Patents

Literature

35results about How to "To achieve the purpose of rust removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

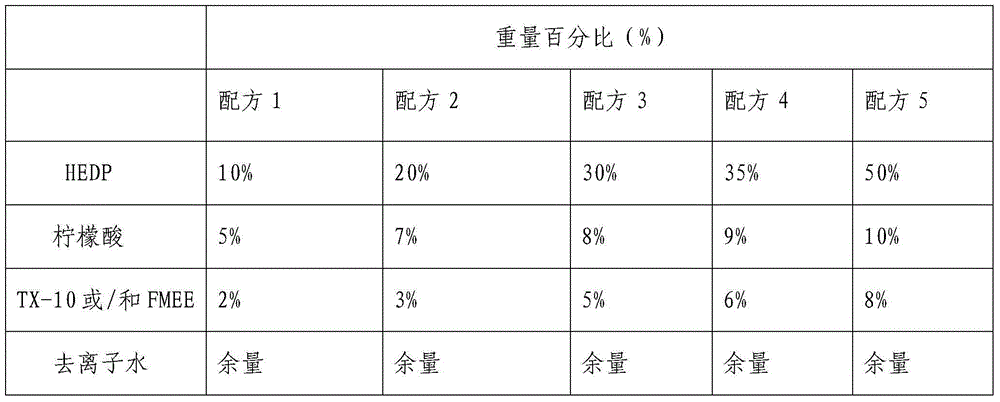

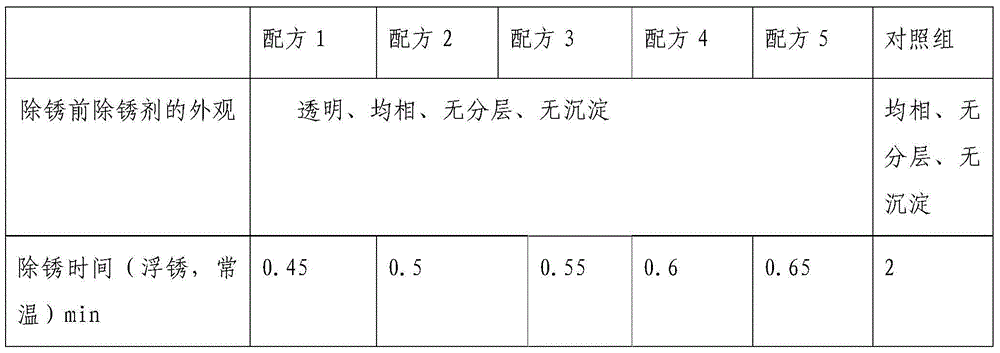

A steel environmental rust remover

The invention discloses a steel environmental rust remover. The rust remover comprises the following components by weight percentage: 10-50 % of organic phosphonic acid, 5-10 % of citric acid, and 3-5% of surfactant, with the balance being water. The surfactant is one of TX-10 and FMEE or a mixture of both. By adopting the technical solution of the invention, good rust removing effect can be achieved, the rust removing process is gentle and does not damage the surface of a steel article, and the use and manufacturing cost is low.

Owner:赵理奎

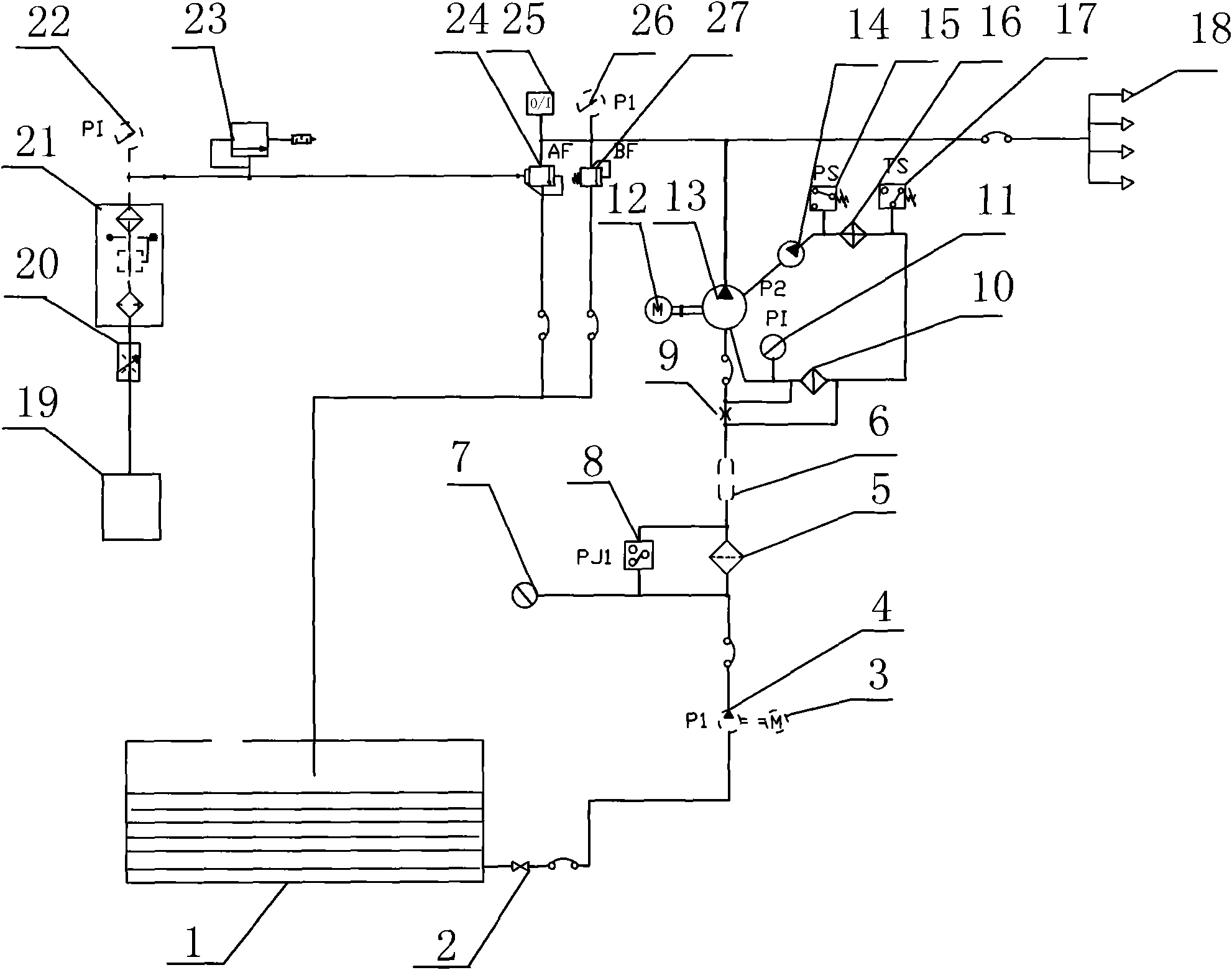

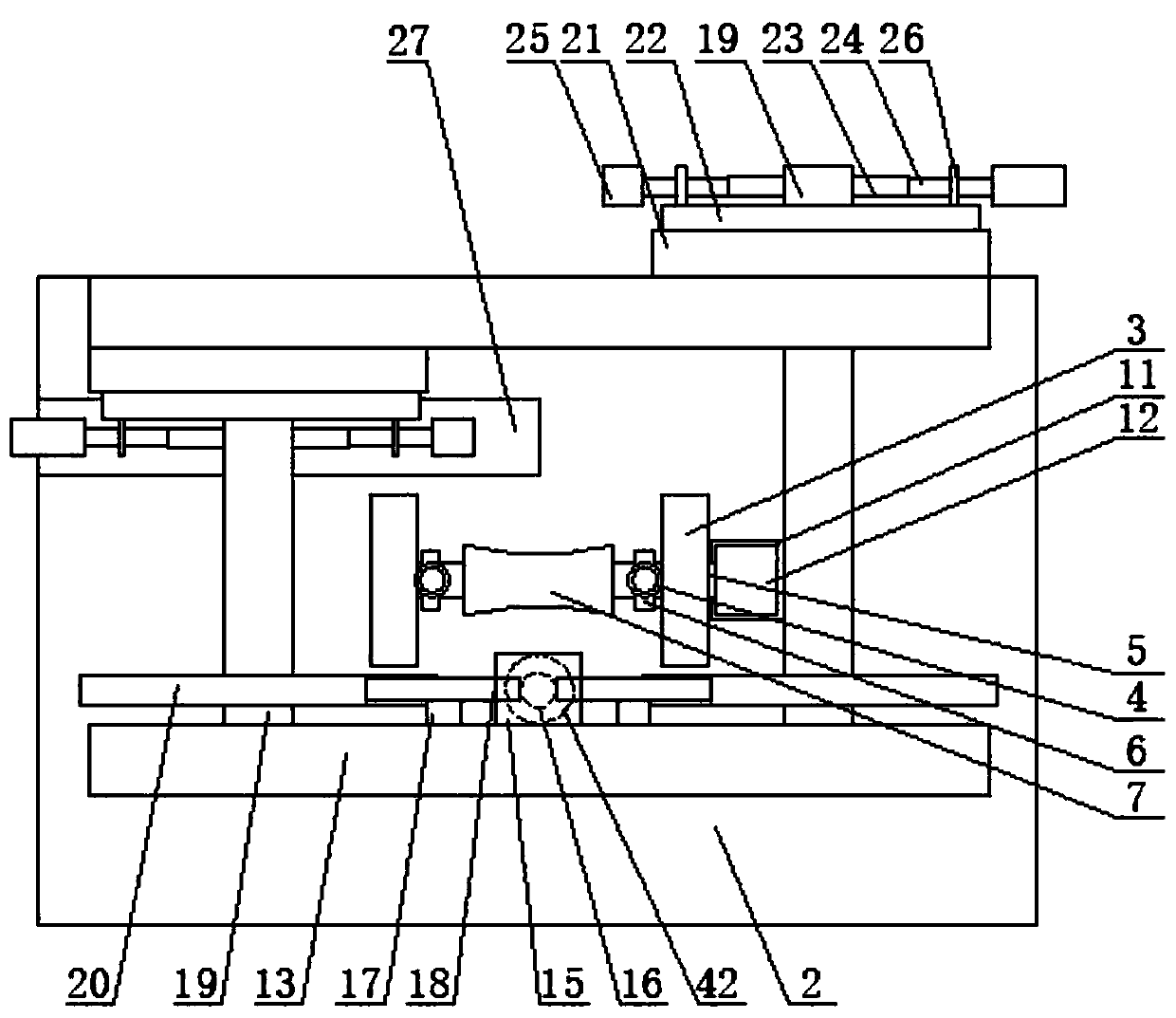

High-pressure water jet flow system for removing rust of ships and working method thereof

InactiveCN101875045ASolve delivery problemsHigh energy level densityCleaning using liquidsVolumetric Mass DensityHigh pressure water

The invention discloses a high-pressure water jet flow system for removing rust of ships and a working method thereof. The system of the invention comprises a low-pressure water pipeline, a super-high pressure water pipeline, a cooling pipeline and a pneumatic pipeline, wherein the super-high pressure water pipeline comprises a lubricating oil cooler of a super-high pressure pump, a cooling pressure gauge, an super-high pressure motor and the super-high pressure pump; one end of the lubricating oil cooler of the super-high pressure pump is also connected with the super-high pressure pump through the cooling pressure gauge; the other end is connected the super-high pressure pump sequentially through a cooling temperature relay, a cooling filter, a lubricating oil cooling pump and a cooling pressure relay; and a rust removing nozzle is installed at the output end of the super-high pressure pump. The method comprises the steps of sucking stable water flow to be converted into super-high pressure water and jetting the super-high pressure water out through the rust removing nozzle. In the invention, because the high pressure water with the pressure up to 250 MPa, which is generated by the super-high pressure pump, is directly used to be passed through a spray nozzle and the high-speed water flow with extreme high level density is jetted out, the rust removing effect is good and delivering abrasive materials is not needed.

