Sand blasting device for processing inner wall surface of pipeline

A surface treatment and sandblasting device technology, applied in abrasive jet machine tools, abrasives, metal processing equipment, etc., can solve the problems of reducing the service life of pipelines, harsh production environment, serious pollution, etc., and achieve stable quality and low rust removal cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

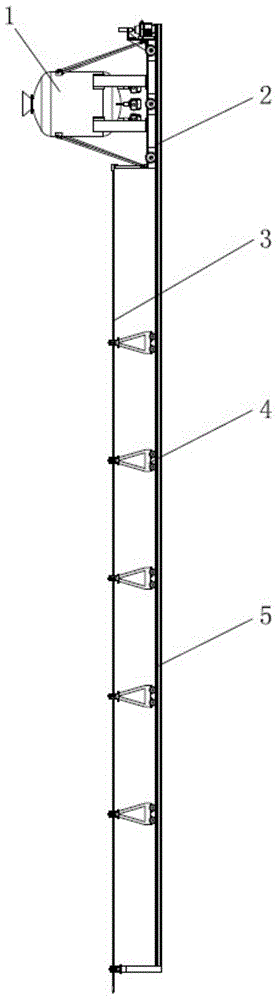

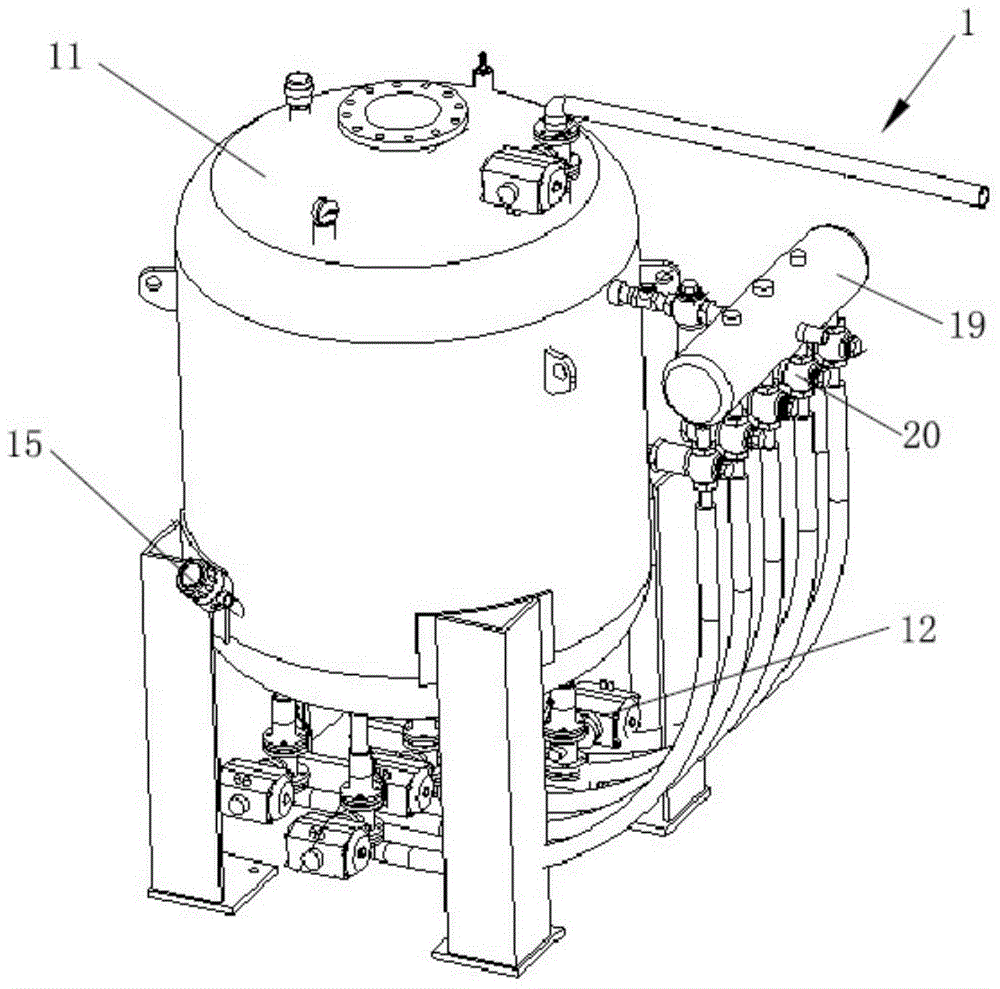

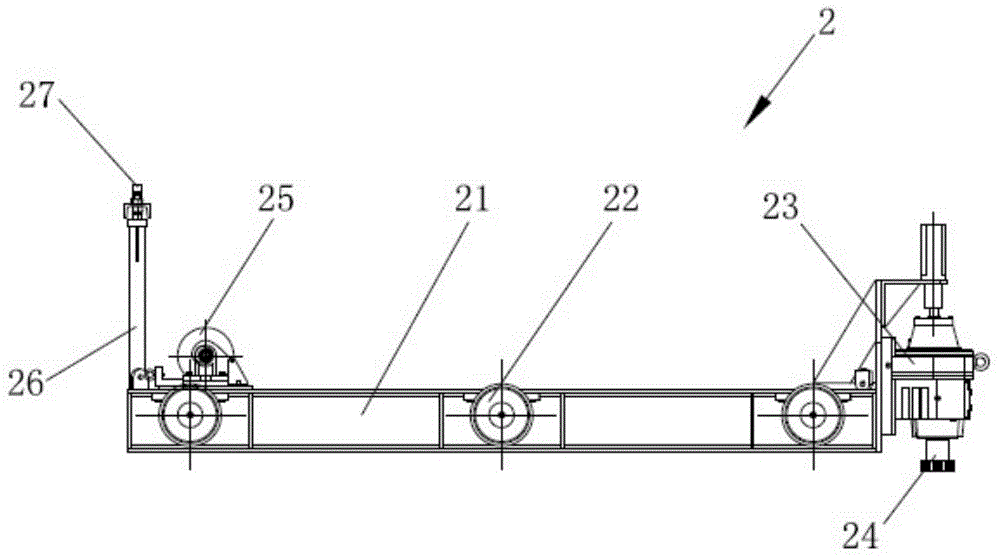

[0022] Attached below Figure 1~5 And further illustrate the technical scheme of the present invention through the specific embodiment,

[0023] A sandblasting device for surface treatment of the inner wall of a pipeline, comprising a running trolley 2 arranged on a rail system 5 and a sandblasting machine 1 erected on the running trolley 2, one end of the running trolley 2 is provided with a The driving assembly 23 of the driving force of the running trolley 2, the other end is provided with several spray gun frames 26 for fixing the spray gun assembly 3, and the spray gun assembly 3 includes a spray gun rod 34 erected on five spray gun support mechanisms 4 and connected with the spray gun assembly 3. The spray gun head 35 connected to one end of the spray gun rod 34, the end of the spray gun head 35 is provided with a sand blaster (36) on the inner wall of the pipeline, and the bottom of the spray gun support mechanism 4 is provided with a track wheel set 40, and the track w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com