A vertical transport building construction hoist

A technology for building construction and vertical transportation, applied in elevators, sustainable buildings, transportation and packaging, etc., can solve problems such as slipping and safety hazards, and achieve the effect of improving safety performance, reducing safety hazards, and maintaining convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

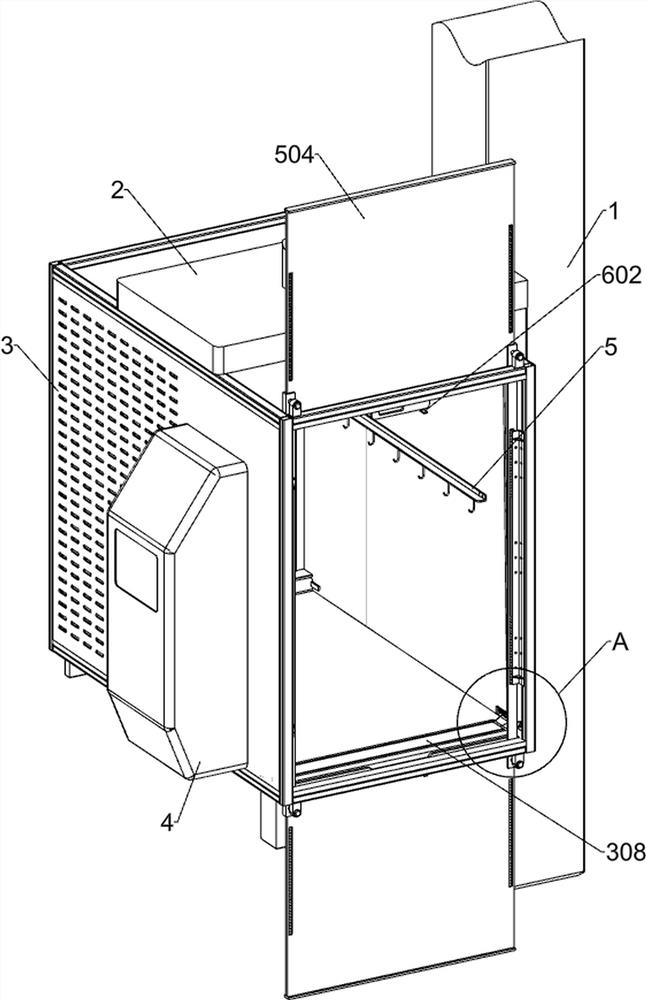

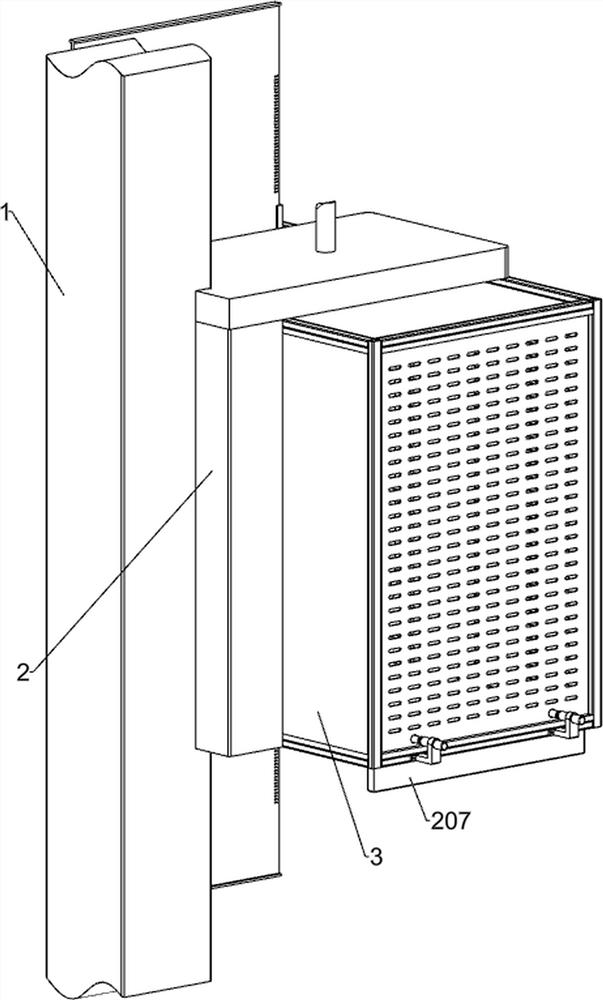

[0034] A vertical transport building construction hoist such as Figure 1-6 As shown, it includes a first support frame 1, a lifter 2, a box body 3, a cockpit body 4, a cleaning assembly, a collection assembly, an impurity removal assembly, a protection assembly and a locking assembly; the left part of the first support frame 1 is installed There is a lifter 2; a box body 3 is installed inside the lifter 2; the cockpit body 4 is connected to the left side of the box body 3; a cleaning component is installed at the rear of the box body 3; a collection component is installed at the lower front side of the box body 3; 3. The lower part of the front side is equipped with an impurity removal assembly, and the impurity removal assembly is located on the upper part of the collection assembly; the front part of the box body 3 is installed with a protective assembly; the upper part of the protective assembly is installed with a lock assembly.

