Robot quantitative pouring method

A quantitative pouring and robotic technology, which is used in equipment supplying molten metal, manufacturing tools, metal processing equipment, etc., can solve the problems of molten metal overflow, splashing, and inconsistent temperature changes of molten metal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

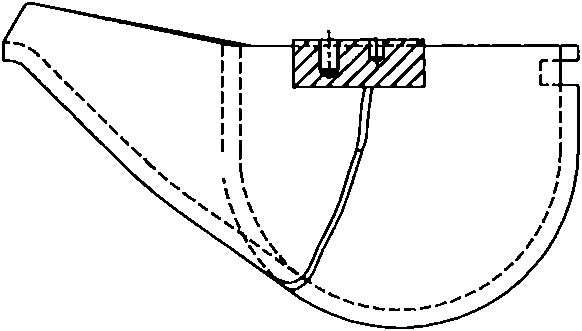

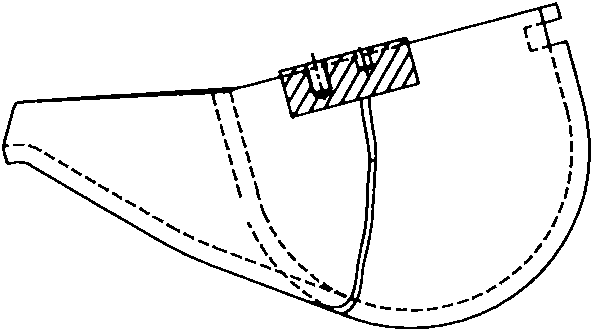

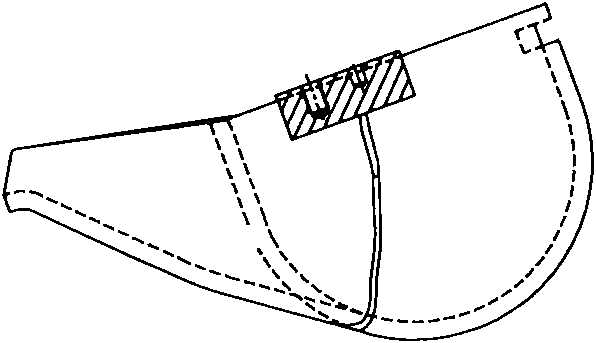

[0028] Such as Figure 1~4 As shown, it is four state schematic diagrams when the set rotation range of the ladle of the present invention is divided into three angle segments by PLC, and the turning time of each angle segment is set by PLC at the same time, so that the robot takes the ladle in each Each angle segment is flipped at a constant speed, that is, according to the following Figure 5 The broken line segment b of the corresponding relationship between the rotation angle and the time shown is poured, so that the defects of the prior art can be avoided.

Embodiment 2

[0030] Let the robot carry the ladle according to the following Figure 6 The gradual curve c of the corresponding relationship between the rotation angle and the time shown is poured, so that the defects of the prior art can be avoided. Moreover, the speed between the various angle segments is continuous, which can better avoid the splashing of molten metal caused by sudden changes in speed.

[0031] The industrial robot controls the rotation angle of the ladle, and divides the rotation angle of the ladle, such as into three angles, or it can be divided into any angle according to the needs, and each angle is input through the external PLC control program. The time variable is associated, and the value of the time variable can be manually input through the PLC operation terminal. For example, the time variable of 0-15 degrees is 2 seconds, which means that the machine will control the ladle from 0 degrees to 15 degrees in 2 seconds. , if the time variable is set to 5 seconds...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com