Brush roller and metal plate surface rust removal treatment device

A metal plate and brush roller technology, applied in metal processing equipment, manufacturing tools, grinding machines, etc., can solve the problems of easy wear and tear of abrasive wire, high price of abrasive wire, and high cost of rust removal, and achieve the effect of reducing the cost of rust removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

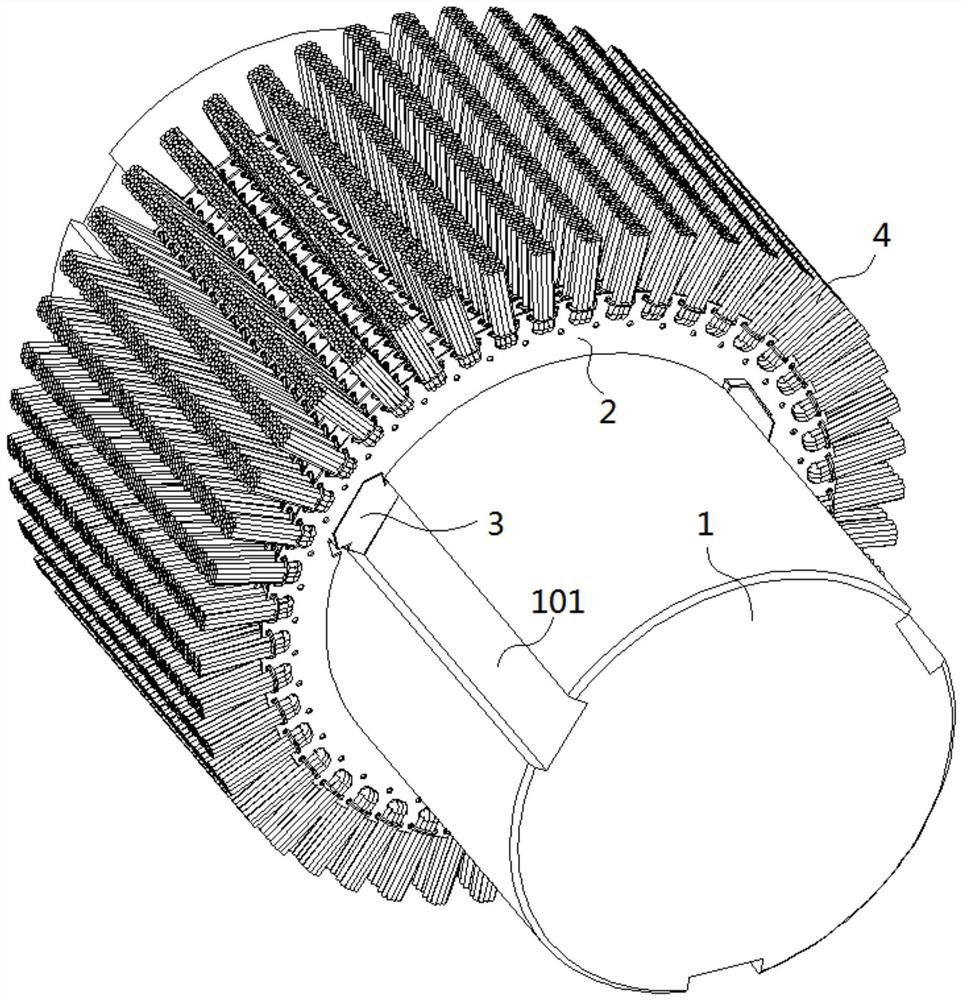

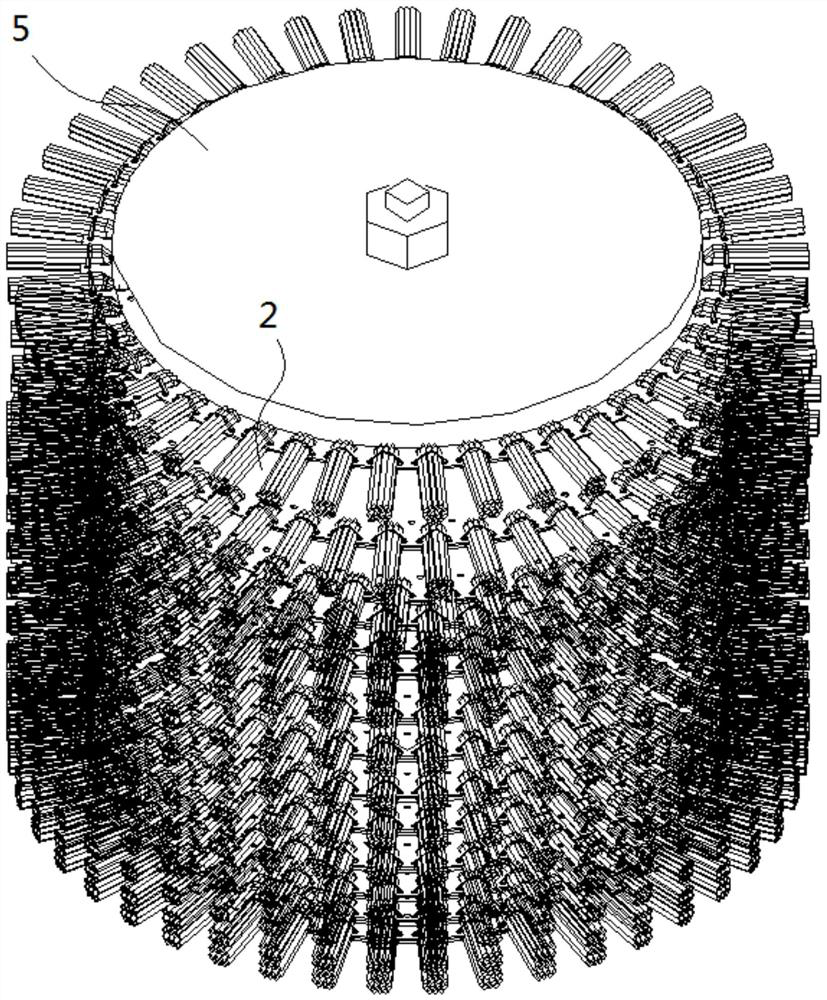

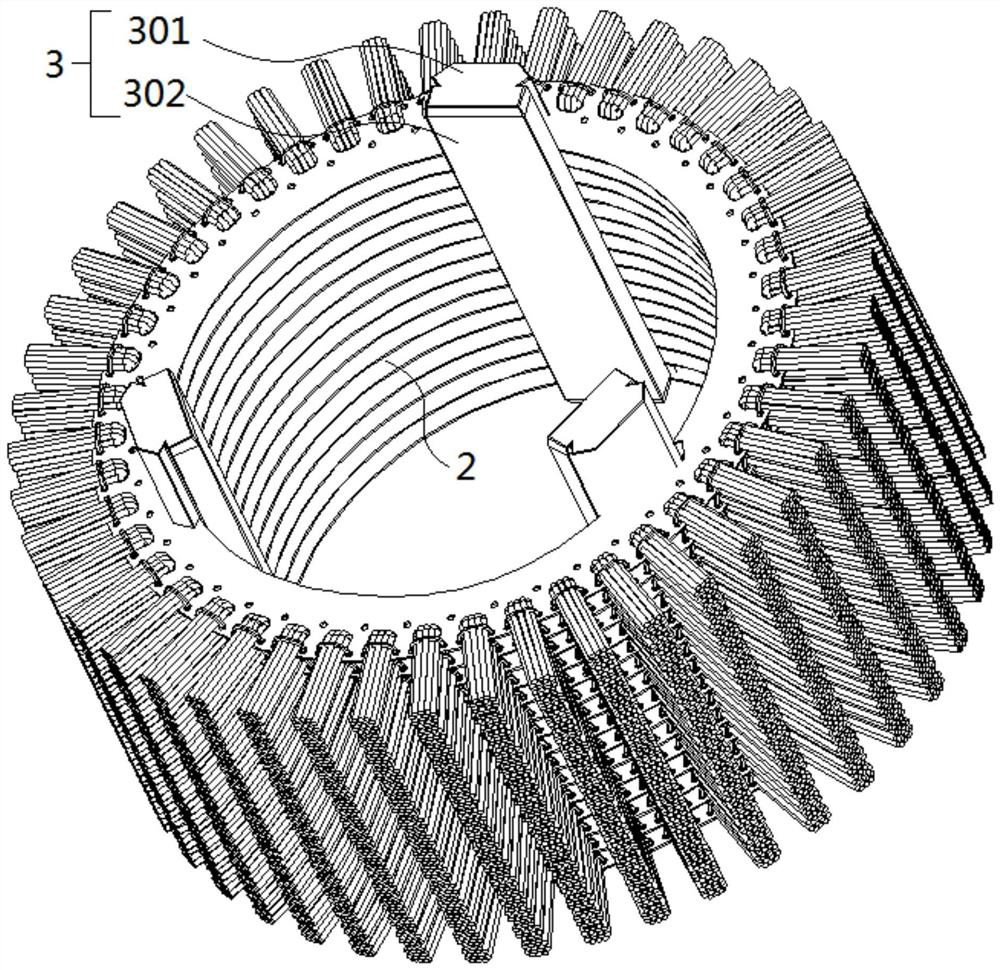

[0048] Example 1: See Figure 5-8 , the present embodiment proposes a metal material surface derusting equipment, including a frame on which a pre-treatment device and several second brush rollers are sequentially arranged along the conveying direction of the metal plate 11 . In this solution, the pre-treatment device includes a fixed seat 10, a sandblasting pipe 9. and a first brush roller 7. Wherein the fixed seat 10 includes a top plate 1001, the left and right ends of the top plate 1001 are provided with connecting blocks 1002, the roller core 701 of the first brush roller 7 runs through the connecting blocks 1002 at the left and right ends of the top plate 1001, so that the first brush roller 7 can The connecting blocks 1002 relative to the left and right ends of the top plate 1001 rotate. And one end of the first brush roller 7 is connected with a motor through a transmission shaft, and the first brush roller 7 can rotate relative to the fixed seat 10 under the drive of...

Embodiment 2

[0069] Example 2: See Figure 9 The main difference between this embodiment and the metal material surface derusting equipment proposed in the above-mentioned embodiment 1 is that a baffle plate 1003 is provided on the peripheral side of the fixing seat 10 . The baffle 1003 is fixedly connected with the top plate 1001, and the baffle 1003 prevents sand from splashing out of the equipment during the rust removal process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com