Rust removal construction method for reserved steel bars in buildings

A technology for reserving steel bars and construction methods, applied in the direction of manufacturing tools, metal processing equipment, and used abrasive processing devices, can solve the problems of low rust removal efficiency and poor rust removal effect, and achieve shortened construction period and clean The effect of good degree and avoiding cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

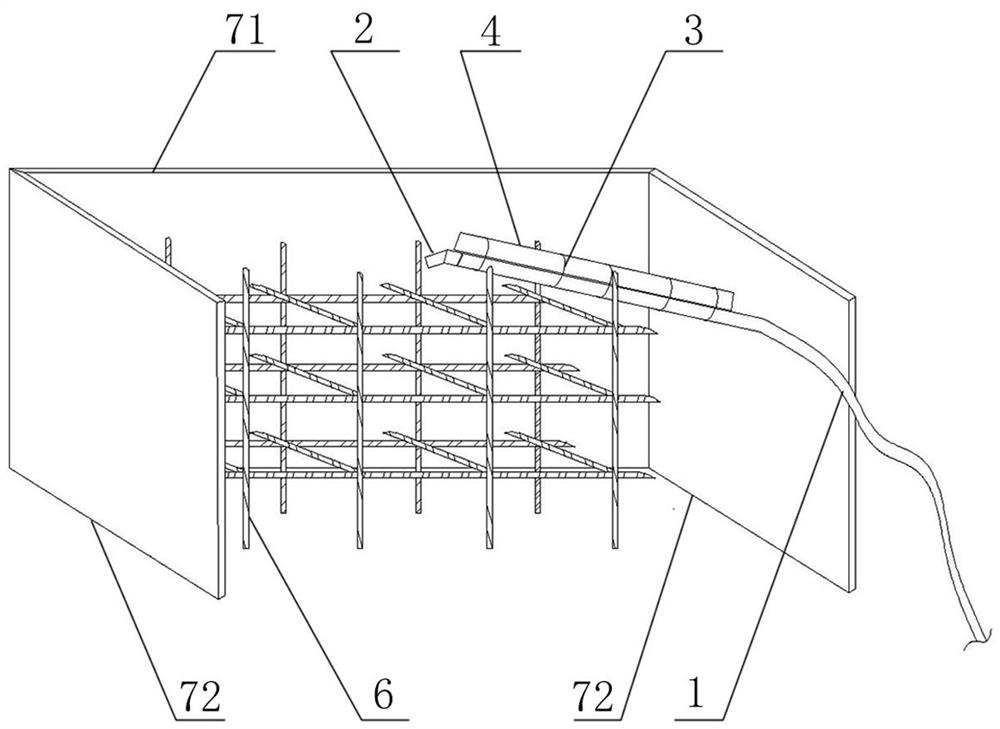

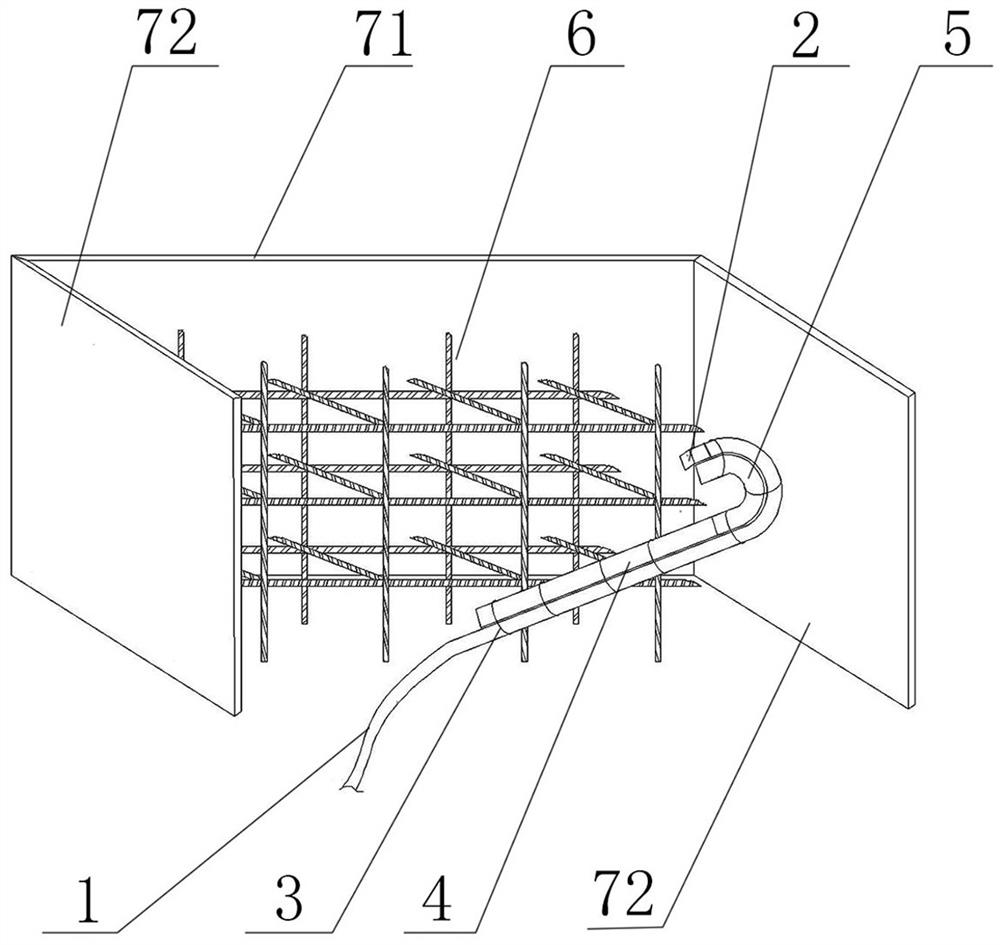

[0021] Such as figure 1 and figure 2 Shown, the construction method for derusting steel bars reserved for building in the present invention may further comprise the steps:

[0022] a. Prepare dry sand material. The particle size range of the sand material is 0.25mm~0.35mm. The sand material is made of quartz sand, corundum or mixed sand made of quartz sand and corundum.

[0023] B, prepare air compressor and sandblasting machine, according to sandblasting machine model, be equipped with corresponding specification air compressor, in the present embodiment, the height of sandblasting machine body is 1500mm, diameter 600mm, volume is 0.3 cubic meter, air The displacement of the compressor is 2 cubic meters per minute, and the rated power of the air compressor is 15Kw. There are movable casters at the bottom of the air compressor and the bottom of the sandblasting machine respectively. The air outlet of the air compressor is connected and communicated with the air inlet of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com