Soup spoon for soup feeding machine

A soup feeder and soup spoon technology, applied in the field of casting machinery and equipment, can solve the problems of long time consumption, long soup time, and inability to feed soup at a close distance, so as to improve product quality and pass rate, improve work efficiency, The effect of reducing the pouring time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

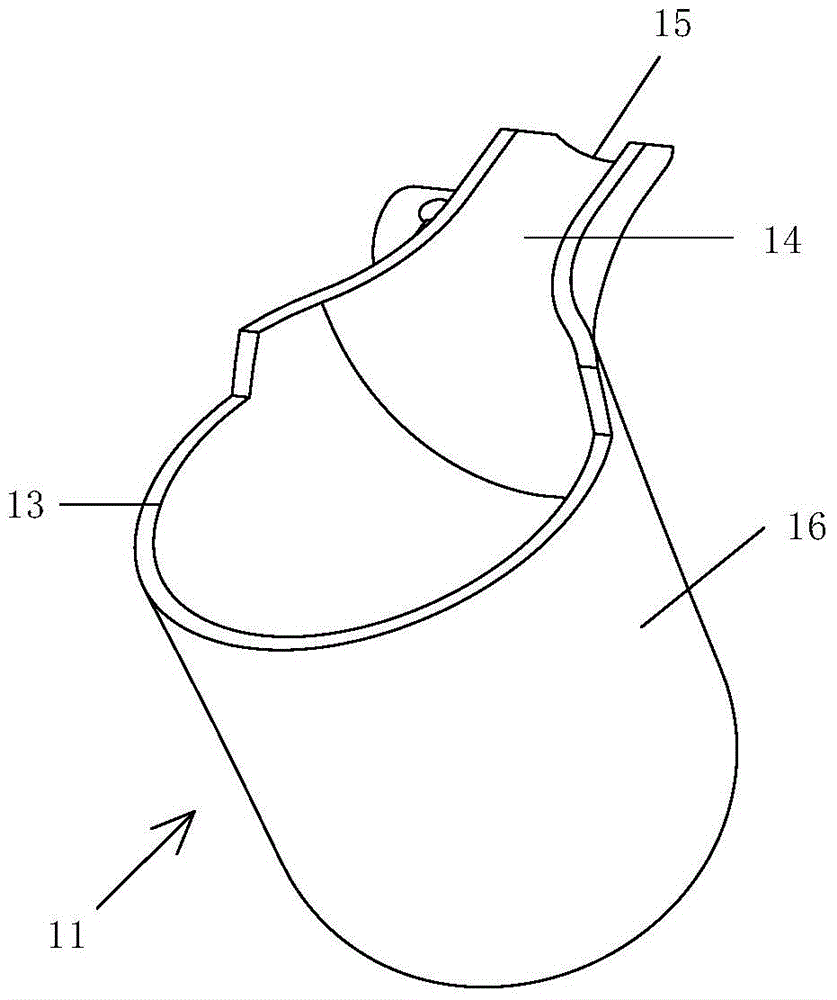

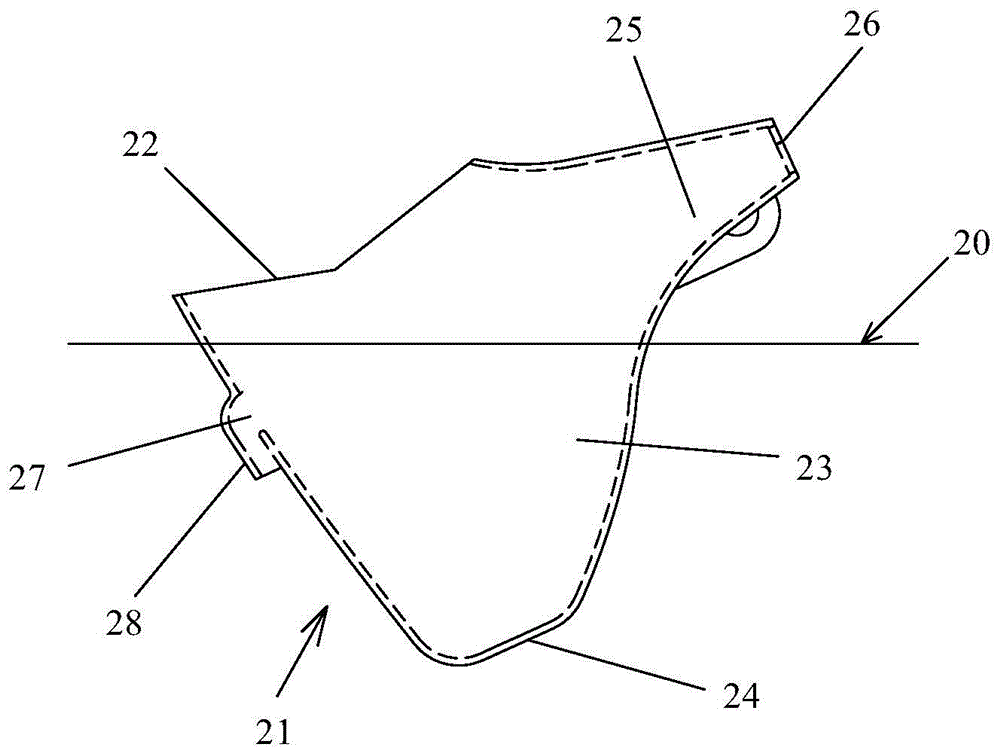

[0022] like image 3 , Figure 4 and Figure 5 As shown, the soup ladle 21 used for the soup dispenser of the present invention includes a ladle mouth 22, a ladle body 23, a ladle bottom 24, a soup outlet 25 