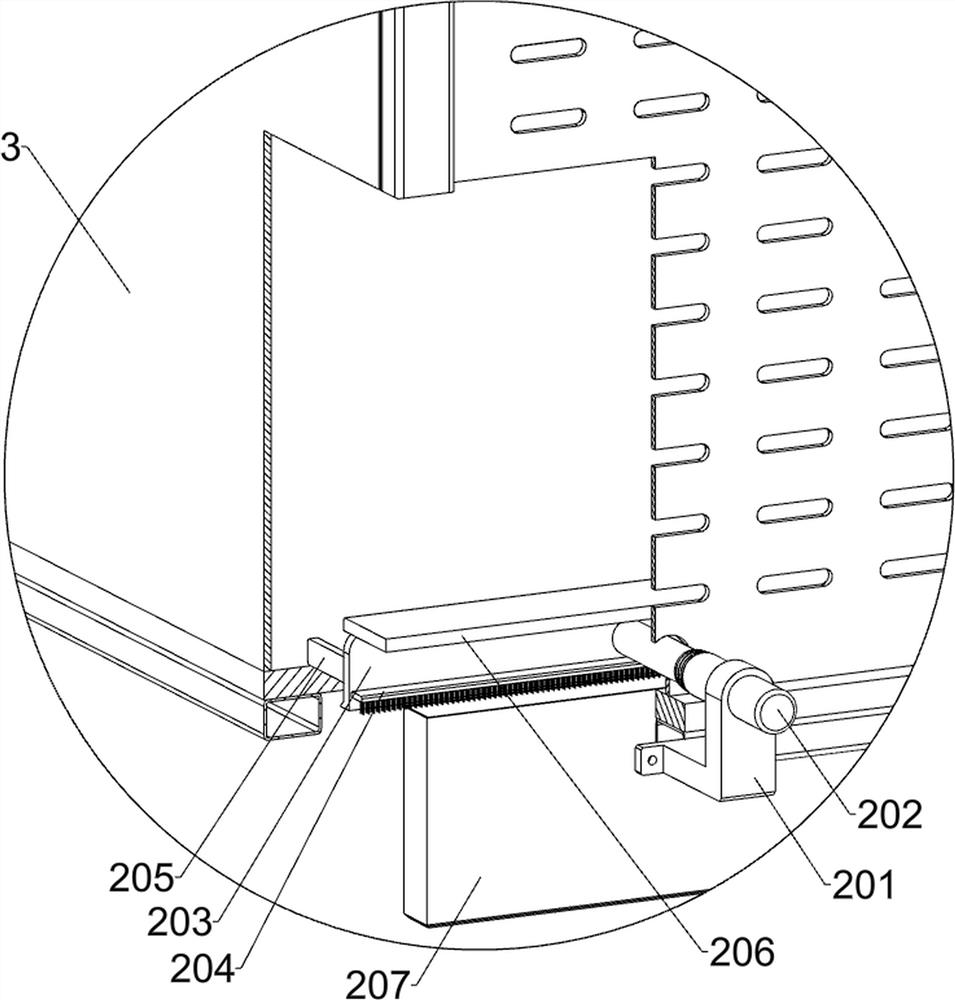

[0035]The cleaning assembly includes a fi...

Embodiment 2

[0040] On the basis of Example 1, such as figure 1 and Figure 7-14 As shown, the protective assembly includes a fourth connecting block 501, a fourth elastic telescopic rod 502, a slide rail 503, a first sliding door 504, a second sliding door 505, a pulley 506, a third rope 507, and a second support frame 508 and limiting plate 509; two fourth connecting blocks 501 are welded on the front part of the upper side of the box body 3; two other fourth connecting blocks 501 are welded on the front part of the lower side of the box body 3; four fourth connecting blocks 501 are internally welded A fourth elastic telescopic rod 502 is fixedly connected; a sliding rail member 503 is fixedly connected to the telescopic ends of each corresponding two fourth elastic telescopic rods 502; a first sliding door 504 is slidably connected between the upper parts of the two sliding rail members 503 A second sliding door 505 is slidably connected between the lower parts of the two slide rails 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com