A steel environmental rust remover

A rust remover, an environmentally friendly technology, applied in the field of metal rust removal, can solve the problems of inability to dilute the rust stains, poor rust removal effect, high production cost, etc., achieve good rust removal effect, good rust removal effect, and low use cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also relates to a preparation method of rust remover, the method steps are: a. according to the weight percentage of each component given by the formula, under normal temperature conditions, citric acid is dissolved in water, and continuously stirred until fully Dissolve; b. Continue to add organic phosphonic acid and stir continuously until fully dissolved; c. Continue to add TX-10 or / and FMEE and continue to stir until fully dissolved and homogeneous, that is, the preparation is completed.

[0032] The rust remover of the present invention can be applied to rust removal and cleaning of different steel products, such as pipelines, plates, steel equipment and other complete steel products.

[0033] When using the rust remover of the present invention to remove rust, different cleaning methods such as soaking and wiping can be used according to the structure of the workpiece to be derusted and the degree of rust on the surface.

Embodiment 1

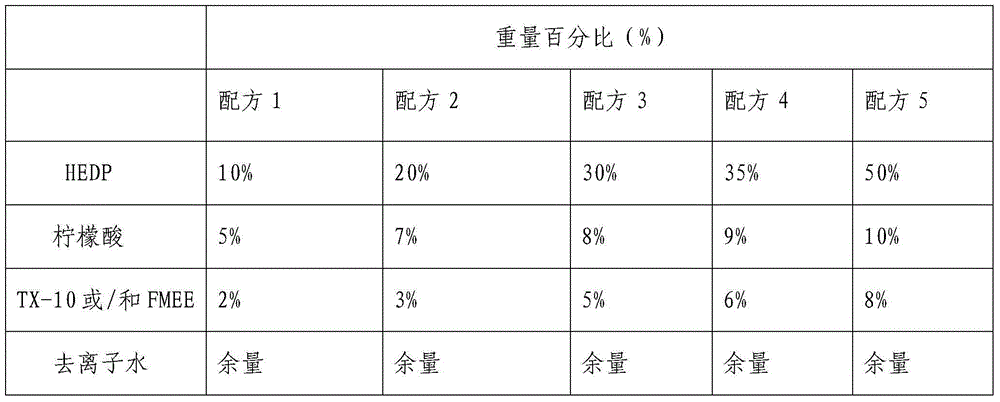

[0036] Embodiment 1 prepares the rust remover of different formulations

[0037] Prepare rust remover of the present invention according to following formula, and concrete formula sees the following table:

[0038]

[0039]According to the weight percentage of each component given in the above formula, under the condition of normal temperature, dissolve citric acid in water, stir continuously until fully dissolved; then continue to add hydroxyethylene diphosphonic acid (HEDP), continue to stir , until the hydroxyethylene diphosphonic acid (HEDP) is fully dissolved; then continue to add TX-10 or / and FMEE, and continue to stir until it is fully dissolved and appears homogeneous, that is, the preparation is completed.

Embodiment 2

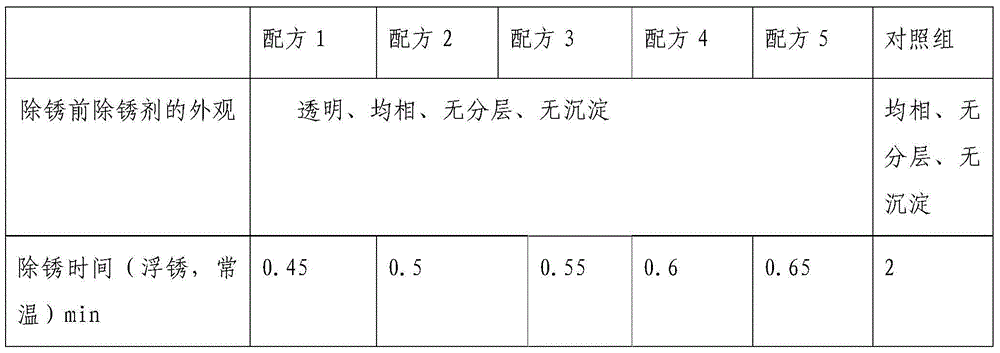

[0040] The embodiment of embodiment 2 performance test

[0041] Carry out performance test according to " water-based metal cleaning test method ", take the technical scheme formula 1-5 of rust remover in embodiment 1 as experimental group, take the common rust remover in the prior art as control group, select three kinds of different The steel sheets with the degree of corrosion, respectively floating rust, moderately rusted and heavily corroded steel sheets are used as the experimental objects of this experiment, and the method of this experiment is the soaking method. The specific experimental data is shown in the table below:

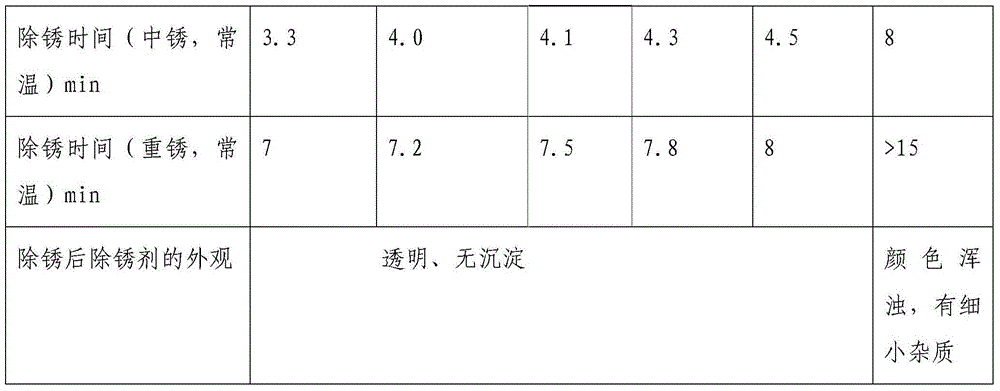

[0042]

[0043]

[0044] It can be seen from the above table that the rust remover of the present invention can effectively remove the rust on the surface of steel products, and the floating rust can be removed in about half a minute, and the moderately corroded steel sheet can be easily removed in 3-5 minutes , the rust of heavily corroded s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com