A five-axis linkage CNC manipulator polishing machine

A five-axis linkage and manipulator technology, which is applied in the direction of grinding/polishing equipment, grinding drive devices, grinding machine parts, etc., to achieve the effects of reducing labor intensity, good flexibility, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

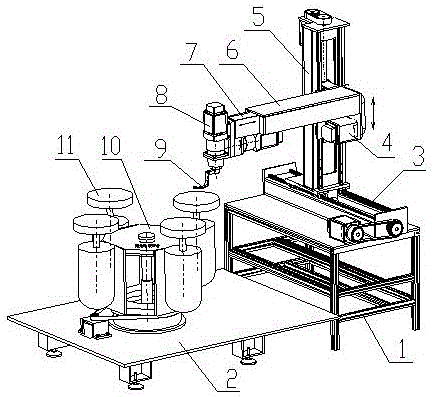

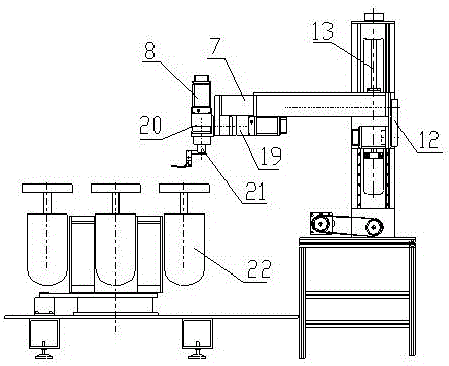

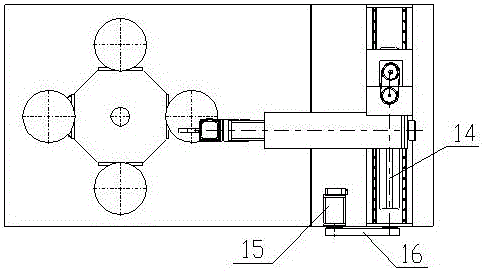

[0017] In this embodiment, a five-axis linkage CNC manipulator polishing machine, see Figure 1 to Figure 4 , mainly composed of the Y axis arranged horizontally, the Z axis whose bottom is located on the Y axis and arranged vertically, the X axis that moves up and down along the Z axis and is perpendicular to Zl, the A axis parallel to the X axis, and the end of the A axis It consists of a C-axis perpendicular to the A-axis, plus a polishing wheel rotary table 10 corresponding to the C-axis and having an independent structure.

[0018] Specifically, a Y-axis base 3 is provided on the fixed frame 1 , and a Y-axis servo motor 15 is disposed in the Y-axis base 3 , and the Y-axis servo motor 15 drives a Y-axis ball screw 14 through a Y-axis timing belt 16 . The lower end of the Z-axis module frame 5 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com