UHPC small box girder structure

A technology of small box girders and box girders, which is applied to bridges, bridge parts, bridge materials, etc., can solve the problems of prestressed reinforced concrete structures, self-heaviness of steel-concrete composite structures, and large on-site construction operations. Facilitate on-site assembly construction, simplify the construction process, and save materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

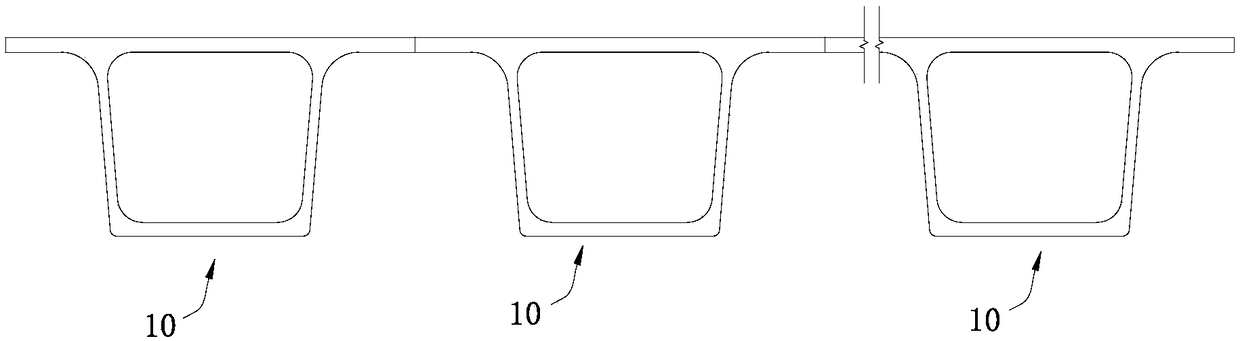

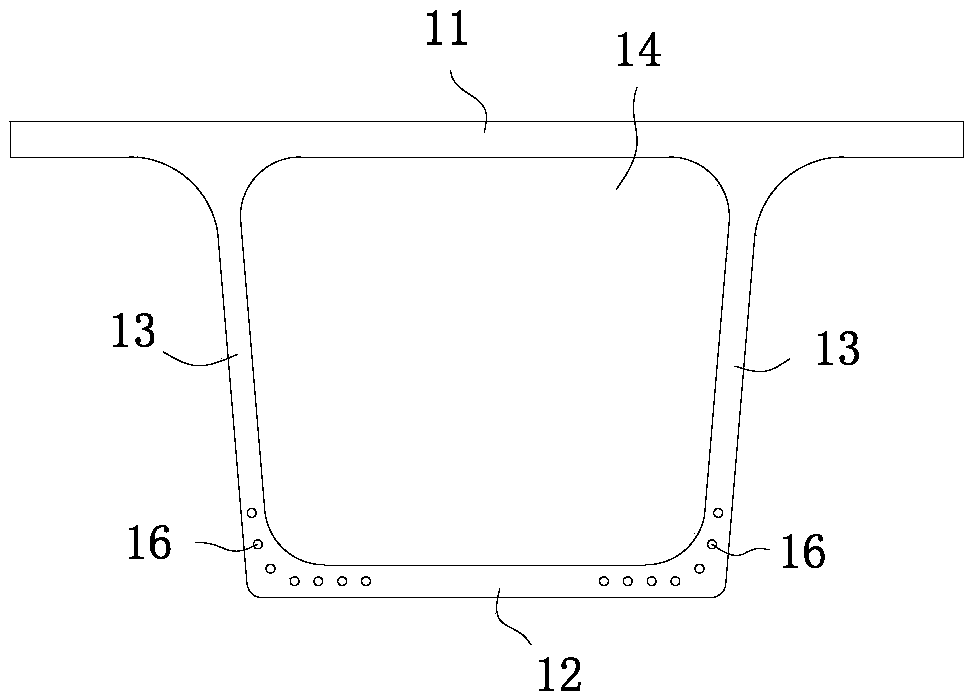

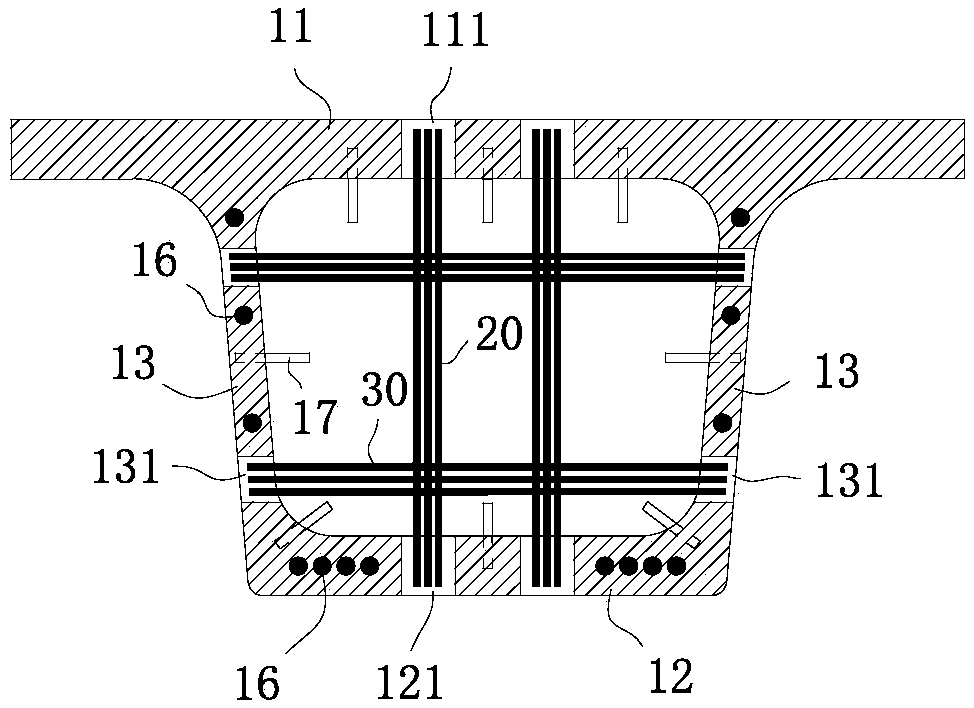

[0027] refer to Figure 1 to Figure 7 , the UHPC small box girder structure of the present invention includes a plurality of adjacent box girder bodies 10, the box girder body 10 is prefabricated by ultra-high performance concrete, and the box girder body 10 can also be used in combination with ultra-high performance concrete (UHPC, Ultra-High Performance Concrete) similar materials, such as CRC, DSP, FRHPC, HPFRCC, RPC, STC, UHPFRC and other high-performance cement-based composite materials, the box girder body 10 is composed of a top plate 11, a bottom plate 12, a web 13, a mid-span partition 14 and an end The thickness of the top plate 11, bottom plate 12, and web 13 changes along the longitudinal direction, that is, the thickness of the top plate 11, bottom plate 12, and web 13 is relatively large at the end of the box girder body 10, and the thickness of other parts is relatively thick. Small. The box girder body is a thin-walled box girder made of UHPC (Ultra High Perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com