Large-inside-diameter steel pipe inner wall derusting device for machining

A technology for machining the inner wall of steel pipes, used in grinding drives, metal processing equipment, manufacturing tools, etc., can solve the problems of large workload of rust removal, intensified corrosion, slow speed, etc., to achieve high rust removal efficiency, The effect of saving rust removal cost and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with specific embodiment, the technical scheme of this patent is described in further detail:

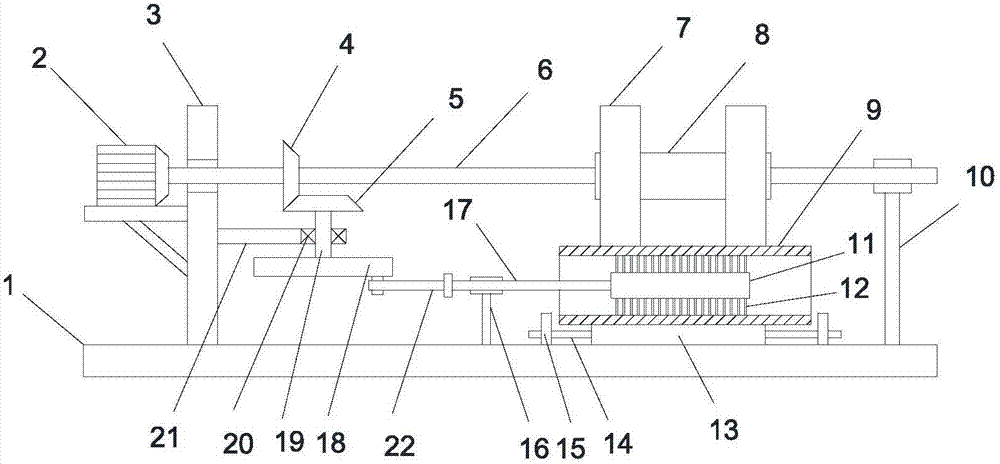

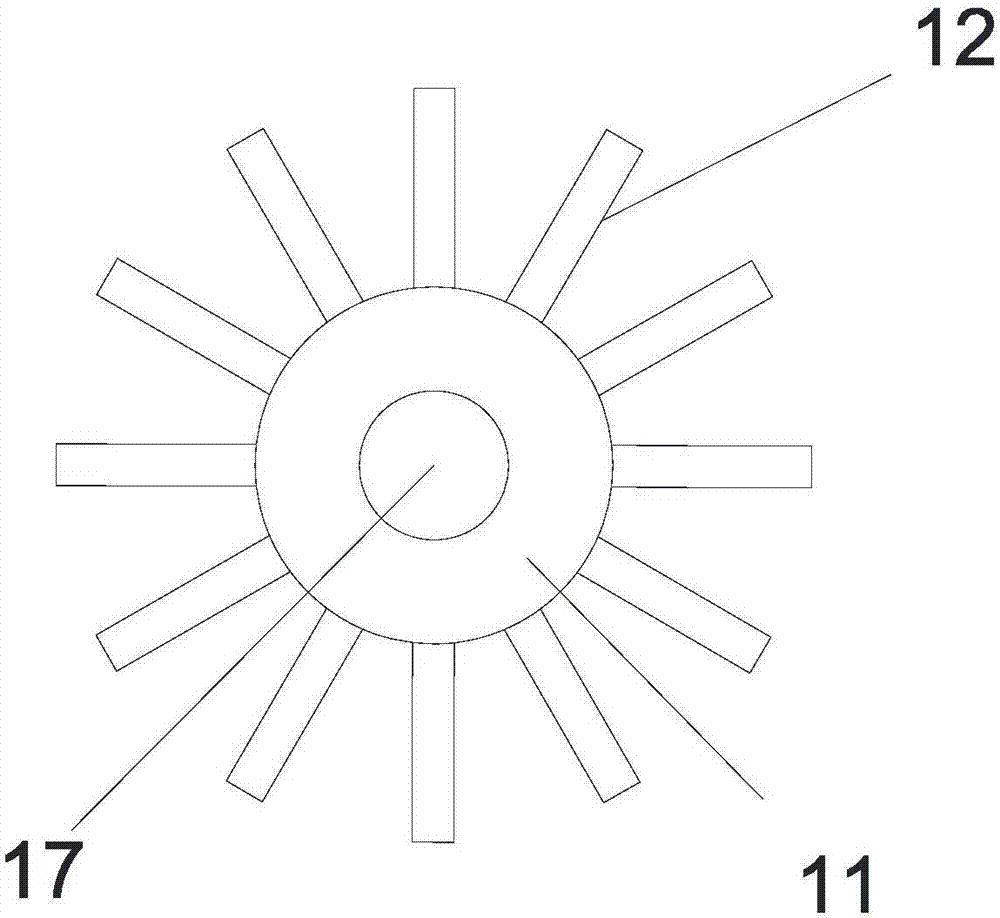

[0018] see Figure 1-2 , a large internal diameter steel pipe inner wall derusting device for mechanical processing, including a base plate 1, a column 3 is vertically welded and fixed on the base plate 1, a rotating motor 2 is fixedly installed on the left side of the column 3 through a bracket, and the output of the rotating motor 2 A drive shaft 6 is fixedly installed horizontally on the shaft, and a first shaft support 10 is fixedly installed vertically on the bottom plate 1, and the first shaft support 10 is movably connected with the right end of the drive shaft 6; A bevel gear 4, the right side wall of the column 3 extends to the right and is provided with a cantilever beam 21, and the right end of the cantilever beam 21 is provided with a bearing seat 20, and the vertical rotation type on the bearing seat 20 is provided with a driven shaft 19, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com