Aluminum alloy formwork keel structure and construction method thereof

A technology of aluminum alloy formwork and construction method, which is applied in the direction of formwork/formwork/work frame, formwork treatment, building construction, etc., and can solve the problems that the main keel profile is not easy to disassemble, cannot be tightly matched, and is unfavorable for quick disassembly. , to achieve the effects of quick and early dismantling, firm locking and reduced construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

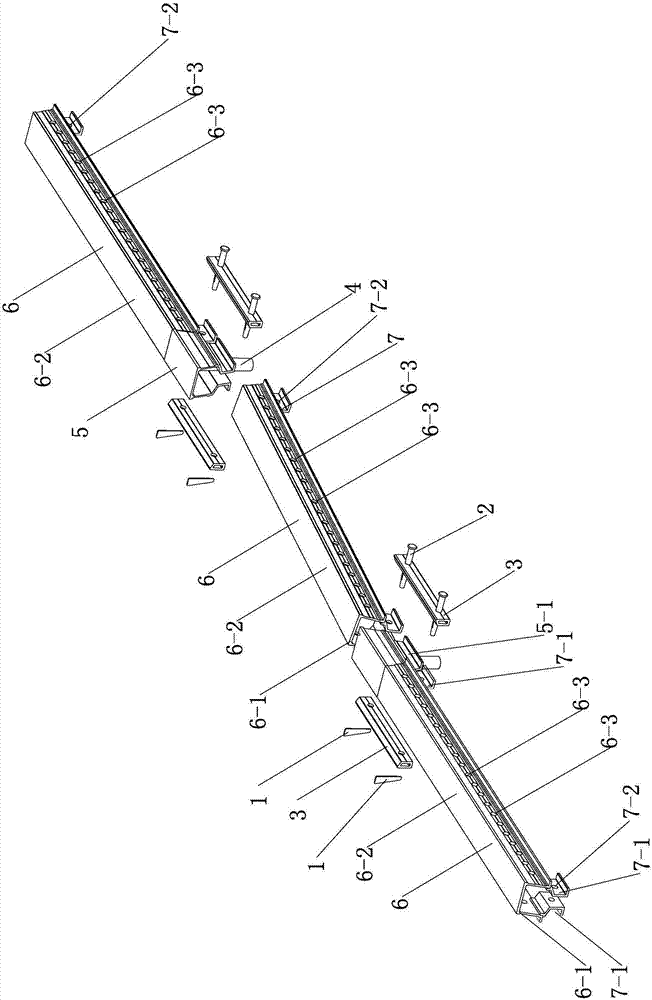

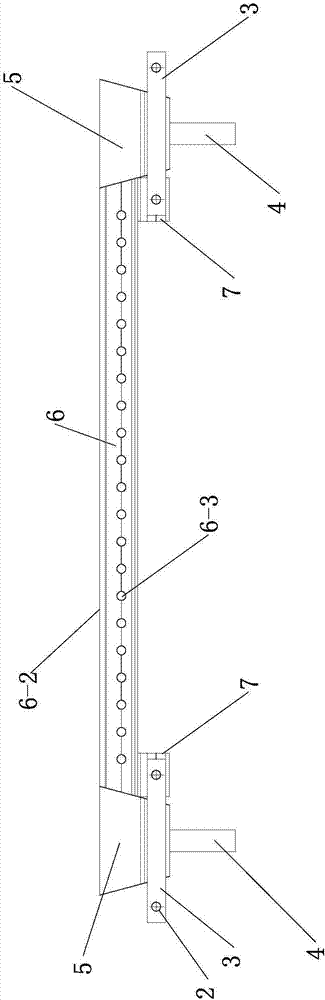

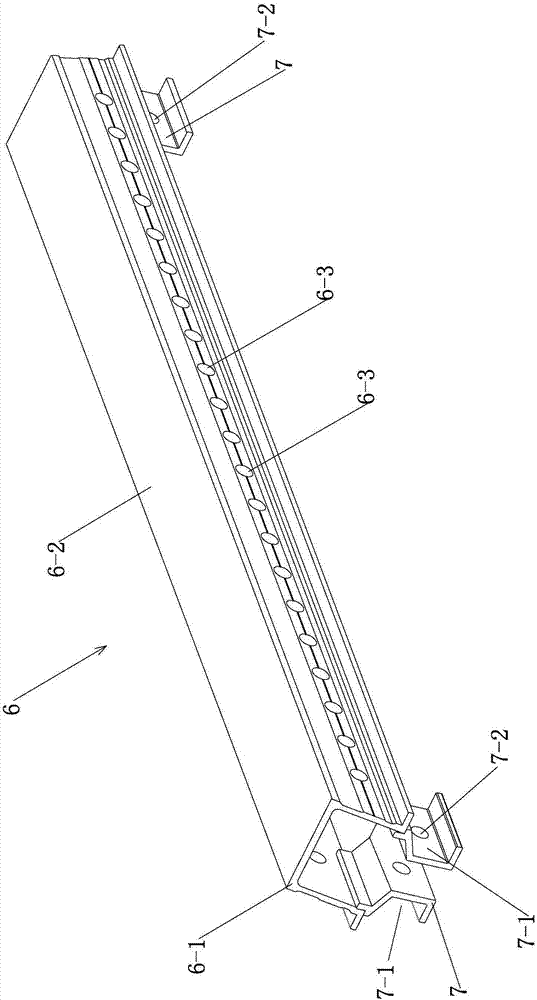

[0028] Such as Figure 1-Figure 3 As shown, the aluminum alloy formwork keel structure of this embodiment includes a plurality of early dismantling heads 5, main keel profiles 6 and keel locking strips 3, and every two main keel profiles 6 are detachably connected to two early dismantling heads 5. end, the two end surfaces 6-1 of the main keel profile 6 are inclined planes, and the angle between it and the upper plane 6-2 is between 100° and 140°; The early dismantling head 5 and the main keel profile 6 can be closely matched; the lower parts of the two ends of the main keel profile 6 are respectively fixed with two keel brackets 7, and the front and rear sides of the keel bracket 7 are provided with symmetrical trapezoidal cross-sections. The first draw-in slot 7-1, the lower end of the early dismantling head 5 is provided with the second draw-in slot 5-1 corresponding to the first draw-in slot 7-1, and the two ends of the keel lock bar 3 are respectively inserted into two ad...

Embodiment 2

[0038] combine Figure 1-Figure 3 As shown, the specific structure of the keel structure of the aluminum alloy formwork in this embodiment is as follows: it includes at least one early demolition head 5 and at least one keel 6, the cross section of the keel 6 is groove-shaped, and the two sides of the keel 6 are provided with aluminum alloy formwork Connected mounting hole 6-3, the end of the keel 6 is compatible with the end of the early dismantling head 5 and the two are detachably connected, the angle formed between the end face of the early dismantling head 5 and the upper plane is less than or equal to 90°, and the early The upper plane of the head 5 and the upper plane 6-2 of the keel are on the same plane.

[0039] In this embodiment, the number of early dismantling heads 5 is 2, the number of keels 6 is 3, and two adjacent keels 6 are connected by one early dismantling head 5 . Of course, the number of keels 6 is M, and the number of early dismantling heads 5 is M+1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com