Owner:DALIAN MARITIME UNIVERSITY

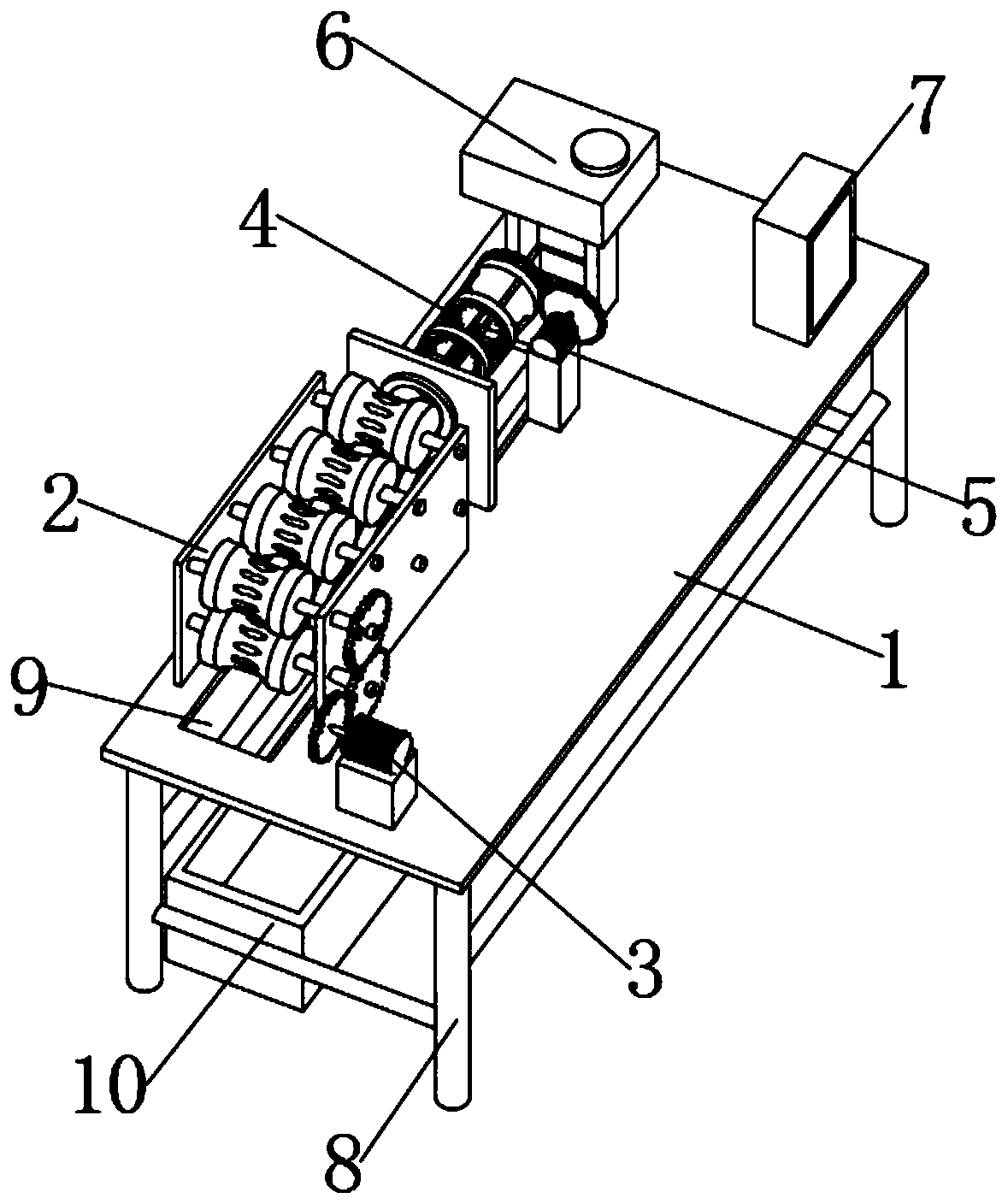

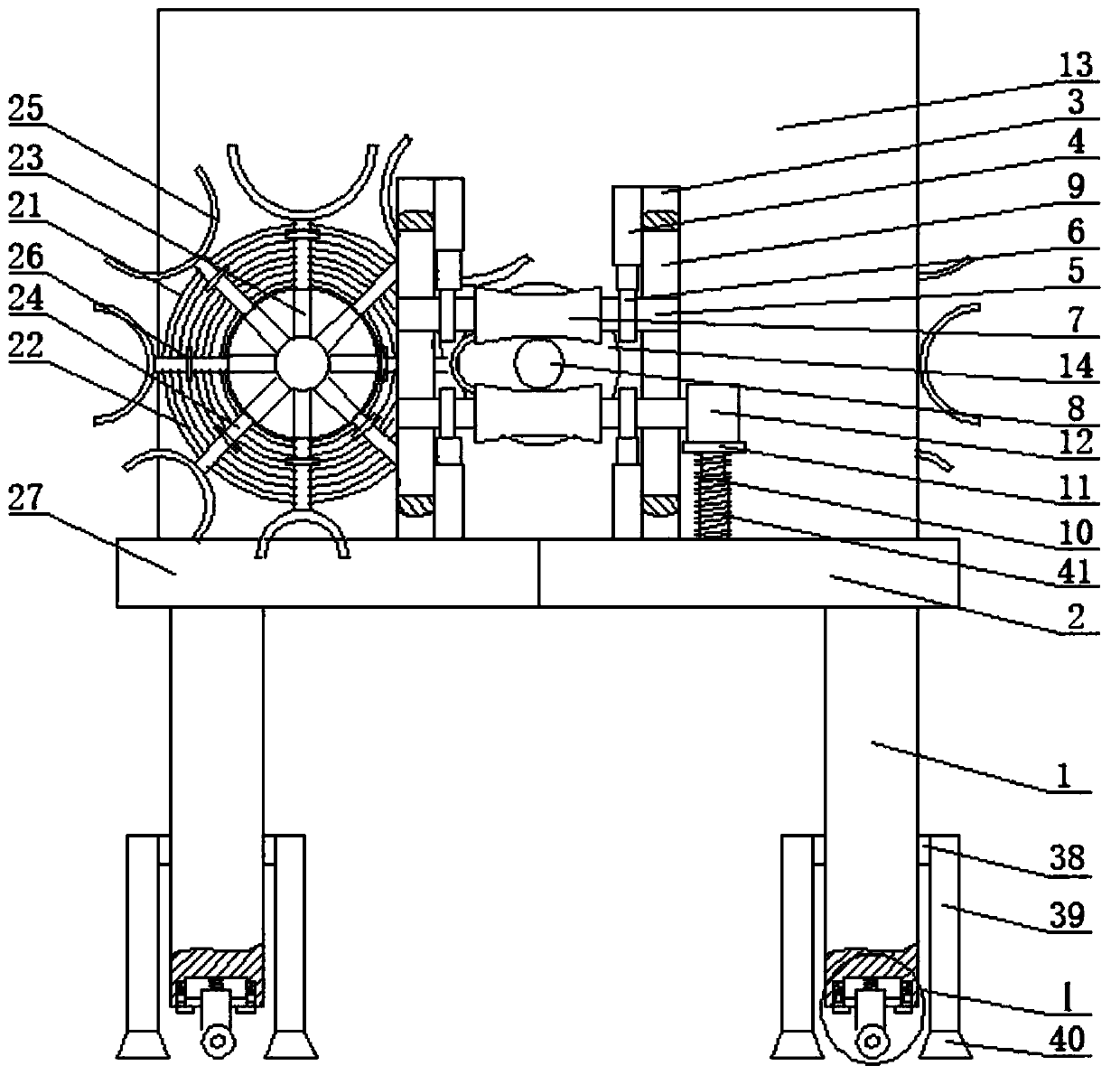

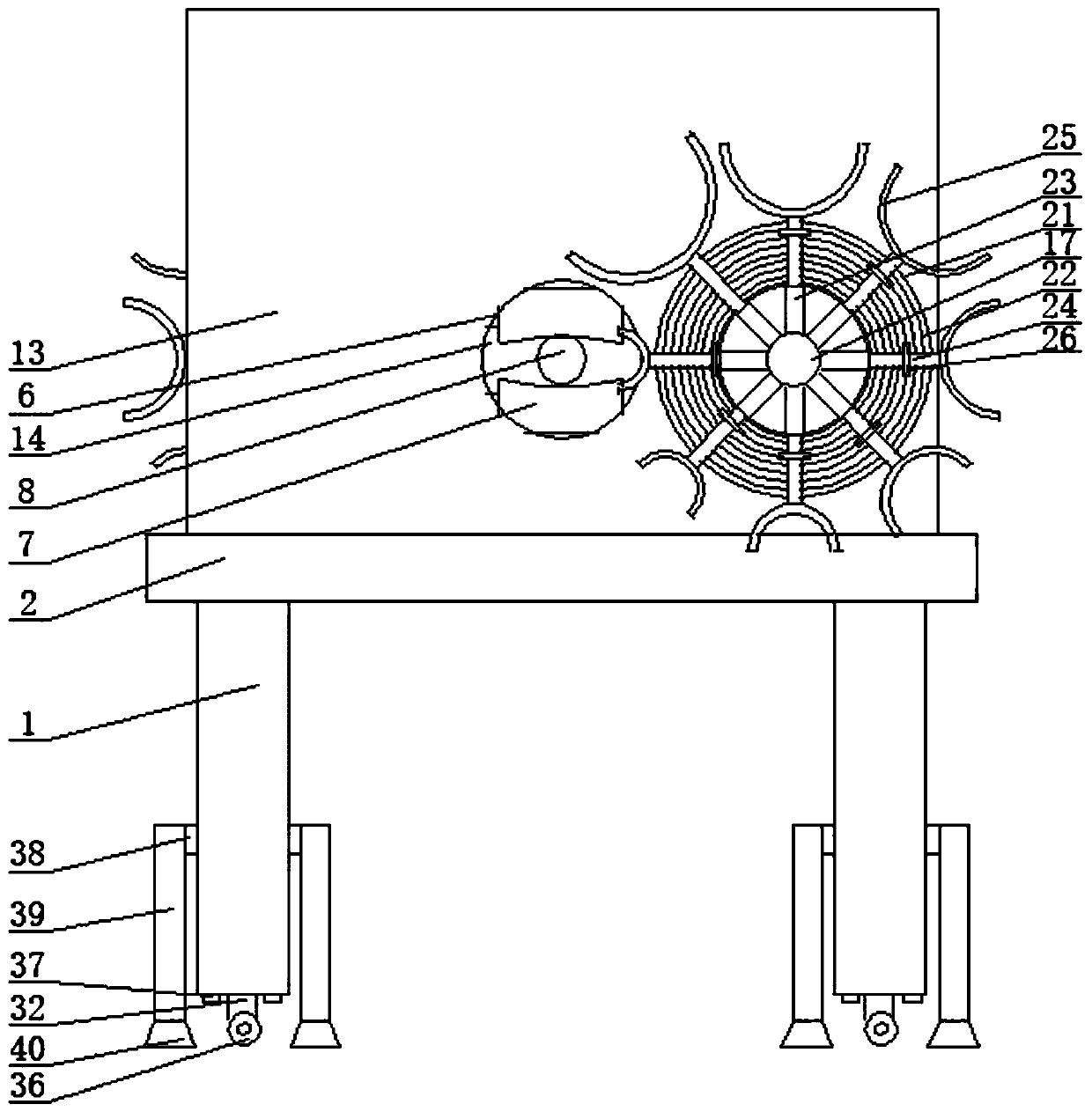

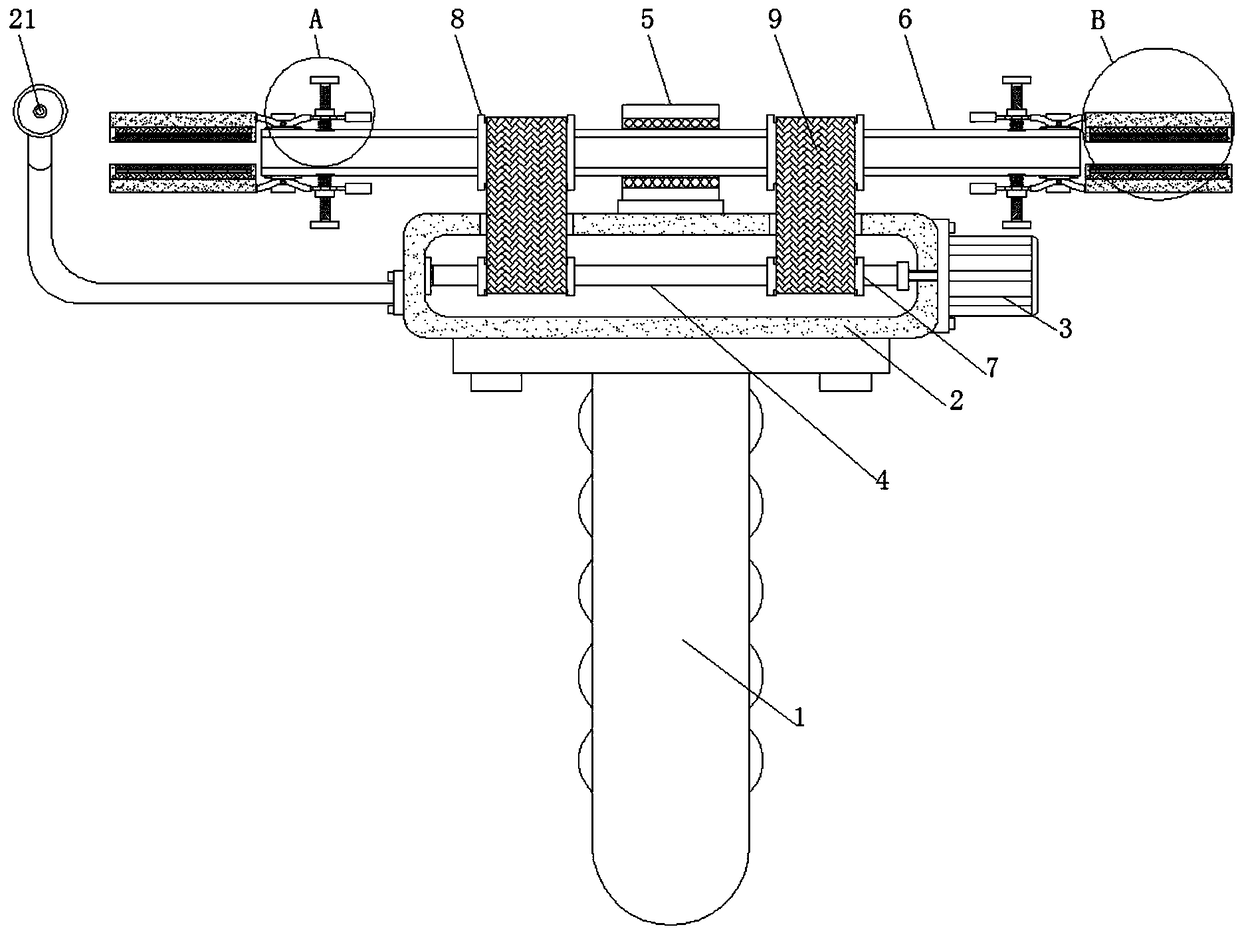

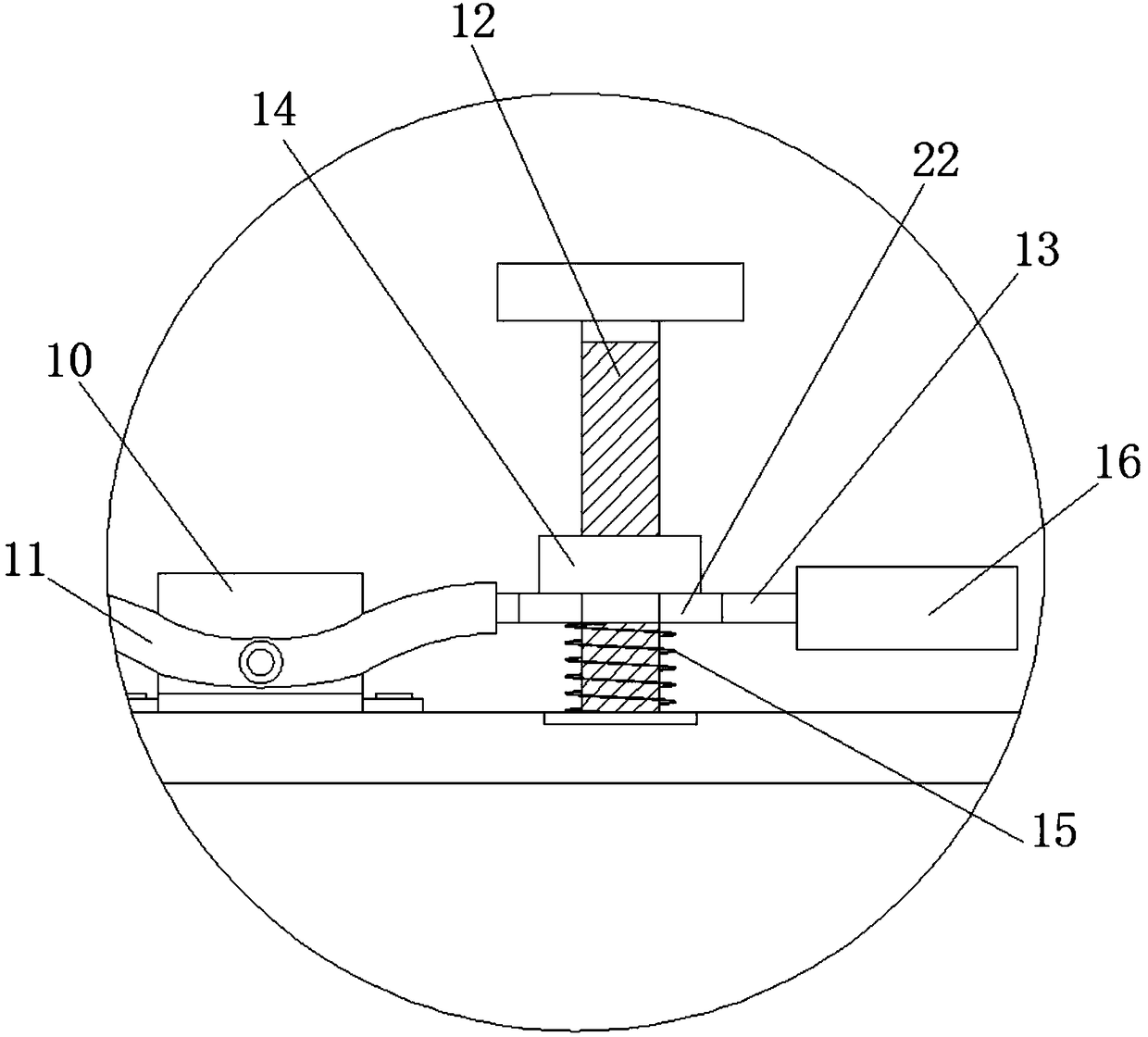

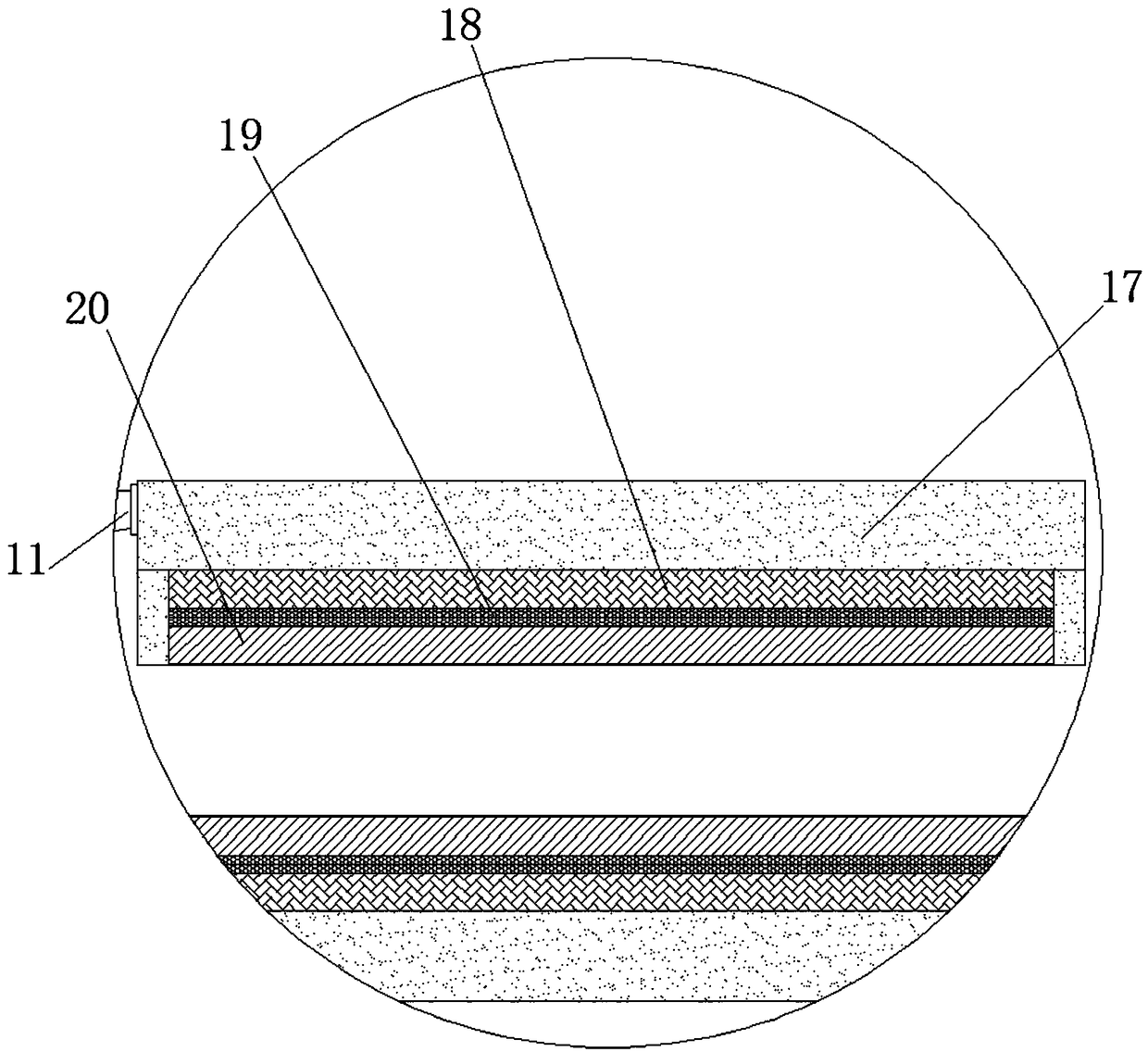

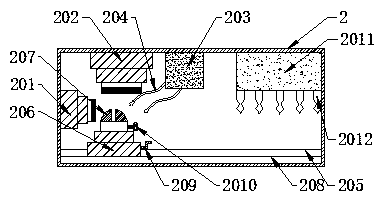

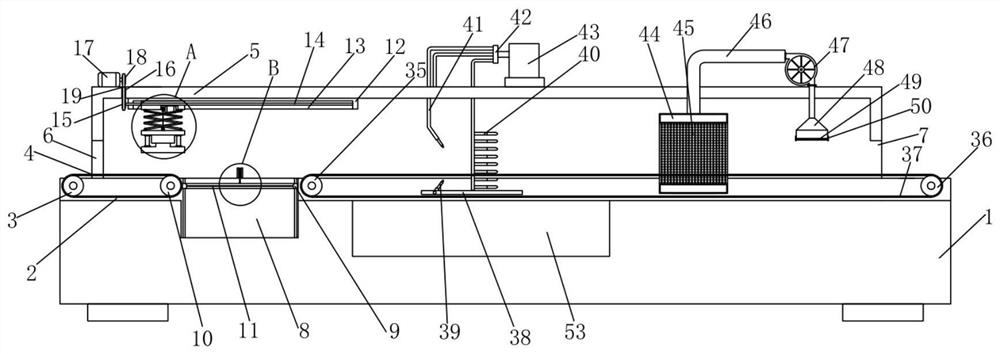

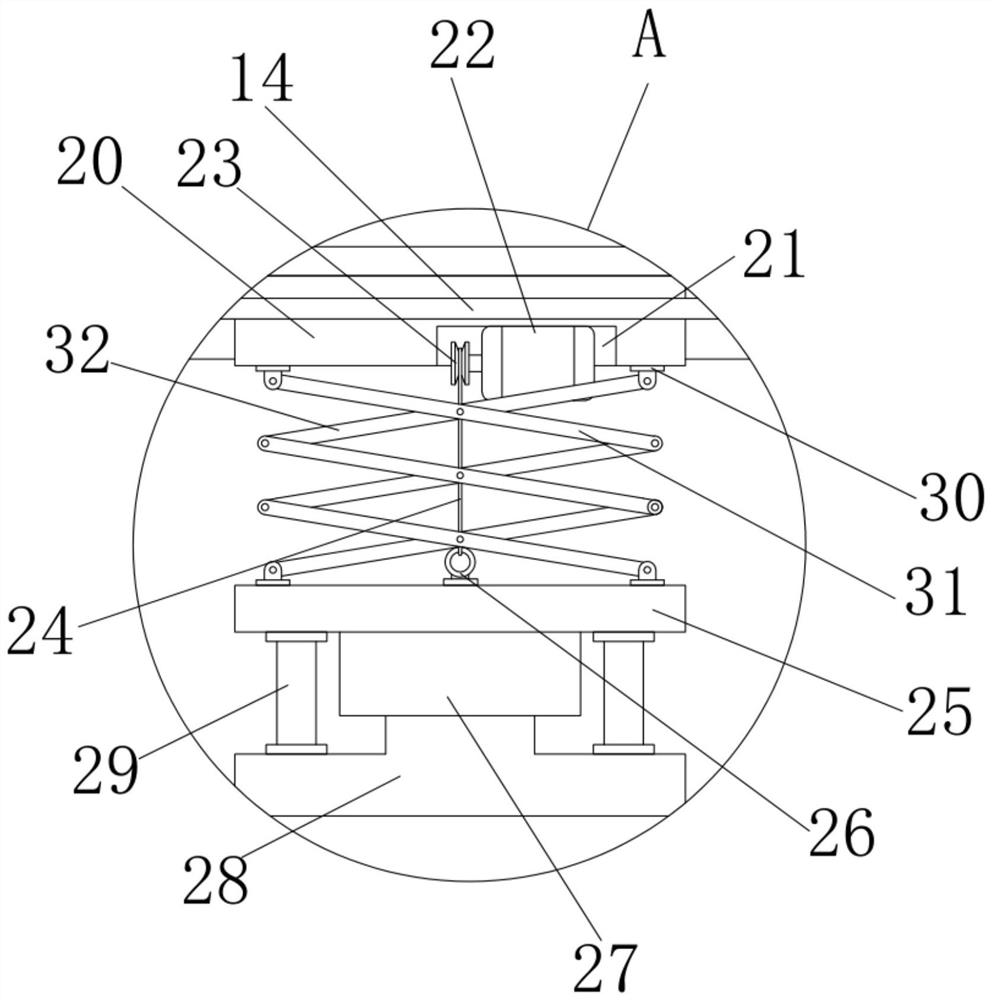

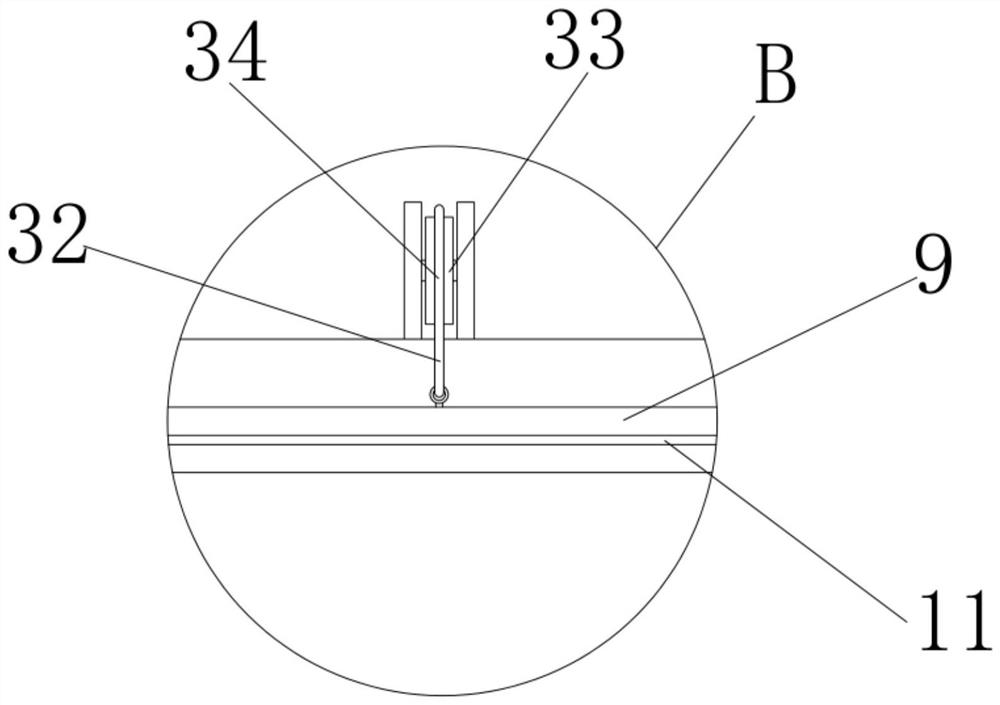

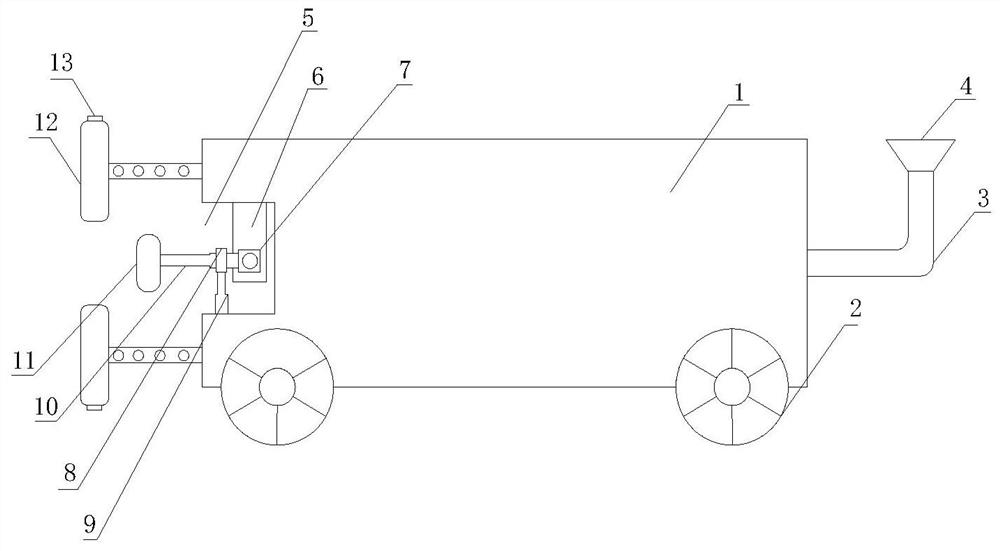

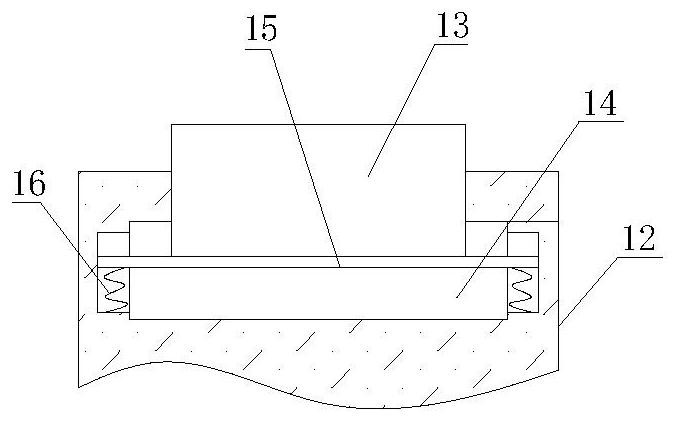

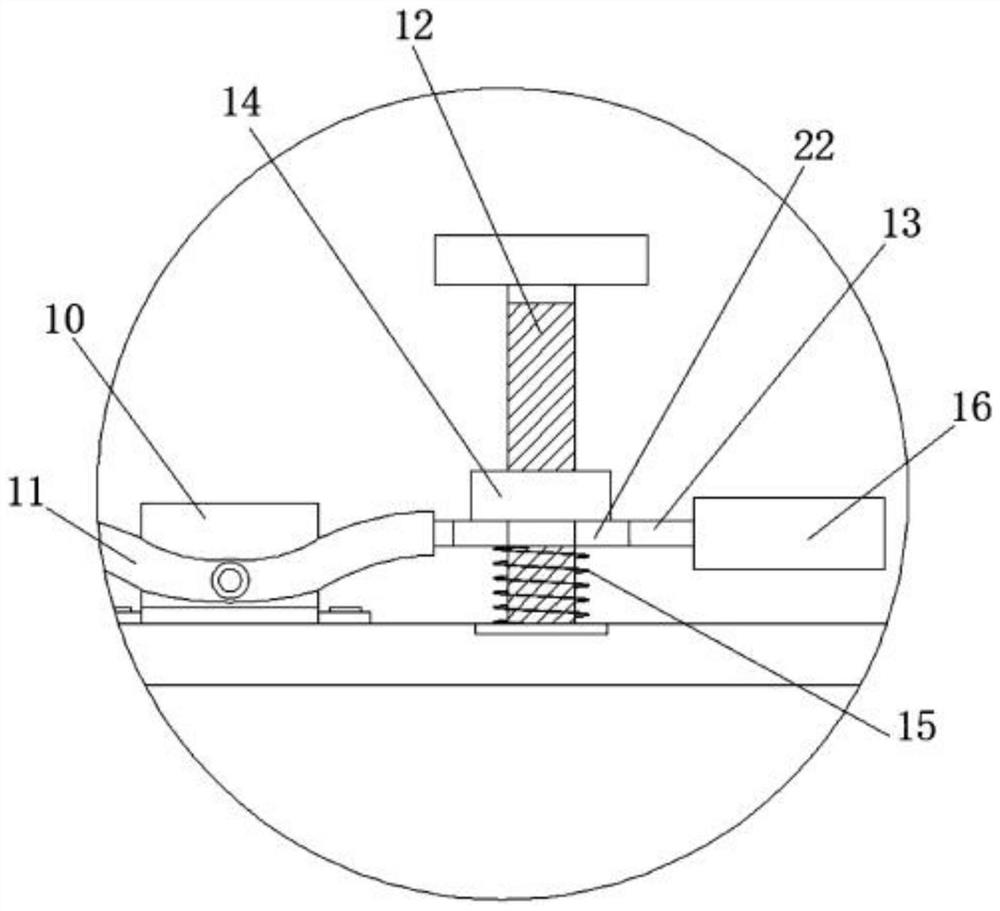

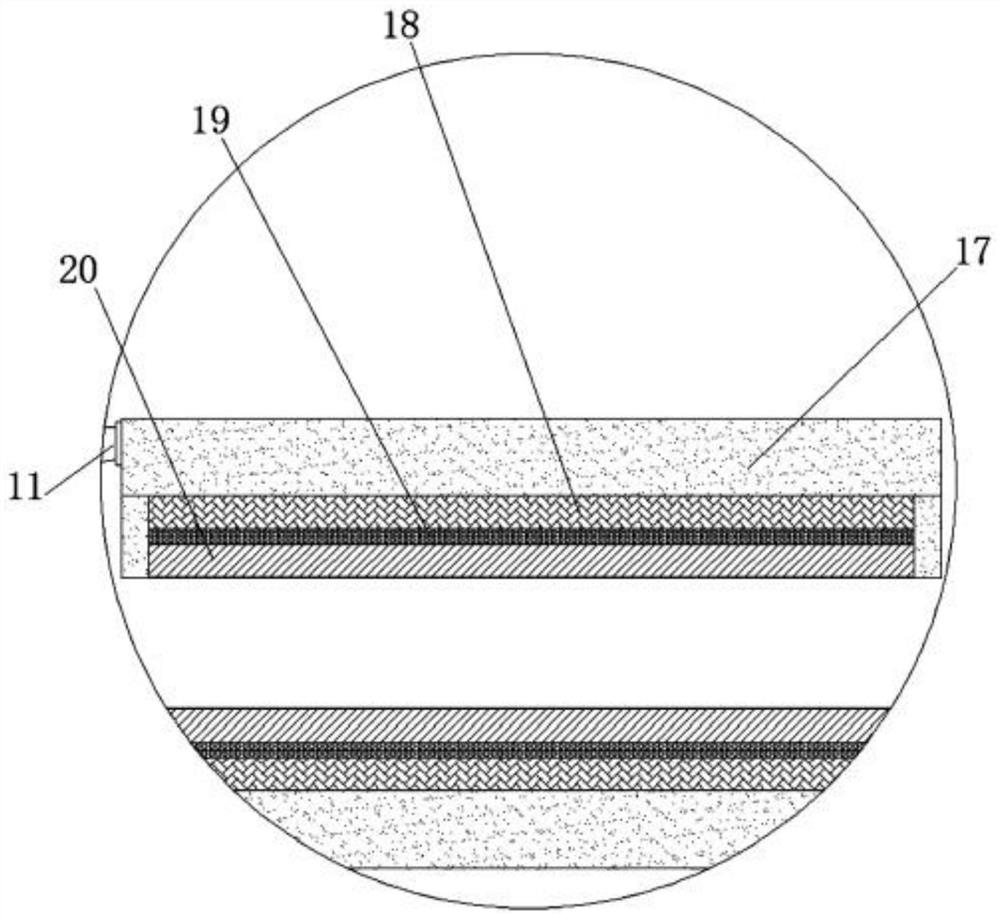

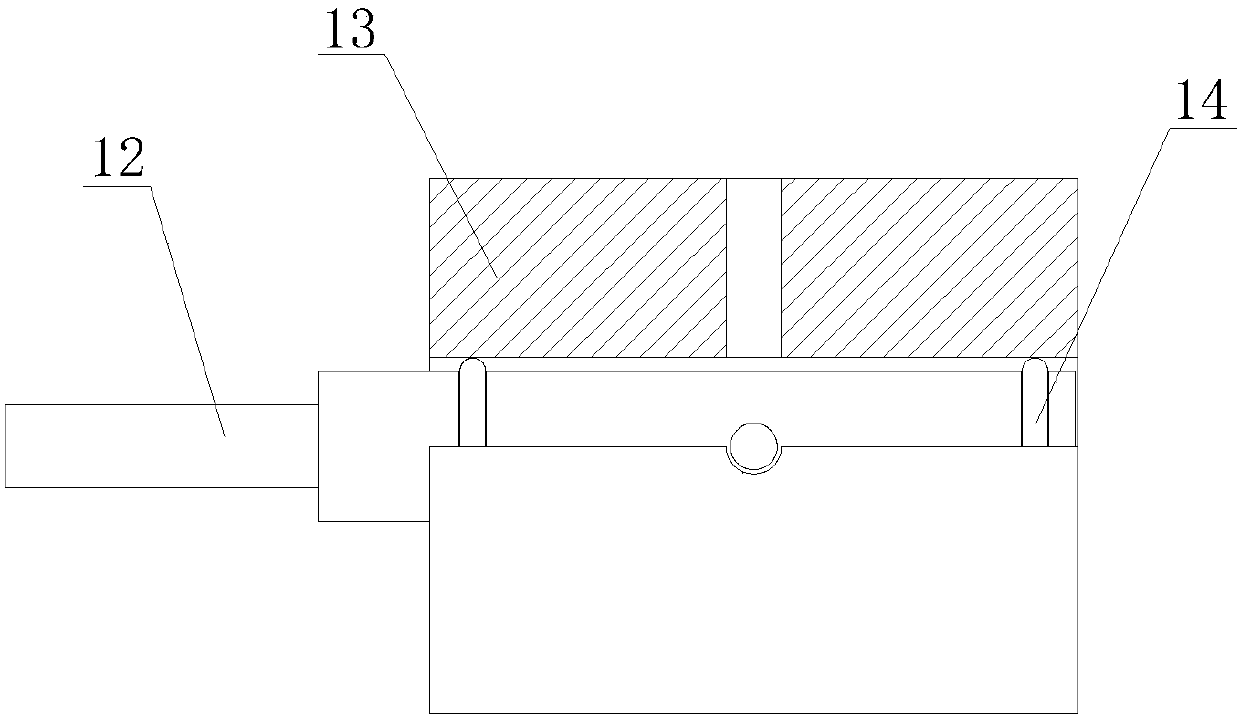

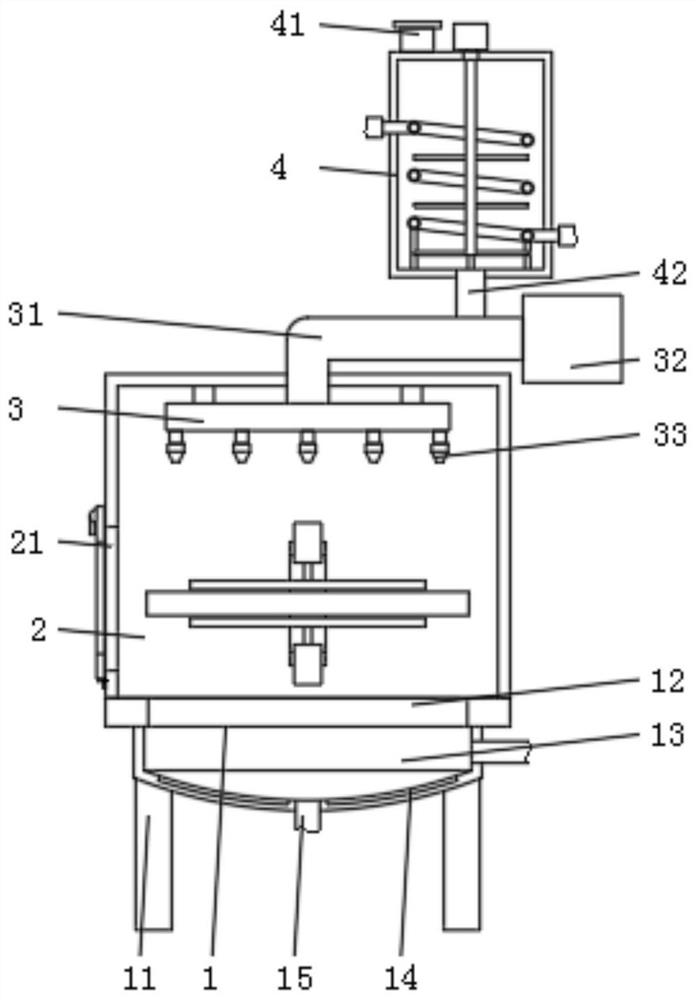

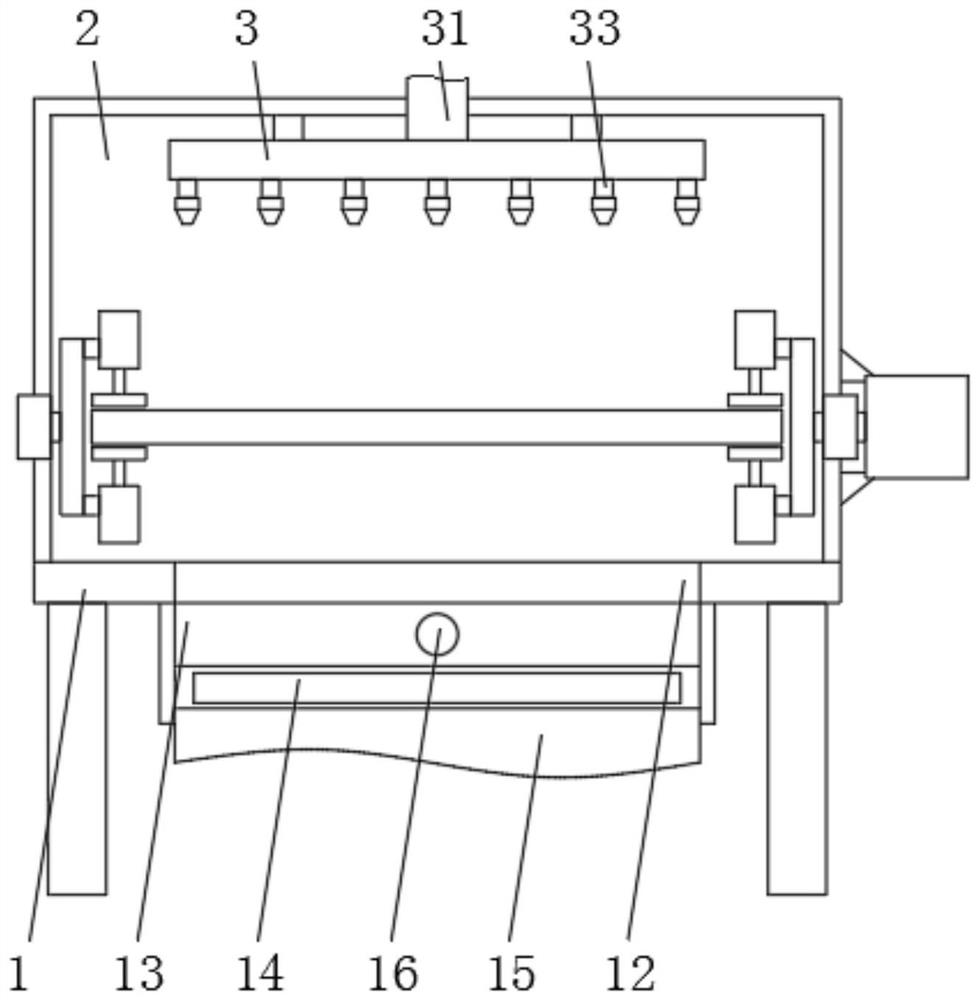

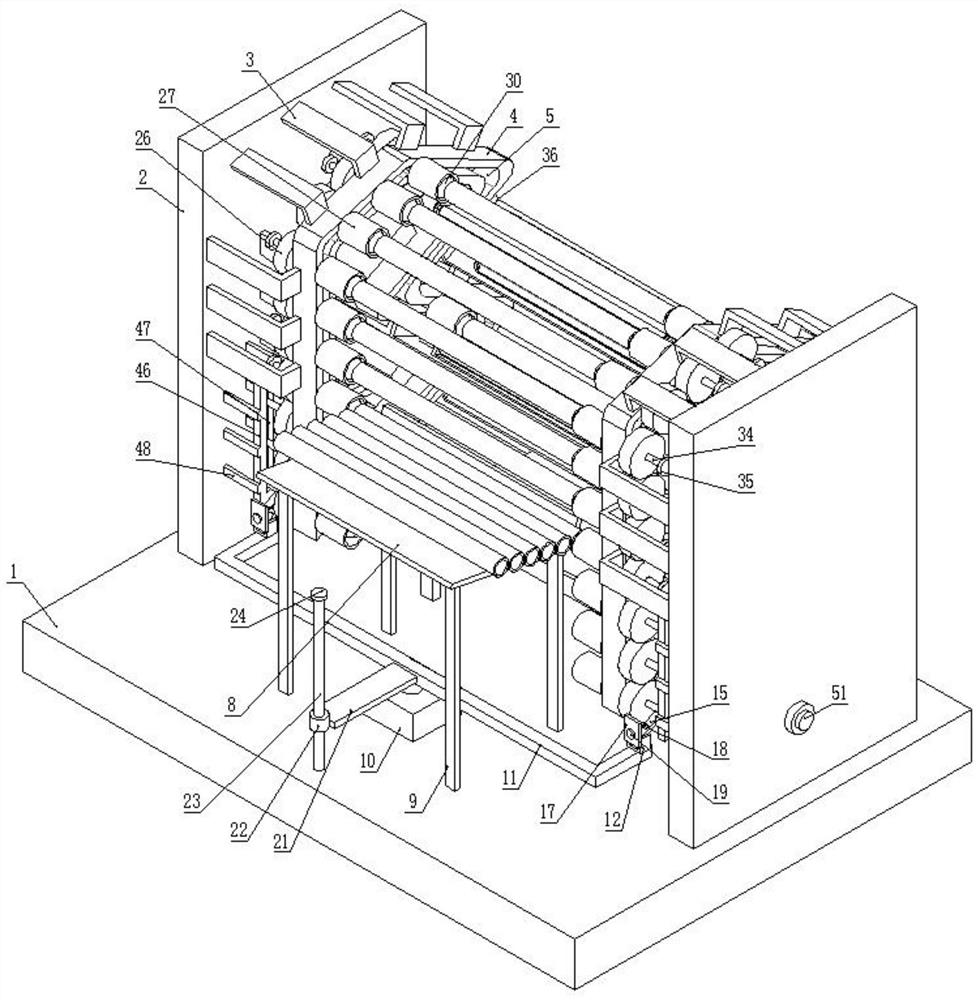

Electric automation reinforcing steel bar straightening machine

InactiveCN111531073AEasy to cleanTo achieve the purpose of rust removalLiquid surface applicatorsGrinding drivesRebarWorkbench

The invention discloses an electric automation reinforcing steel bar straightening machine, which comprises a workbench and a collection box, wherein the front part of the upper end of the workbench is fixedly provided with a straightening device, a rust removal device and an oil coating device; the straightening device, the rust removal device and the oil coating device are arranged in sequence from left to right; a position, which is positioned behind the straightening device, of the upper end of the workbench is provided with a first driving mechanism; a position, which is positioned behindthe rust removal device, of the upper end of the workbench is provided with a second driving mechanism; the right rear corner of the workbench is fixedly provided with an electronic control box; thelower end of the workbench is fixedly provided with a supporting frame; the upper end of the workbench is provided with a blanking groove which is vertically through; and an opening on the upper end of the collection box is positioned just below the blanking groove. The electric automation reinforcing steel bar straightening machine disclosed by the invention combines working procedures, includingreinforcing steel bar straightening, reinforcing steel bar rust removal, reinforcing steel bar straightening rust prevention and the like, into a whole, working efficiency can be greatly improved, better economic benefits can be brought, and the electric automation reinforcing steel bar straightening machine is suitable to be popularized and utilized.

