Construction technology for long-spiral cast-in-place pile extruded into rock

A construction process and technology of long screw pile driver, which is applied to sheet pile walls, rotary drilling, rotary drilling rigs, etc., can solve the problems of easy collapse of the hole wall, low construction efficiency, repeated hole cleaning, etc. The effect of fast hole forming speed and safe and reliable working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

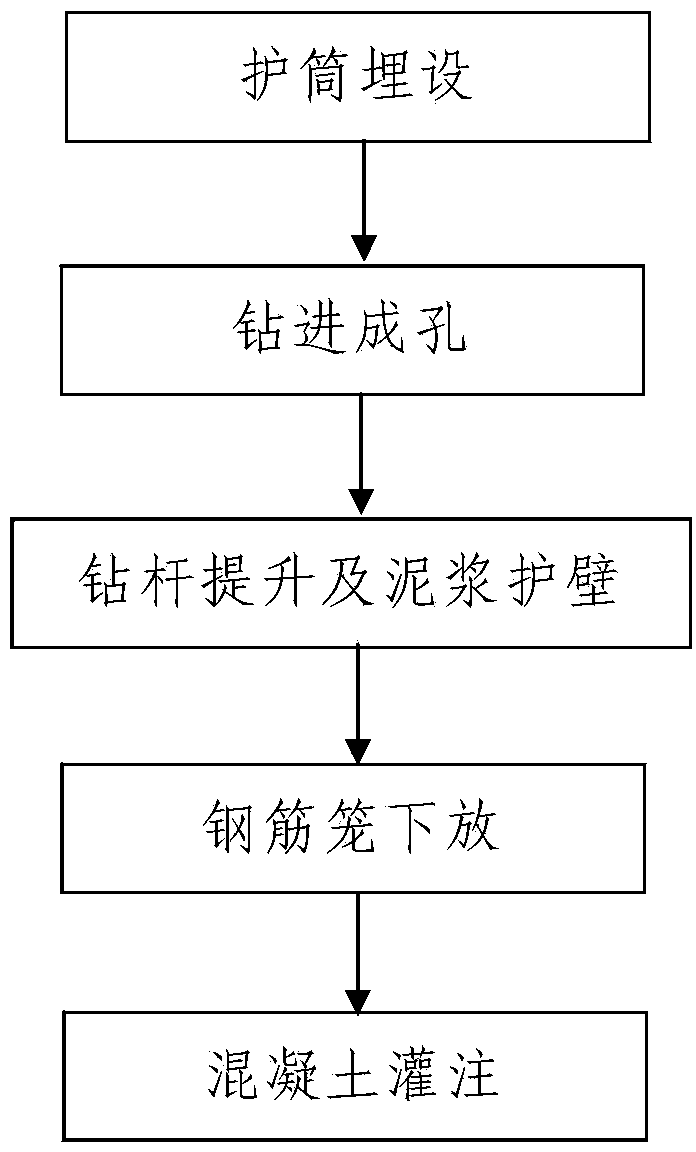

[0088] Such as figure 1 The construction technology of a long spiral extruded cast-in-place pile shown includes the following steps:

[0089] Step 1. Casing embedding: First, measure and set out the pile position of the constructed long screw extruded cast-in-place pile, and then bury the casing on the pile position obtained by measuring and setting out.

[0090] The casing is a cylindrical cylinder arranged coaxially with the constructed long screw extruded cast-in-rock pile. It is 1m ~ 2m.

[0091] Step 2. Drilling to form a hole: Utilize the casing buried in step 1, and use a long screw pile driver to drill down, and obtain a construction-shaped borehole after drilling in place.

