Drilling equipment for network transformer

A technology for network transformers and punching equipment, which is applied in drilling/drilling equipment, metal processing equipment, boring/drilling, etc. Hole error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

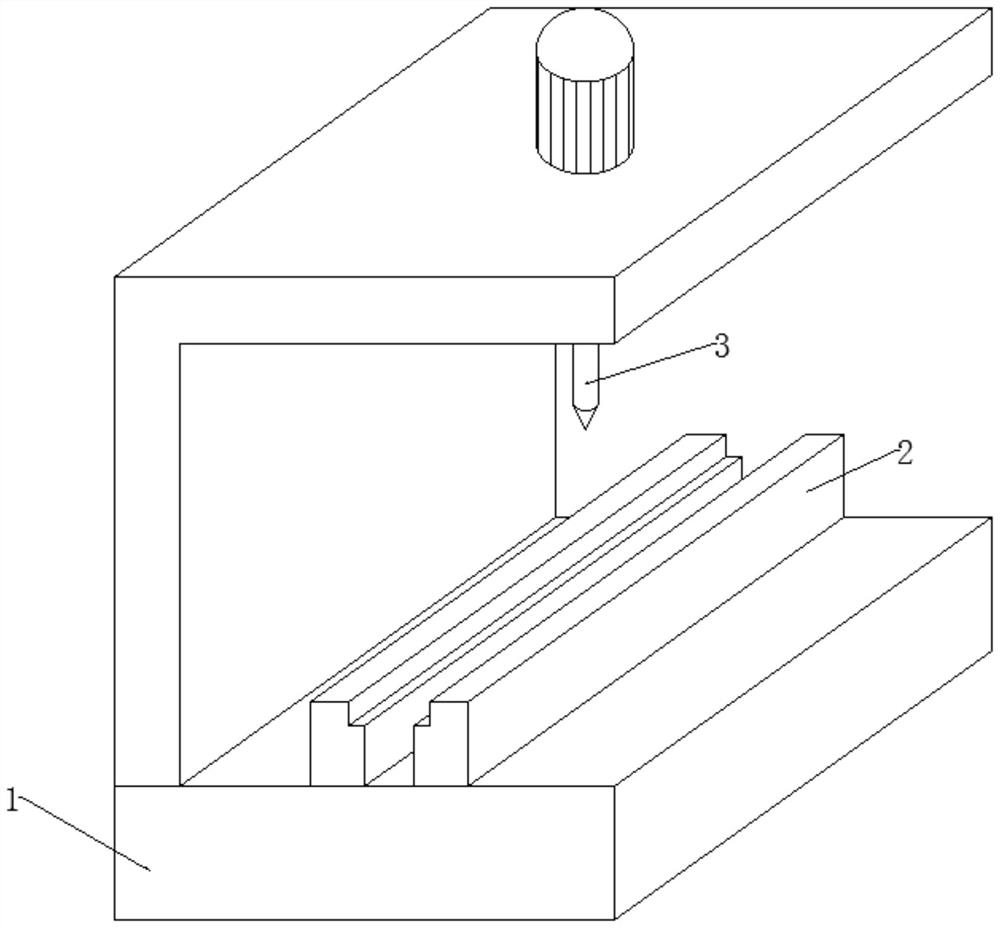

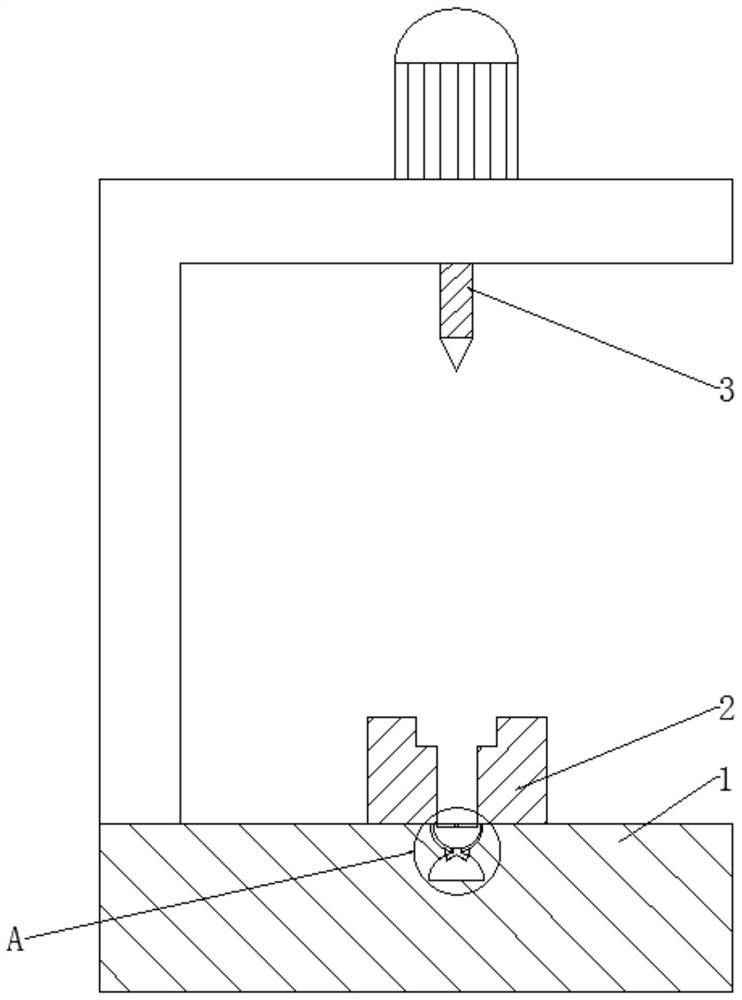

[0041] see Figure 1-3 , in an embodiment of the present invention, a punching device for network transformers, including a workbench 1, two limit seats 2 and a drill bit 3, the inner surface of the top side of the workbench 1 is close to the space between the two limit seats 2 The position of the groove is in the front and back horizontal direction, and there are several cleaning components 4 that can clean the work surface and are slidingly installed in equal rows;

[0042] Each group of cleaning components 4 includes a dust control component 401 that can control the ingress and egress of dust, a water storage component 402 that can store clean water, and a dust collection component 403 that can collect and absorb dust;

[0043] Here, the installation of the cleaning component 4 is set to slide for the convenience of taking out and cleaning after the cleaning component 4 has collected dust, for the next use.

[0044] In the embodiment of the present invention, the appearanc...

Embodiment 2

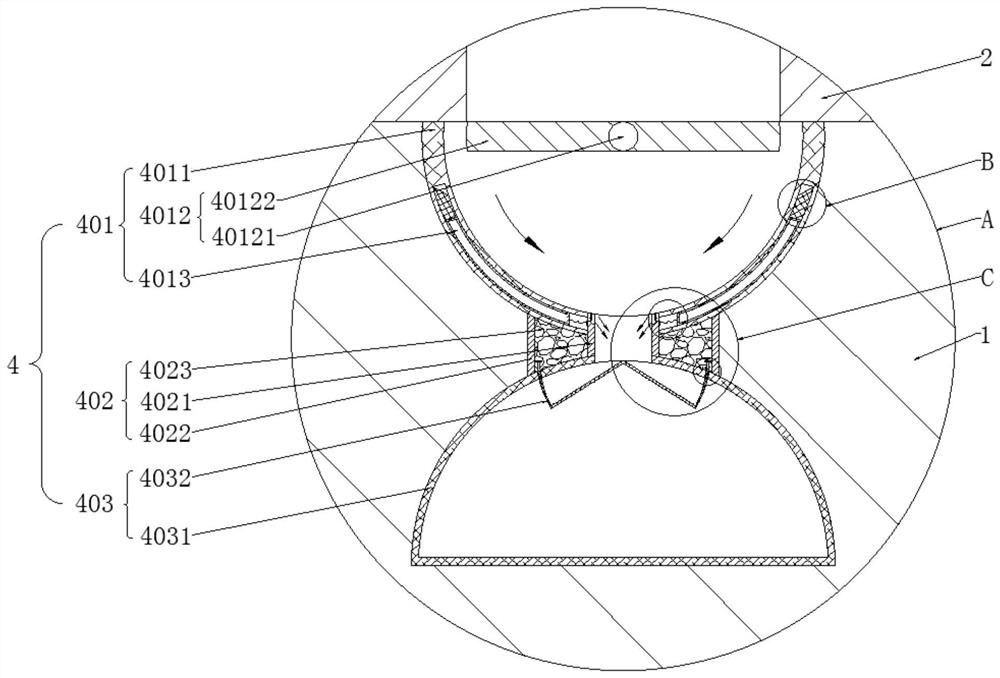

[0048] see Figure 3-6 Compared with Embodiment 1, this embodiment of the present invention differs from Embodiment 1 in that each set of dust control components 401 includes an upper spherical shell 4011, a balance component 4012 that can be introduced according to the weight of dust, and an auxiliary component that can assist in speeding up the introduction of dust. Component 4013.