Owner:武汉船舶职业技术学院

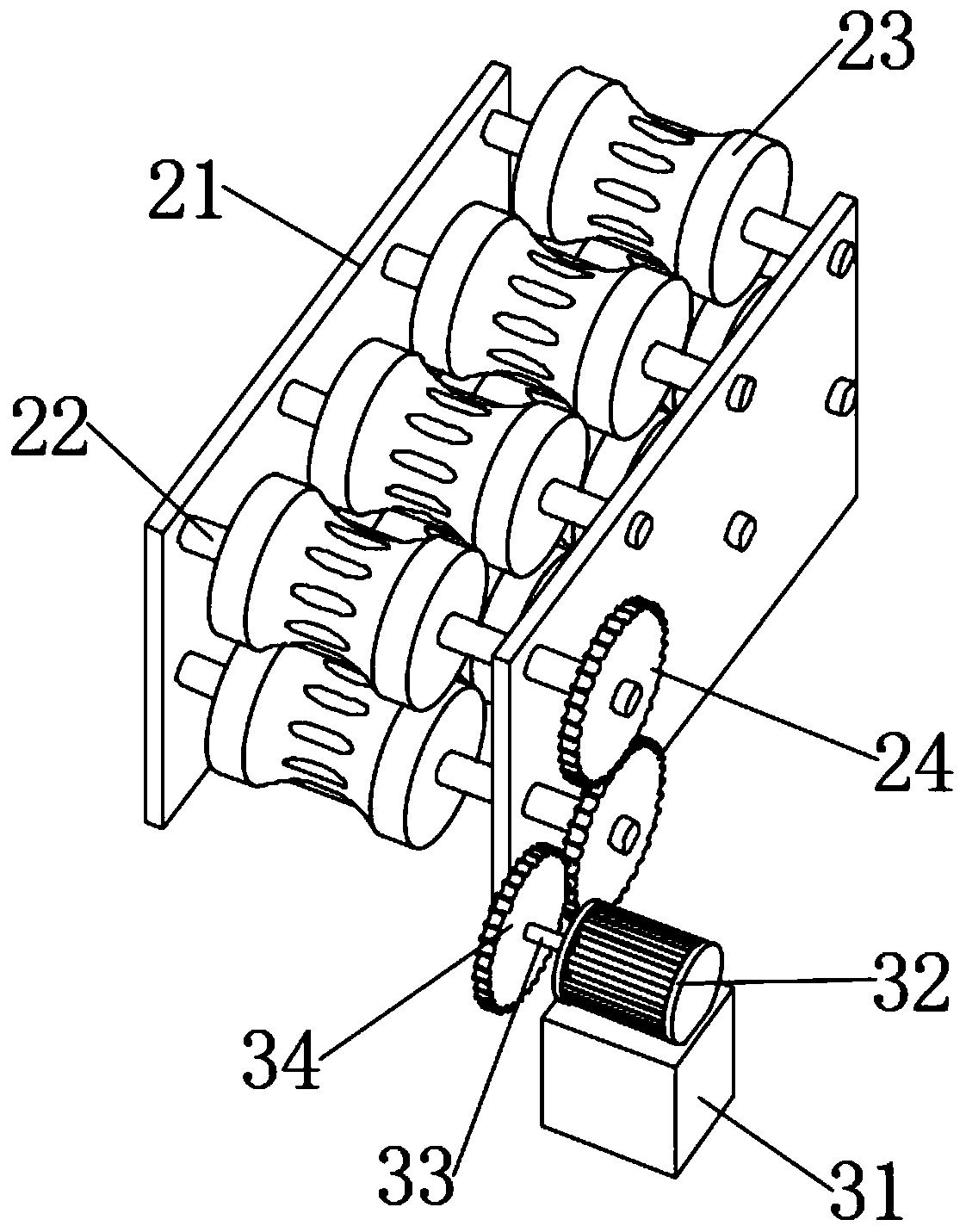

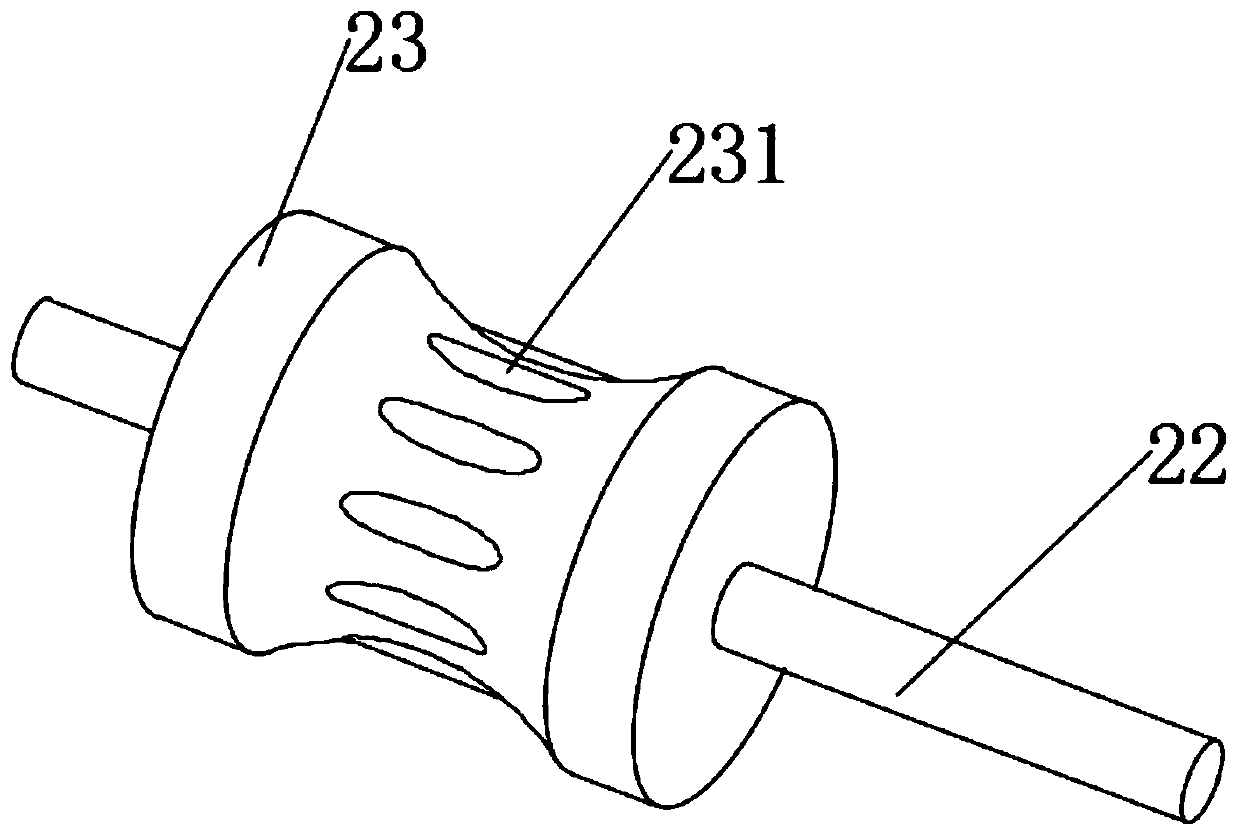

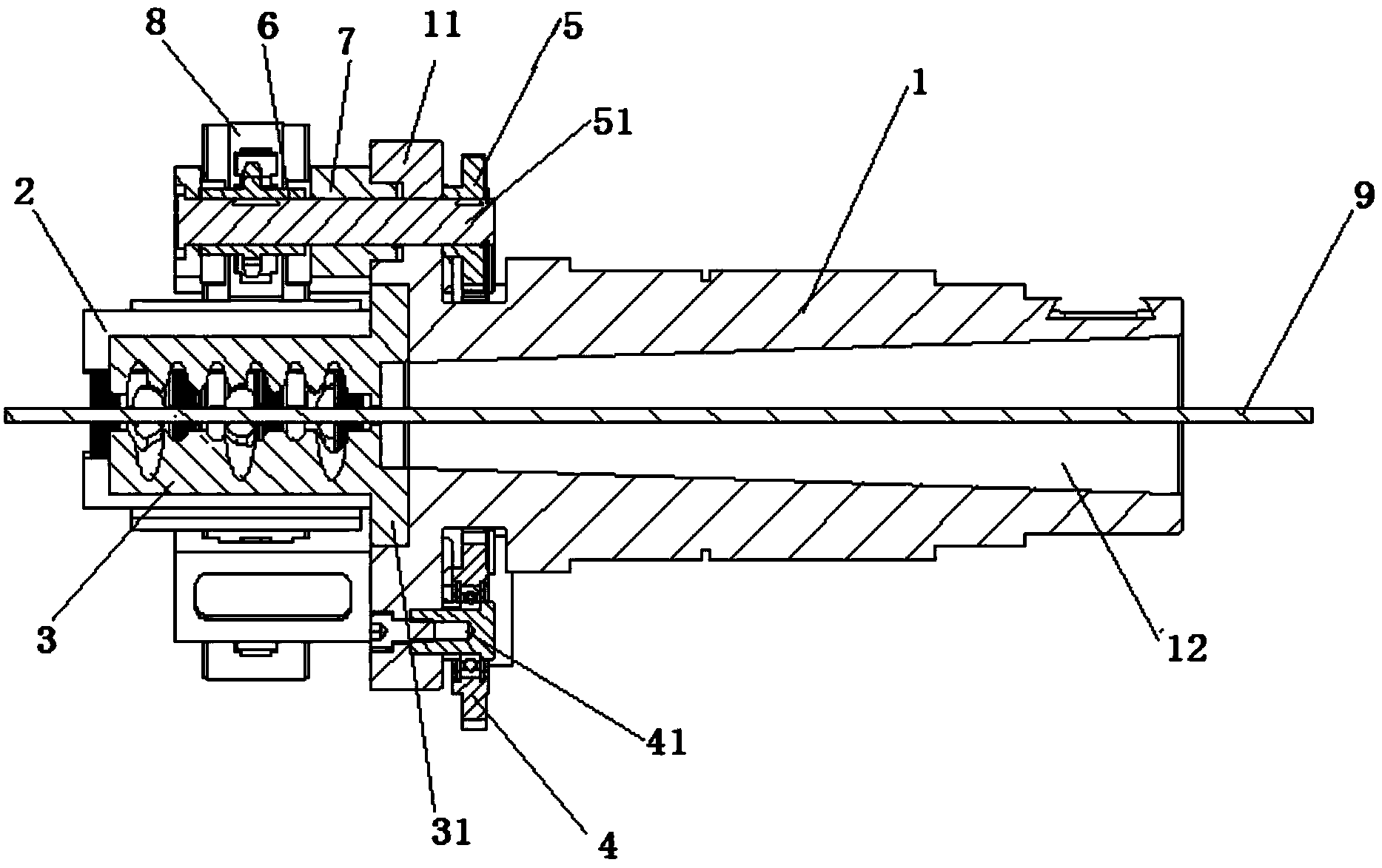

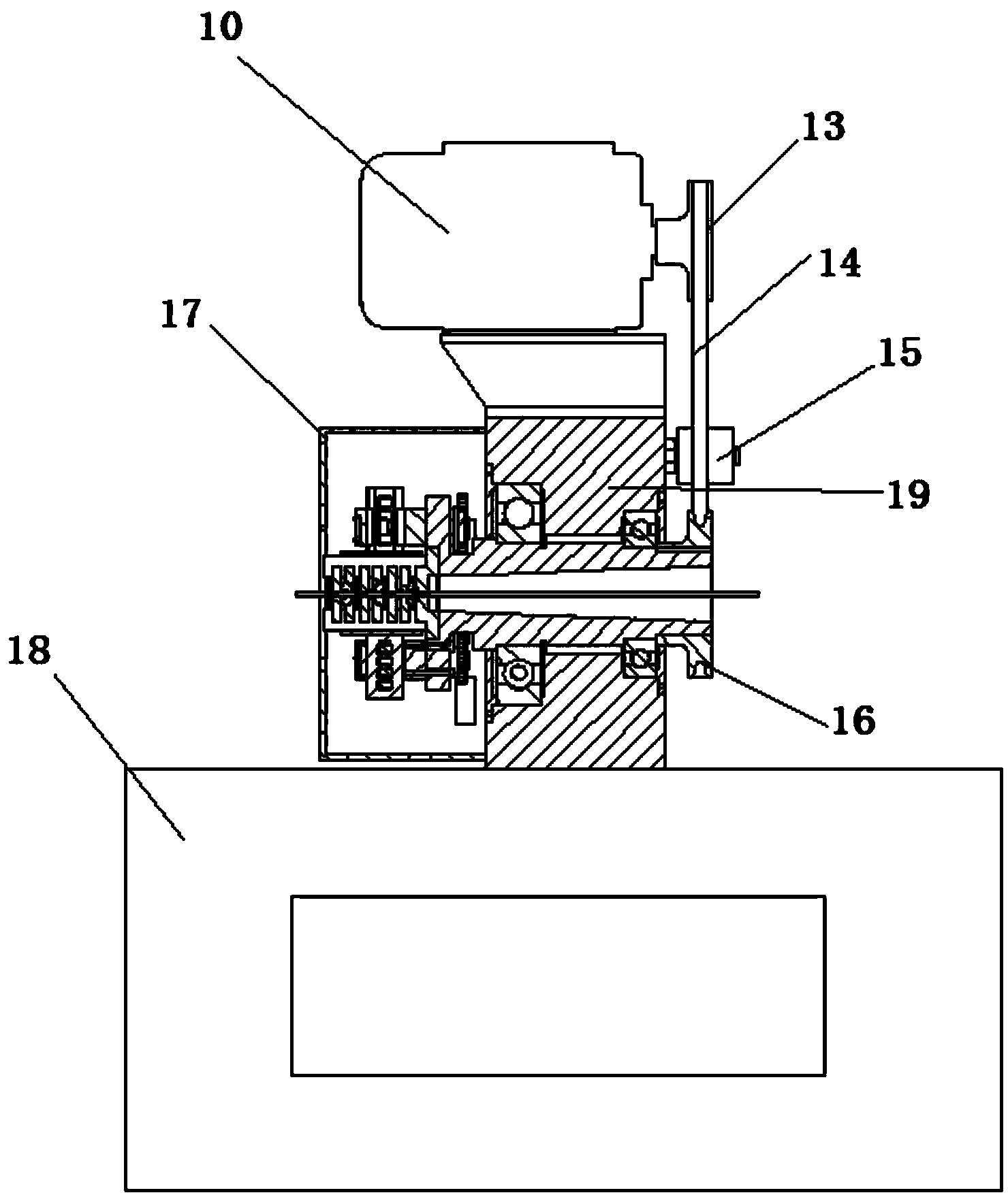

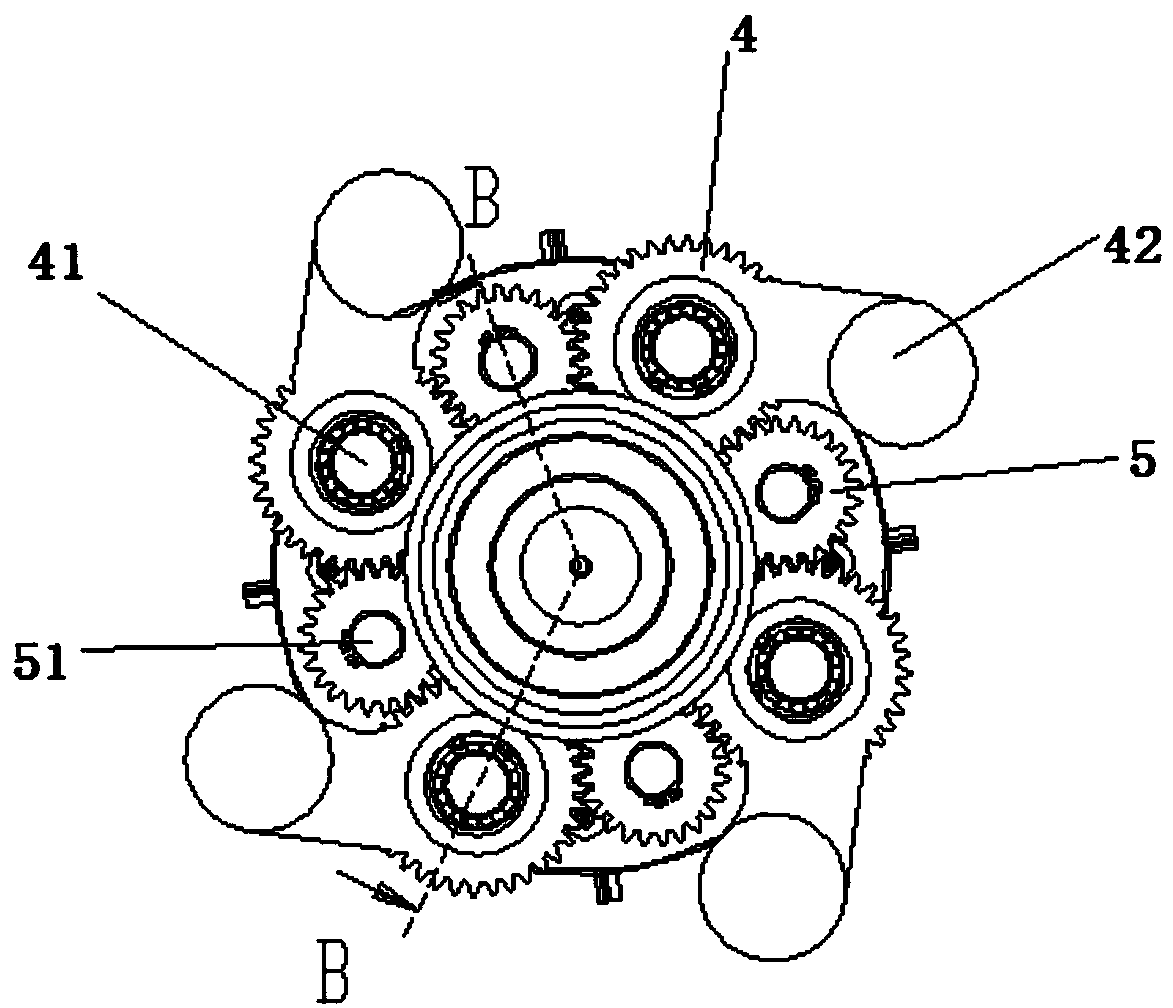

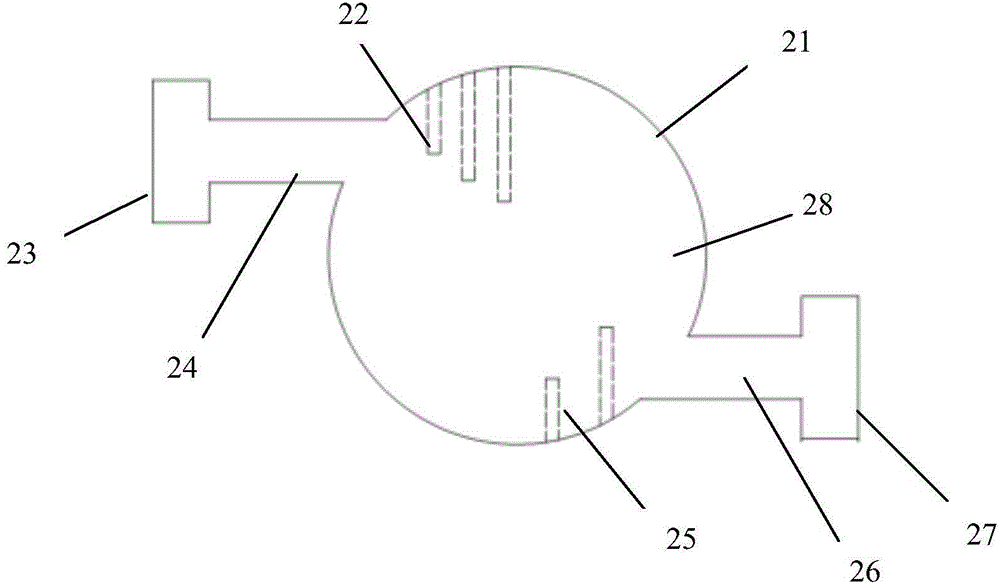

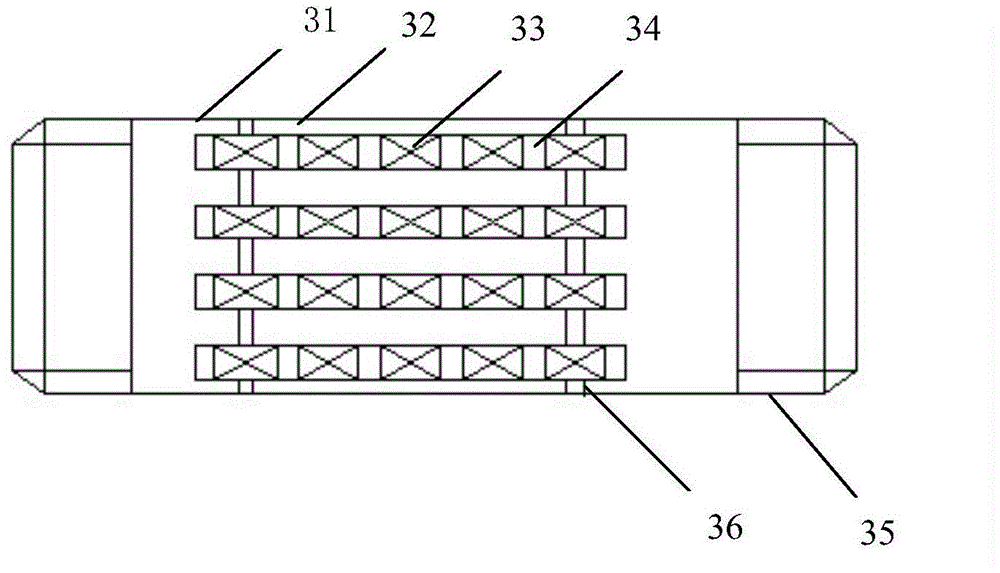

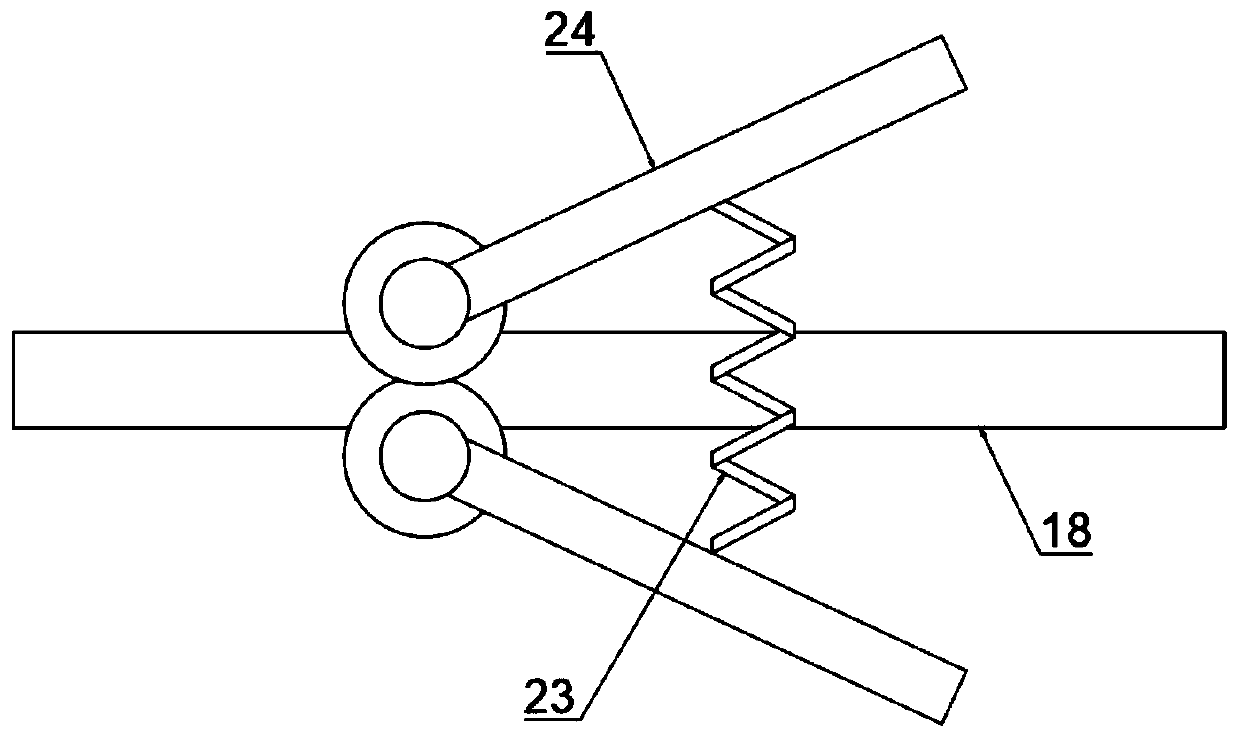

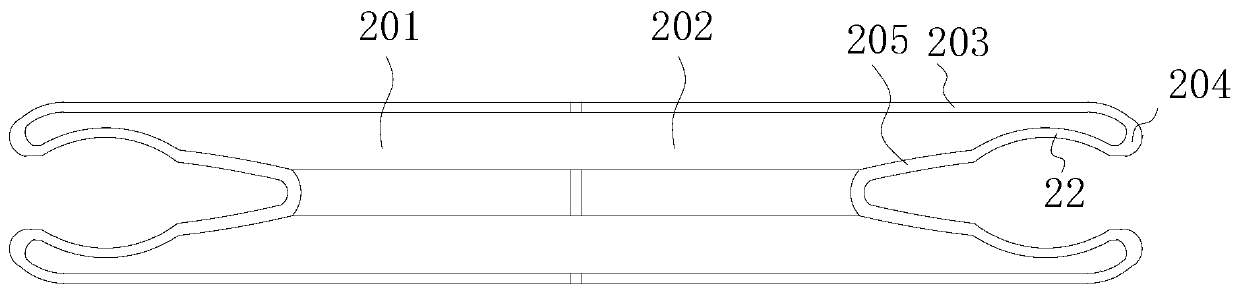

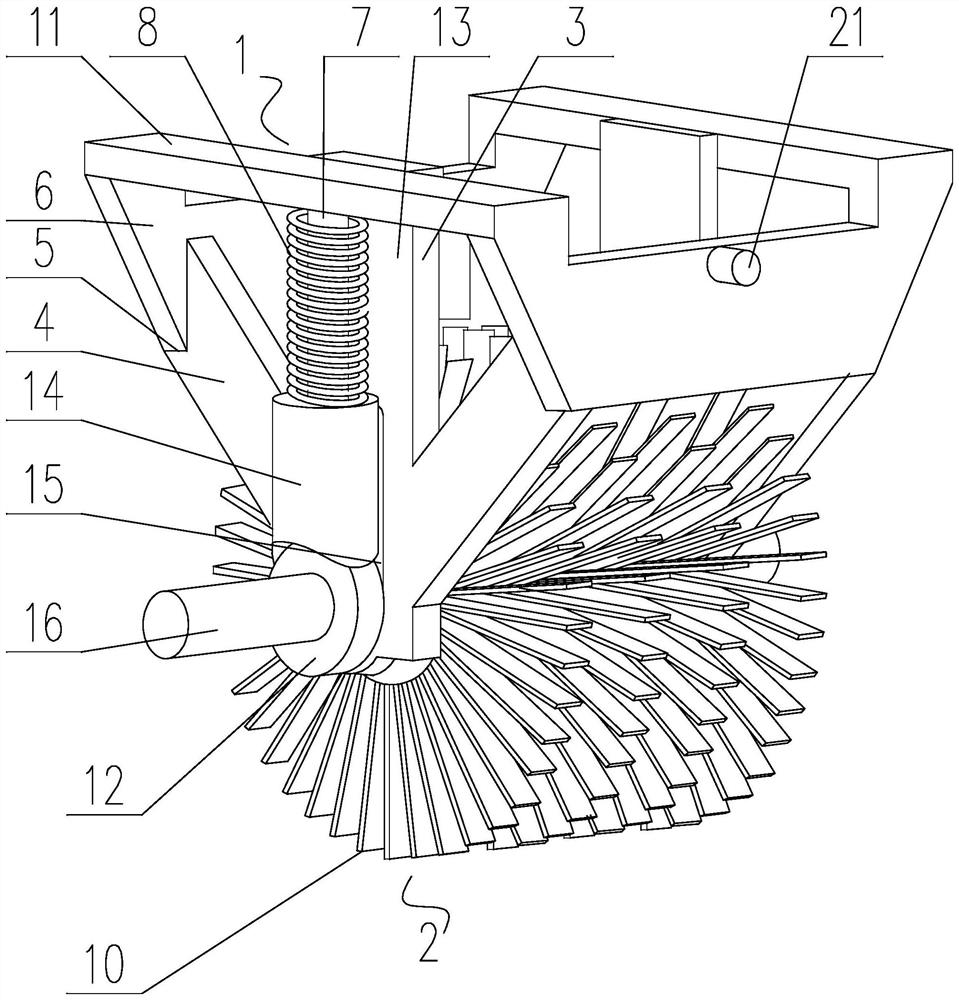

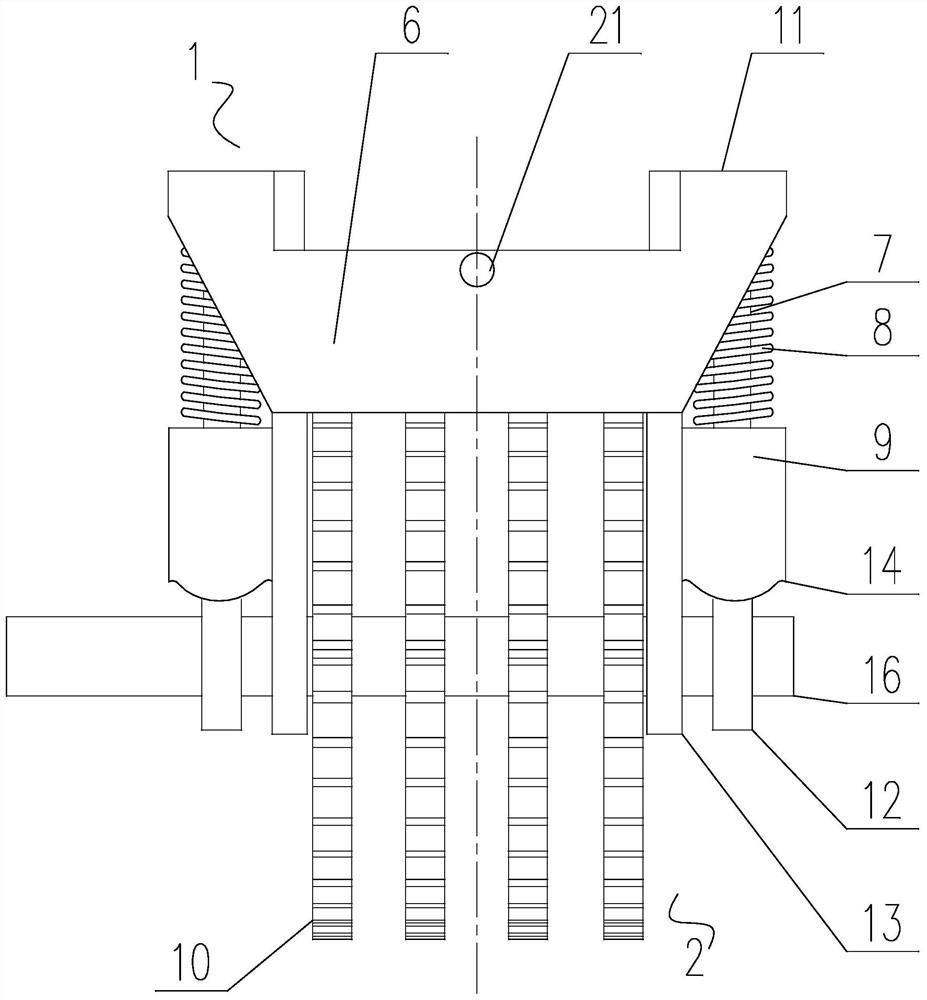

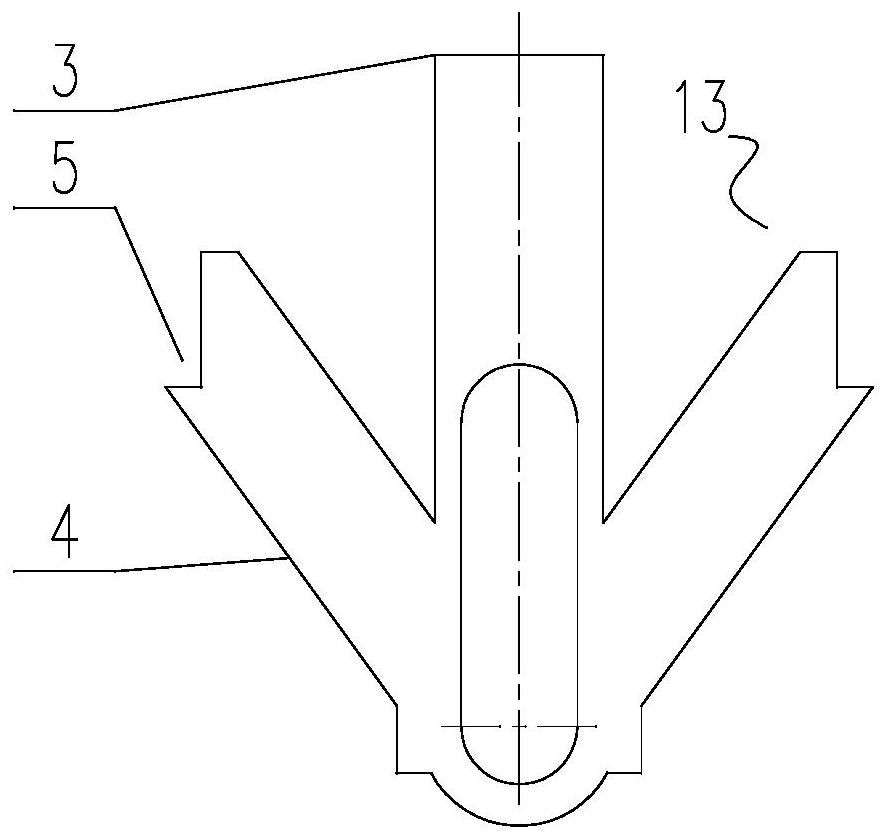

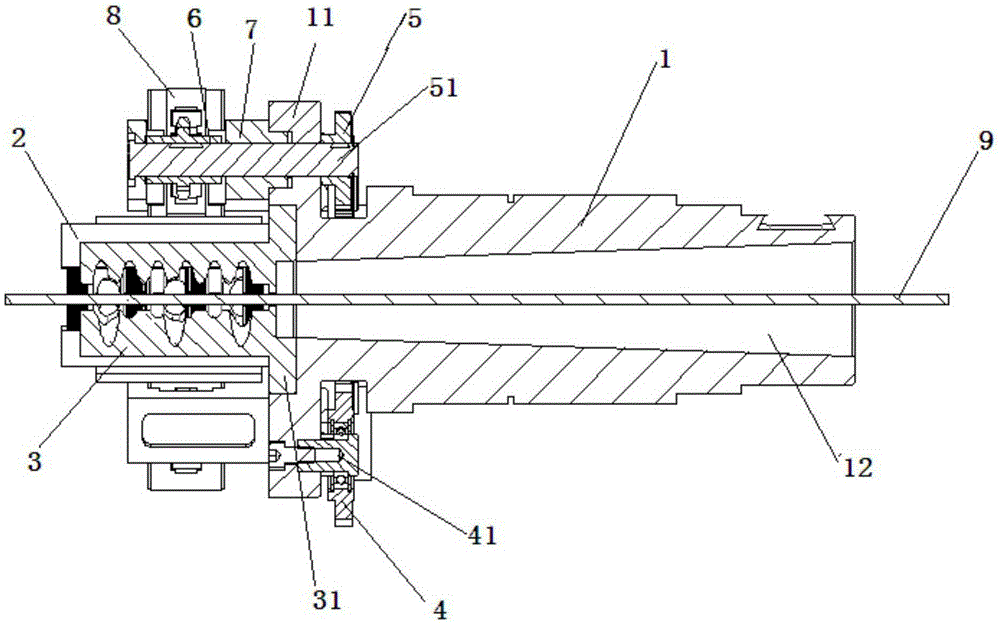

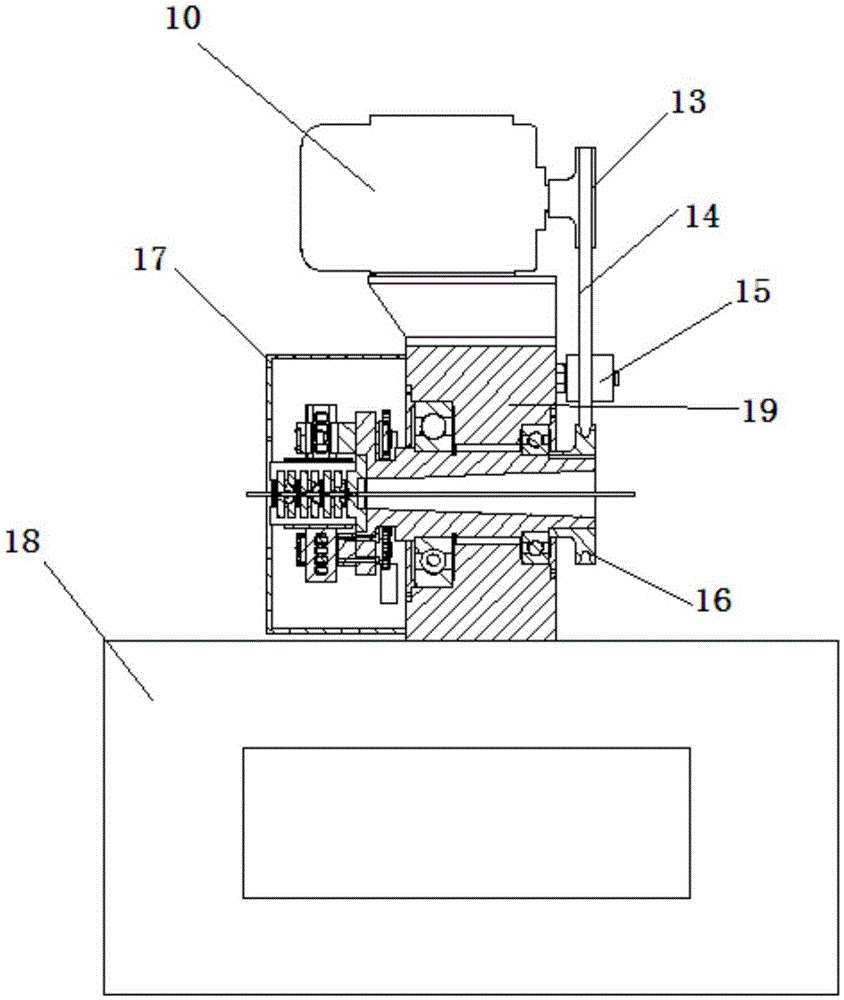

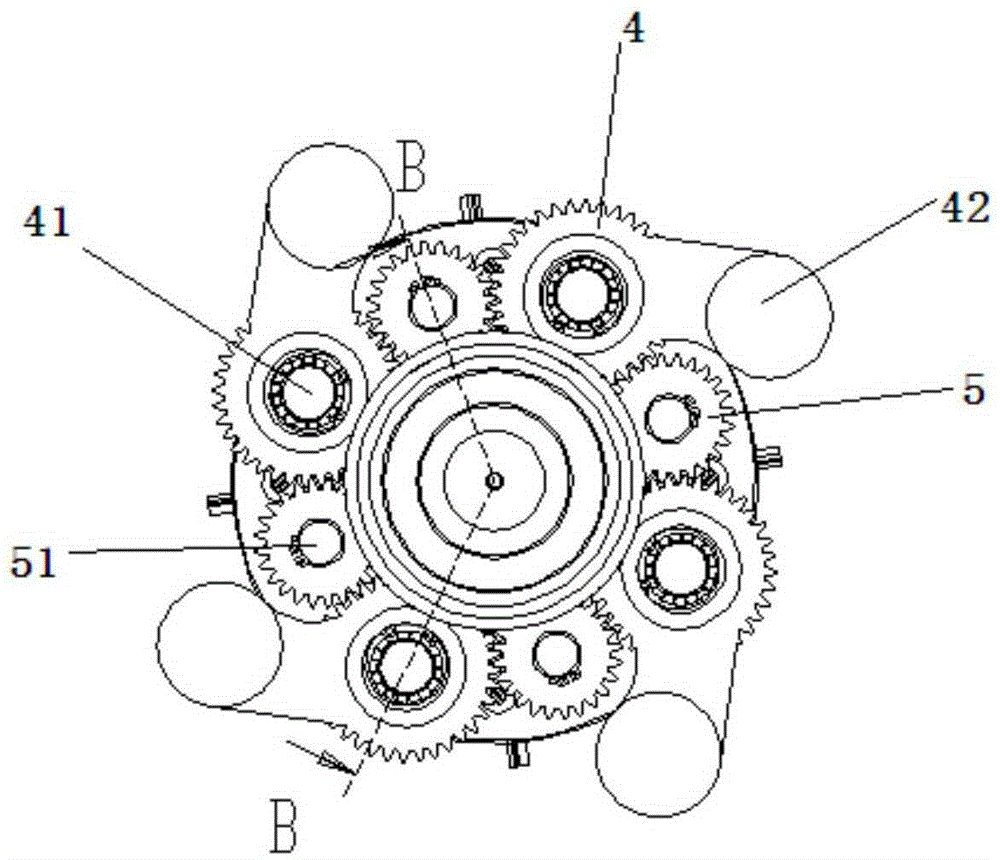

Friction type wire rod rust removal tool

ActiveCN103522153AGuaranteed uptimeTo achieve the purpose of rust removalGrinding machinesWire rodEngineering

The invention provides a friction type wire rod rust removal tool which comprises a main shaft, a plurality of long brushes, an opening groove shaft, a transmission mechanism and a brush inner pressing mechanism. The long brushes are located in the opening of the opening groove shaft, and the main shaft rotates and drives the brush inner pressing mechanism through the transmission mechanism to press the long brushes inwards, so that brush bristles rub a wire rod for rust removal. The tool has the advantages that the steel wire brushes can press the surface of the wire rod at constant pressure while revolving around the axis of a main shaft combined body to form a stable friction state and achieve the aim of rust removal; the tool is stable in operation, high in work efficiency, simple to operate, wide in application range, and capable of totally taking the place of acid pickling to serve as rust removal equipment free of acid pickling in the wire welding industry.

