An obstacle-climbing robot

A technology of wall-climbing robots and racks, which is used in motor vehicles, transportation and packaging, etc., can solve the problems of large cycle and cost, endanger the safe operation of the wall body, and cannot meet the industrial management requirements of safety and cleanliness. The effect of obstacles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

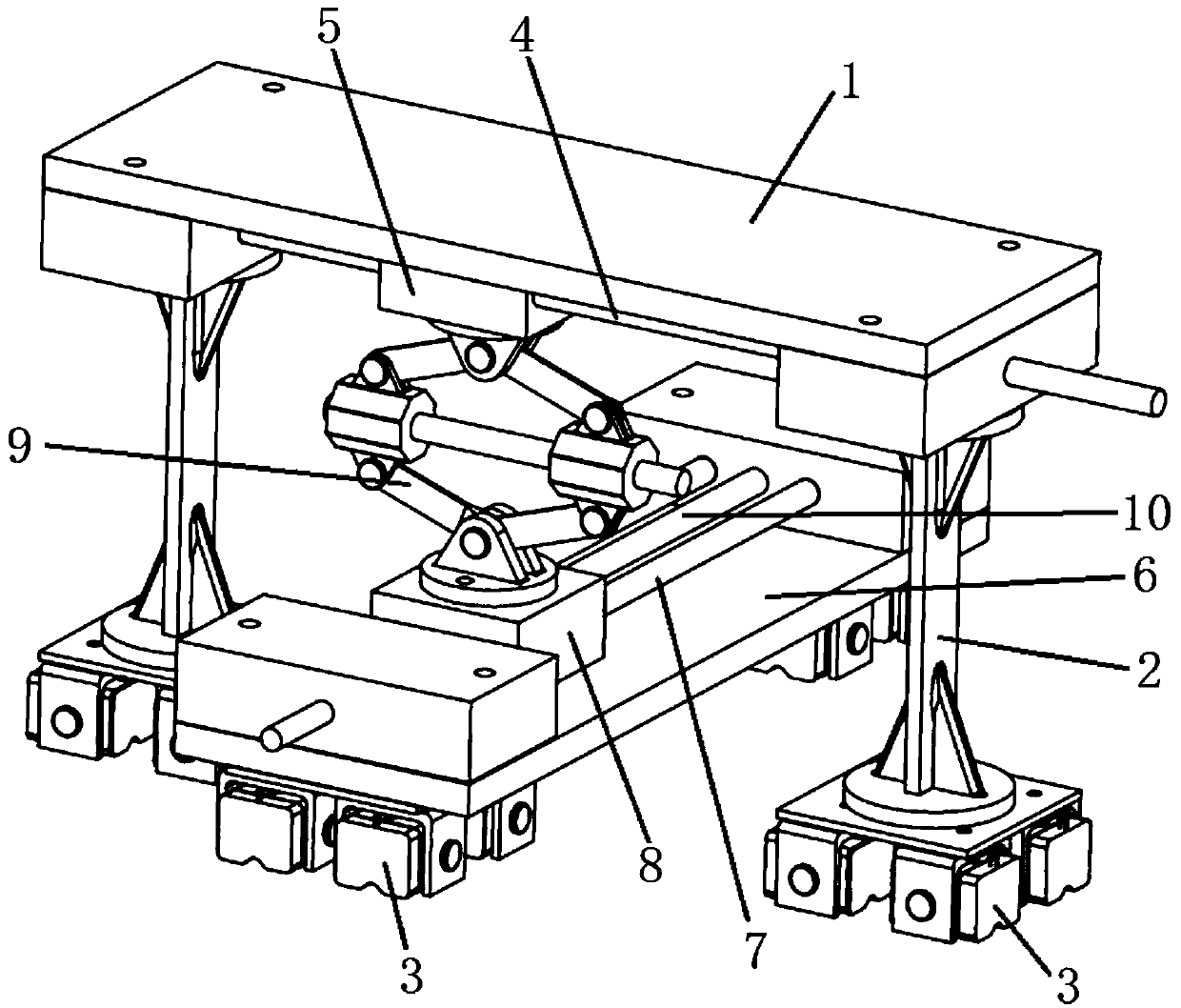

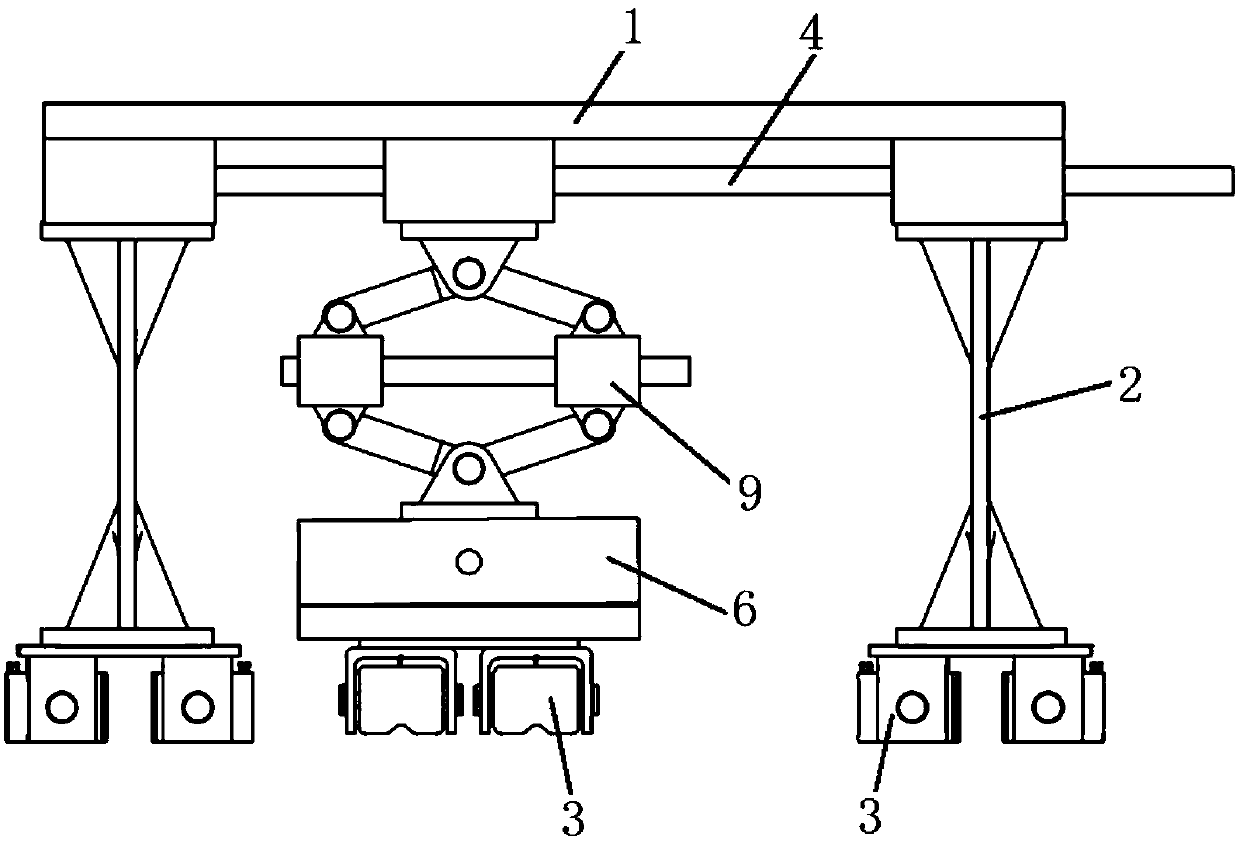

