Novel-structure cathode conductive rod rust removal module, device and system

A cathode conductive rod and a new structure technology, applied in the direction of grinding drive device, grinding feed movement, grinding machine, etc., can solve the problem of poor cleaning effect of ultrasonic cleaning device on conductive rod, failure to meet production and use requirements, grinding and rust removal Incomplete and other problems, to achieve the effect of reducing the number of burnt boards, improving the grade rate of electro-nickel, and improving the conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

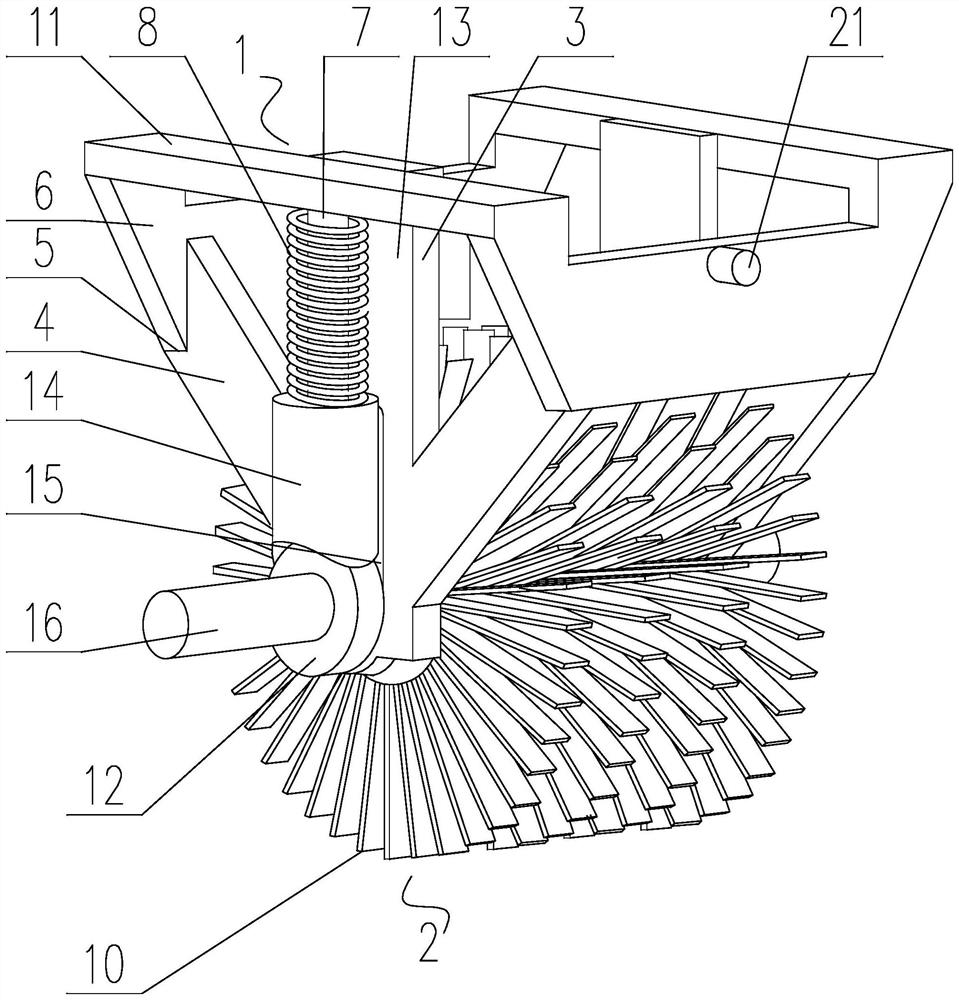

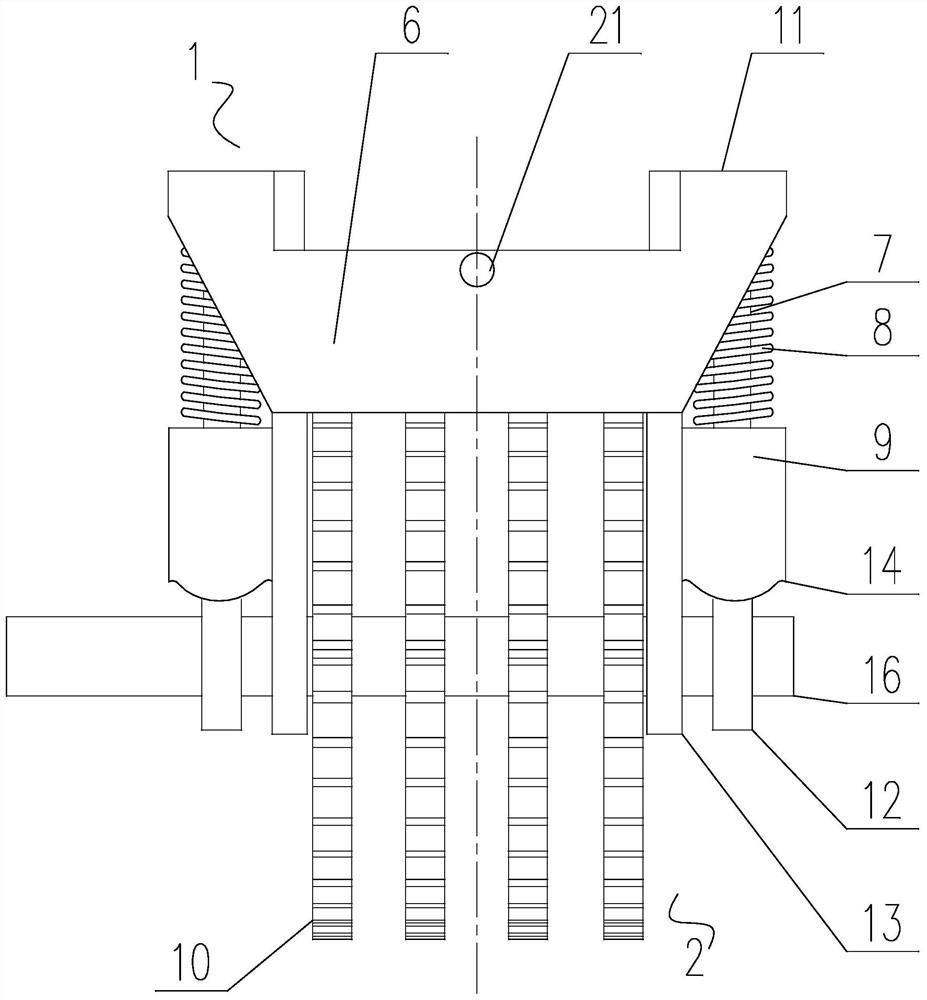

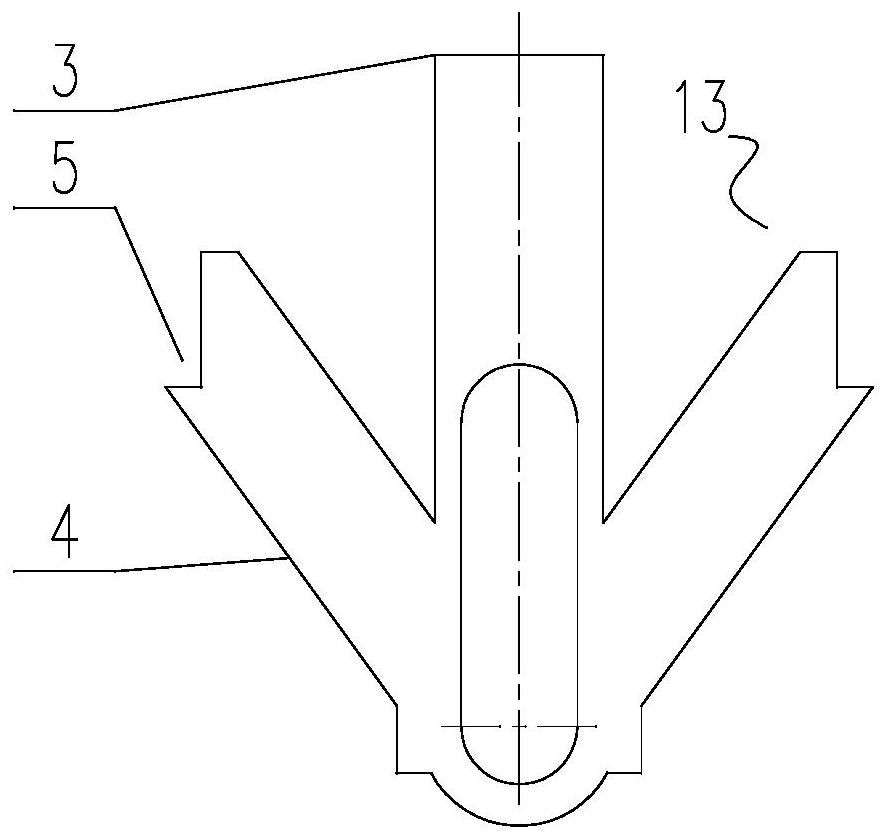

[0043] Such as Figure 1 to Figure 4 As shown, a new structure cathode conductive rod derusting module of the present invention includes a steel brush holder 1 and a rolling brush assembly 2, the steel brush holder includes a top plate 11 and a side end support assembly, and the side end support assembly includes Rotation support assembly 12, guide plate 13 and the spring expansion rod 14 that both ends are fixedly connected with top plate 11 and rotation support assembly 12 shells respectively, described guide plate 13 