[0049] In the embodiment of the present invention, the appearance of each upper spherical shell 4011 is hollow inside, hemispherical shape with a flat top and a convex bottom, and the inner diameter of each upper spherical shell 4011 is greater than the distance between the grooves between the two limit seats 2;

[0050] Here, the appearance of the upper spherical shell 4011 is set as a hollow inside, a hemispherical shape that is flat on the top and convex on the bottom, and the inner diameter is greater than the distance between the grooves between the two limit seats 2. The dust accumulated ...

Embodiment 3

[0057] see image 3 , Figure 5-7 Compared with Embodiment 1, this embodiment of the present invention differs in that each set of dust collecting assemblies 403 includes a lower spherical shell 4031 and a water control assembly 4032 that can control the ingress and egress of water.

[0058] In the embodiment of the present invention, the appearance of each lower spherical shell 4031 is a hemispherical shape with a hollow interior and a convex top and a flat bottom. Each set of water control components 4032 includes a rotating rod 40321, two inclined plates 40322, and two arc rods 40323 And two limit strips 40324;

[0059] Here, the appearance of the lower spherical shell 4031 is set as a hemispherical shape with a hollow interior, a convex top and a flat bottom, so that after the dust slides down the inner wall of the upper spherical shell 4011 and falls into the lower spherical shell 4031, it can be collected and blown out can be reduced.

[0060] In the embodiment of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com