Municipal sewage pipeline laying construction method

A construction method and sewage pipeline technology, applied in pipeline laying and maintenance, mechanical equipment, pipes/pipe joints/pipe fittings, etc., can solve the problems of high risk of operation, long construction period, and long construction time, so as to shorten the construction period , reduced construction period, and improved construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

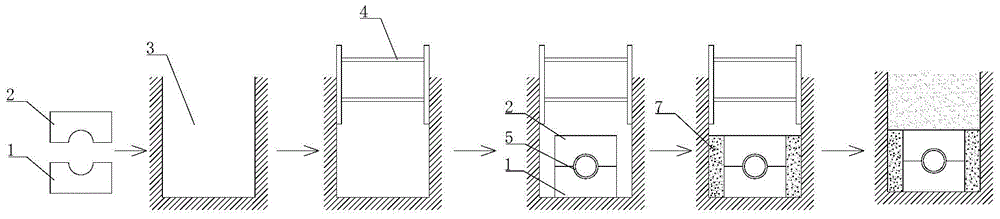

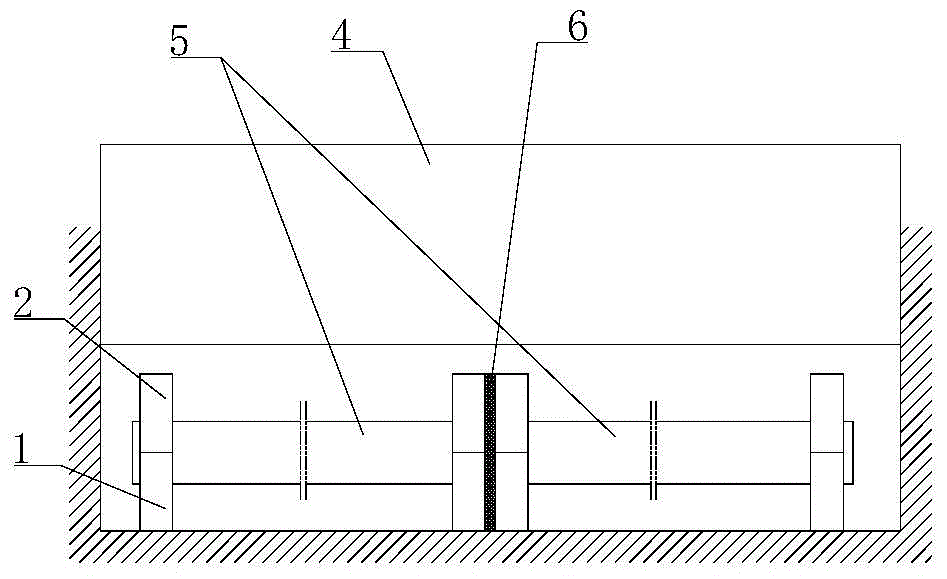

[0034] see figure 1 and 2 , the municipal sewage pipeline laying construction method, the construction method adopts the method of segmented continuous construction for laying, the characteristics of this construction method are: in the laying process of each section, the bottom concrete pad 1 prefabricated in advance and the bottom concrete block 1 are used. Pad to match the top concrete block 2. In the middle of the upper end surface of the bottom concrete block and in the middle of the lower end surface of the top concrete block, there are semicircular grooves matching the outer diameter of the sewage pipeline to be laid, and the two semicircular grooves can be spliced. Position the vias in a full circle. The laying process of each sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com