Rotating type concrete distribution device applied to sliding formwork

A distributing device and rotary technology, applied in the connection of formwork/formwork/work frame, construction material processing, formwork/formwork/work frame, etc., can solve the problem of filling, quality, Insufficient safety, concrete faults, etc., to ensure the quality of pouring, shorten the pouring time of concrete, and have strong structural stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

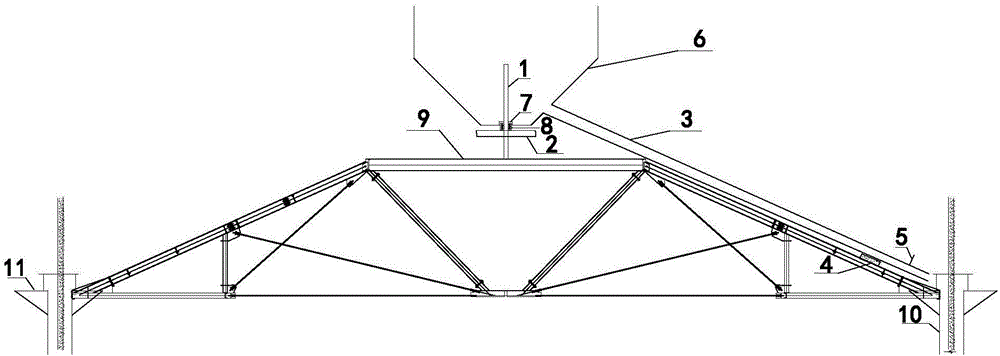

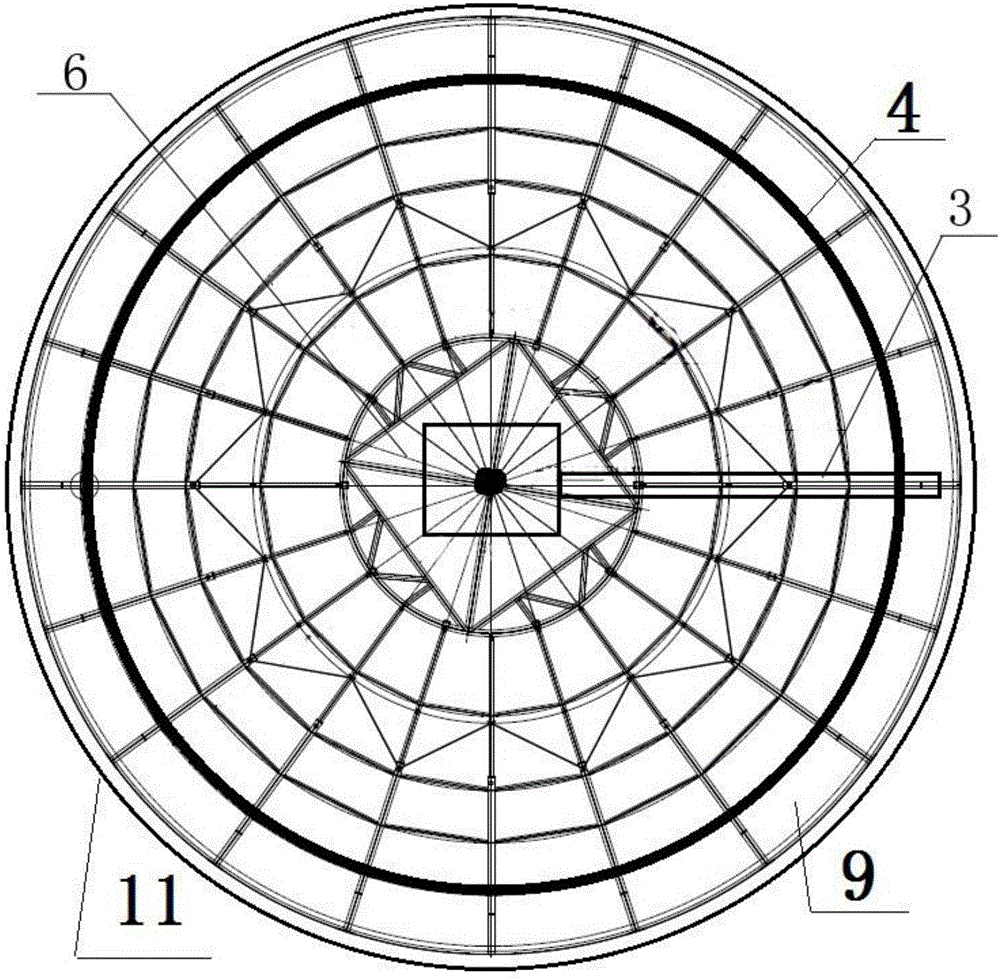

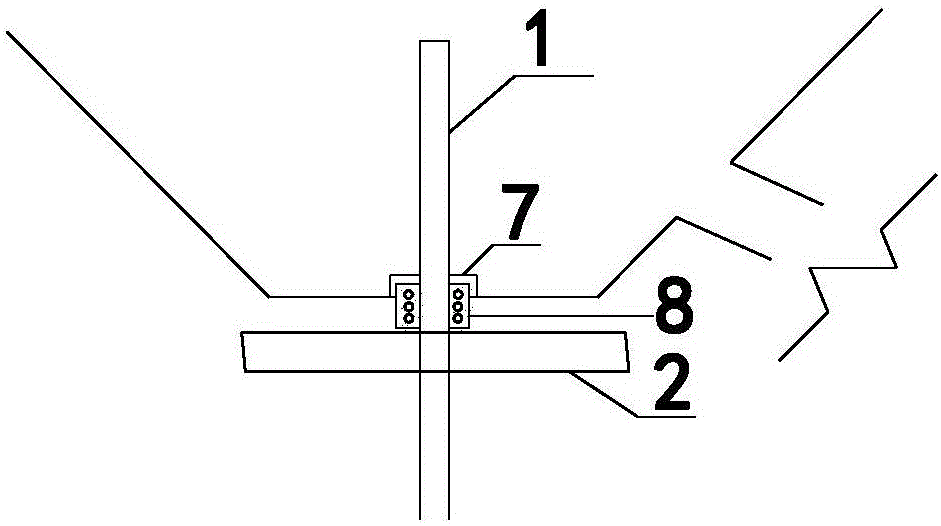

[0018] Such as Figure 1-Figure 3 As shown, the rotary concrete distributing device applied to the sliding form of the present invention includes an umbrella support platform 9, a column 1, a supporting plate 2, a chute 3, a track 4, a funnel 6 and a sliding form system 11.

[0019] The outer edge of the umbrella-shaped support platform 9 is provided with a sliding form system 11, and the middle part of the umbrella-shaped support platform 9 is provided with a column 1, which is in the shape of a circular tube. A support pallet 2 is fixedly arranged on the column 1, and a funnel 6 is arranged above the support pallet 2, and the funnel 6 can rotate around the column 1. The umbrella-shaped steel support is used as a load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com