one side is fixed connection with top plate 11, and on it along the spring expansion rod 14 A radial sliding slot 15 is provided in the telescopic direction, and a section of the core shaft 16 of the rolling brush assembly 2 is located in the radial sliding slot 15, and its end is rotatably matched with the rotating support assembly 12.

[0044] During use, this derusting module is fixed on one side of the conductive rod to be derusted, and the steel brush of t...

Embodiment 2

[0046] Such as Figure 1 to Figure 4 As shown, a new structure cathode conductive rod derusting module of the present invention includes a steel brush holder 1 and a rolling brush assembly 2, and the steel brush holder includes a top plate 11 and two mandrels 16 respectively located at the rolling brush assembly 2 The side end support assembly at both ends, the side end support assembly includes a rotating support assembly 12, a guide plate 13 and a spring telescopic rod 14 that is fixedly connected to the top plate 11 and the rotating support assembly 12 shell at both ends, and one side of the guide plate 13 It is fixedly connected with the top plate 11, and a radial chute 15 is arranged on it along the telescopic direction of the spring telescopic rod 14. A section of the mandrel 16 of the rolling brush assembly 2 is located in the radial chute 15, and its end is connected with the The rotatable support assembly 12 is rotatably fitted.

[0047] The concrete structure of gui...

Embodiment 3

[0053] A cathode conductive rod derusting device with a new structure, including a derusting module, a radial drive unit that drives the radial movement of the derusting module, and an axial drive unit that drives the radial drive unit to move axially,

[0054] The derusting module includes a steel brush holder 1 and a rolling brush assembly 2, and the steel brush holder includes a top plate 11 and a side end support assembly, and the side end support assembly includes a rotating support assembly 12, a guide plate 13 and two ends respectively connected with The top plate 11 and the spring telescopic rod 14 fixedly connected to the shell of the rotating support assembly 12, one side of the guide plate 13 is fixedly connected with the top plate 11, and a radial chute 15 is arranged on it along the telescopic direction of the spring telescopic rod 14. A section of the core shaft 16 of the rolling brush assembly 2 is located in the radial slide groove 15, and its end is rotatably m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com