and a soup outlet channel 26, and the ladle mouth 22 and the ladle bottom 24 are located at the ladle body 23 respectively. One end of the soup channel 26 is connected to the top of the spoon body 23, and the other end is connected to the soup outlet 25. A through hole 27 is provided on the spoon body 23 below the edge of the spoon mouth 22, and the upper edge of the through hole 27 is connected with a A cover 28 that is raised and extends towards the bottom 24 of the spoon.

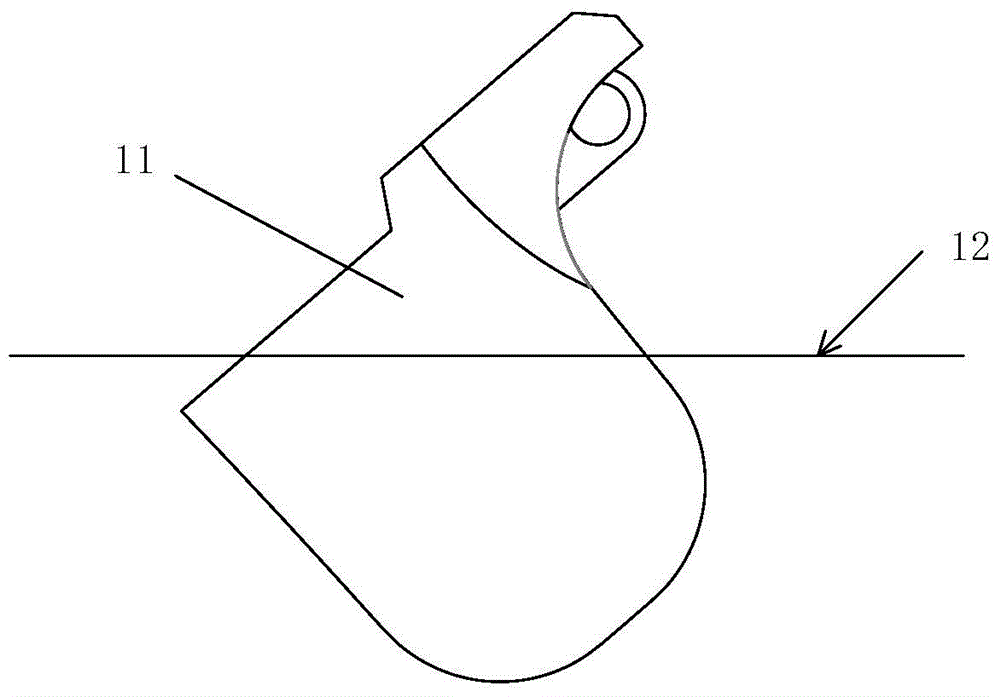

[0023] When the soup spoon scoops soup, the mouth of the spoon 22 is located above the metal liquid surface 20, the through ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com