Owner:TIANJIN GOLDEN BRIDGE WELDING MATERIALS GRP

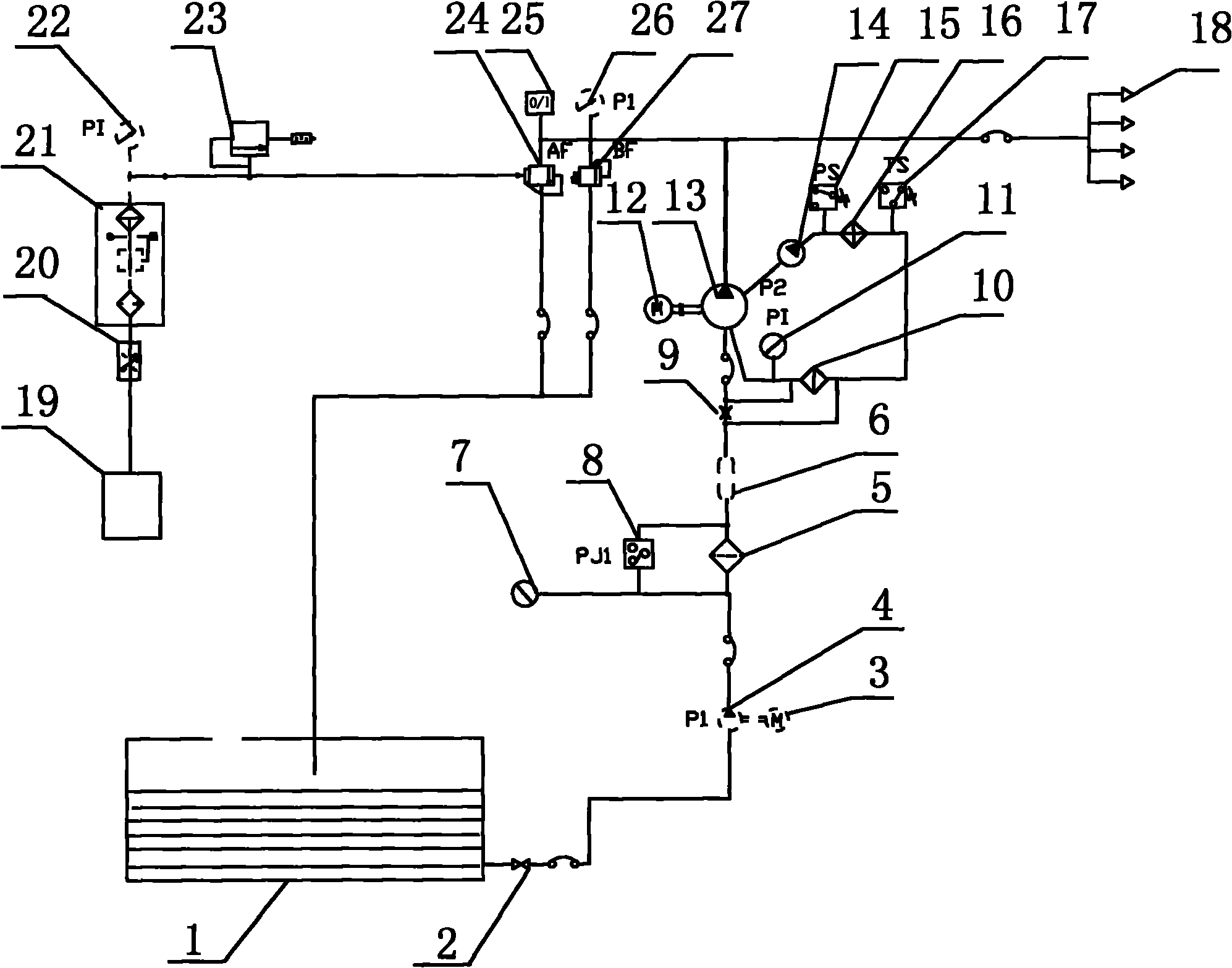

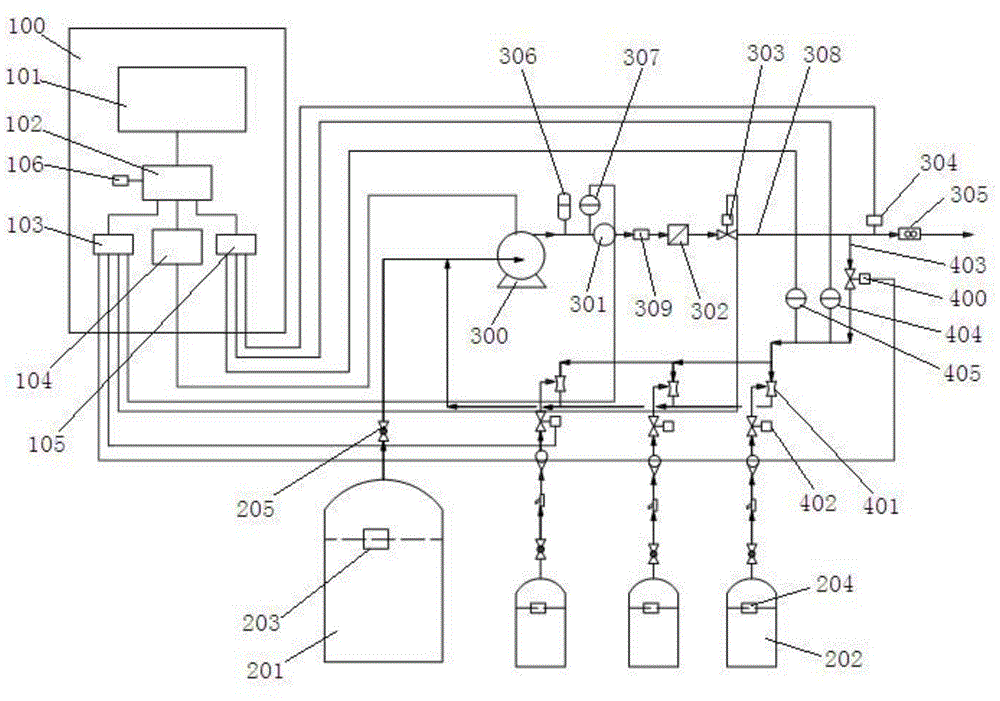

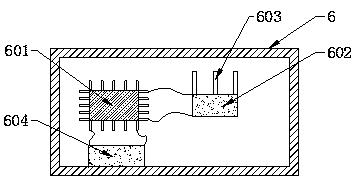

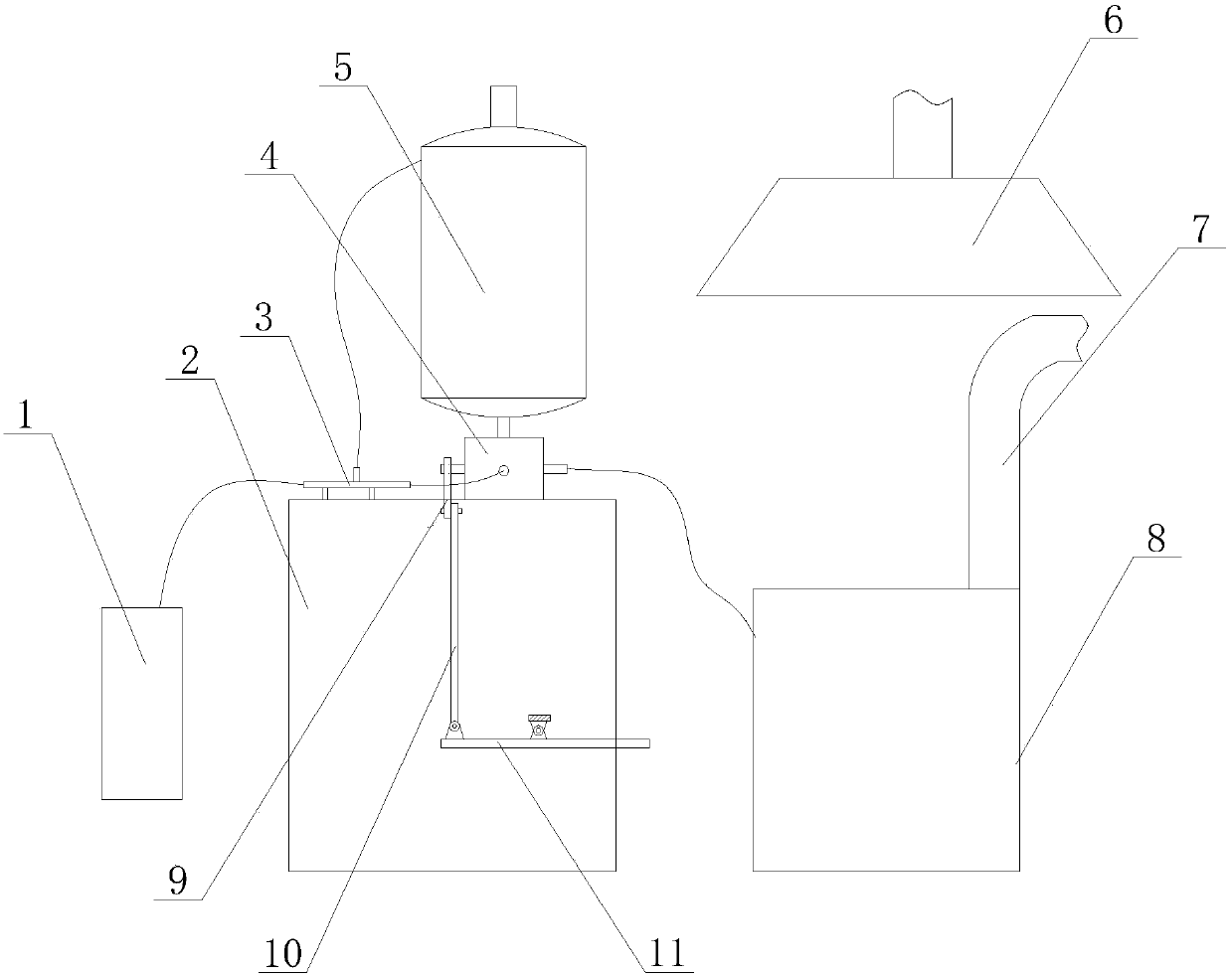

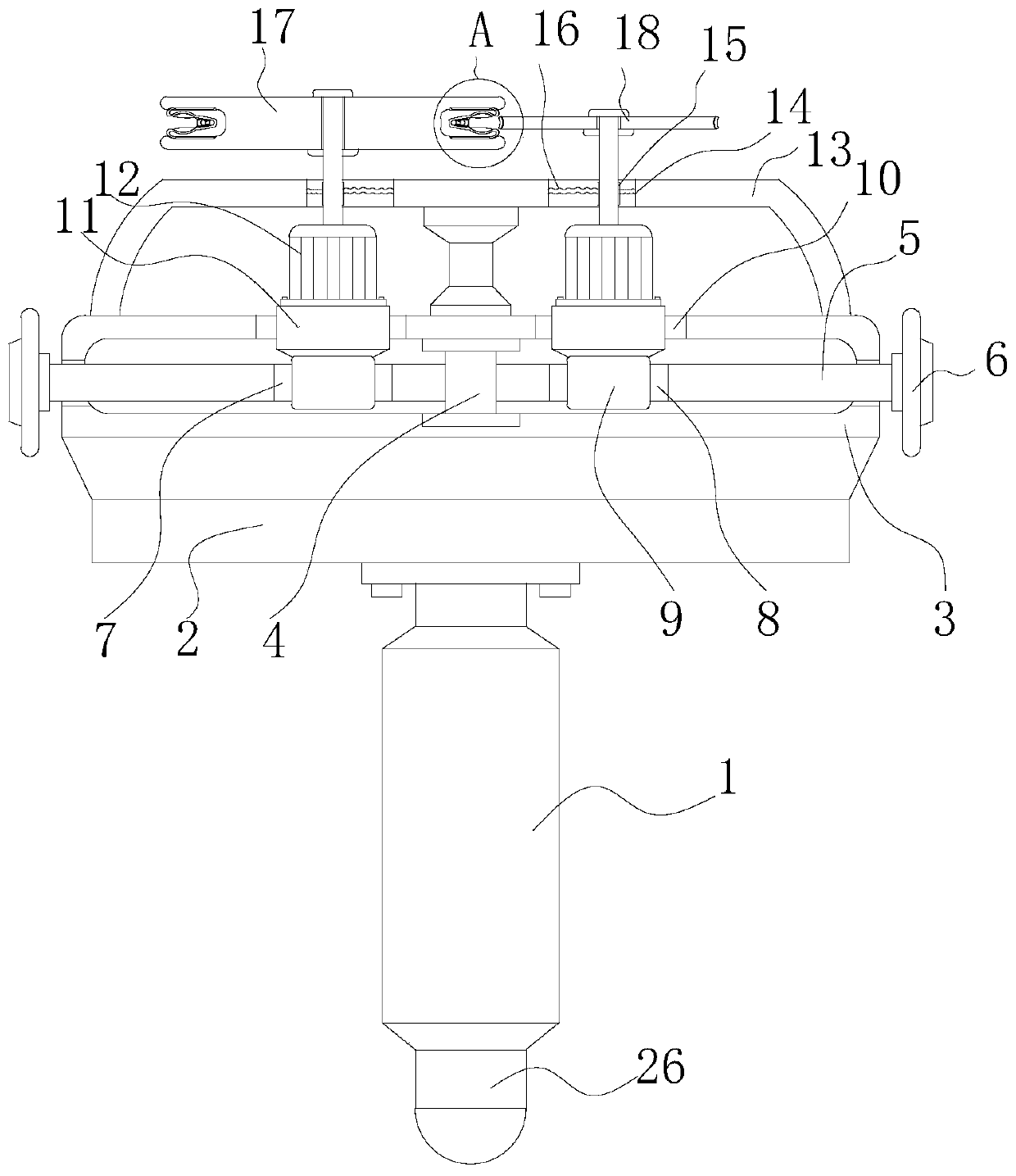

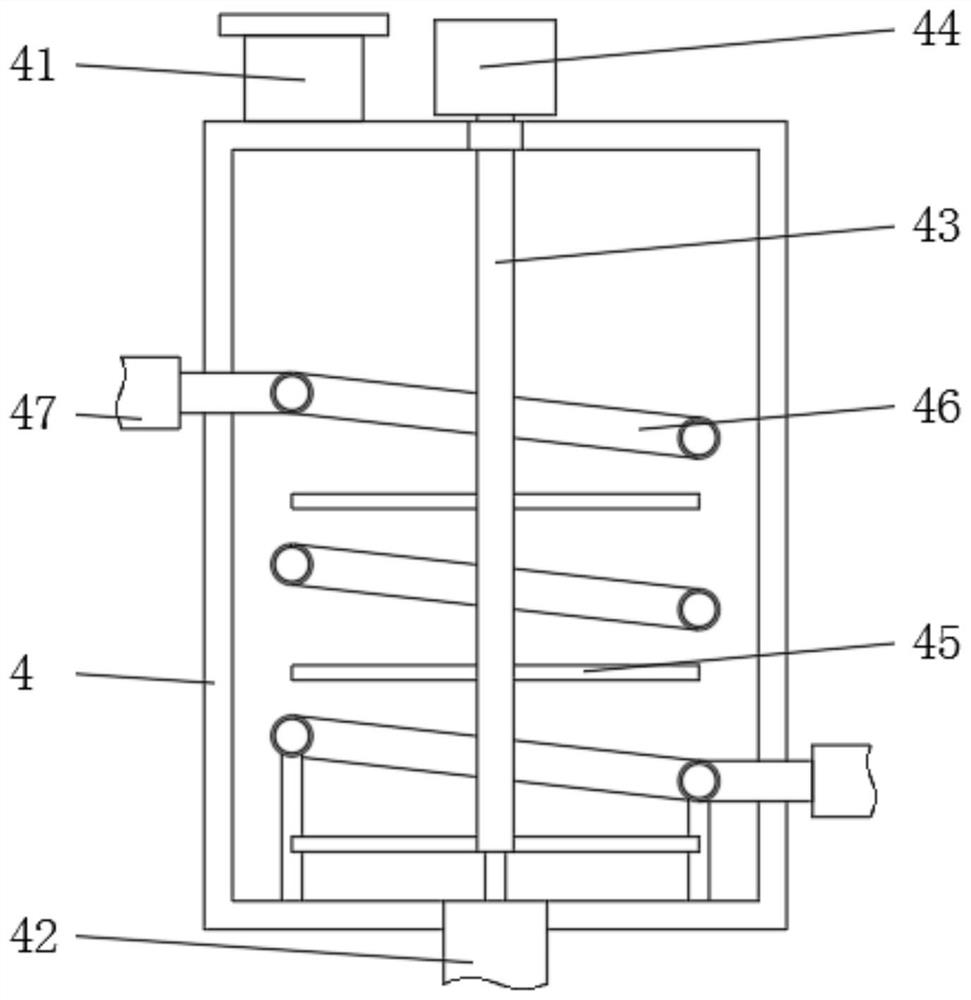

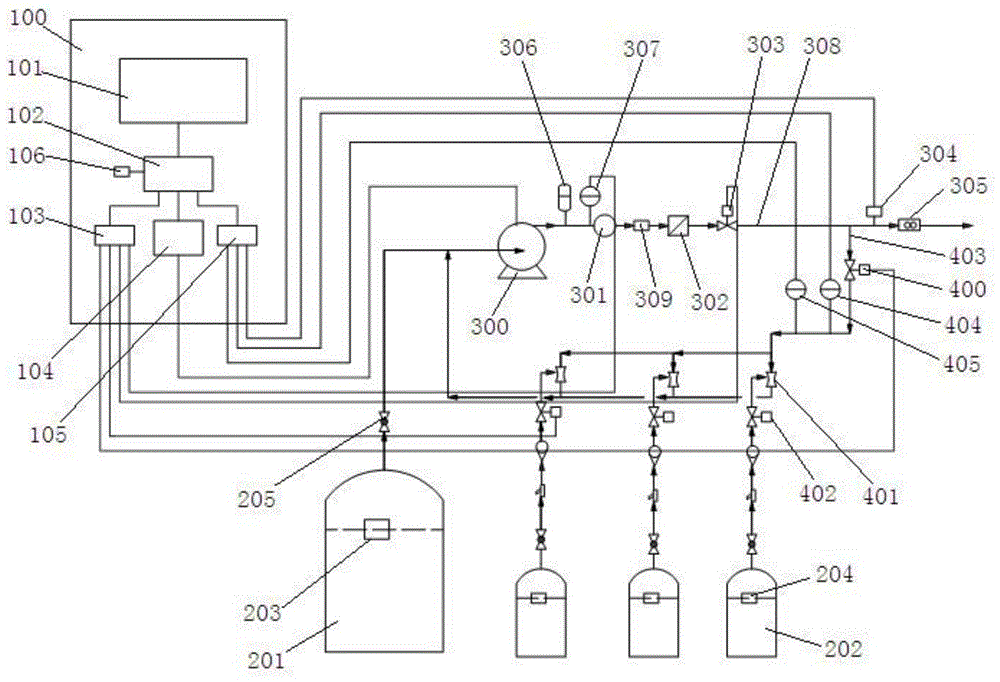

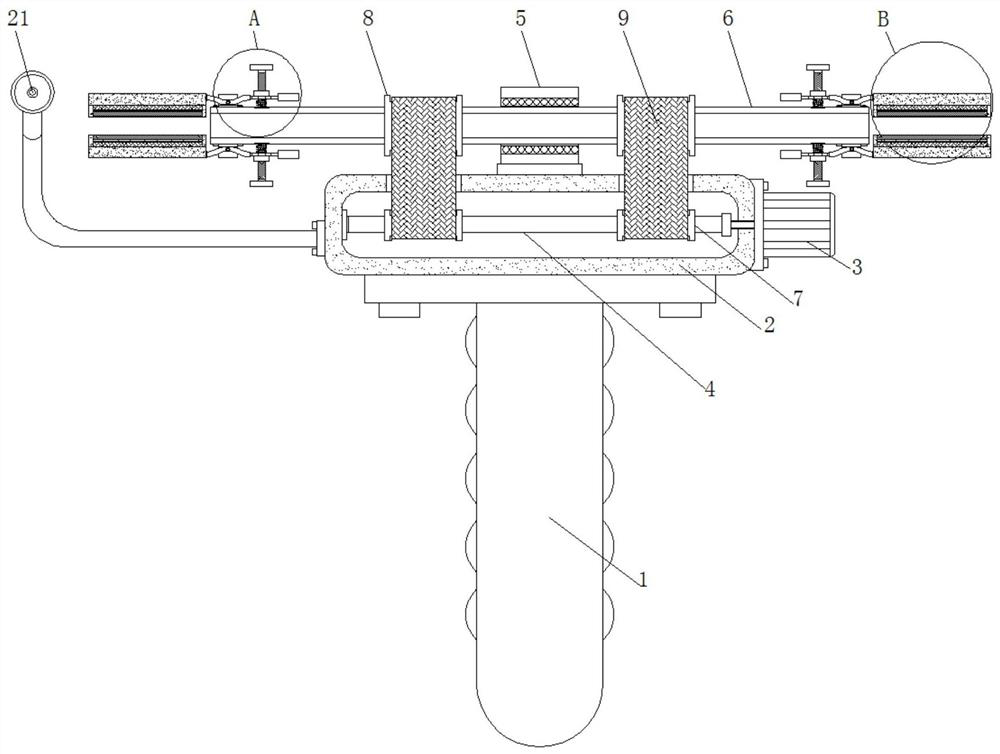

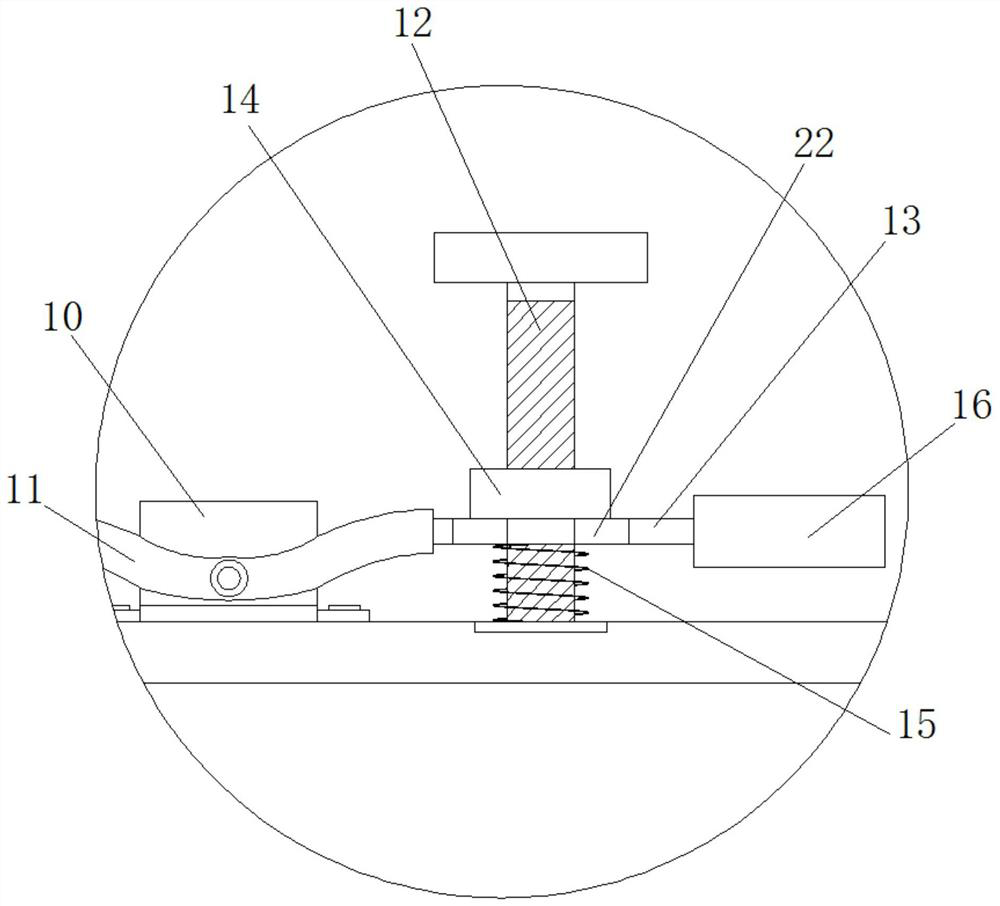

Direct-mixing type multi-purpose automatic accurate fertilizer irrigation system

InactiveCN104584757AShorten mixing timeReduce oxidation reactionPressurised distribution of liquid fertiliserAgriculture gas emission reductionFertilizerAutomatic control

The invention relates to a direct-mixing type multi-purpose automatic accurate fertilizer irrigation system which comprises a clean water tank, a raw fertilizer tank, a venturi tube, a fast fertilizer suction electromagnetic valve, an irrigation pump, an automatic control system, an electro connecting pressure gauge and a spherical fertilizer mixer, wherein the venturi tube sucks a raw fertilizer or an acid solution into a pipeline; the fast fertilizer suction electromagnetic valve controls a fertilizer suction amount; the output end of the irrigation pump is connected with the input end of the spherical fertilizer mixer through the pipeline, the pipeline positioned between the irrigation pump and the spherical fertilizer mixer is provided with the electro connecting pressure gauge; the output end of the spherical fertilizer mixer is respectively connected with an irrigation delivery pipeline and a fertilizer suction feedback pipeline; and the irrigation delivery pipeline is provided with an irrigation electromagnetic valve and a pipeline pressure detection device. The direct-mixing type multi-purpose automatic accurate fertilizer irrigation system disclosed by the invention realizes the immediate usage of a water fertilizer after mixing by adopting the independently developed spherical fertilizer mixer, can be used for furthest shortening the mixing time of a fertilizer and water and reducing the oxidation reaction generated because the fertilize contacts with air and can prevent the fertilizer waste generated in a fertilizer mixing process, provide higher output pressure through a direct-mixing type and cover more irrigated area.

Owner:上海璞研电子科技有限公司

Granite rust remover

The invention relates to a granite rust remover which is prepared by mixing the following components in parts by weight: 15-50 parts of one or more of inorganic acids and organic acids, 1-15 parts of surface active agent, 1-15 parts of hydrogen peroxide and 30-80 parts of polar solvents. The inorganic acid is preferably phosphoric acid and / or hydrochloric acid, the organic acid is preferably at least one of glycolic acid, glyoxylate, oxalic acid, phytic acid, citric acid, malic acid, maleic acid and fumaric acid, and the surface active agent is sodium dodecyl benzene sulfonate or op-10 emulsifier. The rust remover of the invention is smeared on the granite surface, can form a stable colorless complex with iron after reacting for 1-2 days, remove rusty points and rusty lines of the granitein a short time without influencing the granite luster or leaving trails and rapidly remove rust on the granite surface with high efficiency.

Owner:BEIJING ZHONGJIE JINGGONG TECH DEV

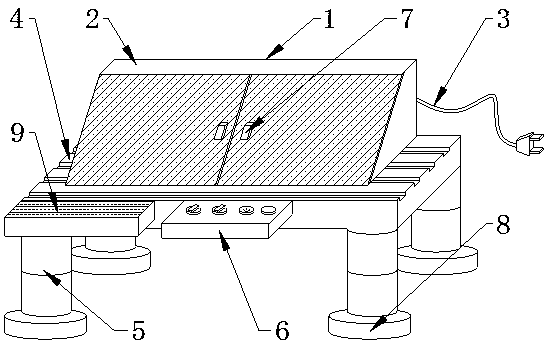

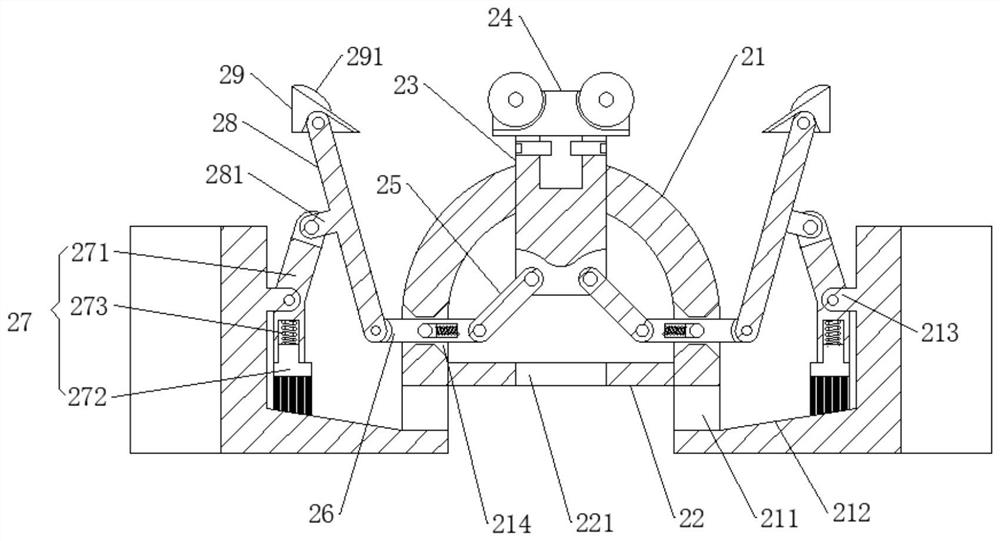

Adjustable steel bar surface rust removal device used in building field

ActiveCN111390731ATo achieve the purpose of rust removalComprehensive rust removalRevolution surface grinding machinesGrinding drivesRebarWorkbench

An adjustable steel bar surface rust removal device used in the building field comprises four supporting legs evenly distributed front and back and left and right. The top ends of the four supportinglegs are fixedly connected through a workbench. Two vertical plates symmetrically distributed left and right are fixedly mounted at the position, close to the front portion, of the middle of the top face of the workbench. Two electric telescopic rods symmetrically distributed up and down are fixedly mounted on the inner sides of the vertical plates, and the moving ends of the electric telescopic rods are opposite. Two cross shafts symmetrically distributed up and down are arranged between the inner sides of the two vertical plates. The cross shafts are located on the inner sides of the electric telescopic rods. Two mounting seats are mounted on the cross shafts through bearings, and the mounting seats are in one-to-one correspondence to the electric telescopic rods. According to the adjustable steel bar surface rust removal device, adjustment can be achieved according to the diameters of to-be-machined steel bars, and therefore the aim of carrying out rust removal on different diameters of to-be-machined steel bars is achieved, and adaptability is high; and meanwhile two corresponding semi-circular grinding plates matched with the to-be-machined steel bars are used for carrying outgrinding and rust removal on the to-be-machined steel bars together, then it can be ensured that comprehensive rust removal is carried out on the outer sides of the to-be-machined steel bars, and therust removal effect is good.

Owner:李书艳

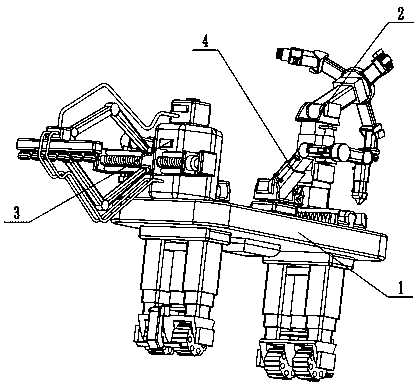

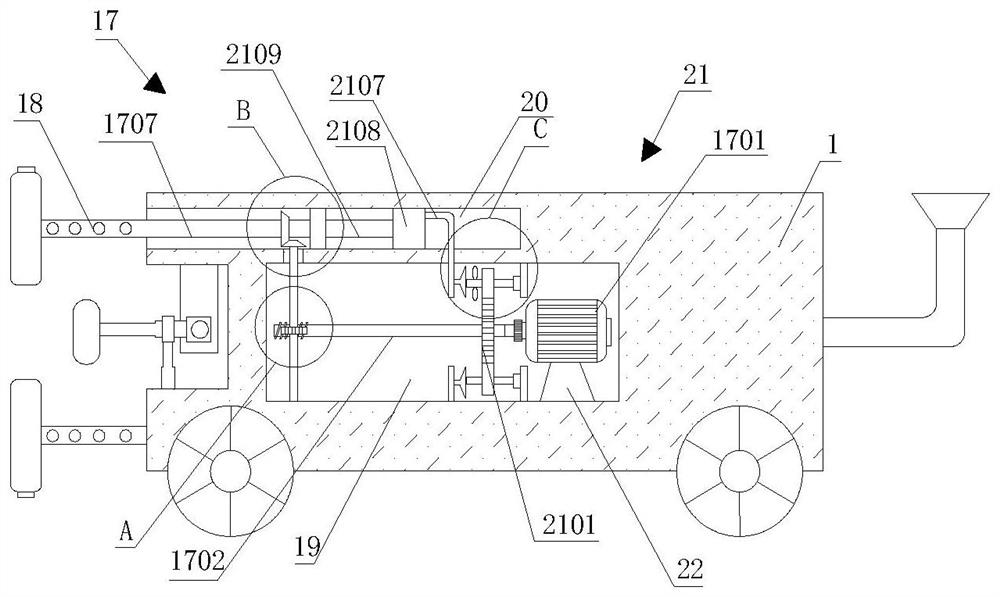

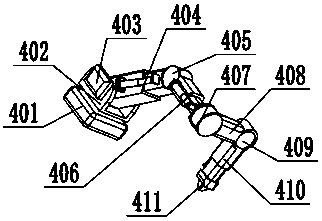

Industrial derusting device and method thereof

ActiveCN110103113APrevent rustAvoid secondary rustGrinding drivesGrinding machinesElectric power systemGrinding wheel

An industrial derusting device comprises a moving part, a mechanical part, a chemical part and an air blowing and fire spraying part, wherein the lower end surface of a chute plate of the mechanical part is fixedly connected with the upper end surface of a long plate of the moving part; an acidic solution tank of the chemical part is fixedly arranged on the upper end surface of the long plate of the moving part; and a motor B of the air blowing and fire spraying part is fixedly arranged on the upper end surface of the long plate of the moving part. Working position of an electric turntable isadjusted by coordinating work between a steering engine A, a telescopic mechanism B, a steering engine B and a connecting arm A. One of a grinding wheel, a pneumatic needle bundle device and a steel wire brush is selected to carry out work through rotation of the electric turntable. The grinding and derusting of the wheel grind are achieved through a built-in power system; the pneumatic needle bundle device is provided with an air pump and a pneumatic needle, and knocking rust removal is achieved through coordinated work of the air pump and the pneumatic needle; and the steel wire brush utilizes the rotation of the specially-made round steel wire brush to remove iron rust by impact and friction.

