Dust collection equipment for slag bin

A technology for dust collection equipment and slag silo, which is applied in the directions of loading/unloading, conveyor objects, conveyor control devices, etc. The effect of raising dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

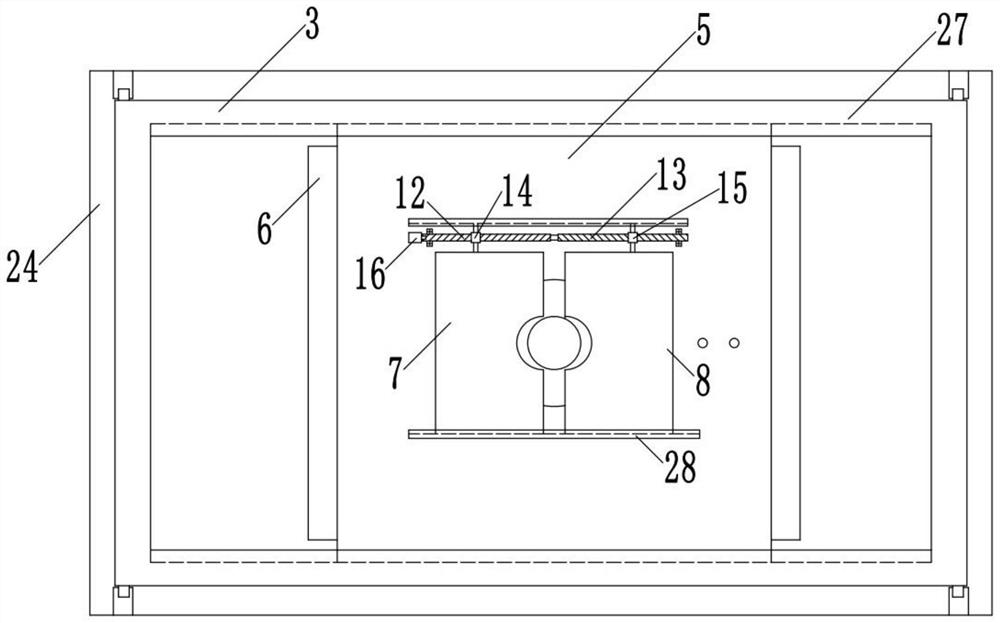

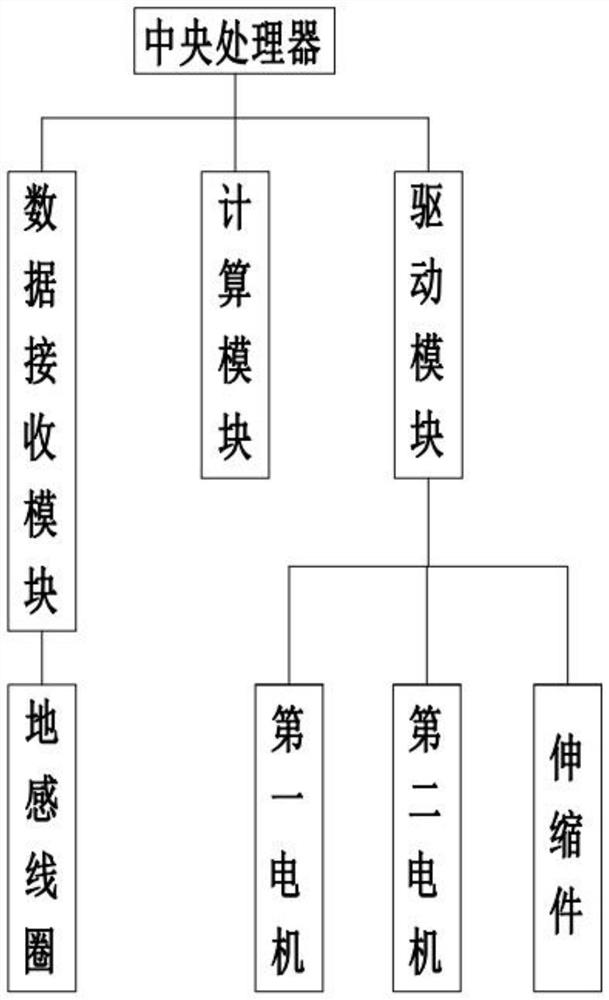

[0051] like figure 1 As shown, the embodiment of the present invention provides a kind of slag bin dust collection equipment, including a support frame 1, a telescopic member 2 is fixed on the support frame 1, and the telescopic end of the telescopic member 2 is vertically downward and connected with the support frame 3 to support A moving mechanism is fixed on the frame, and the moving parts of the moving mechanism are connected to the dust-proof device; the slag bin dust collection equipment also includes a control system, which includes: a plurality of ground induction coils 4, which are laid on the ground to sense the front of the vehicle. The position of the rear wheel of the wheel; the data receiving module is connected with each of the ground induction coils 4 for receiving the oscillation signal produced by it; the calculation module is connected with the data receiving module for calculating the two generated oscillation signals Describe the distance between the groun...

