Automatic defective product removing device for chip detection

A chip detection and rejection device technology, which is applied in the cleaning method using gas flow, transportation and packaging, cleaning method and utensils, etc., can solve the problems of chip surface adhesion, the collection box does not have a dust collection function, and chip damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

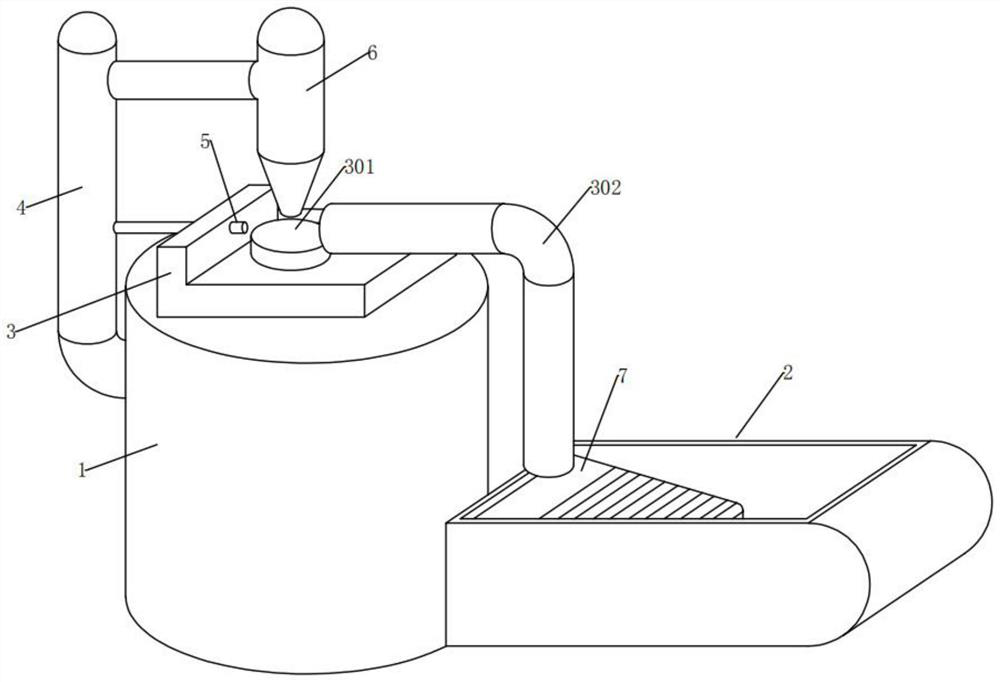

[0045] see Figure 1-3 , in an embodiment of the present invention, a device for automatically rejecting defective products for chip detection, comprising

[0046] Chip testing platform 1, a bracket 3 is fixedly installed at the center of the top of the chip testing platform 1, and the appearance of the bracket 3 is in the shape of "┗" in a longitudinal section, and a chip placement platform 301 is fixedly installed at the center of the top outer surface of the bracket 3 ;

[0047] The support 3 here is provided for the convenience of arranging the chip placement table 301, the collection pipe 302 and the air blowing device 5;

[0048] The collection box 2 is fixedly installed at the bottom of the right end of the chip testing platform 1. The collection box 2 is hollow inside, open up and closed down, and has a straight left and right convex shape;

[0049] The collection box 2 here is to collect dust for the convenience of accommodating defective chips and dust collection c...