Owner:天长市西达克家居有限公司

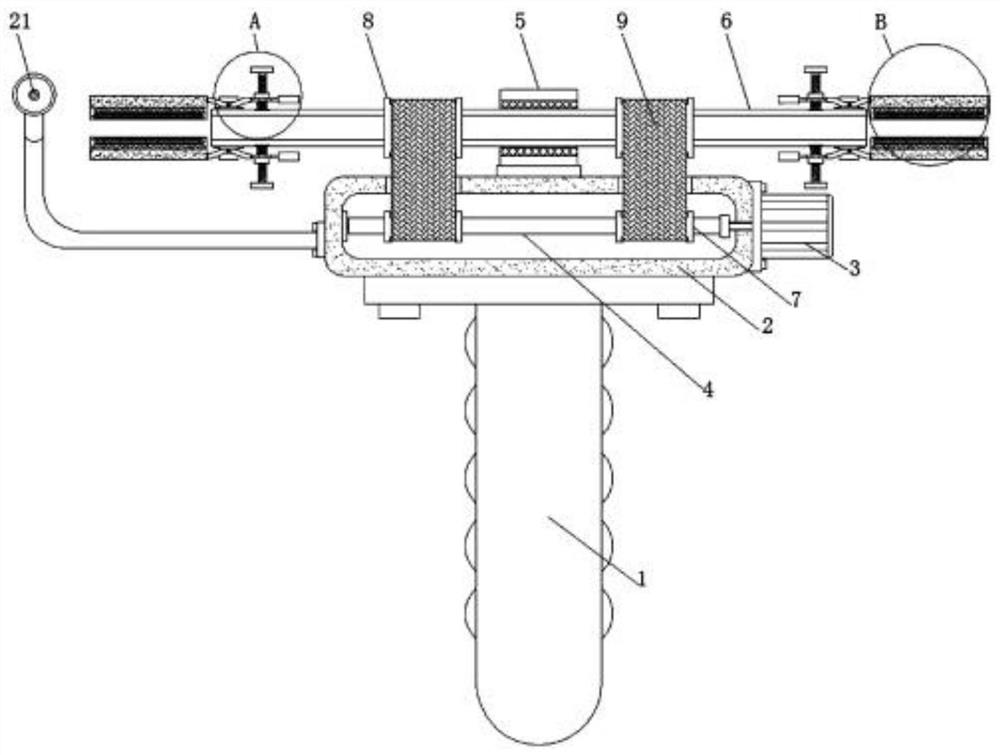

Handheld iron wire rust removing device

ActiveCN109129134AChange the way of rust removalReduce operating labor intensityGrinding drivesPortable grinding machinesDrive wheelLow speed

The invention relates to the technical field of iron wire rust removing and discloses a handheld iron wire rust removing device. The handheld iron wire rust removing device comprises a holding handle.The top of the holding handle is fixedly connected with a transverse fixing cylinder through a bolt. The right side end face of the transverse fixing cylinder is fixedly connected with a low-speed motor through a bolt. An output shaft of the low-speed motor penetrates the right side face of the transverse fixing cylinder and is fixedly connected with a torque rotating shaft through a coupler. Theend, away from the low-speed motor, of the torque rotating shaft is movably connected to the inner wall of the left side of the transverse fixing cylinder through a bearing base. The middle positionof the top of the transverse fixing cylinder is fixedly connected with a middle fixing bearing through a bolt. A transverse transmission pipe is fixedly inserted in the inner side of the middle fixingbearing in a penetrating manner, and two drive wheels are fixedly inserted in the torque rotating shaft in a penetrating manner. Driven wheels corresponding to the two drive wheels are inserted in the transverse transmission pipe in a penetrating manner. By means of the handheld iron wire rust removing device, a traditional manner for removing rust of iron wires manually is changed, and the operation labor intensity of rust removing of the iron wires is lowered.

Owner:南通市华星钢丝制品有限公司

Electromechanical product rust removing device

InactiveCN109176273AEmbody inventivenessGood rust removal effectGrinding carriagesGrinding drivesEngineeringRust

The invention discloses an electromechanical product rust removing device which comprises a rust removing device body, a dust removing bin and a bearing plate, wherein the dust removing bin is fixedlyconnected with the top of the dust removing device body; the bearing plate is fixedly connected with the bottom of the dust removing device body; a first grinding knife is fixedly connected with themiddle part of one side of the interior of the dust removing bin; a second grinding knife is fixedly connected with the top of one side of the interior of the dust removing bin; spray heads are fixedly connected with the interior of the dust removing bin; and a clamping device is movably connected with the bottom of the interior of the dust removing bin. The grinding knives can be driven by the clamping device to clean up rust on the surface of a product more rapidly, so that the high efficiency of the rust removing device body can be reflected; through the strong control capability of an NS16032 control chip, the convenience and the rapidness of the dust removing device body can be reflected; through a plating liquid, the product of which the rust is removed can have the anti-rust function after being treated, and then the multifunctionality of the dust removing device body can be reflected; and the electromechanical product rust removing device is convenient to use, is high in safety, is applicable to the technical field of dust removing devices, and has broad development prospects in the future.

Owner:含山县人和铸造有限公司

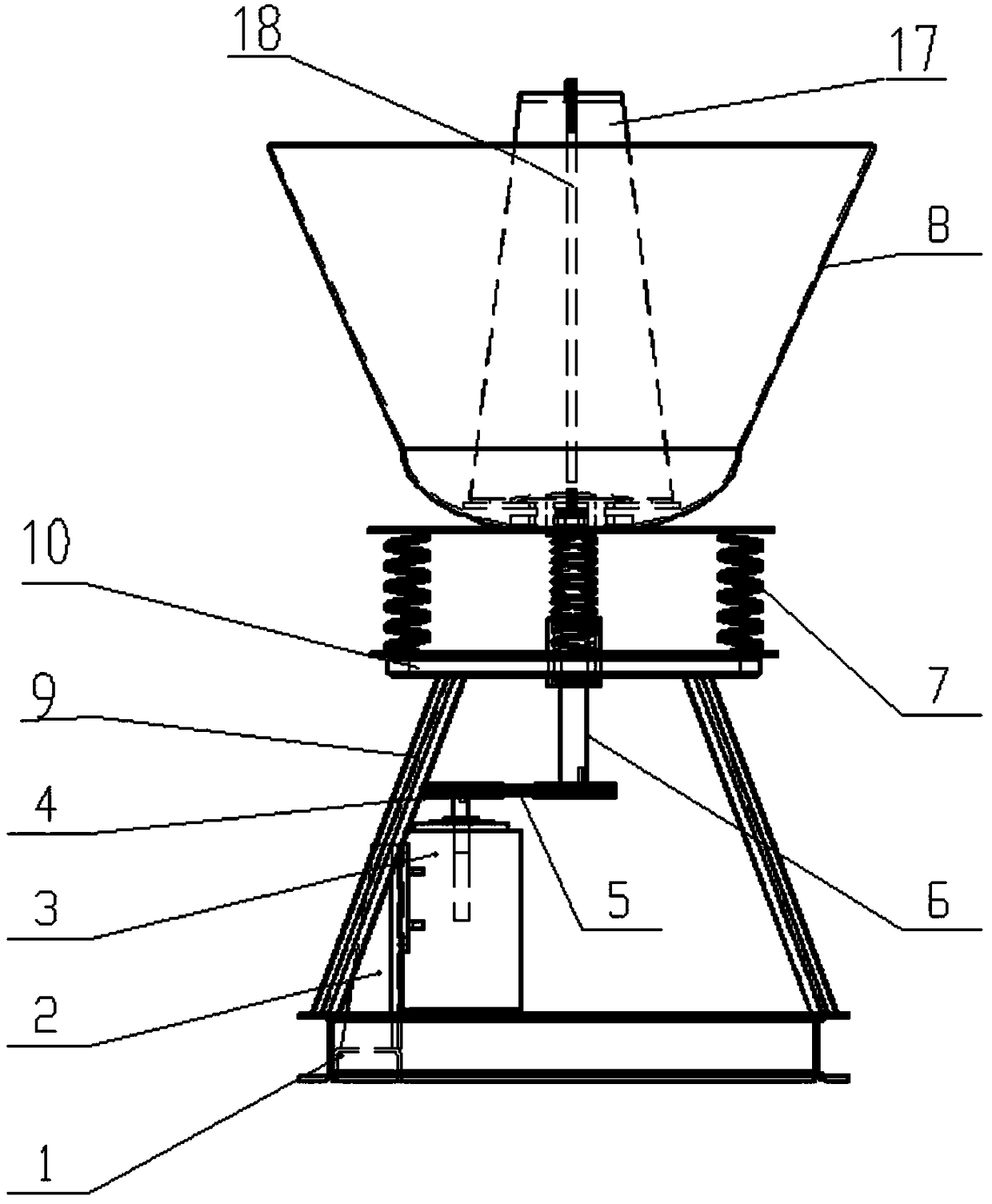

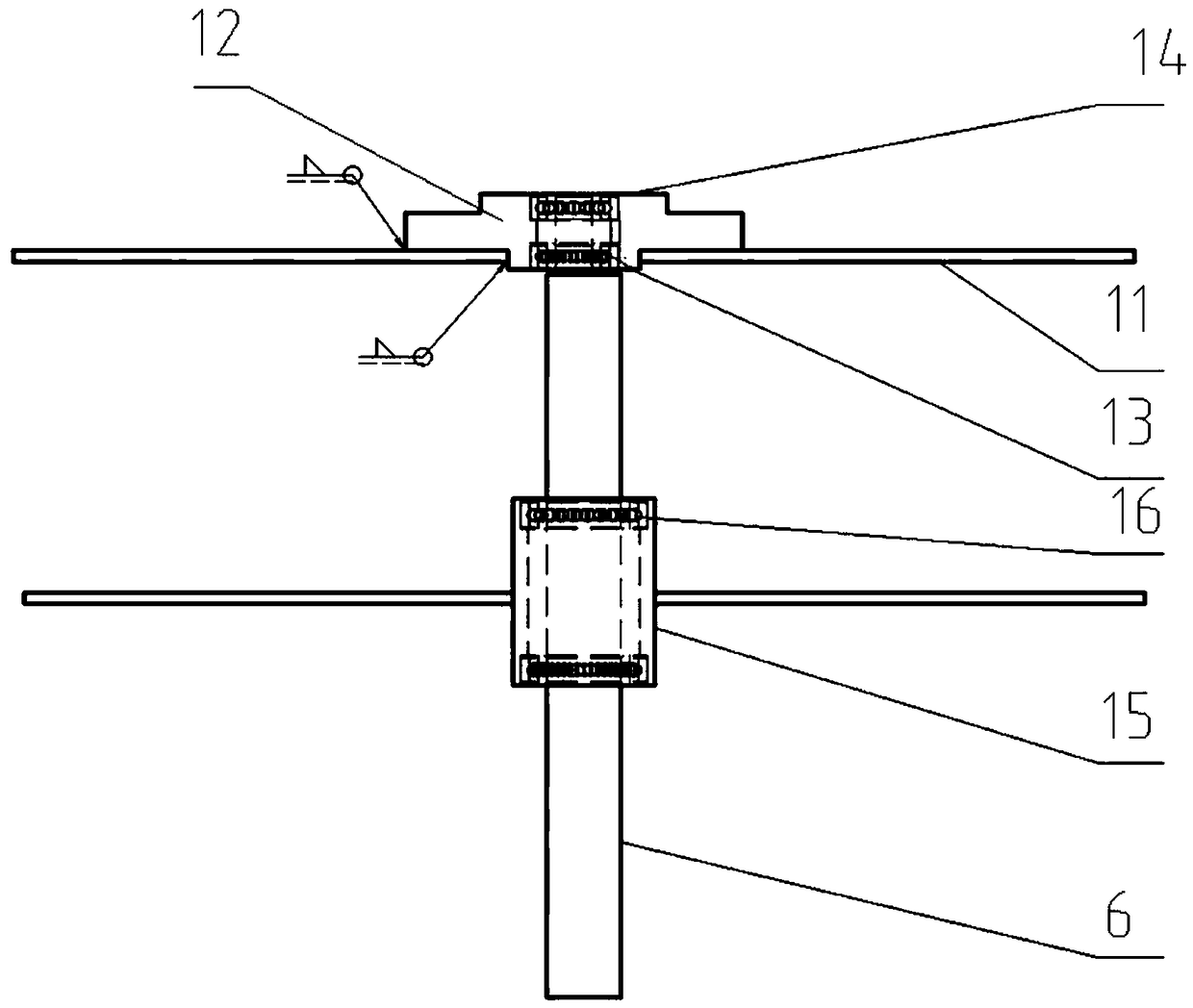

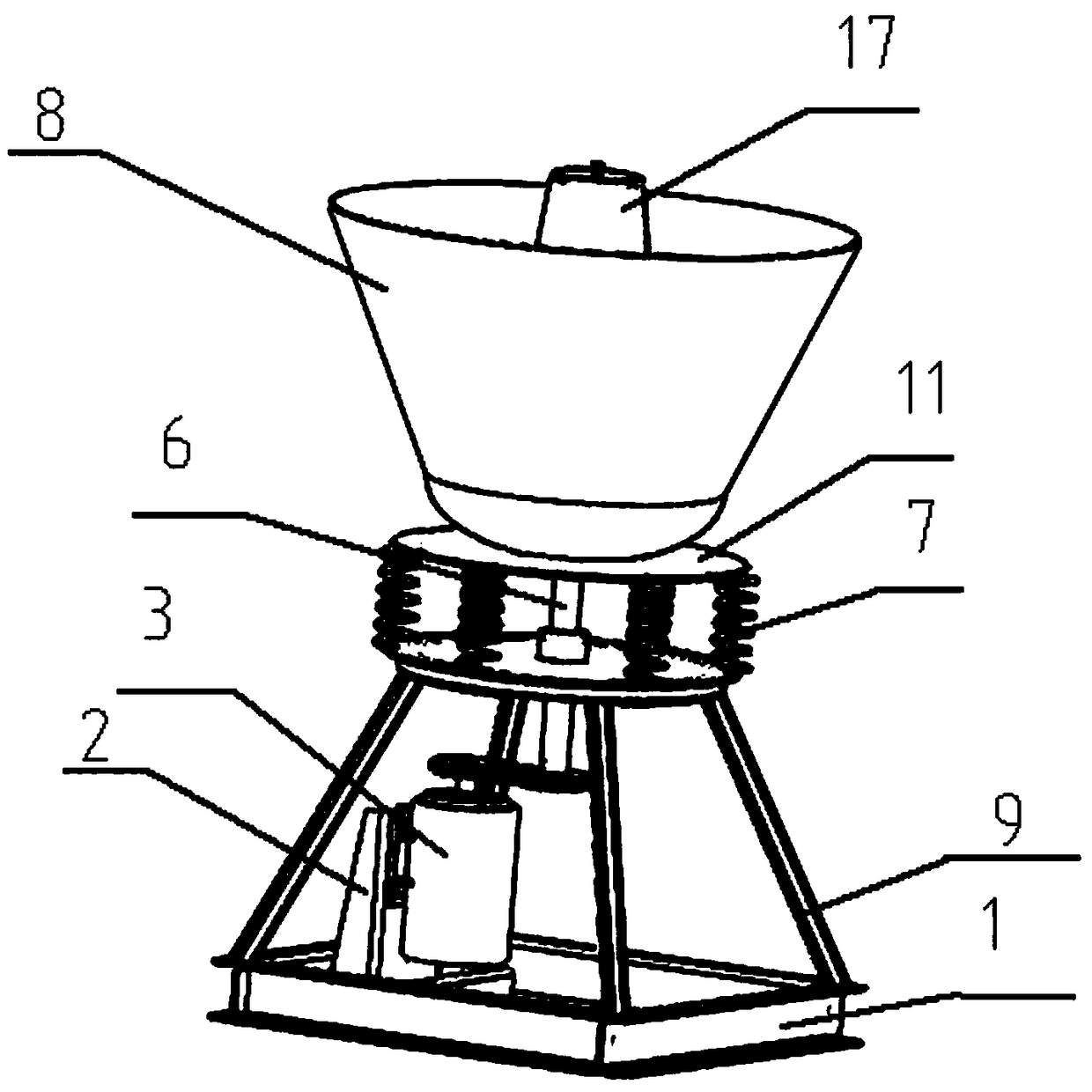

Novel accessory derusting equipment and working method thereof

PendingCN109129166ARealize indiscriminate derustingReduce noiseEdge grinding machinesPolishing machinesEngineeringSteel ball

The invention provides novel accessory derusting equipment. A bracket is connected with an equipment base. A motor is fixed into a bracket forming space. An output shaft of the motor is connected witha belt wheel, and is connected with a belt wheel at an eccentric shaft through a belt. The eccentric shaft penetrates through a fixing plate, and then is connected with a vibration tray. The structure of the connecting position between the vibration tray and the eccentric shaft is arranged to be that a flange disc is fixedly connected to the vibration tray; a hole is formed in the center of the flange disc and the vibration tray; a first beating protection sleeve is mounted in the hole; and the eccentric shaft is mounted in the first bearing protection sleeve through a first bearing. Supporting springs are fixed between the fixing plate and the vibration tray. An accessory container is fixedly connected with the vibration tray. The accessory container is internally provided with steel balls with different diameters and steel emery. The invention further provides a working method the the accessory derusting equipment. The accessory derusting equipment is easy to manufacture and is lowin cost, is convenient to use, and is free of pollution. Indistinguishable derusting to special-shaped accessories can be achieved.

Owner:中通新能源汽车有限公司

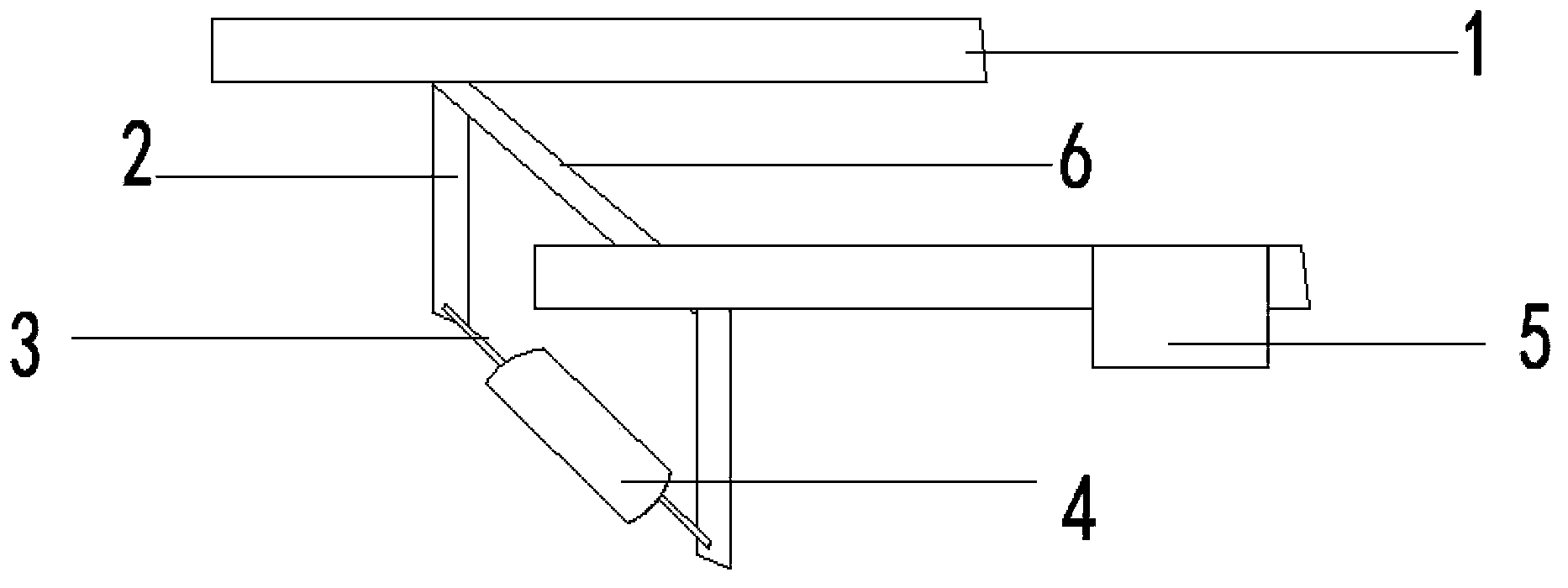

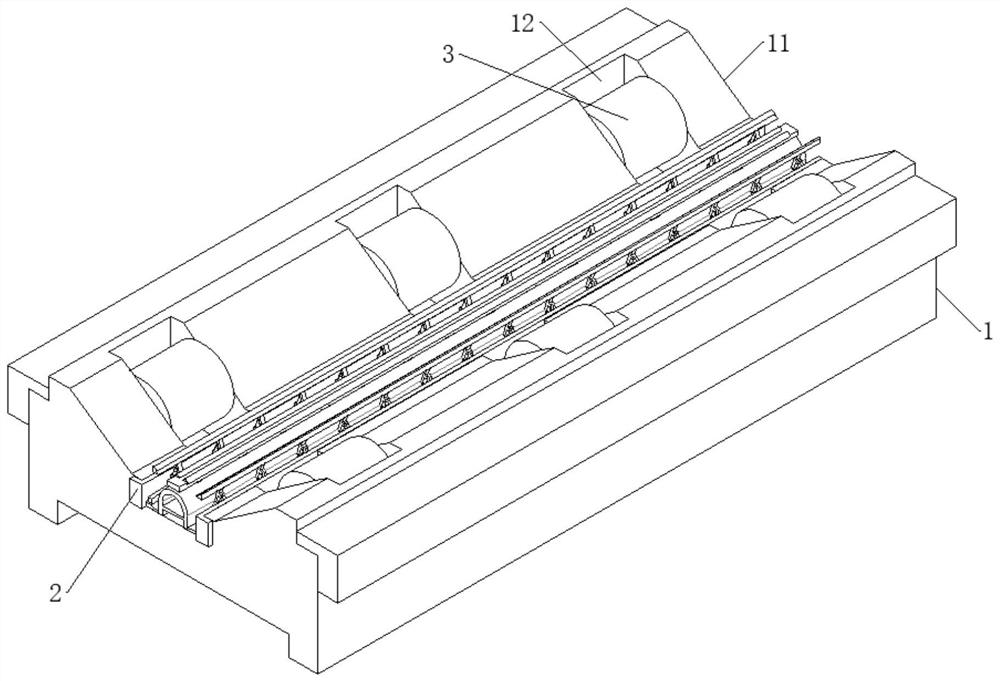

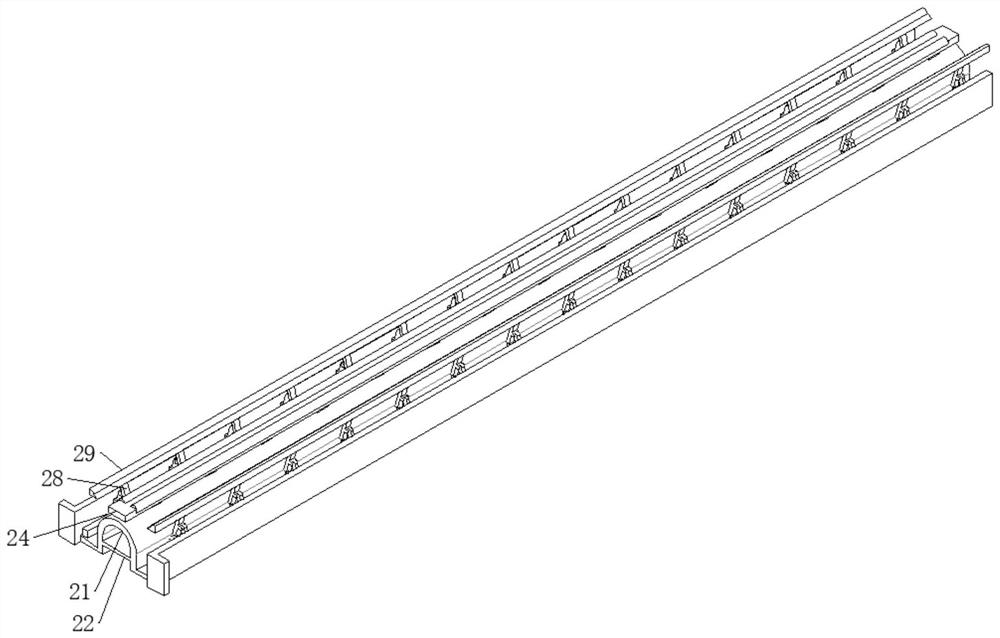

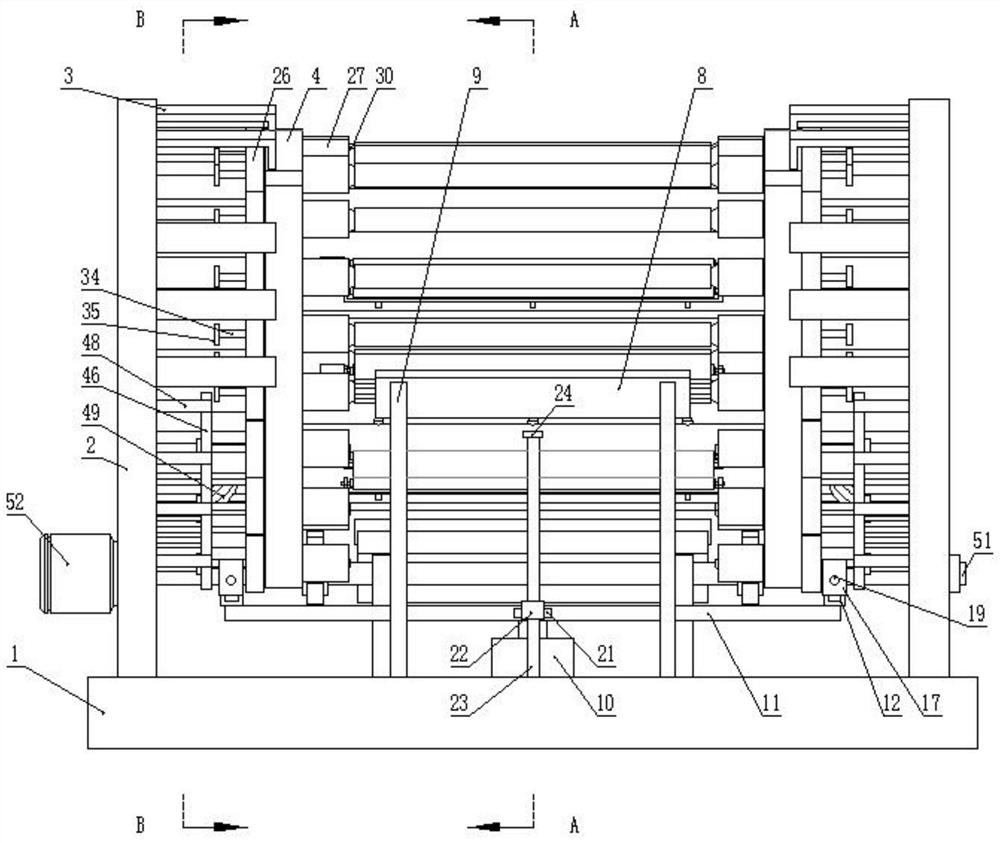

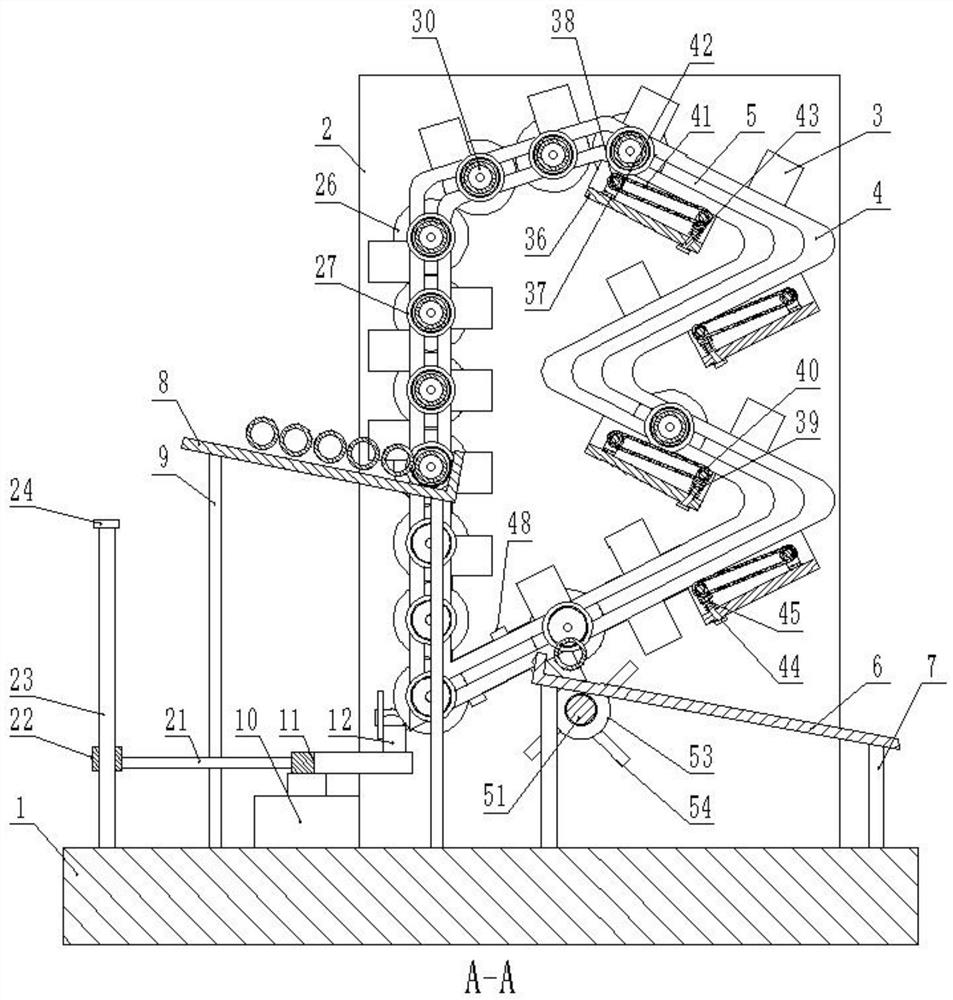

Intelligent conveying belt rust removing device

InactiveCN103662738AFully contactedTo achieve the purpose of rust removalCleaningEngineeringMechanical engineering

The invention discloses an intelligent conveying belt rust removing device. The device comprises a beam, the two ends of the beam are respectively provided with a sliding rail, connection rods are symmetrically arranged in the vertical direction of the beam, the bearing seats are arranged at the two ends of the connection rods respectively, sand rolls are arranged between the bearing seats, and a motor is fixed to the lateral wall of the beam. The intelligent conveying belt rust removing device has the advantages that the sliding rails arranged at the two ends of the beam respectively are used for fixing the rust removing device to a conveying belt, the connection rods are symmetrically arranged in the vertical direction of the beam, the bearing seats are arranged at the two ends of the connection rods respectively, the sand rolls are arranged between the bearing seats, the requirement for conveying belts of different specifications is met, sufficient contact of the sand rolls and the conveying belt part is ensured to achieve the aim of rust removing.

