A kind of steel structure derusting device and derusting process

A technology of steel structure and steel bar, applied in the direction of grinding drive device, manufacturing tool, metal processing equipment, etc. The effect of shifting stability, reducing labor intensity and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

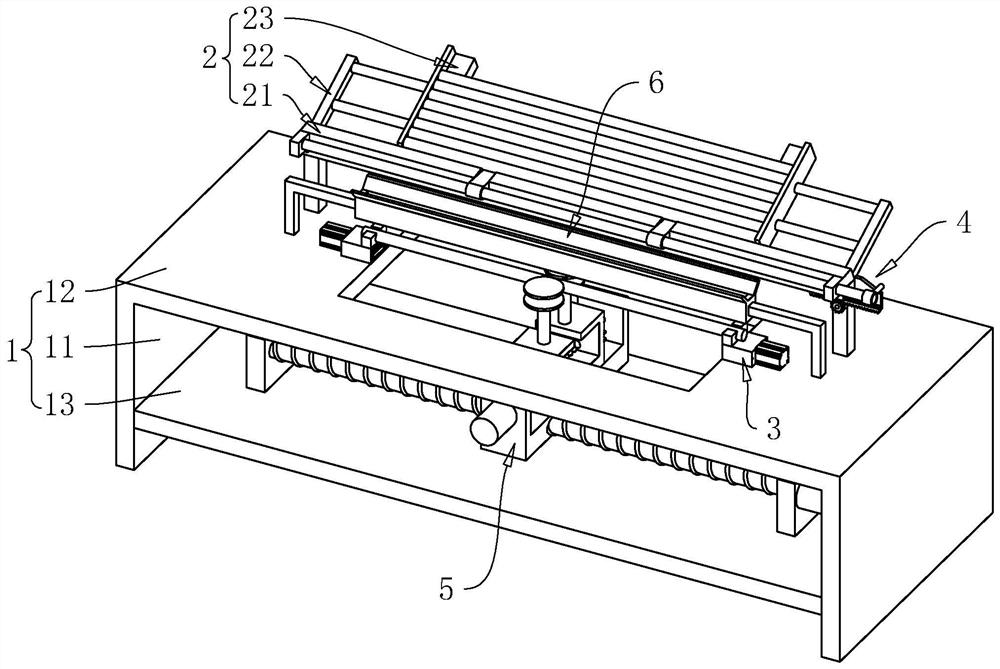

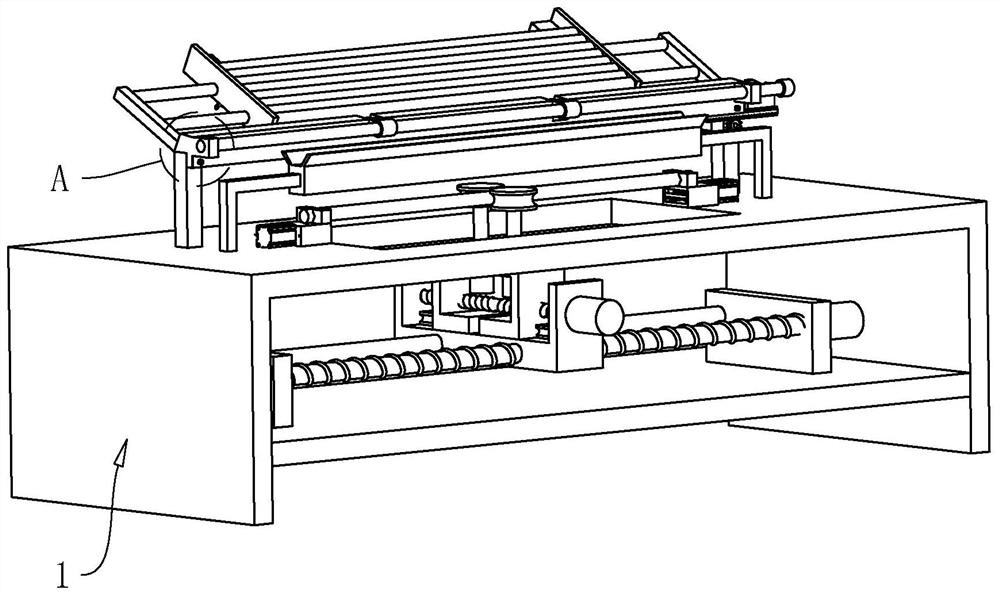

[0067] Referring to FIG. 1, the workbench 1 includes two support plates 11 and an installation plate 12, and the two support plates 11 are arranged vertically, and the installation

