Environment-friendly efficient sand making machine adopting centrifugal crushing and sand discharging

A sand making machine and environmental protection technology, applied in grain processing and other directions, can solve the problems of difficult reuse and sludge stacking, difficult to meet the cleaning standard of sewage, difficult to ensure the quality of machine-made sand, etc. The effect of increasing the strength and number of strikes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

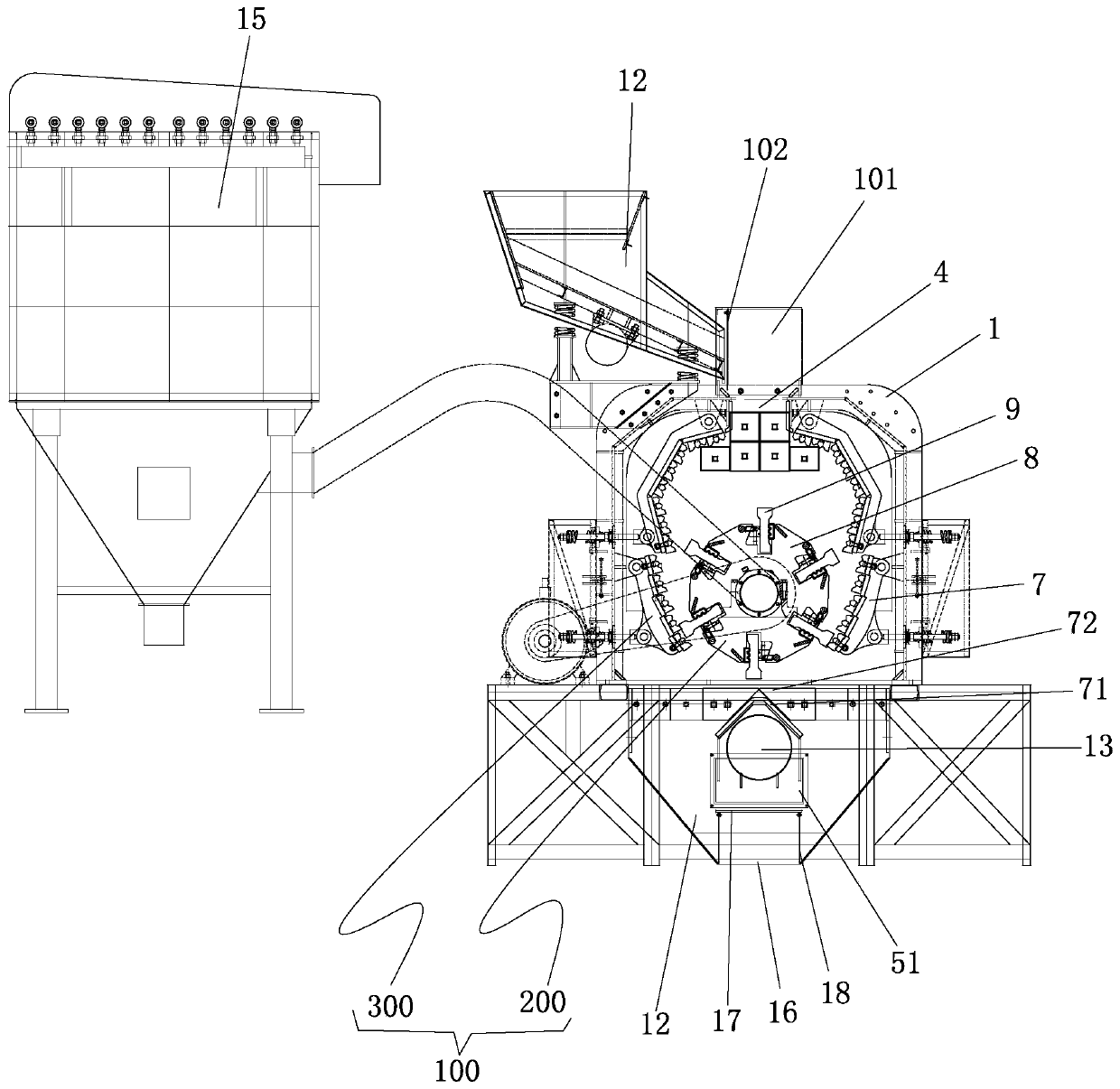

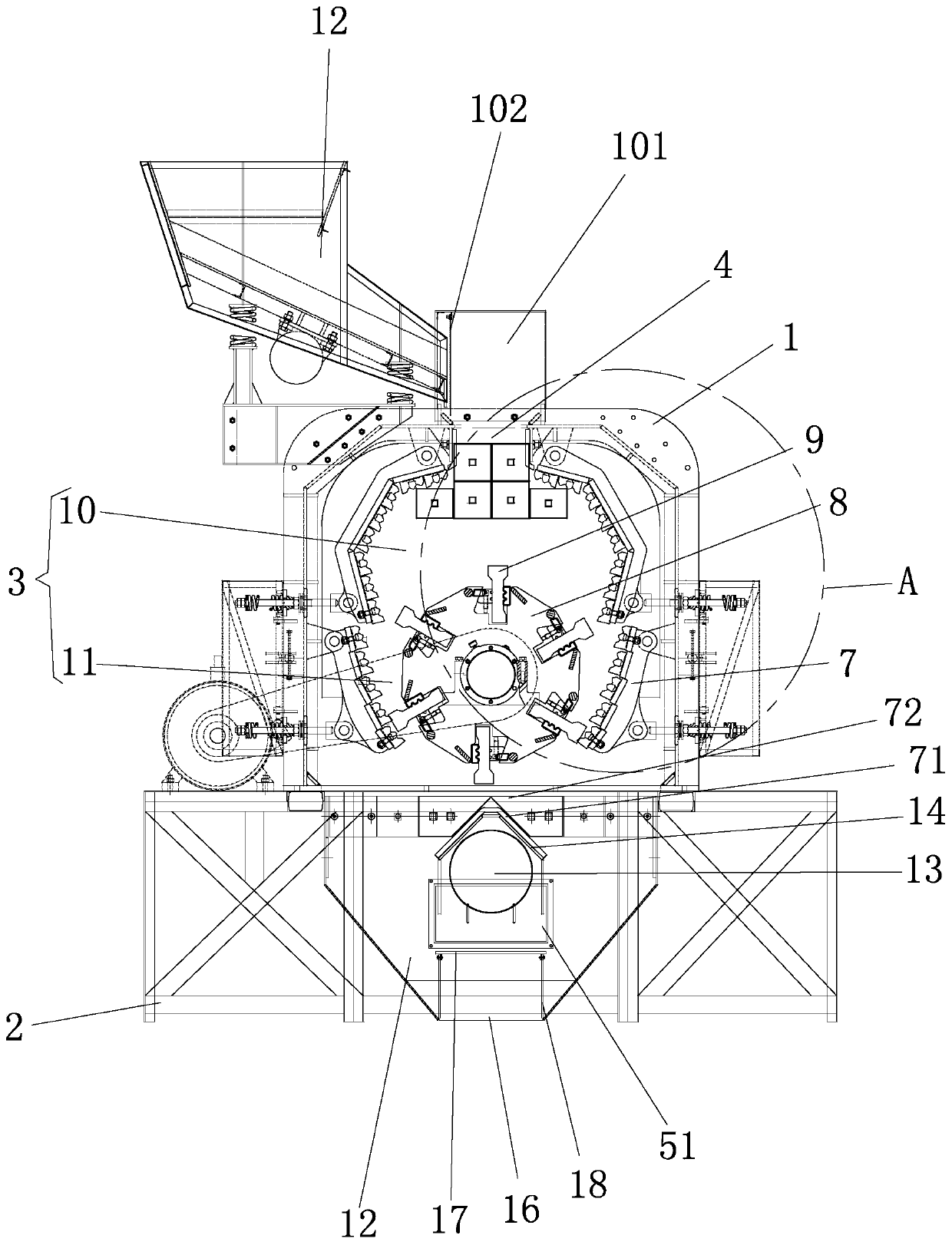

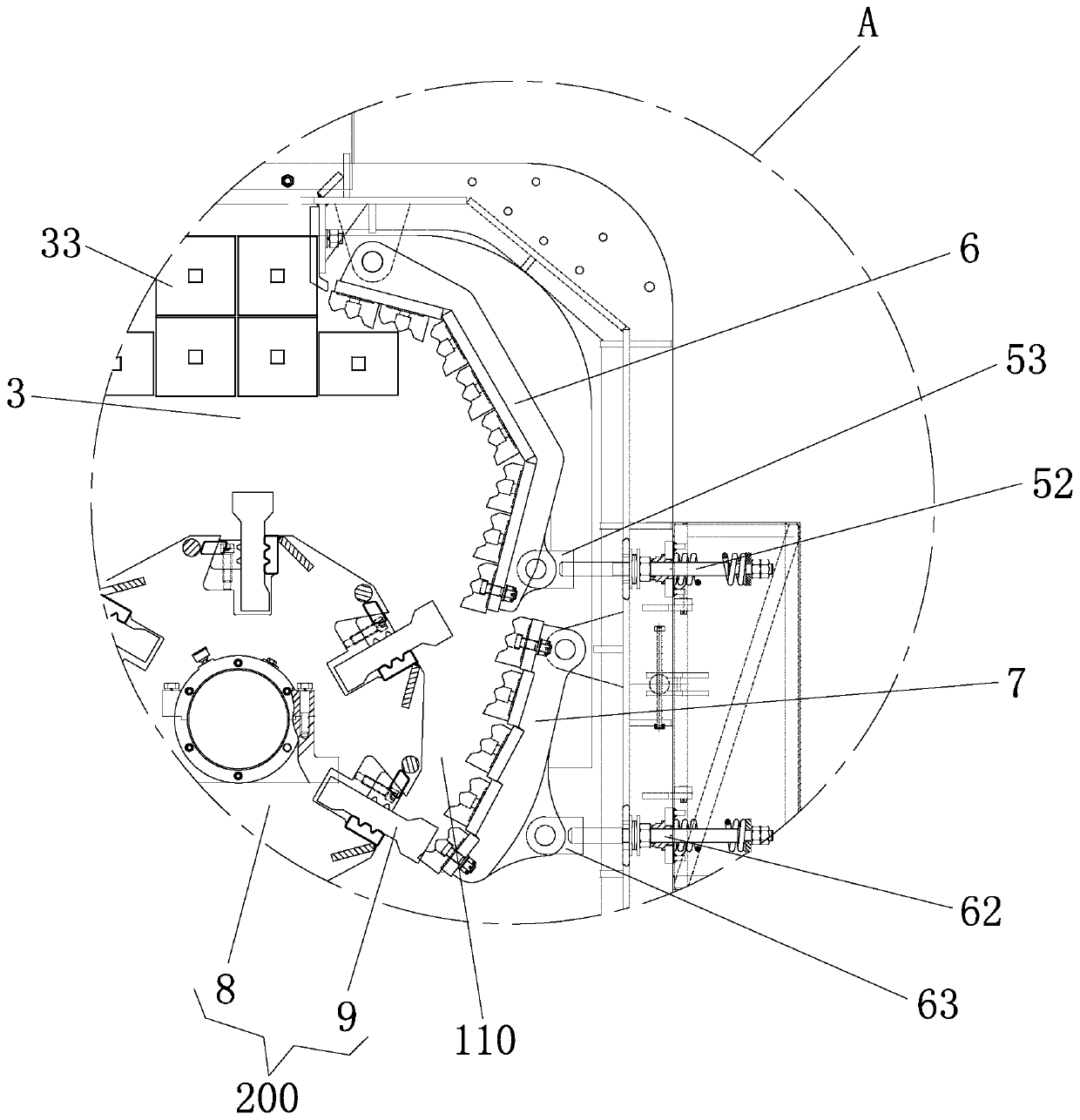

[0024] Such as Figures 1 to 2 The shown environment-friendly centrifugal crushing and sand-discharging high-efficiency sand making machine has the specific implementation as follows: it includes a crushed stone sand making main machine 1 and a base 2 connected to the bottom of the crushed stone sand making main machine 1, and the crushed stone sand making main machine 1 is provided with a crushing chamber 3, and the upper and lower ends of the gravel sand making machine 1 are respectively provided with a feed port 4 and a discharge port 5 communicating with the crushing chamber 3, and in the crushing chamber 3 there are Stone crushing device 100, the crushing device 100 includes a crushing rotor assembly 200 mounted on the front and rear walls of the crushing chamber 3 and crushing wall plates 300 mounted on the left and right inner wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com