Owner:西安欧德节能新材料有限责任公司

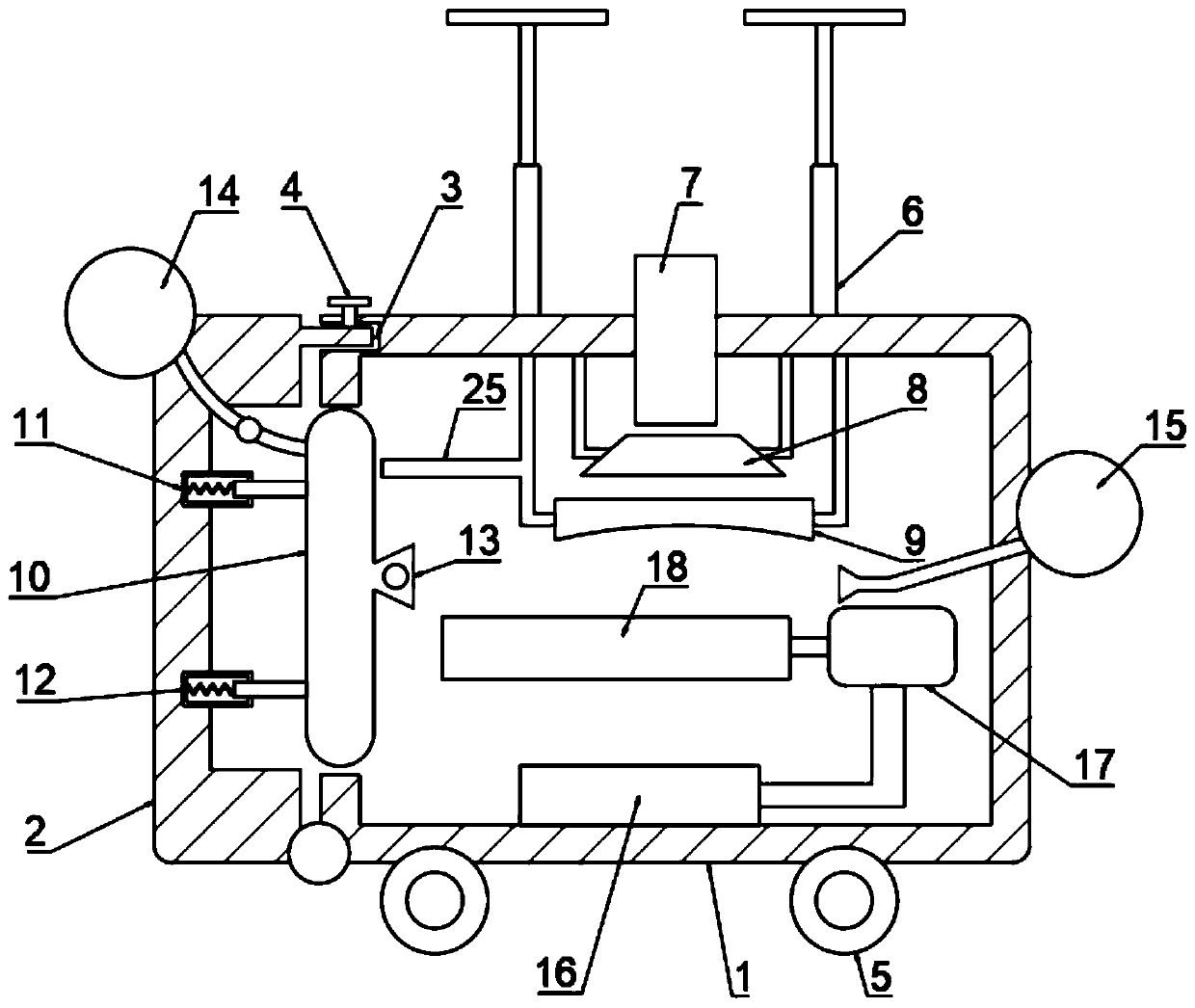

Portable device for derusting metal surface through semiconductor laser

InactiveCN110665906AEasy to moveIncrease laser intensityDirt cleaningCleaning using gasesErbium lasersNitrogen gas

The invention discloses a portable device for derusting a metal surface through the semiconductor laser. The portable device for derusting the metal surface through the semiconductor laser comprises atank, wherein an end cover is rotatably connected to one end of the tank; a connecting mechanism is arranged between the end cover and the tank; multiple rolling wheels are arranged on the lower sidewall of the tank; two pull rods are fixed to the upper side wall of the tank; a laser device is fixed to the inner top wall of the tank; the drive end of the laser device is vertically downward; a beam expanding mirror and a focusing mirror are sequentially arranged on the lower side of the laser device; connecting rods are fixedly connected between the outer side wall of the beam expanding mirror and the inner top wall of the tank as well as the outer side wall of the focusing mirror and the inner top wall of the tank; and a telescopic rod I is fixed to the inner bottom wall of the tank. According to the portable device for derusting the metal surface through the semiconductor laser provided by the invention, the derusting work on a workpiece surface is realized through realizing the moving and steering of the clamping work and the contact of a laser beam, so that the thoroughness in derusting is realized, and no metal damage or environment pollution can be caused; and meanwhile, nitrogen is sprayed out for protecting the metal and blowing away powder dust, so that the derusting work is ensured to be well carried out.

Owner:南理工泰兴智能制造研究院有限公司

Mechanical metal material surface rust removal device

PendingCN112064041AAvoid the problem of poor rust removal effectTo achieve the purpose of rust removalMetallic materialsElectric machinery

The invention relates to the technical field of rust removal devices, in particular to a mechanical metal material surface rust removal device which comprises a base, and a conveying groove is formedin the left side of the upper side wall of the base. A rust removal groove, a stainless steel supporting net and a second traction motor are arranged, thus diluted hydrochloric acid can be injected into an inner cavity of the rust removal groove during rust removal, the second traction motor is started to work after a metal material to be subjected to rust removal falls on the stainless steel supporting net, the second traction motor drives a second winding disc to rotate, a wound second traction rod is unwound, further, a rust steel mounting frame and the stainless steel supporting net move downwards under the action of gravity until the metal material to be derusted is immersed in the diluted hydrochloric acid in the inner cavity of the rust removal groove, so that rust on the surface ofthe metal material can be effectively corroded by the diluted hydrochloric acid, and the derusting purpose is achieved. The problems that in a traditional material grinding mode, rust removal is conducted on metal materials, pollution is large in the rust removal process, and the rust removal effect on part of special-shaped metal materials is poor are solved.

Owner:王娜娜

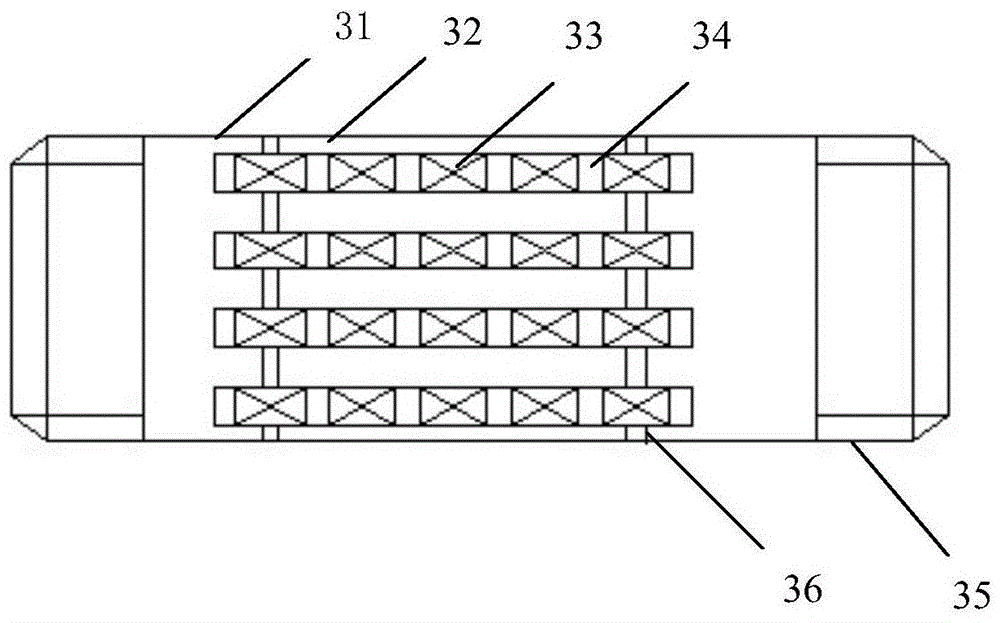

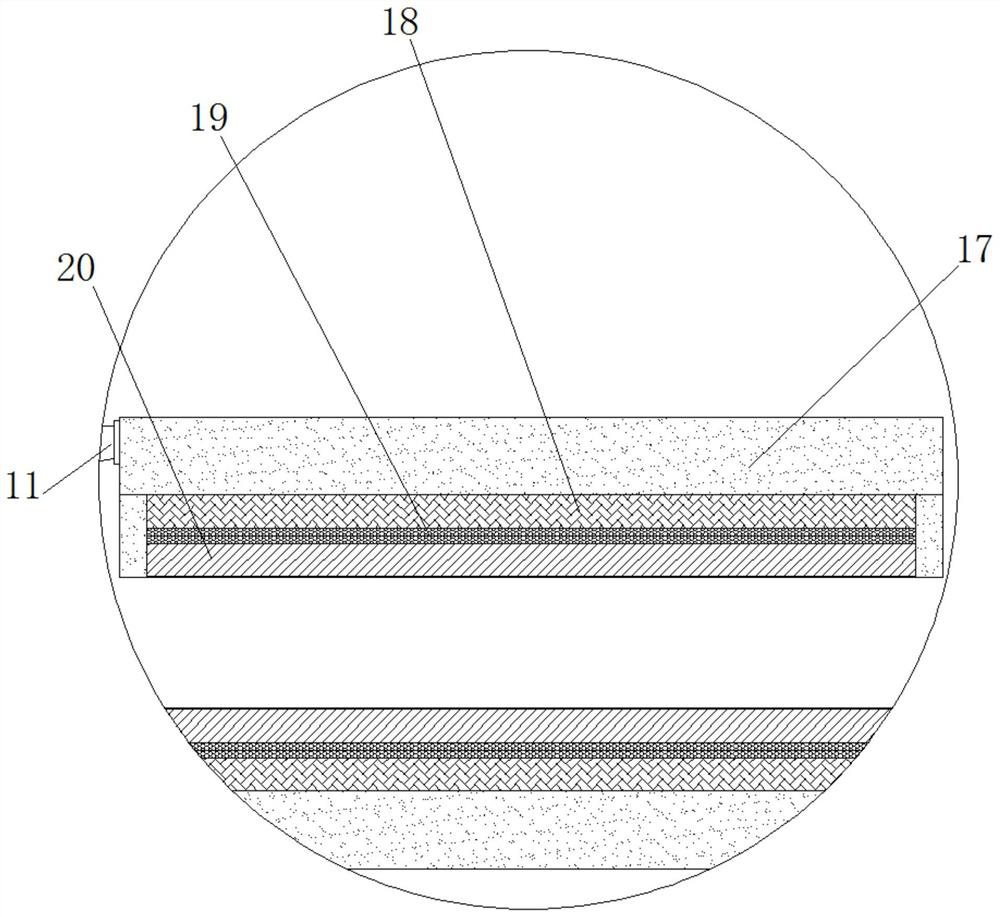

Electroplating process of nickel-plated steel strip for battery

The invention provides an electroplating process of a nickel-plated steel strip for a battery. A base strip is subjected to unwinding, pickling, electroplating, water washing and rewinding to be produced into the nickel-plated steel strip. The pickling step specifically includes the steps that the base strip is placed in a pickling solution for 0.5-1.0 min with a certain traveling speed, the pickling solution is prepared form hydrochloric acid, sulfuric acid and water, the mass concentration of chloride ions in the pickling solution is controlled to be 4.2-5.0g / L, and the pH value of the pickling solution is controlled to be 0.1-1.0. The electroplating process of the nickel-plated steel strip for the battery is simple and feasible, the steps are simplified, the yield of good products of the steel strip is increased, and the waste water treatment cost and the electroplating solution management and control cost can be reduced.

Owner:CHANGDE LYRUN MATERIAL

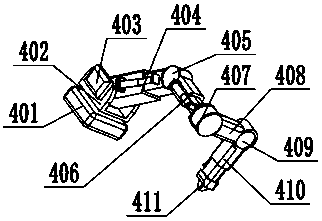

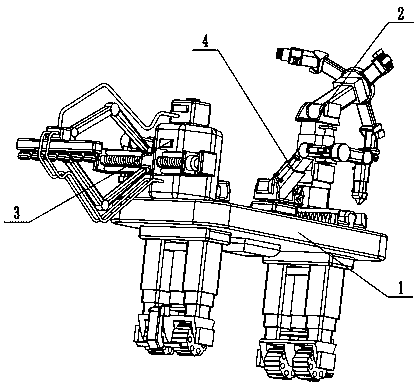

Pipeline inner wall repairing robot

PendingCN113400171ATo achieve the purpose of rust removalAct as a barrierRevolution surface grinding machinesGrinding drivesDrive wheelDrive shaft

The invention relates to the technical field of pipeline repairing, and discloses a pipeline inner wall repairing robot. The robot comprises a vehicle body, a second hollow groove and a third hollow groove are formed in the vehicle body, and a grinding mechanism and a dust collection mechanism are arranged in the second hollow groove; the grinding mechanism comprises a micro motor, a worm, a worm gear, a transmission shaft, a first bevel gear, a second bevel gear and a hollow pipe; the dust collection mechanism comprises a first gear, a second gear, a shaft, a fixing plate, fan blades, a suction nozzle, an L-shaped pipe, a dust collection box, a connecting pipe and a dust screen; and a spraying pipe is arranged on one side of the vehicle body, one end of the spraying pipe communicates with a high-pressure nozzle, and driving wheels are installed at the bottom of the vehicle body. According to the pipeline inner wall repairing robot, the worm drives the worm gear to rotate by starting the micro motor, so that the transmission shaft drives the first bevel gear to rotate, then the second bevel gear drives the hollow pipe to rotate, and finally the purpose that a polishing plate removes rust on the inner wall of a pipeline can be achieved.

Owner:云南埃菲尔管业有限公司

Handheld iron wire rust removal equipment and using method

InactiveCN112372462AChange the way of rust removalReduce operating labor intensityGrinding drivesPortable grinding machinesFixed bearingDrive wheel

The invention relates to the technical field of iron wire rust removal, and discloses handheld iron wire rust removal equipment and a using method thereof. The handheld iron wire rust removal equipment comprises a holding handle, wherein a transverse fixing barrel is fixedly connected to the top of the holding handle through a bolt, and a low-speed motor is fixedly connected to the right side endface of the transverse fixing barrel through a bolt; an output shaft of the low-speed motor penetrates through the right side face of the transverse fixing barrel and is fixedly connected with a torque rotating shaft through a coupler, and the end, away from the low-speed motor, of the torque rotating shaft is movably connected to the inner wall of the left side of the transverse fixing barrel through a bearing base; and a transverse transmission pipe is fixedly inserted into the inner side of a middle fixing bearing in a penetrating manner, two driving wheels are fixedly inserted into the torque rotating shaft in a penetrating manner, and driven wheels corresponding to the two driving wheels are fixedly inserted into the transverse transmission pipe in a penetrating manner. According to the handheld iron wire rust removal equipment, the traditional manual iron wire rust removal mode is changed, and the operation labor intensity of iron wire rust removal is reduced.

Owner:杨喜光

a sand blasting device

ActiveCN105904349BReduce pollutionProtect healthAbrasive feedersAbrasive machine appurtenancesAir pumpEngineering

Owner:山东奥维特汽车零部件有限公司

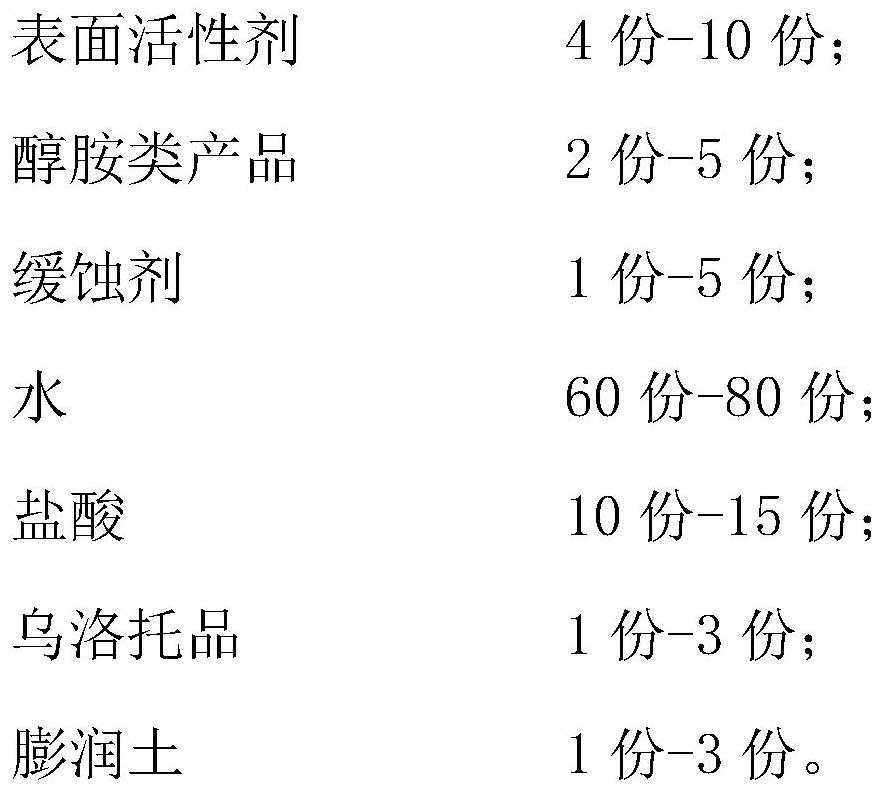

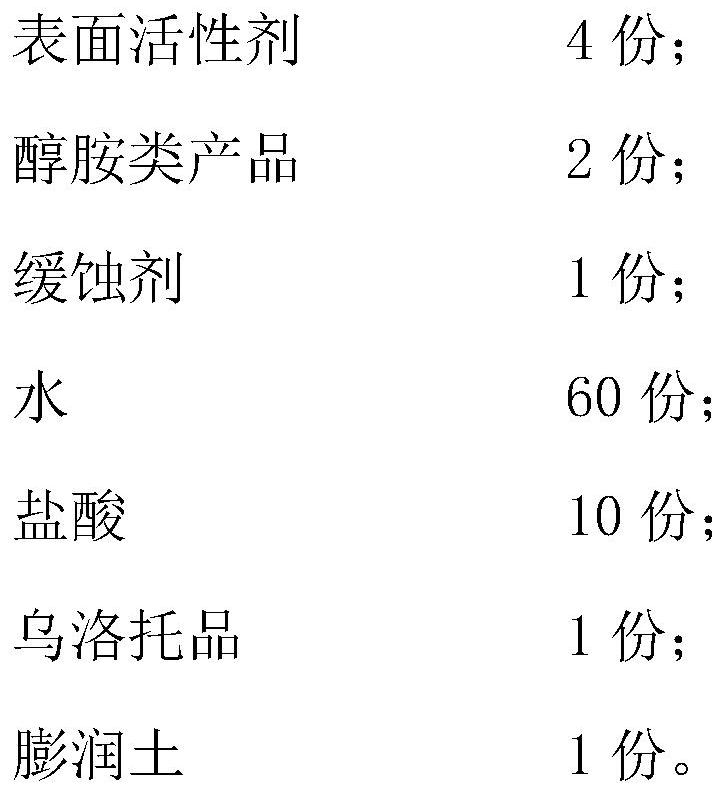

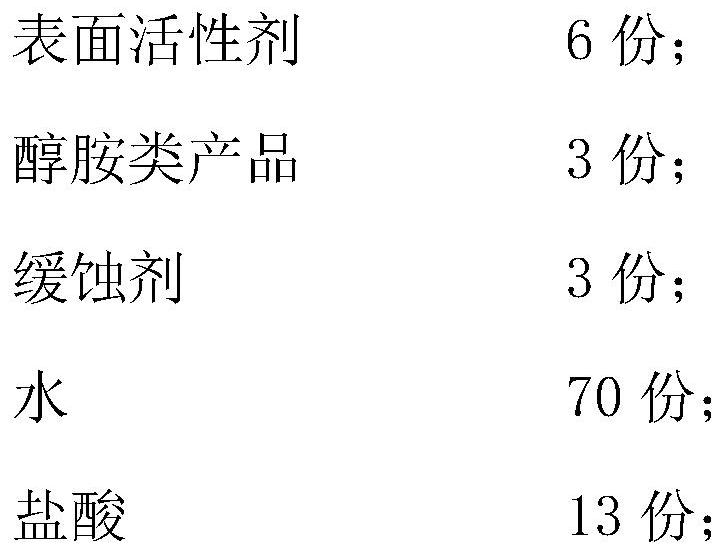

Mist-inhibiting rust remover and preparation method thereof

The invention discloses a mist-inhibiting rust remover and a preparation method thereof. The mist-inhibiting rust remover comprises the following raw materials in parts by weight: 4 to 10 parts of surfactant; 2 to 5 parts of amine product; 1 to 5 parts of corrosion inhibitor; and 60 to 80 parts of water. The invention relates to the technical field of chemical engineering. According to the mist-inhibiting rust remover and the preparation method thereof, 4 to 10 parts of the surfactant is arranged, the surfactant can foam and remove dirt on the metal surface, generated foam can play a role in blocking acid mist; 2 to 5 parts of alcohol amine product is arranged, so that the surfactant can be attached to the metal surface to avoid rusting after rust removal is finished; 1 to 5 parts of corrosion inhibitor is arranged, rust removal of hydrochloric acid can be assisted, the rust removal efficiency is improved; 60 to 80 parts of water is arranged to serve as a carrier solution; and 10 to 15parts of hydrochloric acid is arranged, the hydrochloric acid can be subjected to a chemical reaction with rust and metal oxide to generate soluble salt, so that the rust removal purpose is achieved.

