Composite pressure-resistant metal part machining device and manufacturing process thereof

A technology for metal parts and processing devices, which is applied in the field of composite pressure-resistant metal parts processing devices, can solve the problems of sand agglomeration due to moisture, avoid sand agglomeration, facilitate centralized collection and processing, and ensure the integrity of rust removal. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

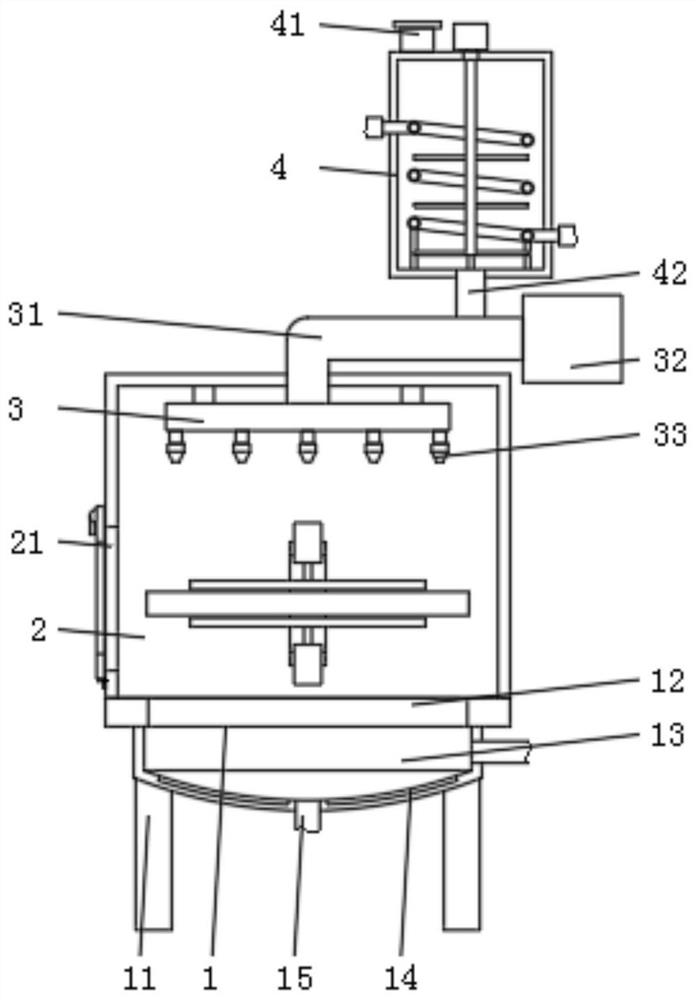

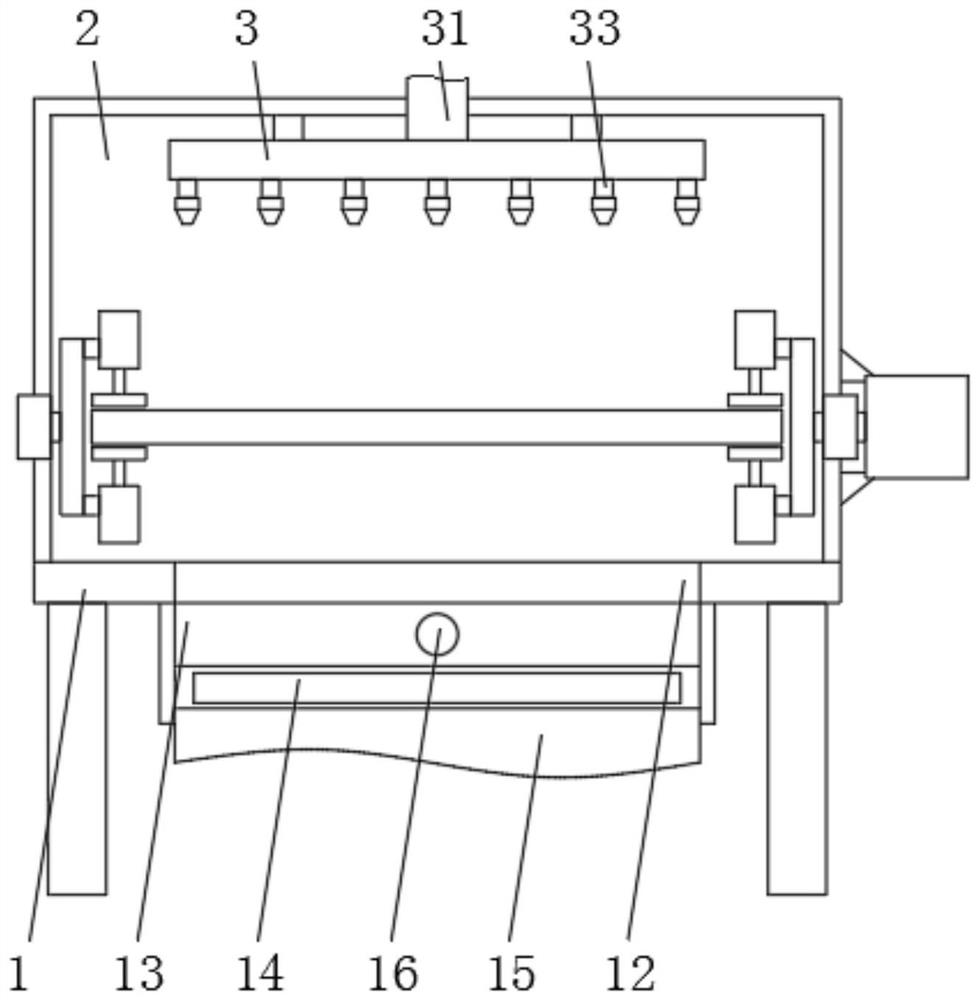

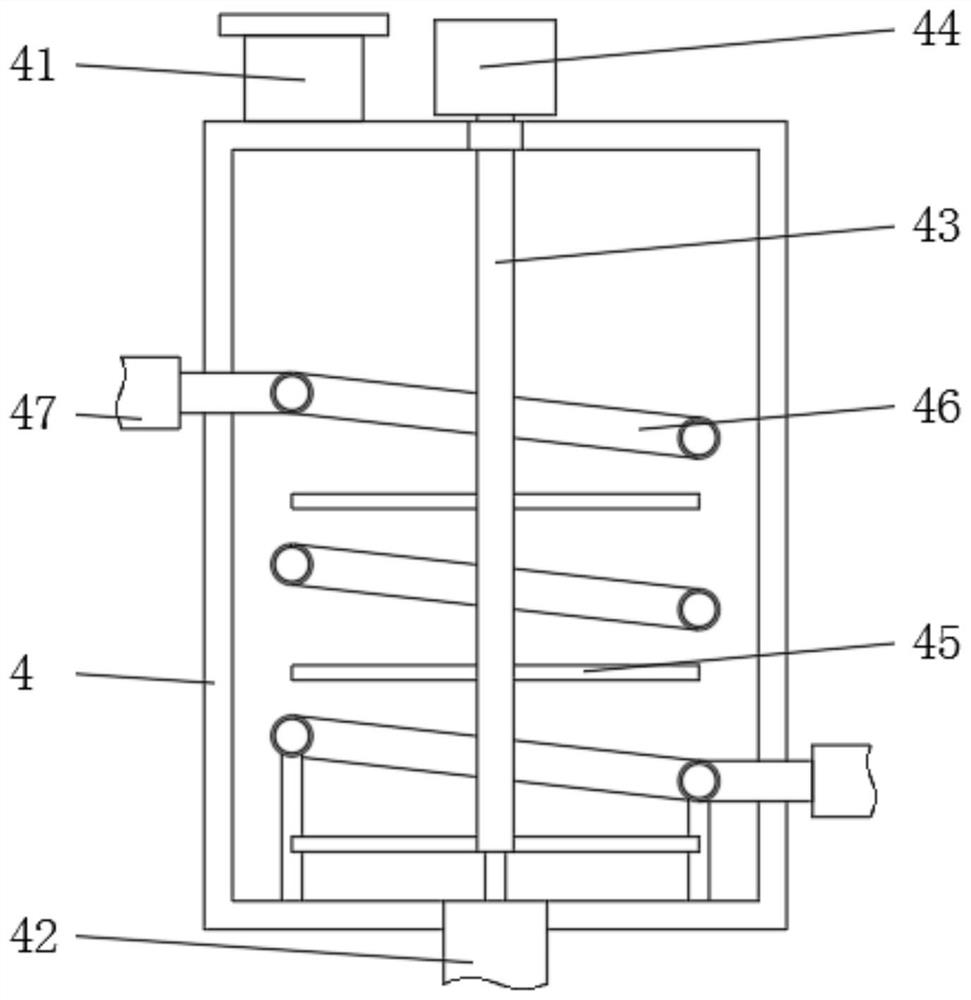

[0035] Embodiment 1: A composite pressure-resistant metal parts processing device and its manufacturing process, including a working plate 1, a protective cover 2, a shunt pipe 3, a storage tank 4 and a nozzle 33, and a protective cover is installed on the outer wall of the upper end of the working plate 1. Cover 2, the inside of the working board 1 is provided with a discharge port 12, the four corners of the outer wall of the lower end of the working board 1 are equipped with a support frame 11, the outer wall of the lower end of the working board 1 is equipped with a connecting cover 13, and the upper side of the