Vertical pouring and fast homogenizing device and method for pipe cores of PCCPs

A vertical, tube core technology, applied in supply devices, ceramic molding machines, manufacturing tools, etc., can solve the problems of wasted labor costs, long pouring molding time, and unguaranteed pouring quality, saving labor costs and reusing The effect of high rate and improving pouring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are clearer and easier to understand through the description.

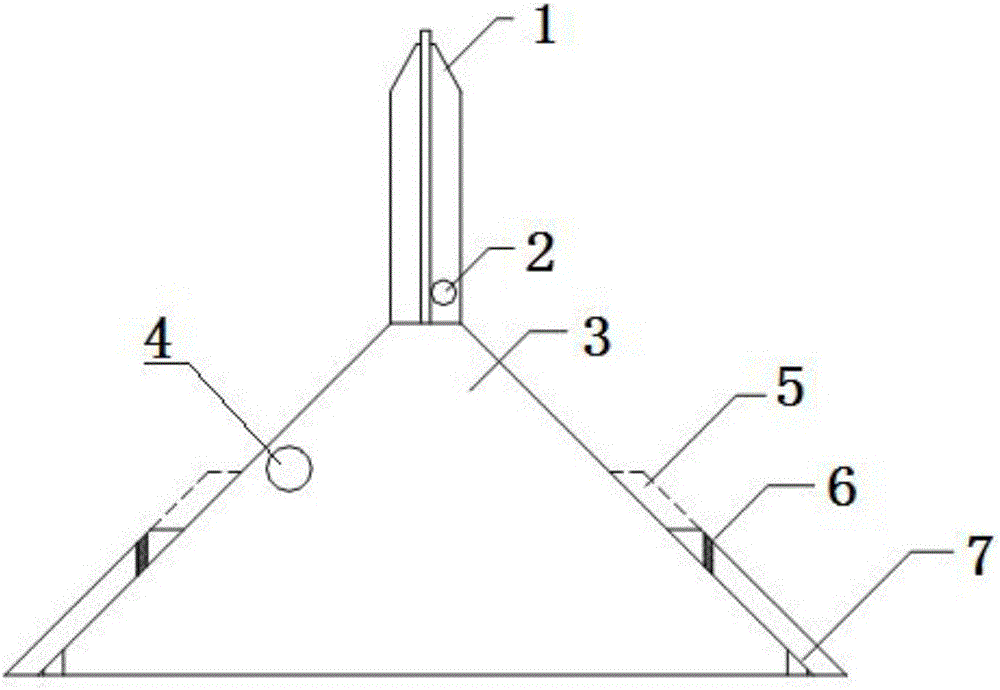

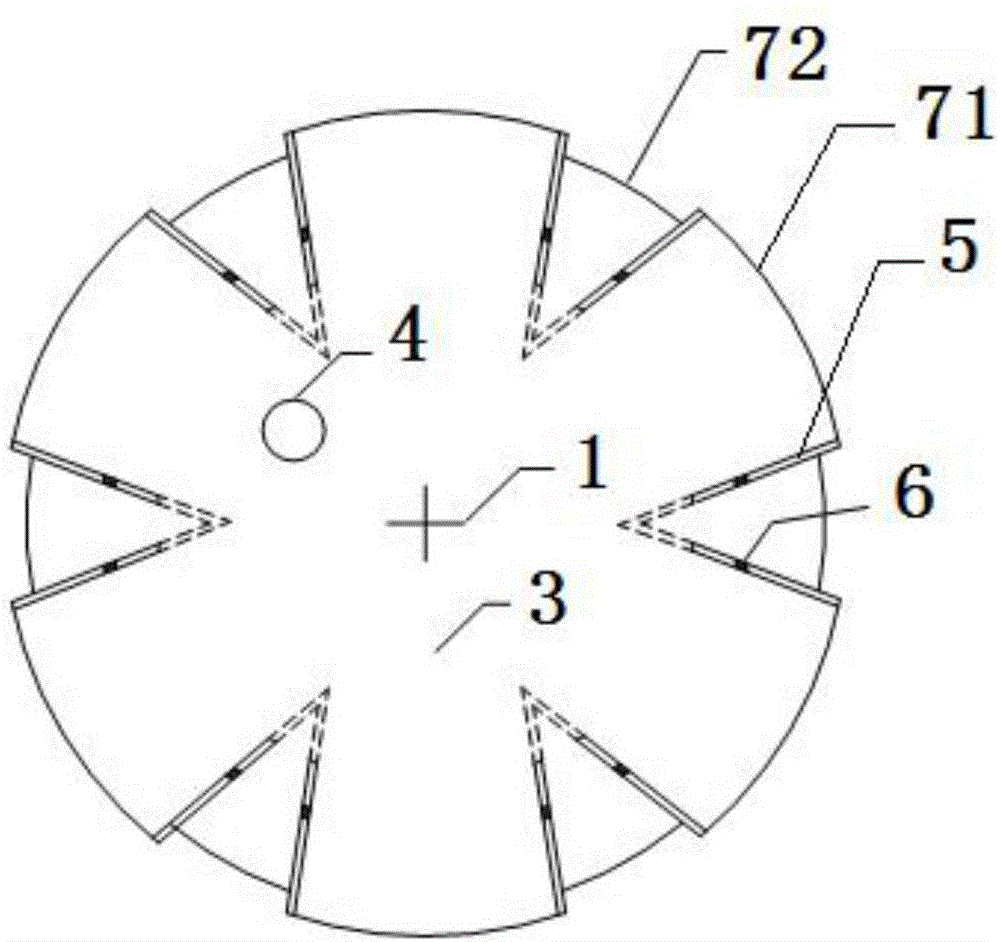

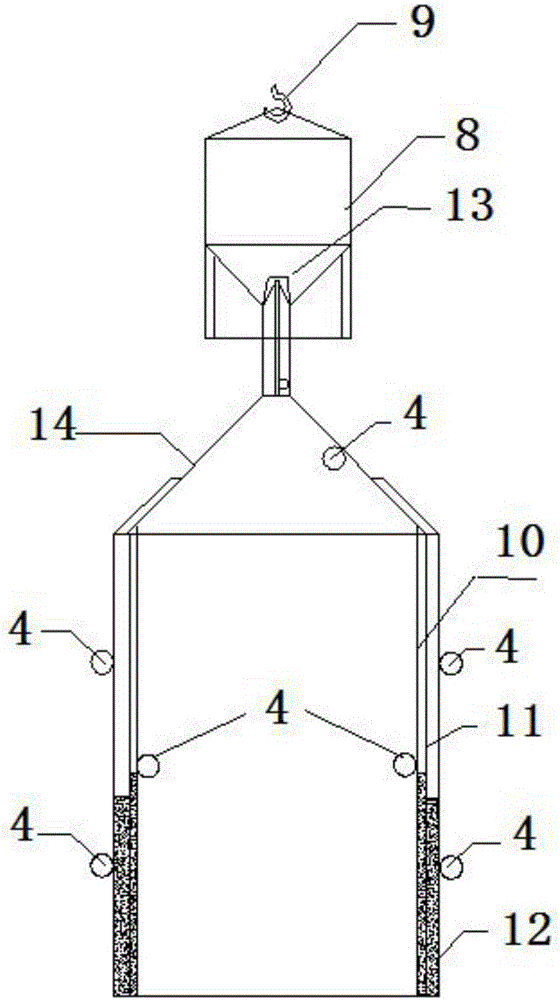

[0032] Referring to the accompanying drawings, it can be seen that the PCCP pipe core vertical pouring rapid homogenization device includes a mandrel 1 and a homogenization cone 3, and is characterized in that it also includes an attached pneumatic vibrator 4 and a partition plate 5. The attached The type pneumatic vibrator 4 is attached to the inner wall of the homogenizing cone 3; the lifting lug 2 is located at the middle and lower part of the ejector rod 1, and the bottom end of the ejector rod 1 is connected to the cone top of the homogenizing cone 3 ; The partition plate 5 is evenly distributed on the outer wall of the uniform materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com