[0072] Referring to Figure 5, when the staff needs to rebar or steel pipe, the staff can be along the length of the first guide rod 222

[0074] Referring to FIG. 8, the clamping mechanism 3 includes a cylinder 31, a mounting block 32, a sliding block 33 and two clamping members 34, and the mounting block 32

[0075] Continue to refer to FIG. 8, the upper surface of the mounting block 32 is provided with a second sliding groove 323, and the length of the first sliding groove 322 is square.

[0076] Continue to refer to FIG. 8, for each clamping mechanism 3, the two clamping blocks 342 close to each other on the side walls are provided with

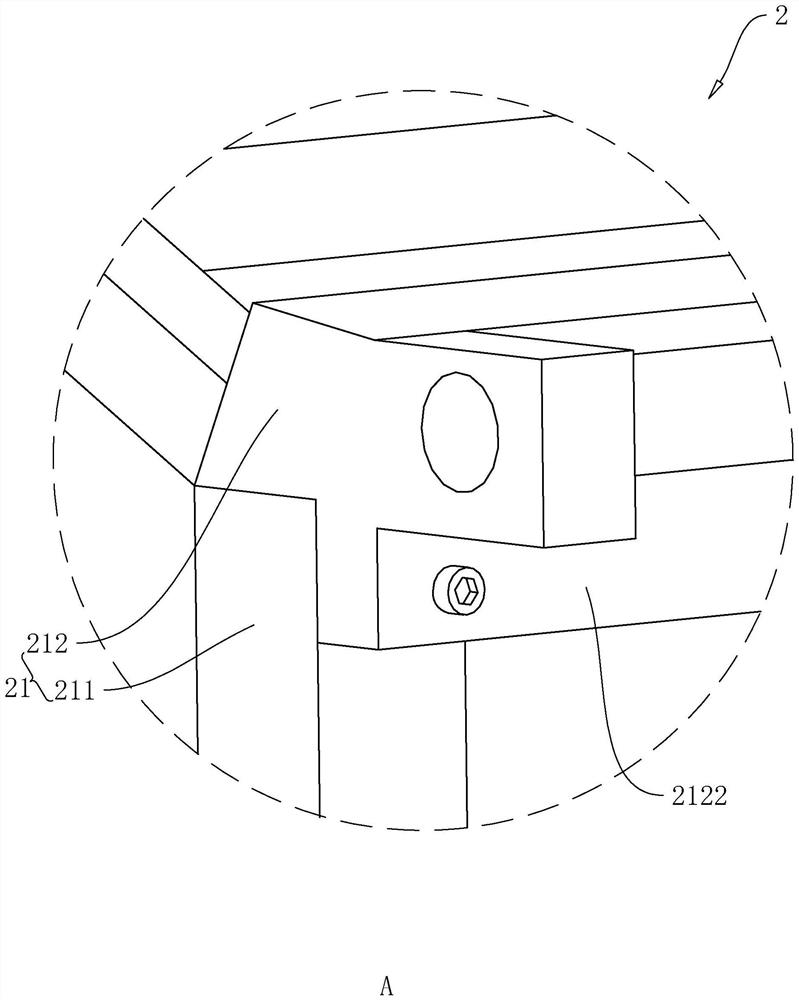

[0078] Referring to FIG. 6, in order to increase the rotation angle of the two inversion blocks 412, the upper surface of the blocking rod 212 is provided with two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com