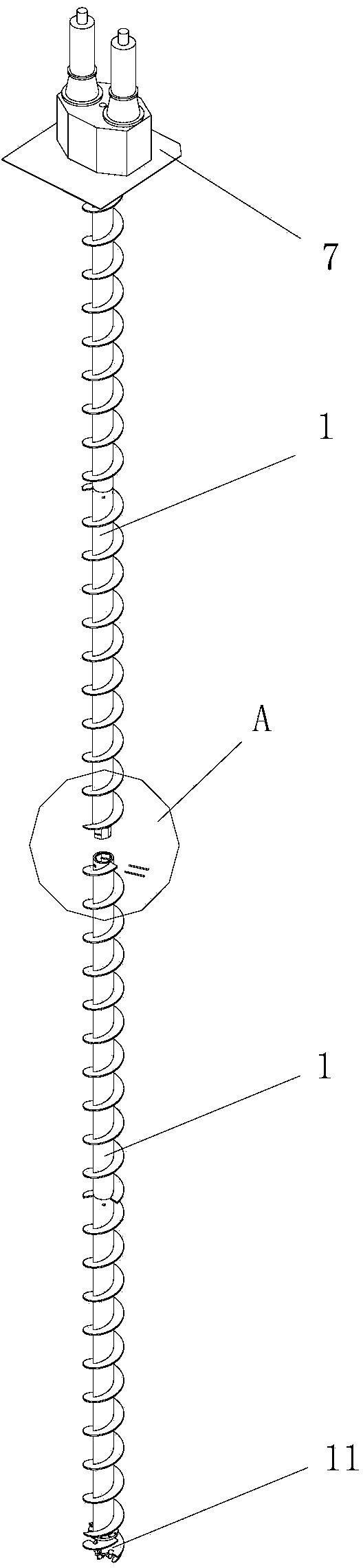

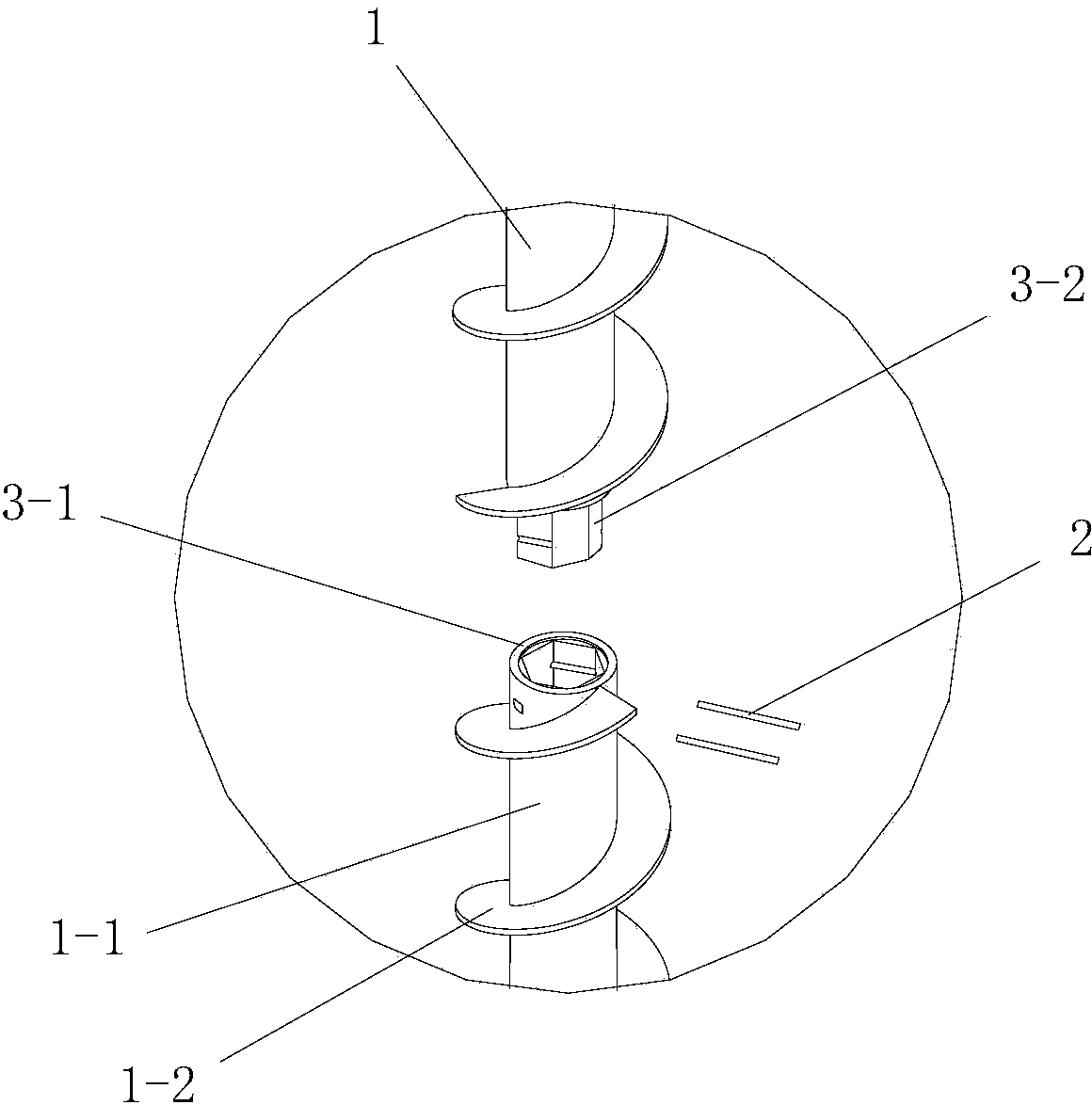

[0092] The long screw pile machine includes a pile frame and a drilling device installed on the pile frame, and the drilling device includes a drill rod, a drill bit 11 coaxially installed at the bottom of the drill rod and drives the drilling device to carry out continuous drilling. A rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com