Owner:仙桃市环美化工有限公司

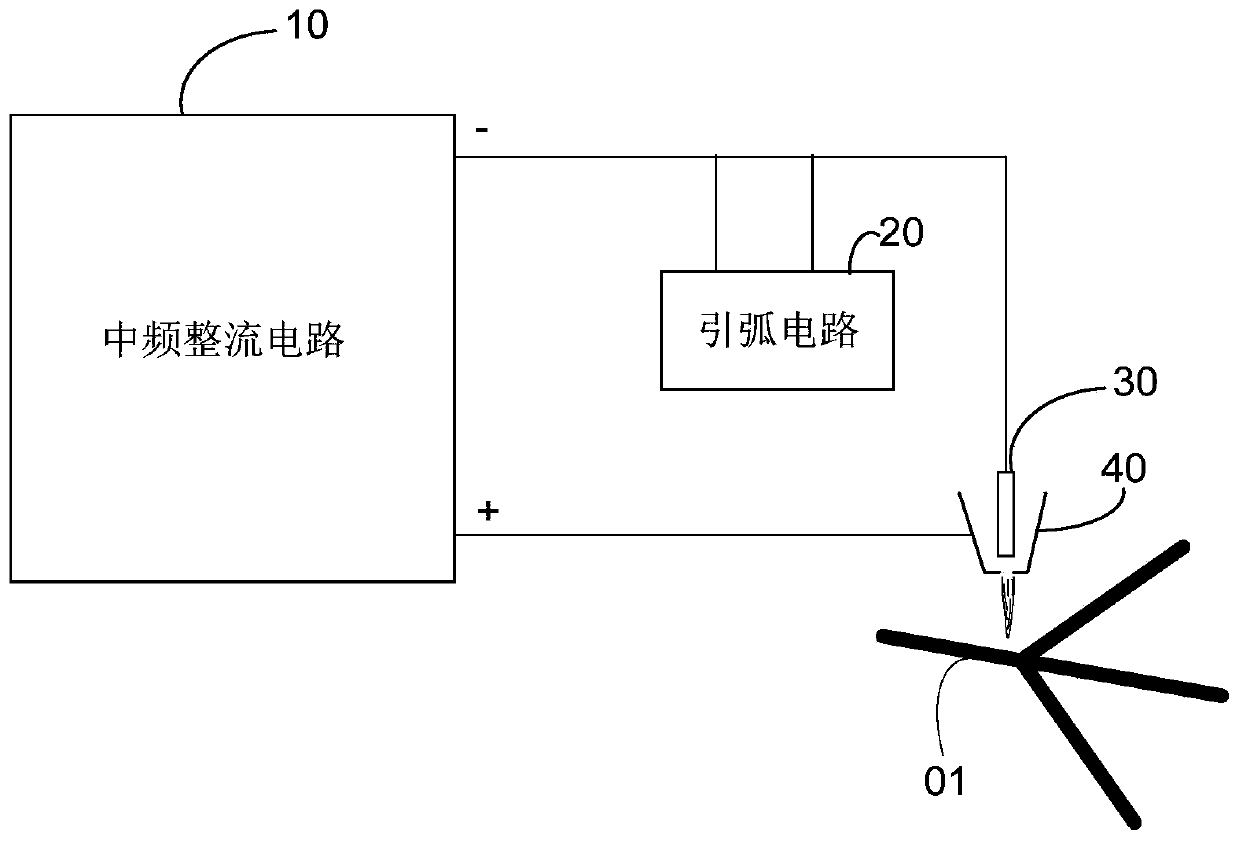

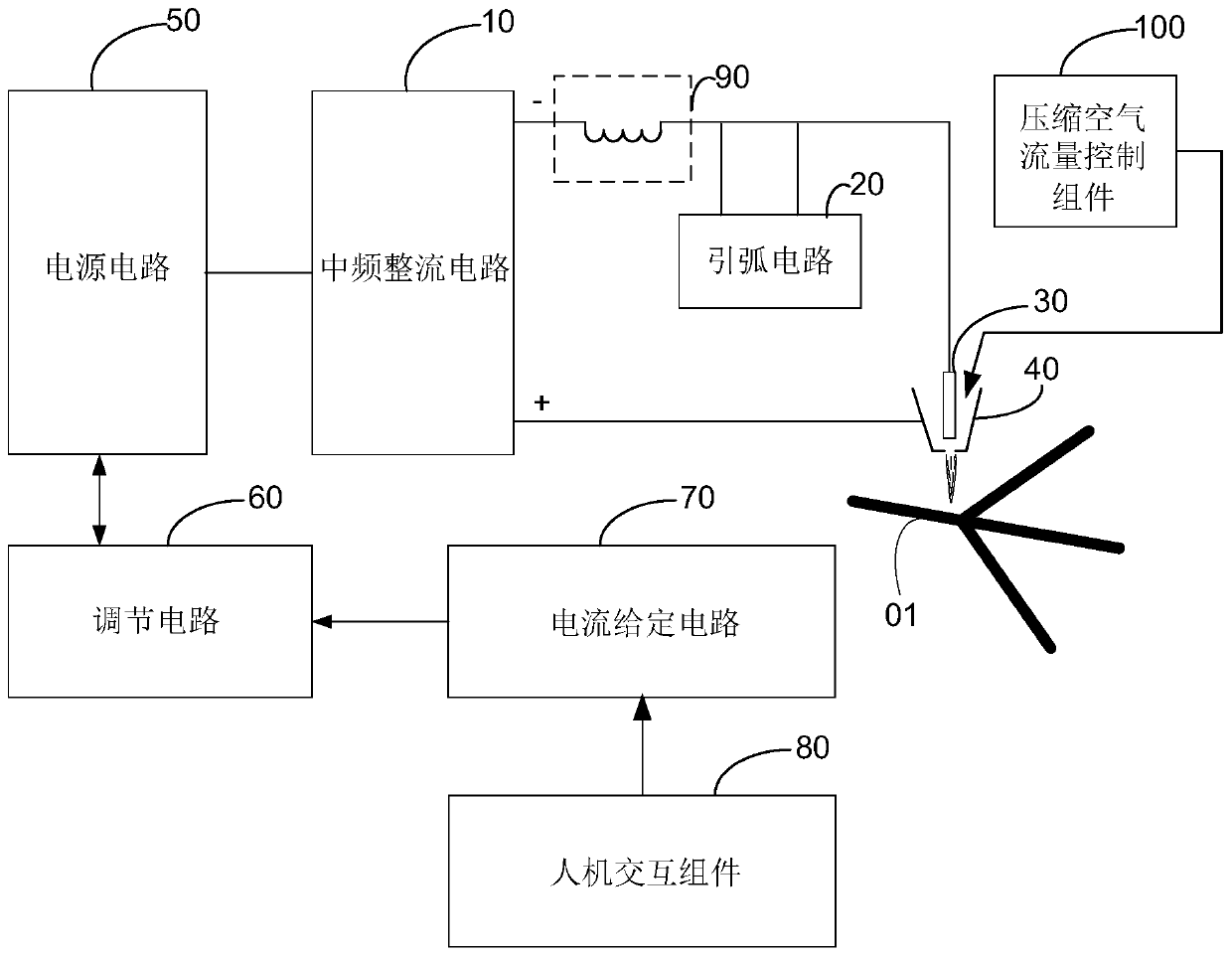

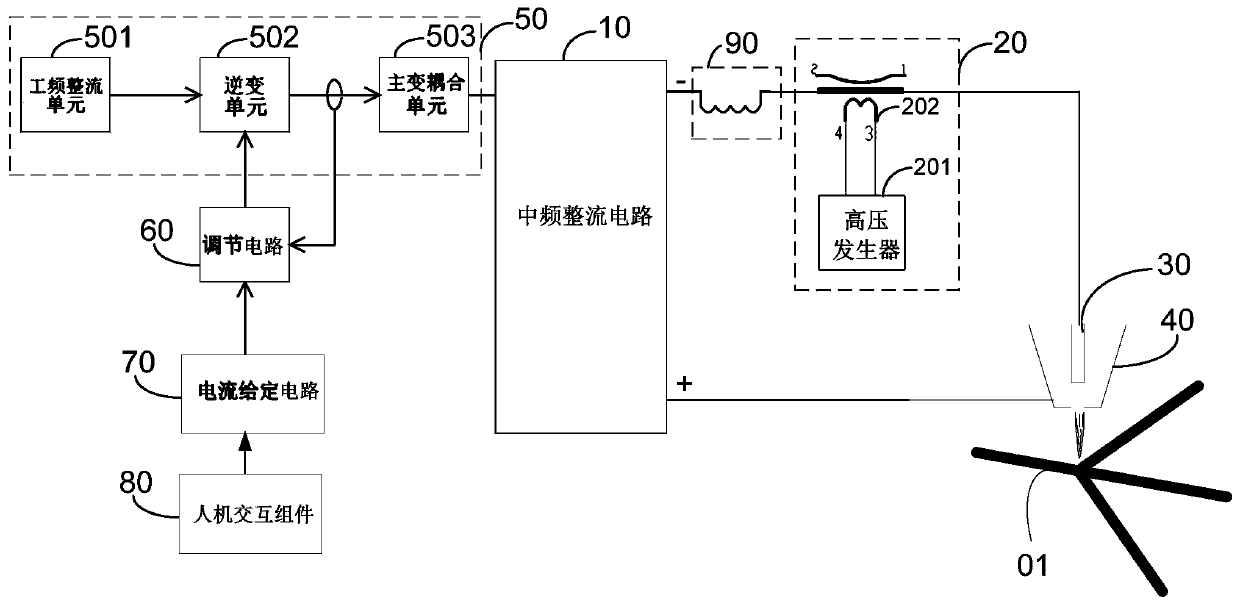

Rust removal device and method

PendingCN110860772AAvoid it happening againLow efficiencyPlasma welding apparatusLow noiseMetallurgy

The invention discloses a rust removal device and method. The rust removal method comprises the steps that after intermediate frequency rectification of an incoming intermediate-frequency low-voltagealternating current signal is carried out through an intermediate frequency rectification circuit, a direct current signal is output to a nozzle and an electrode through a positive electrode output end and a negative electrode output end, an arc starting circuit outputs a target frequency signal and the target frequency signal is coupled to the negative electrode output end to enable an electrodeto discharge, and a gas igniting arc between the electrode and the nozzle is broken down; and the arc is ejected from a narrow hole channel of the nozzle by compressed gas, the compressed arc energy is more concentrated, and the gas in an arc column is fully ionized to form a high-temperature plasma arc. The high-temperature and high-speed plasma arc acts on a rusty workpiece, and after rust markson the surface of the rusty workpiece are heated by the plasma arc and subjected to the high-speed impact of a plasma, the rust marks instantly expand, deform, break and finally fall off the surfaceof the workpiece to achieve the effect of rust removal. According to the rust removal device and method, rust marks on various shapes of workpieces can be efficiently cleaned, large amount of dust produced by mechanical friction is avoided, low noise and environmental protection are achieved, no special rust removal site is required, and the practicality is high.

Owner:SHENZHEN JASIC TECH

A kind of industrial descaling equipment and method

ActiveCN110103113BReduce construction intensityReduce construction costsGrinding drivesGrinding machinesElectric machineElectric power system

An industrial derusting device comprises a moving part, a mechanical part, a chemical part and an air blowing and fire spraying part, wherein the lower end surface of a chute plate of the mechanical part is fixedly connected with the upper end surface of a long plate of the moving part; an acidic solution tank of the chemical part is fixedly arranged on the upper end surface of the long plate of the moving part; and a motor B of the air blowing and fire spraying part is fixedly arranged on the upper end surface of the long plate of the moving part. Working position of an electric turntable isadjusted by coordinating work between a steering engine A, a telescopic mechanism B, a steering engine B and a connecting arm A. One of a grinding wheel, a pneumatic needle bundle device and a steel wire brush is selected to carry out work through rotation of the electric turntable. The grinding and derusting of the wheel grind are achieved through a built-in power system; the pneumatic needle bundle device is provided with an air pump and a pneumatic needle, and knocking rust removal is achieved through coordinated work of the air pump and the pneumatic needle; and the steel wire brush utilizes the rotation of the specially-made round steel wire brush to remove iron rust by impact and friction.

Owner:天长市西达克家居有限公司

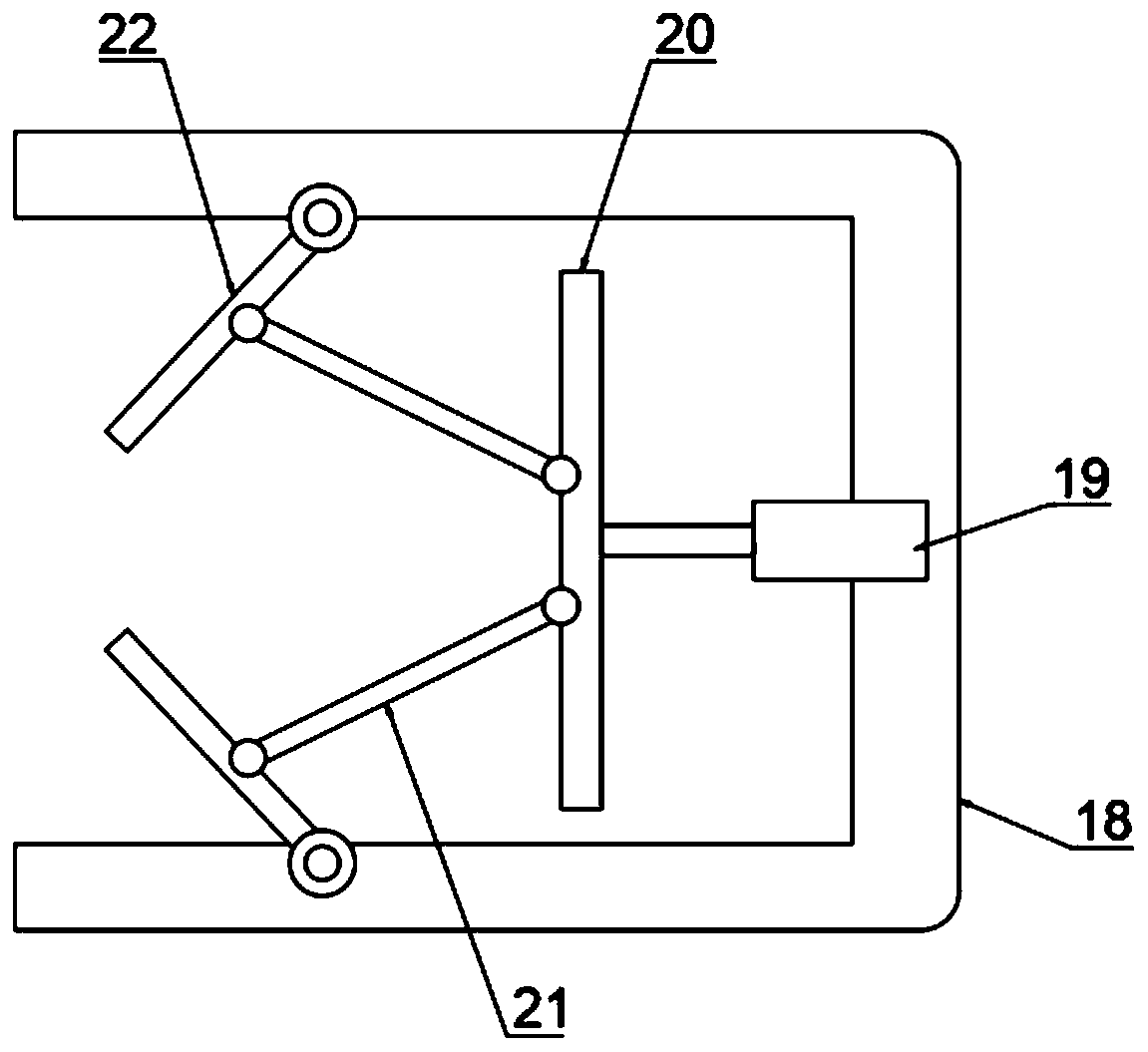

Metal pipe fitting rust removal device

InactiveCN112959199AEasy to placeTo achieve the purpose of rust removalRevolution surface grinding machinesGrinding drivesPipe fittingDrive shaft

The invention discloses a metal pipe fitting rust removal device, and relates to the technical field of metal machining equipment. The metal pipe fitting rust removal device comprises a support, a V-shaped groove distributed in the length direction of the support is formed in the support, a plurality of deep grooves are evenly distributed in the two opposite side faces of the V-shaped groove, and a clamping groove is formed in the bottom face of the V-shaped groove; transmission wheels are installed in the two oppositely-distributed deep grooves, transmission shafts penetrating through the transmission wheels fix the transmission wheels to the support, and the ends of the transmission wheels are in transmission connection with a power assembly; and a rust removal part is fixedly mounted in the clamping groove and is attached to the surface of a pipe body placed in the V-shaped groove. A movable block arranged in the rust removal part is connected with a multi-connecting rod, the placed metal pipe body pushes the movable block to move downwards, meanwhile, a friction part is pushed by the multi-connecting rod to move upwards, the friction part is attached to the surface of the metal pipe body, and the rust removal effect is conveniently improved.

Owner:沈雅娟

Rust-proof paste for treating surface corrosion of metal material

InactiveCN104099628ATo achieve the purpose of rust removalReduce manufacturing costThioureaMetallic materials

The invention discloses rust-proof paste for treating surface corrosion of a metal material. The rust-proof paste consists of the following raw materials in parts: 10-15 parts of sodium hydroxide, 20-25 parts of sodium carbonate, 50-80 parts of nitric acid, 5-10 parts of charcoal powder, 10-12 parts of corncob powder, 12-15 parts of bauxite powder, 5-10 parts of fireproofing mud glue, 12-15 parts of ethylenediamine, 3-5 parts of eriochrome black t, 5-8 parts of thiourea, 2-5 parts of formaldehyde, and 50-80 parts of de-ionized water. The rust-proof paste for treating the surface corrosion of the metal material is paste at the normal temperature, and can be utilized to coat a metal rust place, then the paste is scraped off after several minutes, and the rust-proof purpose can be achieved after the water cleaning. The rust-proof paste is low in production cost, can help to improve the working environment and shorten the process steps, and is easy to operate and master.

Owner:梁胜光

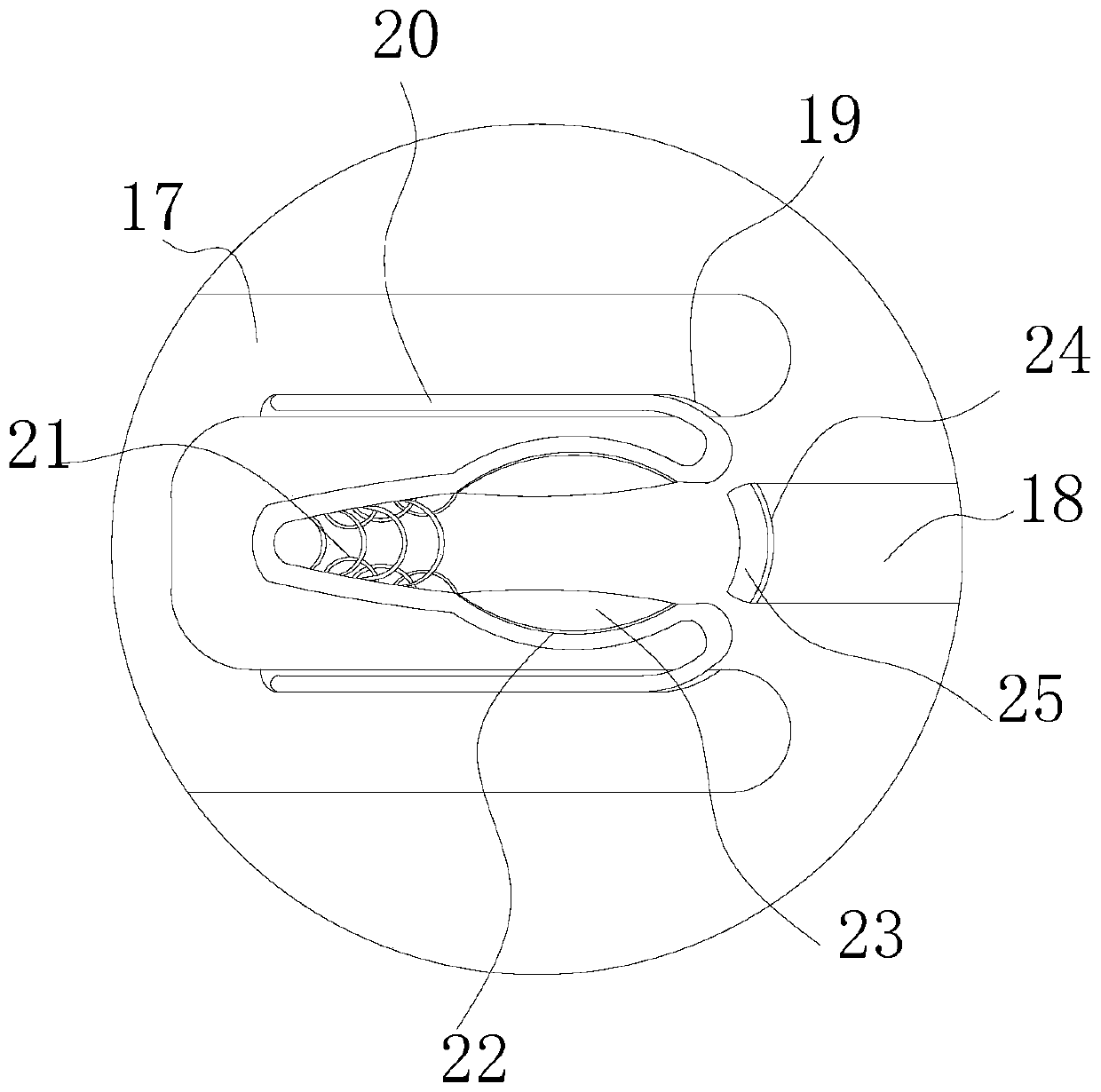

Handheld type iron wire surface rust treatment device

ActiveCN110238741APrevent disengagementTo achieve the purpose of friction rust removalGrinding drivesPortable grinding machinesBristleEngineering

The invention relates to the technical field of iron wire treatment, and discloses a handheld type iron wire surface rust treatment device. A mounting base is fixedly mounted on the top of a handle, a transverse adjusting box is fixedly mounted on the top of the mounting base, a middle bearing is fixedly mounted on the bottom of the inner side of the transverse adjusting box, a transverse polish rod transversely penetrates through the bearing inner ring of the middle bearing in an inserted manner, the two ends of the transverse polish rod penetrate through the left inner side wall and the right inner side wall of the transverse adjusting box correspondingly, and are fixedly connected with two star handles correspondingly, and a positive thread and a reverse thread are formed on the transverse polish rod. According to the handheld type iron wire surface rust treatment device, an elastic rust removal piece in an inner pressing ring carries out rotary repeated extrusion friction on the annular side face of an iron wire, mutually staggered arc bristles of an arc brush can make sufficient contact with the side of the iron wire, the elastic rust removal piece is connected with the arc brush, rust removal leaving of the iron wire side can be avoided, and the iron wire rust removal aim is achieved.

Owner:杭州卓维机械有限公司

Composite pressure-resistant metal part machining device and manufacturing process thereof

InactiveCN113458980AIncrease temperaturePrevent damp cakingBlast gunsAbrasive feedersProcess engineeringStructural engineering

The invention discloses a composite pressure-resistant metal part machining device and a manufacturing process thereof. The composite pressure-resistant metal part machining device comprises a working plate, a protective cover, a flow dividing pipe, a storage barrel and a spray head, the protective cover is installed on one side of the outer wall of the upper end of the working plate, a connecting cover is installed on one side of the outer wall of the lower end of the working plate, the flow dividing pipe is installed on one side of the upper end of the inner wall of the protective cover, a feeding pipe is inserted into one side of the outer wall of the upper end of the flow dividing pipe, the spray head is inserted into one side of the outer wall of the lower end of the flow dividing pipe, and the storage barrel is arranged on one side of the outer wall of the upper end of the protective cover. By arranging a stirring paddle, the protective cover, a connecting cover and an electromagnet, the effects of separately collecting and treating waste sand and metal rust and preventing sand from being affected with damp and caking are achieved, the sand spraying smoothness is guaranteed, the rust removal effect of the equipment on materials is guaranteed, workers can conveniently collect and treat the waste sand in a centralized mode, the phenomenon that waste sand and metal rust splash is avoided, and the working environment is prevented from being polluted.

Owner:孙铭

A direct-mixing multi-purpose automatic precision fertilization and irrigation system

InactiveCN104584757BMix and playShorten mixing timePressurised distribution of liquid fertiliserAgriculture gas emission reductionAutomatic controlEngineering

The invention relates to a direct-mixing type multi-purpose automatic accurate fertilizer irrigation system which comprises a clean water tank, a raw fertilizer tank, a venturi tube, a fast fertilizer suction electromagnetic valve, an irrigation pump, an automatic control system, an electro connecting pressure gauge and a spherical fertilizer mixer, wherein the venturi tube sucks a raw fertilizer or an acid solution into a pipeline; the fast fertilizer suction electromagnetic valve controls a fertilizer suction amount; the output end of the irrigation pump is connected with the input end of the spherical fertilizer mixer through the pipeline, the pipeline positioned between the irrigation pump and the spherical fertilizer mixer is provided with the electro connecting pressure gauge; the output end of the spherical fertilizer mixer is respectively connected with an irrigation delivery pipeline and a fertilizer suction feedback pipeline; and the irrigation delivery pipeline is provided with an irrigation electromagnetic valve and a pipeline pressure detection device. The direct-mixing type multi-purpose automatic accurate fertilizer irrigation system disclosed by the invention realizes the immediate usage of a water fertilizer after mixing by adopting the independently developed spherical fertilizer mixer, can be used for furthest shortening the mixing time of a fertilizer and water and reducing the oxidation reaction generated because the fertilize contacts with air and can prevent the fertilizer waste generated in a fertilizer mixing process, provide higher output pressure through a direct-mixing type and cover more irrigated area.

Owner:上海璞研电子科技有限公司

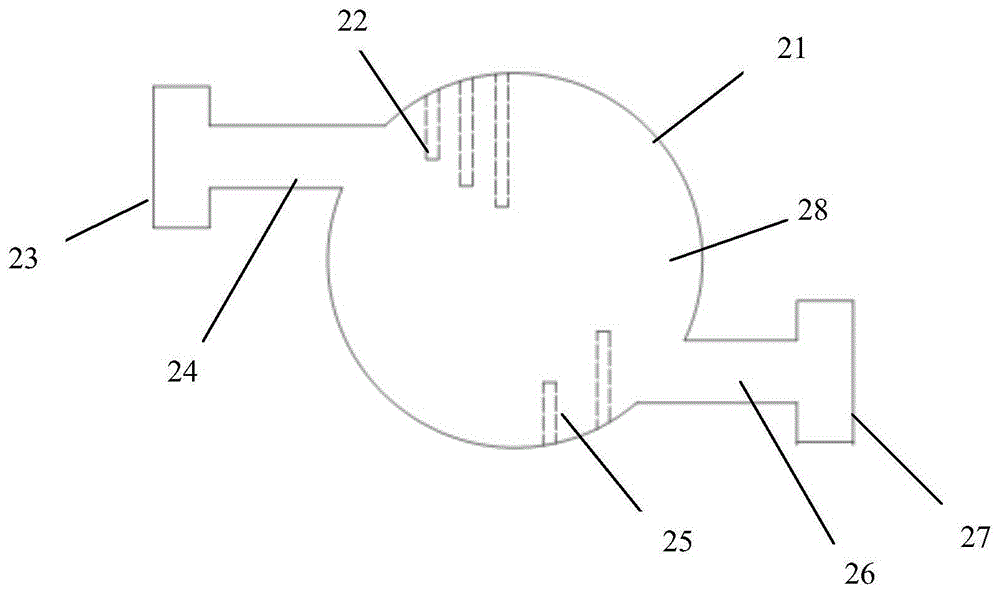

Novel-structure cathode conductive rod rust removal module, device and system

PendingCN113858006AFlat surfaceImprove conductivityGrinding drivesGrinding machinesElectrolysisStructural engineering

The invention discloses a novel-structure cathode conductive rod rust removal module, device and system, relates to the technical field of nickel sulfide diaphragm electrolysis, and solves the technical problems of incomplete rust removal and frequent replacement of a steel brush in the prior art. The rust removal module comprises a steel brush fixator and a rolling brush assembly, the steel brush fixator comprises a top plate and a side end supporting assembly, the side end supporting assembly comprises a rotating bearing assembly, a guide plate and a spring telescopic rod, a radial sliding groove is formed in the guide plate, one section of a mandrel of the rolling brush assembly is located in the radial sliding groove, and the end of the mandrel of the rolling brush assembly is in rotating fit with the rotating bearing assembly. According to the rust removal module designed by the invention, the surface of a conductive rod is smoother, the conductivity is better, the number of burnt plates is reduced, the grade rate of electric nickel is improved, and the power consumption is saved; and based on a spring telescopic rod, the rolling brush assembly can be adjusted in the radial direction of the conductive rod, then the abraded size of a steel brush is compensated based on the elastic telescopic amount of the spring telescopic rod within a certain range, the service life is prolonged, and the maintenance frequency and the maintenance cost are reduced.

Owner:JINCHUAN GROUP LIMITED

Friction type wire rod derusting equipment

ActiveCN103522153BGuaranteed uptimeTo achieve the purpose of rust removalGrinding machinesWire rodEngineering

The invention provides a friction type wire rod rust removal tool which comprises a main shaft, a plurality of long brushes, an opening groove shaft, a transmission mechanism and a brush inner pressing mechanism. The long brushes are located in the opening of the opening groove shaft, and the main shaft rotates and drives the brush inner pressing mechanism through the transmission mechanism to press the long brushes inwards, so that brush bristles rub a wire rod for rust removal. The tool has the advantages that the steel wire brushes can press the surface of the wire rod at constant pressure while revolving around the axis of a main shaft combined body to form a stable friction state and achieve the aim of rust removal; the tool is stable in operation, high in work efficiency, simple to operate, wide in application range, and capable of totally taking the place of acid pickling to serve as rust removal equipment free of acid pickling in the wire welding industry.

Owner:TIANJIN GOLDEN BRIDGE WELDING MATERIALS GRP

A hand-held iron wire derusting equipment

ActiveCN109129134BChange the way of rust removalReduce operating labor intensityGrinding drivesPortable grinding machinesFixed bearingDrive wheel

The invention relates to the technical field of iron wire derusting, and discloses a hand-held iron wire derusting device, which includes a handle, the top of the handle is fixed with a horizontal fixing cylinder connected by bolts, and the right end surface of the horizontal fixing cylinder is fixed by bolts A low-speed motor is connected, and the output shaft of the low-speed motor runs through the right side of the horizontal fixed cylinder and is fixedly connected with a torque shaft through a coupling. , the middle position of the top of the horizontal fixed cylinder is fixedly connected with an intermediate fixed bearing by bolts, the inner side of the intermediate fixed bearing is fixedly interspersed with a transverse transmission tube, the torque shaft is fixedly interspersed with two driving wheels, and the transverse transmission tube is fixedly interspersed with two The driven wheel corresponding to the driving wheel. The hand-held iron wire derusting equipment has changed the traditional way of manually derusting the iron wire, and reduced the labor intensity of the iron wire derusting operation.

Owner:南通市华星钢丝制品有限公司

Efficient steel pipe rust removal device based on building construction

ActiveCN113400160ARealize automatic sheddingEfficient grinding and rust removal functionGrinding carriagesGrinding drivesArchitectural engineeringFlywheel

The invention discloses an efficient steel pipe rust removal device based on building construction, which comprises a base, and mounting plates are symmetrically fixed to the two ends of the top surface of the base respectively. Through the arrangement of two guide rails and an electric telescopic rod, a steel pipe on a first L-shaped guide plate can be automatically clamped between two opposite conical columns on the two guide rails, the steel pipe is pushed into the position between the two snake-shaped guide rails along with operation of the electric telescopic rod, at the moment, the steel pipe continuously and automatically rolls down along the inclined faces of the snake-shaped guide rails, meanwhile, the steel pipe can continuously roll down along the inclined planes of the S-shaped guide rails better due to the arrangement of flywheels, the outer surface of the steel pipe is polished by frosting layers on the outer ring surfaces of the belts rotating at a high speed in the rolling-down process of the steel pipe between the two S-shaped guide rails, and automatic falling of the steel pipe can be achieved due to the arrangement of the two V-shaped guide rails, so that the device has the functions of automatically clamping the steel pipe and automatically falling off the steel pipe, and meanwhile, the steel pipe can be automatically polished and derusted through automatic rolling of the steel pipe.

Owner:FOSHAN YUANHUIFENG HARDWARE PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com