Three-year shifting mechanizaxion cultivation method of northeast ridge culture intertilled crop water reservoir moisture retension

A crop and combined operation machine technology, applied in the agricultural field, can solve problems such as difficult narrow row spacing requirements, difficult to ensure sustainable utilization of black soil, and lack of straw returning to the field, so as to reduce operating costs, reduce surface exposure, and reduce soil erosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

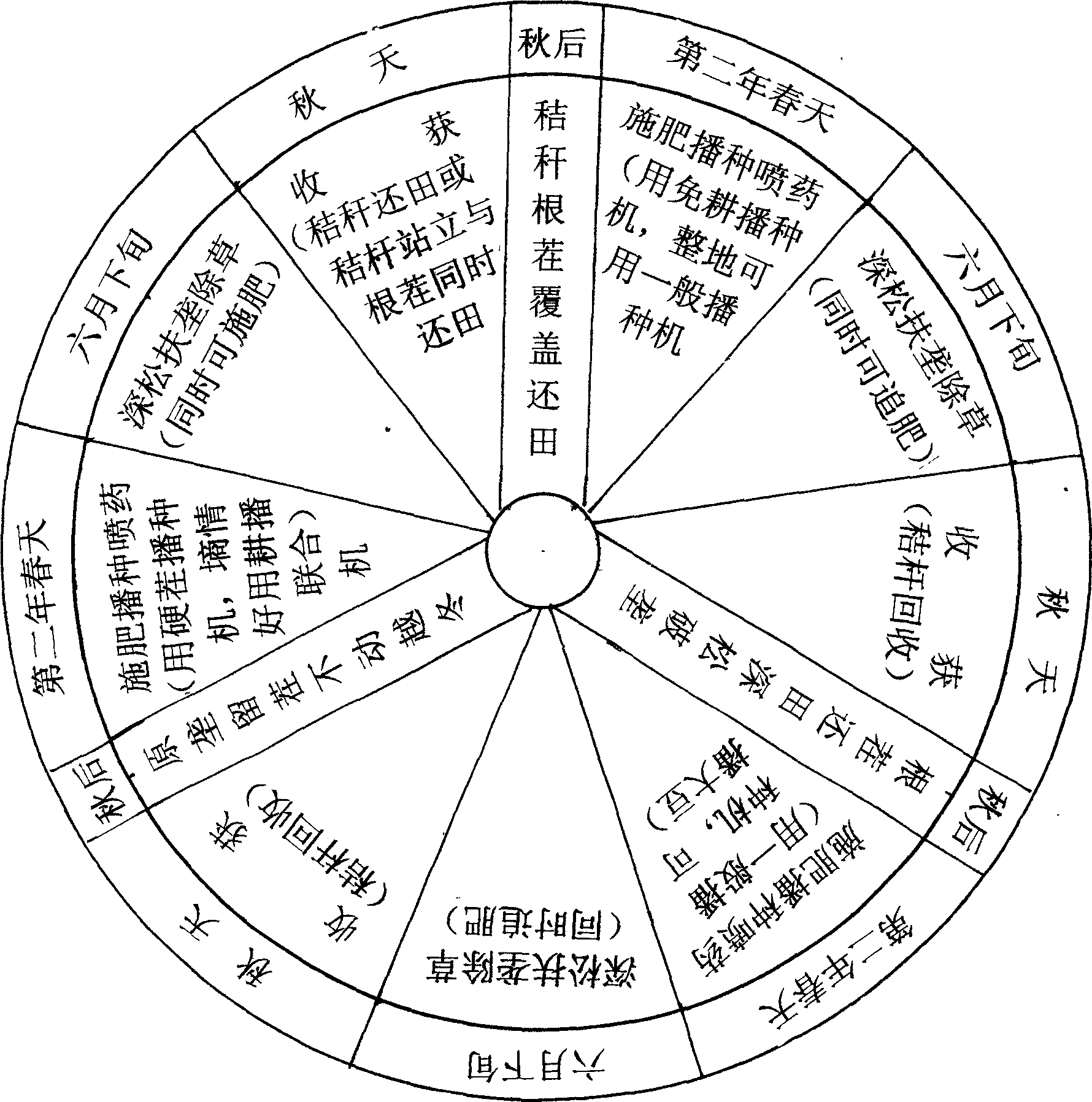

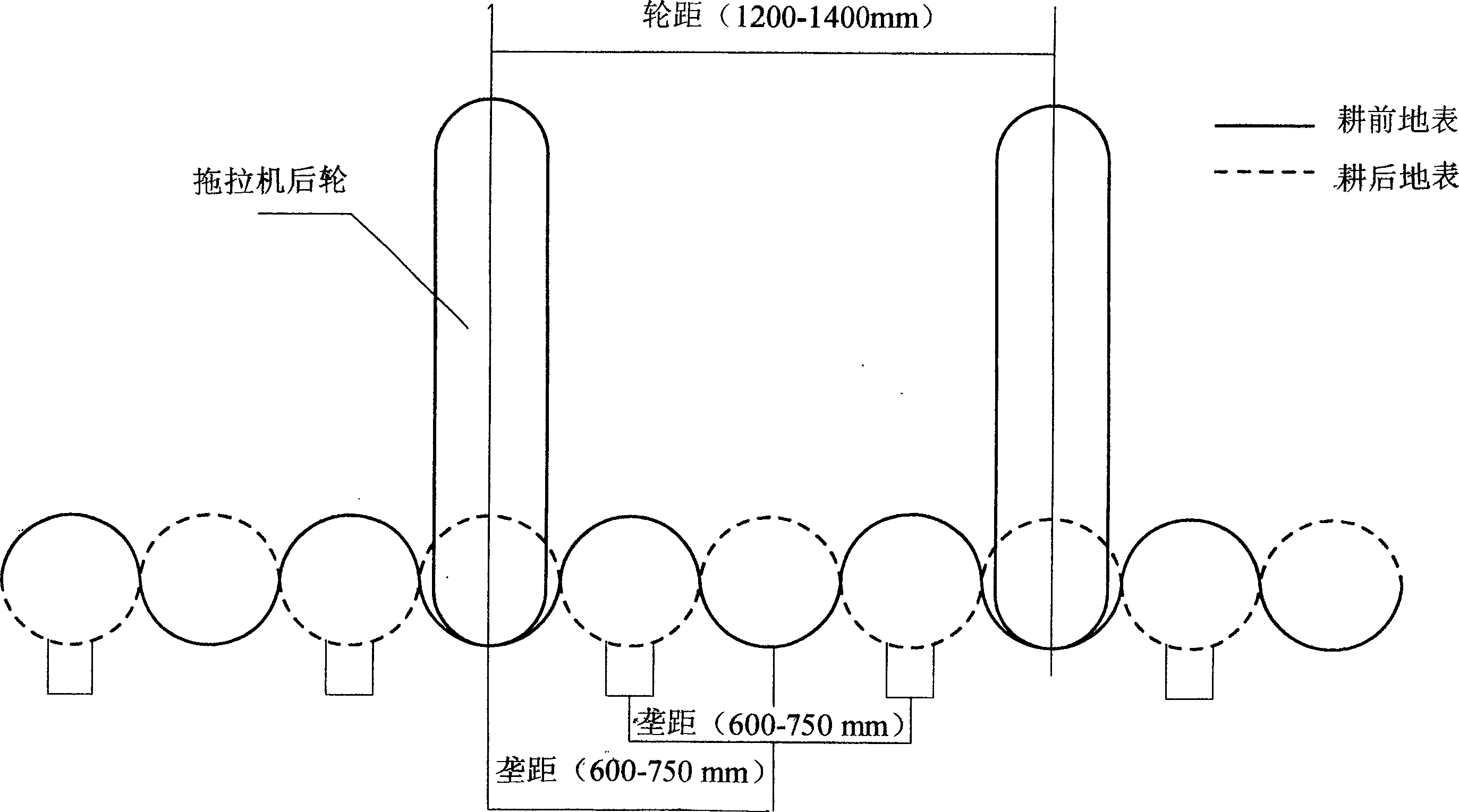

[0032] In the field where corn has been planted in the same year, after harvesting, use the corn harvester to directly crush the straw and return it to the field, or use the straw-root stubble crushing and returning joint operation machine to crush the straw and root stubble and return it to the field at the same time, and then use the tiller The whole combined operation machine removes stubble and ridges. Sow seeds the following spring with a no-till planter. When sowing, narrow ditch (≤5cm), heavy repression (650g / cm 2 ), layered deep fertilization (3-5cm, 8-10cm), precision sowing, spraying herbicides at the same time as sowing. In the middle and late June, the furrows were deep loosened (35cm), the ridges were raised, and weeding and topdressing were carried out at the same time. When harvesting in autumn, collect the spikes and straw, use the plowing and plowing machine to break the stubble, use subsoiling ridges to break the ridges at the original ridge platform to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com