inner wall of the protective cover 2 is installed with Diverter pipe 3, a feed pipe 31 is installed on one side of the outer wall of the upper end of the shunt pipe 3, and a power pump 32 is inserted on the outer wall of the end of the feed pipe 31 away from the shunt pipe 3, and a nozzle is installed on the outer wall side of the lower end of the shunt pipe 3 33. A...

Embodiment 2

[0038] Embodiment 2: A composite pressure-resistant metal parts processing device and its manufacturing process, including a working plate 1, a protective cover 2, a shunt pipe 3, a storage tank 4 and a nozzle 33, and a protective cover is installed on one side of the outer wall of the upper end of the working plate 1. Cover 2, the inside of the working board 1 is provided with a discharge port 12, the four corners of the outer wall of the lower end of the working board 1 are equipped with a support frame 11, the outer wall of the lower end of the working board 1 is equipped with a connecting cover 13, and the upper side of the inner wall of the protective cover 2 is installed with Diverter pipe 3, a feed pipe 31 is installed on one side of the outer wall of the upper end of the shunt pipe 3, and a power pump 32 is inserted on the outer wall of the end of the feed pipe 31 away from the shunt pipe 3, and a nozzle is installed on the outer wall side of the lower end of the shunt p...

Embodiment 3

[0042] Embodiment 3: A composite pressure-resistant metal parts processing device and its manufacturing process, including a working plate 1, a protective cover 2, a shunt pipe 3, a storage tank 4 and a nozzle 33, and a protective cover is installed on one side of the outer wall of the upper end of the working plate 1. Cover 2, the inside of the working board 1 is provided with a discharge port 12, the four corners of the outer wall of the lower end of the working board 1 are equipped with a support frame 11, the outer wall of the lower end of the working board 1 is equipped with a connecting cover 13, and the upper side of the inner wall of the protective cover 2 is installed with Diverter pipe 3, a feed pipe 31 is installed on one side of the outer wall of the upper end of the shunt pipe 3, and a power pump 32 is inserted on the outer wall of the end of the feed pipe 31 away from the shunt pipe 3, and a nozzle is installed on the outer wall side of the lower end of the shunt p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com