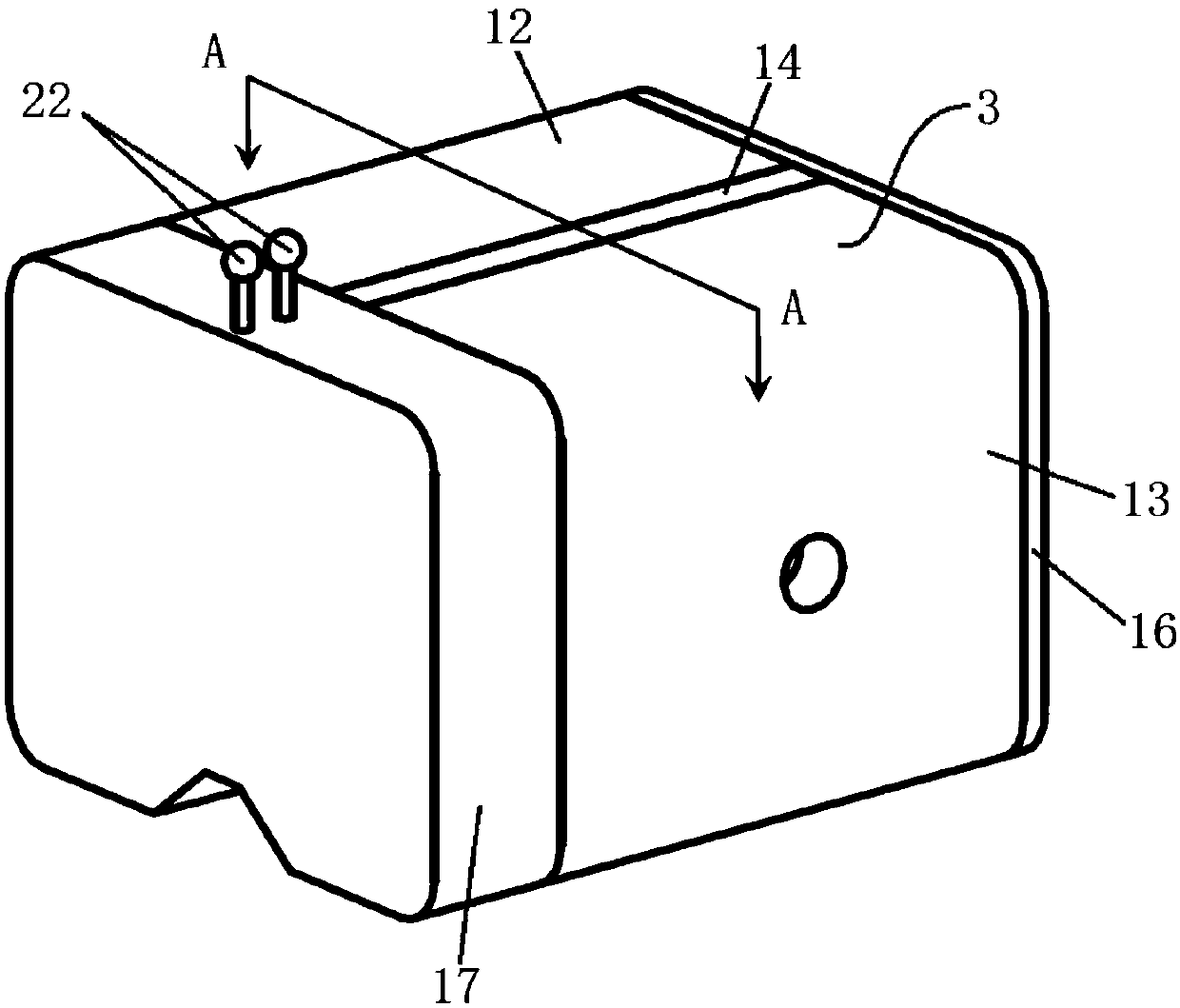

[0018] Such as figure 1 , figure 2 As shown, the present invention includes an upper frame 1, and a support leg 2 is respectively arranged at the bottom of both ends of the upper frame 1, and a plurality of magnetic adsorption units 3 are arranged at the bottom of each support leg 2. The bottom of the upper frame 1 between the two legs 2 is provided with a first lead screw 4, on the first lead screw 4 is connected with a first slide block 5 by threaded fit, and is provided on the upper frame 1 usefully A first motor (not shown) that drives the first lead screw 4 to rotate. A lower frame 6 is arranged below the upper frame 1 , and a plurality of magnetic adsorption units 3 are respectively arranged at the bottoms of both ends of the lower frame 6 . The top of the lower frame 6 is provided with a second leading screw 7, on the second leading screw 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com