High-pressure water jet flow system for removing rust of ships and working method thereof

A high-pressure water jet, ship technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc. Low rust cost, strong equipment versatility, and energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

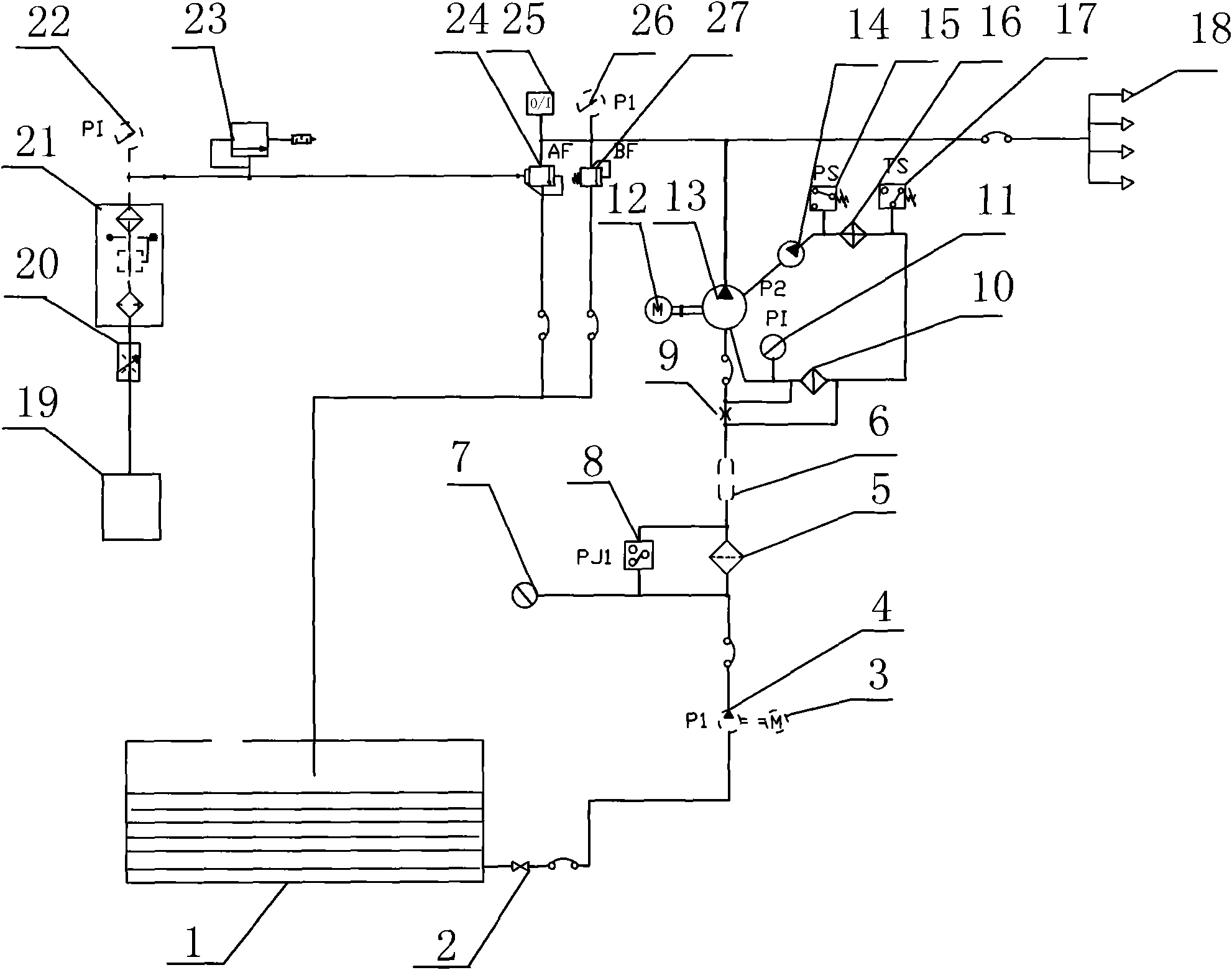

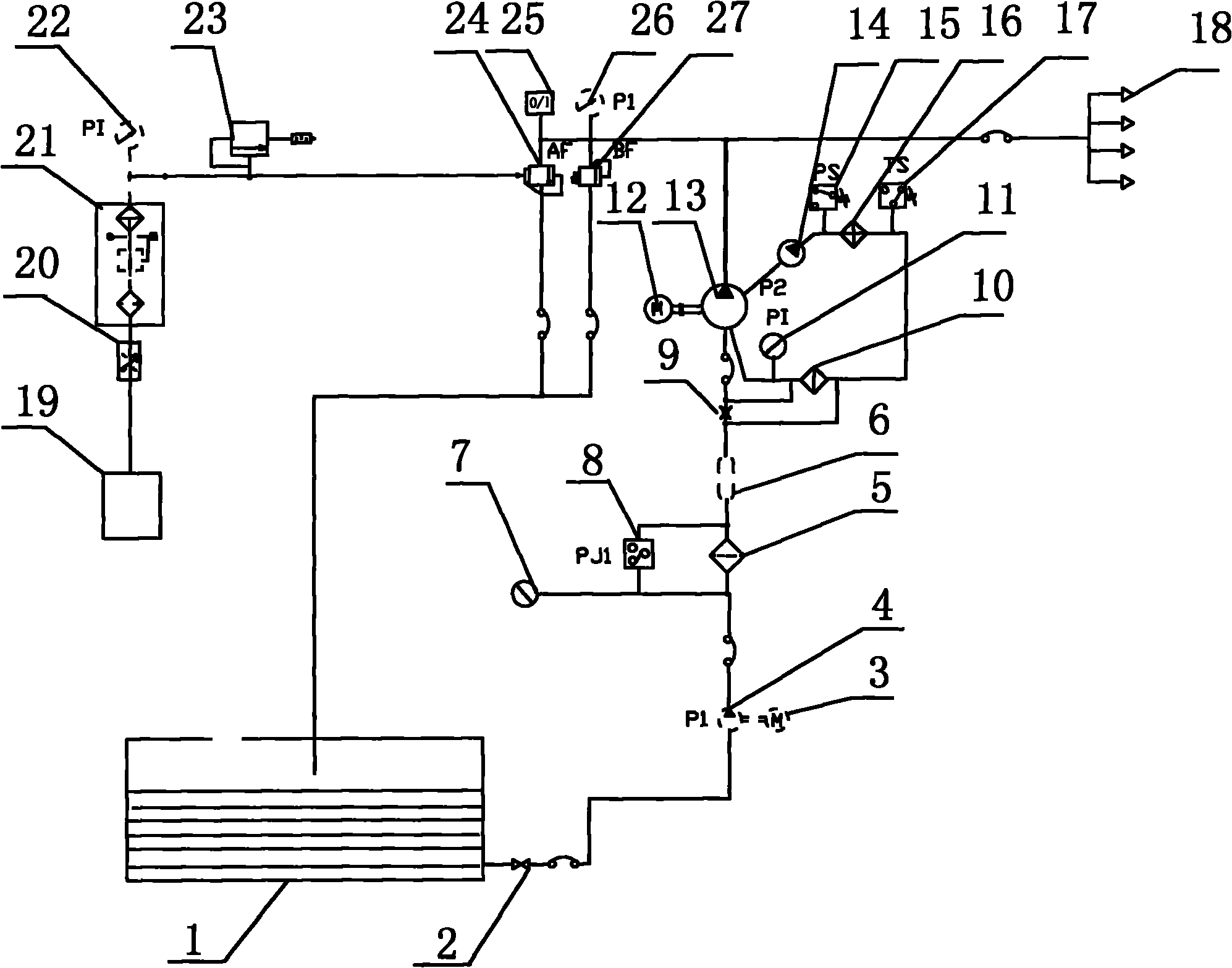

[0020] The present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 As shown, a ship derusting high-pressure water jet system includes a low-pressure water pipeline, an ultra-high-pressure water pipeline, a cooling pipeline, and a pneumatic pipeline; the low-pressure water pipeline includes a low-pressure water tank 1, a low-pressure throttle valve 2, and a front motor 3. Front pump 4, low-pressure filter 5, suction stabilizer 6, low-pressure pressure gauge 7, low-pressure pressure relay 8, the ultra-high pressure water pipeline includes ultra-high pressure pump lubricating oil cooler 10, cooling pressure gauge 11, ultra-high pressure Motor 12, ultra-high pressure pump 13, described cooling pipeline includes lubricating oil cooling pump 14, cooling pressure relay 15, cooling filter 16, cooling temperature relay 17, described pneumatic pipeline includes derusting nozzle 18, air source 19 , gas throttle valve 20, decompre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com