Method for constructing concrete structure of subway contact passage through ground pouring and freezing method

A concrete structure and communication channel technology, which is applied in the fields of earthwork drilling, soil protection, and foundation structure engineering, can solve problems such as hidden dangers in structural quality, difficult quality control, poor continuity, etc., to reduce uneven settlement and shorten pouring time , The effect of saving pouring time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

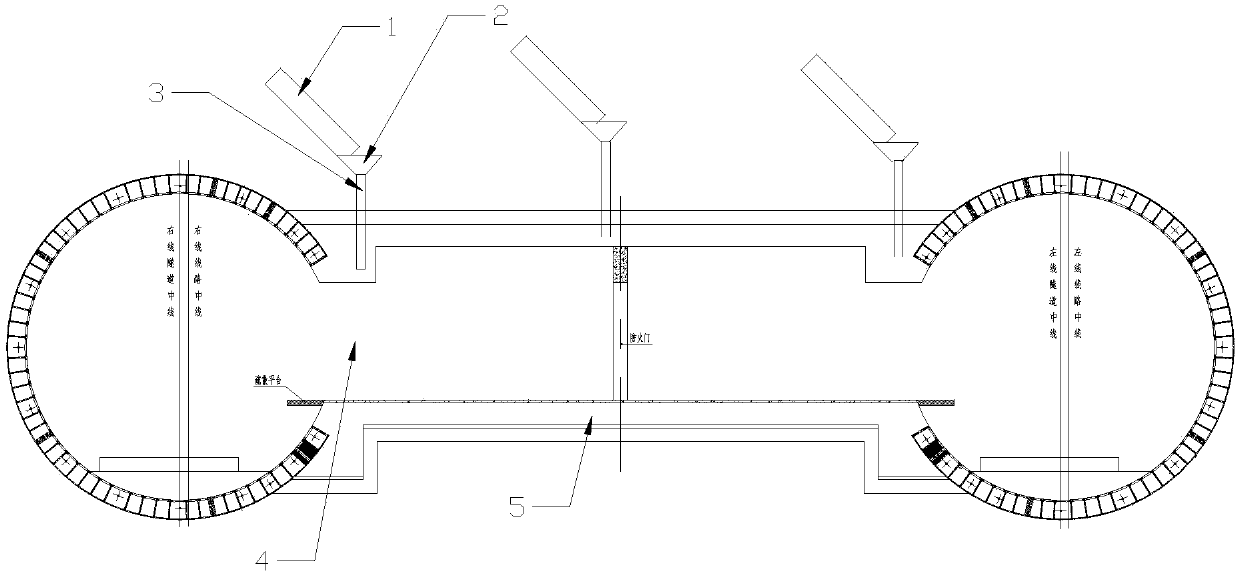

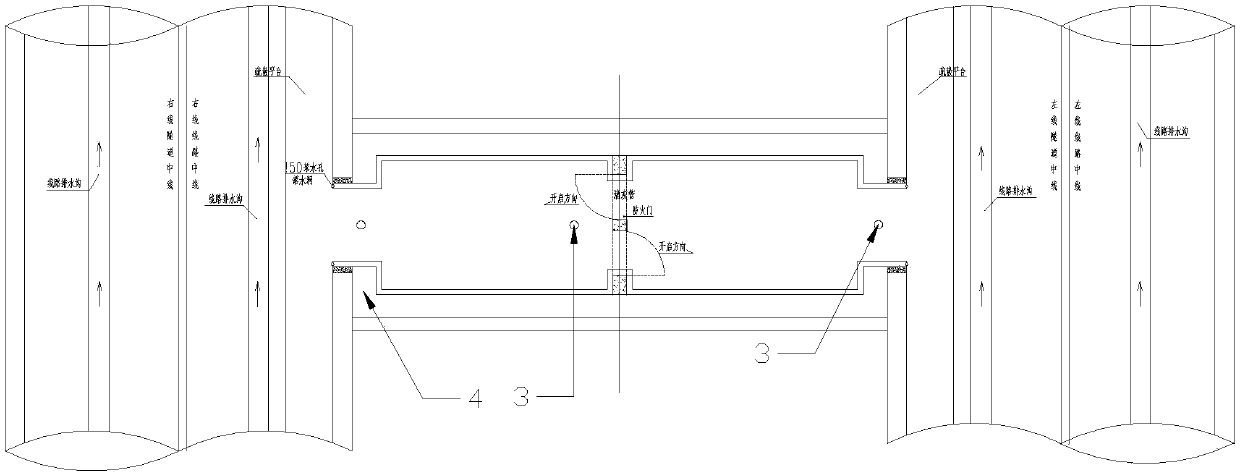

[0039] In order to clearly illustrate the solutions in the present invention, preferred embodiments are given below and detailed descriptions are given in conjunction with the accompanying drawings.

[0040] The method for constructing the concrete structure of the subway communication channel by ground pouring freezing method comprises the following steps:

[0041] (1) Before the construction of the frozen hole in the communication channel, use a drilling rig to drill a hole in the center of the ground communication channel and at the 4 positions of the bell mouth on both sides. Inside, the bottom of the borehole located at the center of the communication channel is located above the bottom plate 5 of the communication channel. Wherein, the diameter of the drilled hole is larger than 159mm.

[0042] Before drilling from the ground above where the communication channel is located to where the communication channel is located, it is necessary to perform ground measurement and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com