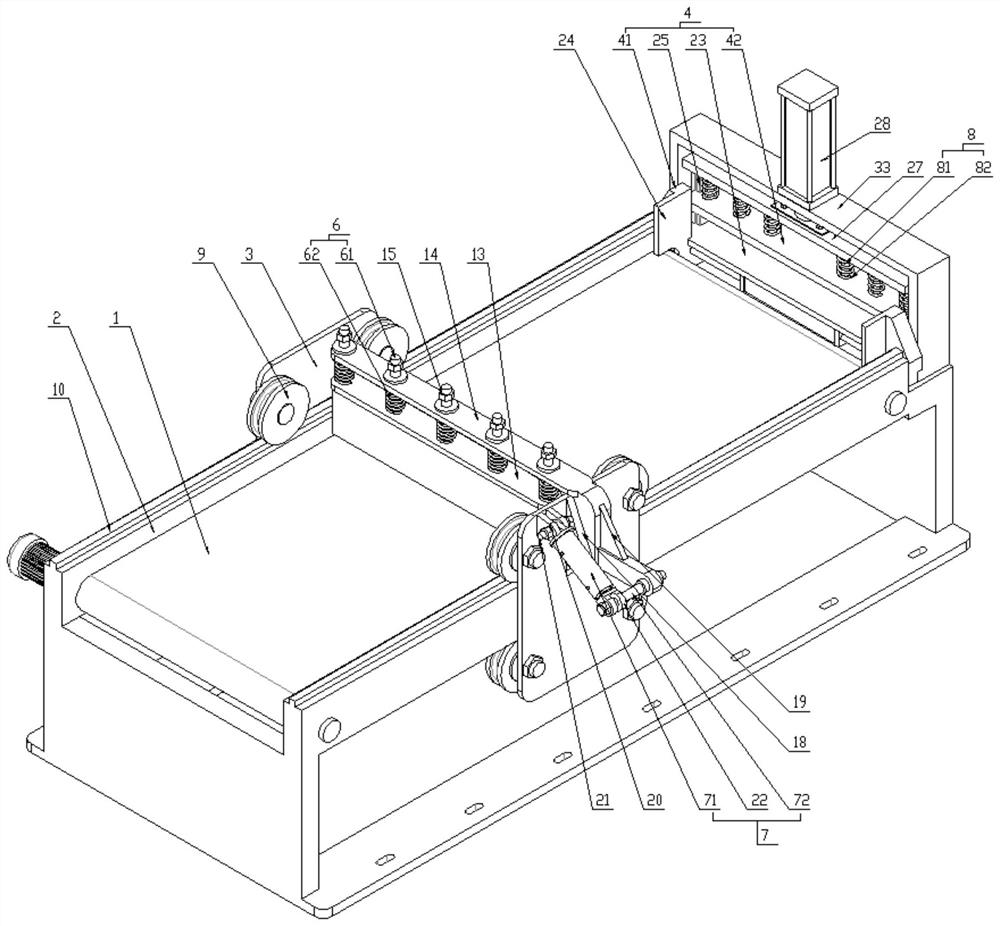

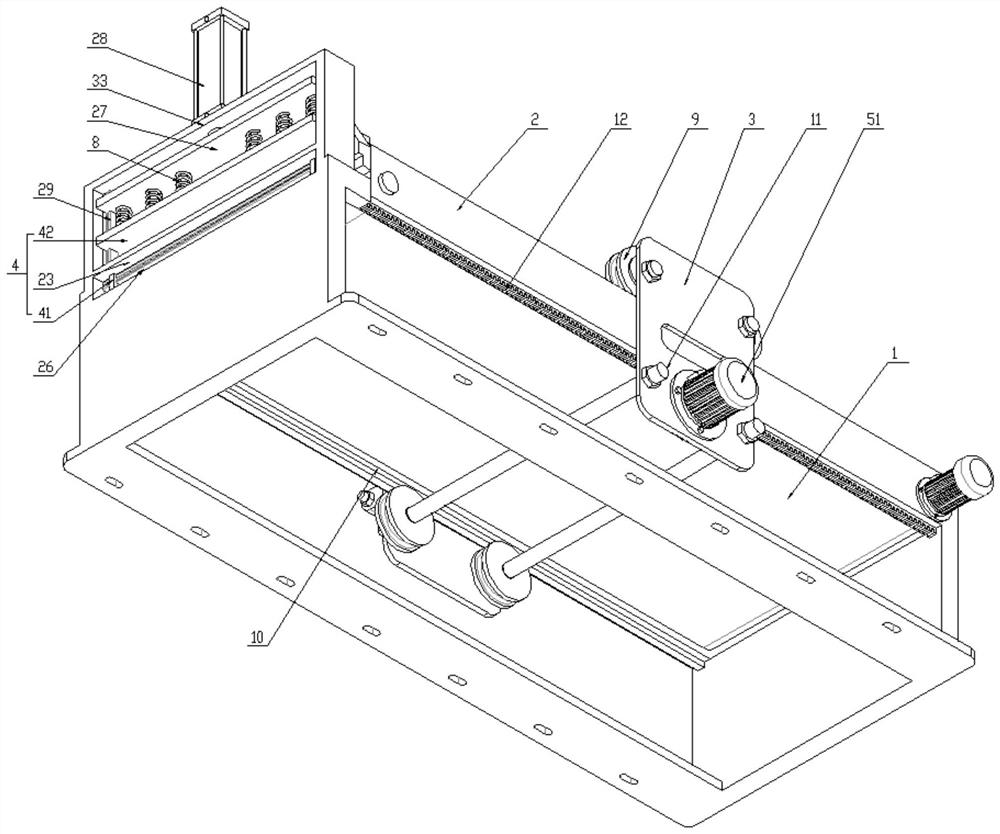

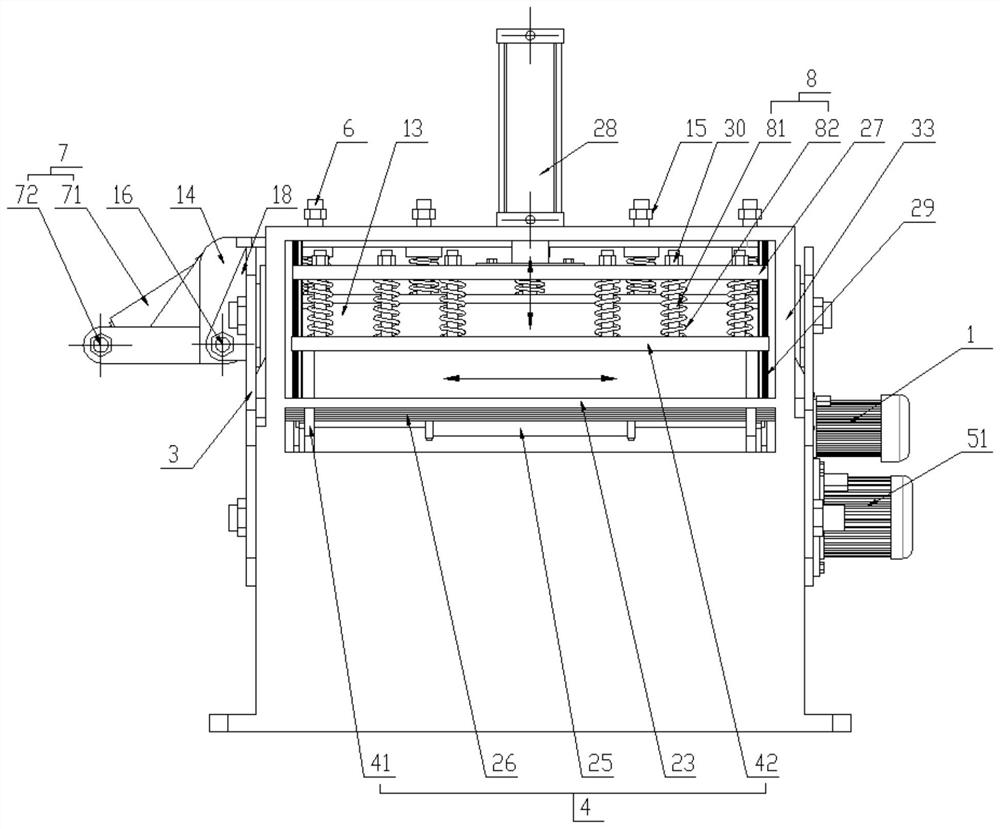

[0027] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0028] A limit clamping device for a machining center, comprising a frame 2 outside the conveyor 1 of the machining center, wherein the frame 2 is provided with at least one limit frame 3 and a clamping mechanism 4, the limit frame 3, a traveling drive mechanism 5 is provided on one side, and the traveling driving mechanism 5 is used to drive the limit frame 3 to reciprocate along the parallel direction of the conveyor 1;

[0029] The spacer 3 includes a first shelf 31 and a second shelf 32 positioned on both sides of the frame 2, and at least one roller 9 is arranged inside the first shelf 31 and the second shelf 32. The frame 2 is provided with a raceway 10 parallel to the conveyor 1 and located at the bottom of the rollers 9 or between the corresponding rollers 9 and rolling with the rollers 9. The rollers 9 at the bottom of the frame 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com