Embodiment 2

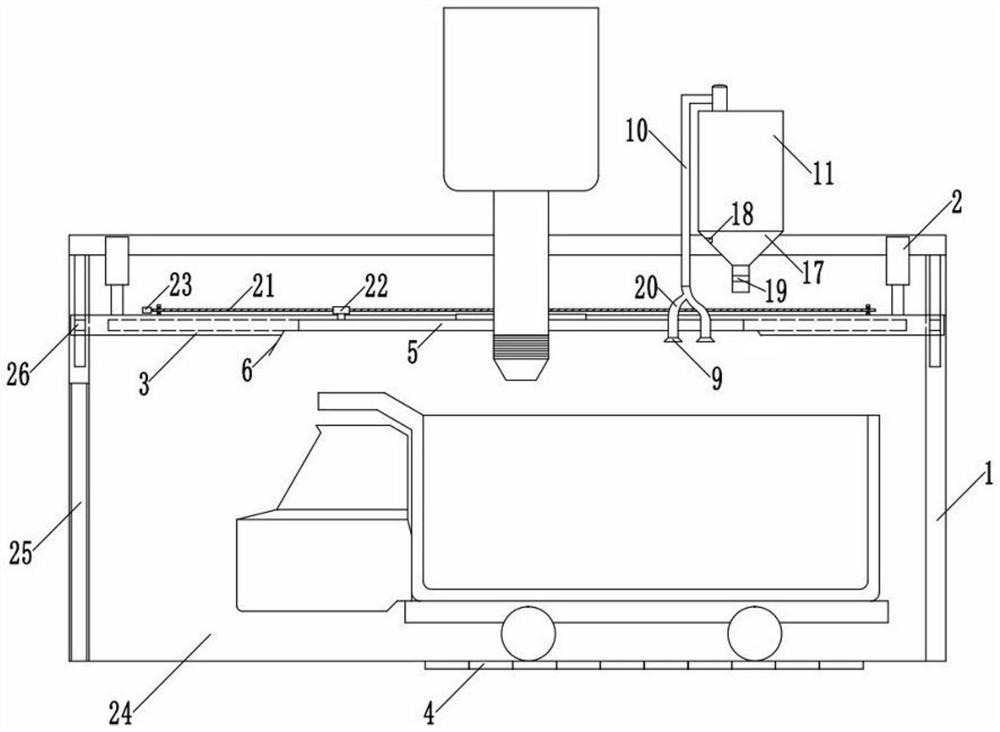

[0058] This embodiment is based on Embodiment 1, and the ash collection device also includes: ash collection hopper 17, fixed on the lower end of the bag filter 11; material level gauge 18, fixed on the inner wall of the ash collection hopper 17 for monitoring ash collection The height of the dust in the bucket 17; the electric valve 19 is fixed on the lower end of the dust collection bucket 17 for opening and closing the dust collection bucket 17.

[0059] Further, the number of the ash collection cover 9 is multiple, and the plurality of ash collection covers 9 are all fixed on the lower surface of the plate body 5, and the upper end of each ash collection cover 9 is connected softly through the connection plate body 5. The pipe 20 is connected with the dust extraction pipe 10 .

[0060] In the present invention, an ash collection device is also fixed on the board body, and the ash collection device uses a bag filter to absorb dust. The dust cover 9 can collect dust in all ...

Embodiment 3

[0062] This embodiment is based on Embodiment 1. The moving mechanism includes: a ball screw 21, located above the support frame 3, the left and right ends of the ball screw 21 are connected to the first pin fixed on the support frame 3 through bearings. The three bearing seats are connected; the ball nut 22 is threadedly connected with the ball screw 21, and the side wall of the ball nut 22 is connected with the plate body 5; the second motor 23 is fixed on the support frame 3, and the second motor 23 is fixed on the support frame 3, and The output shaft of the second motor 23 is connected with one end of the ball screw 21 .

[0063] In the present invention, start the moving mechanism to drive the support frame 3 to move, and the movement of the support frame 3 drives the dustproof device to move to the position in the middle of the vehicle, so as to ensure that the dustproof cover 6 covers the vehicle bucket in the largest range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com