Embodiment 2

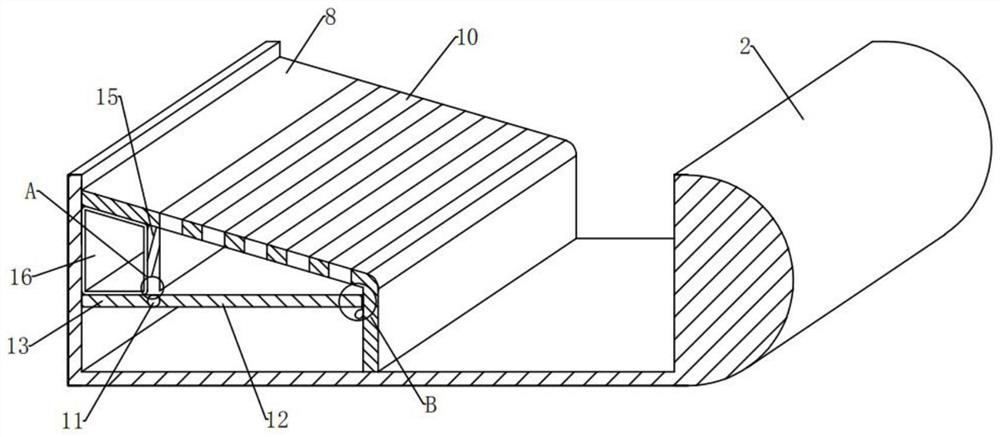

[0061] see Figure 2-4 with Figure 7 Compared with Embodiment 1, the embodiment of the present invention differs in that: the dust extraction assembly 9 includes:

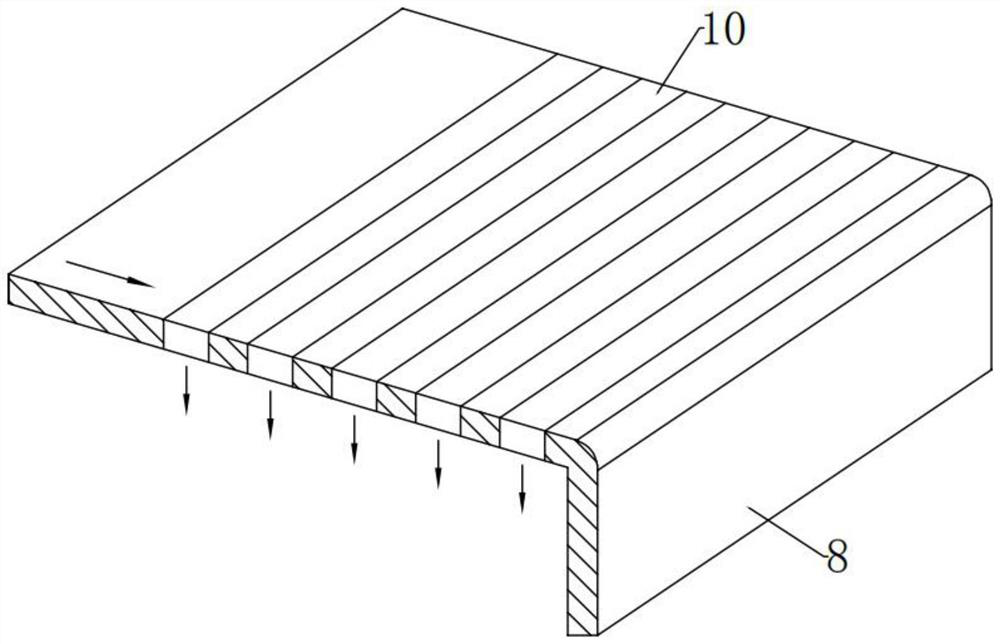

[0062] The dust guide net 10, the position between the top left to the right end of the dust guide slide plate 8 is in the front and rear horizontal direction and is arranged in a row with several through holes penetrating up and down. The through holes are embedded with a dust guide net 10, and the dust guide net 10 Under normal conditions in maximum stretch;

[0063] The dust guide net 10 here is to facilitate the chip defective products falling through the outlet of the tail end of the collection pipe 302 to collect dust through the dust guide net 10 during the process of sliding down the dust guide slide 8. A plurality of dust guide nets 10 can reduce the amount of dust adhered to the surface of defective chips collected at the lower right end of the collection box 2 .

[0064] In the embodiment of the pres...

Embodiment 3

[0073] see figure 2 , Figure 5-7 Compared with Embodiment 1, the embodiment of the present invention differs in that: the dust soaking assembly 14 includes:

[0074] Limiting plate 15, the position of the left end of the bottom side outer surface of the dust guide slide plate 8 is fixedly installed in the vertical direction of the limiting plate 15. The appearance of 15 is a parallelogram shape on a longitudinal section, and the bottom end of the limiting plate 15 is high in the left and low in the right, and the bottom end of the limiting plate 15 is located directly above the rotating shaft 11 and there is a distance between them;

[0075] The limiting plate 15 here is for the convenience of limiting and adorning the air bag 16. After the clockwise rotation of the right plate 12 and the left plate 13, the air bag 16 can be extruded and the clear water in it can be exported to soak dust.

[0076] In the embodiment of the present invention, the dust soaking assembly 14 als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com